Treatment process and equipment of waste books

A technology of processing equipment and processing technology, which is applied in fiber raw material processing, metal processing, textiles and papermaking, etc., can solve the problems of reducing the pulping efficiency and pulping quality of waste books, increasing the cost of waste books processing, and a large amount of industrial waste liquid. , to achieve the effect of improving pulping efficiency and pulping quality, improving cutting efficiency and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

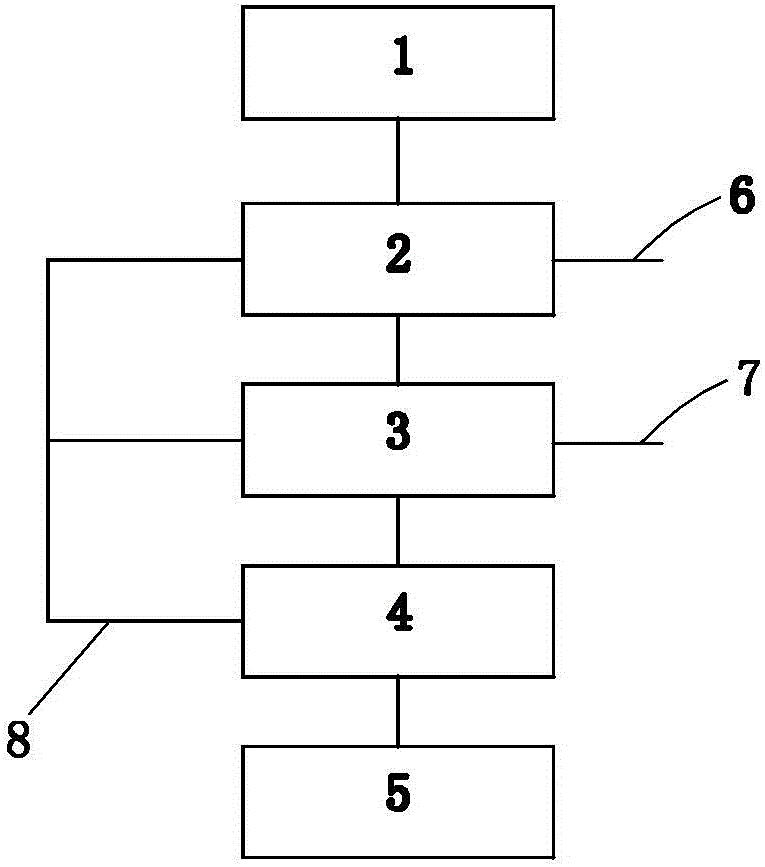

[0034] Such as figure 1 As shown, the present invention provides a process for treating waste and used books, including the following steps arranged in sequence from high to low: (1) edge trimming, the edges of waste and used books with glue or iron nails are cut off by an edge trimmer 1; 2) crushing, the waste books with glue or iron nail edges will be removed through the hydropulper 2, and the ink marks will be discharged through the deinking overflow pipe 6 during the crushing process; (3) pulping, the crushed materials will be Paper pulp is made in the pulping machine 3, and the ink is deinked while stirring during the pulping process, and the ink stains that come out are discharged through the ink discharge pipe 7; (4) concentrate, use the thickener 4 to concentrate; (5) store the pulp, concentrate the The slurry is stored in the slurry storage tank 5. Wherein, the water filtered out after concentration in step (4) is returned to step (2) and step (3) for recycling throu...

Embodiment 2

[0038] Such as figure 1 As shown, the present invention provides a waste book processing equipment, including an edge trimmer 1 for cutting off the edges of waste books with glue or nails, and a machine 1 for cutting off the edges of waste books with glue or nails. The positions of the hydraulic pulper 2, the pulper 3, the thickener 4, and the stock tank 5 for crushing waste books, the trimmer 1, the hydropulper 2, the pulper 3, the thickener 4, and the stock tank 5 Arranged in order from high to low, water delivery pipes 8 are provided between the concentrator 4 and the hydraulic pulper 2 and pulper 3 . The edge trimmer 1, the hydropulper 2, the pulper 3, the thickener 4 and the pulp storage tank 5 are all commonly used equipment in the prior art, and those skilled in the art can directly refer to the existing equipment on the market for implementation.

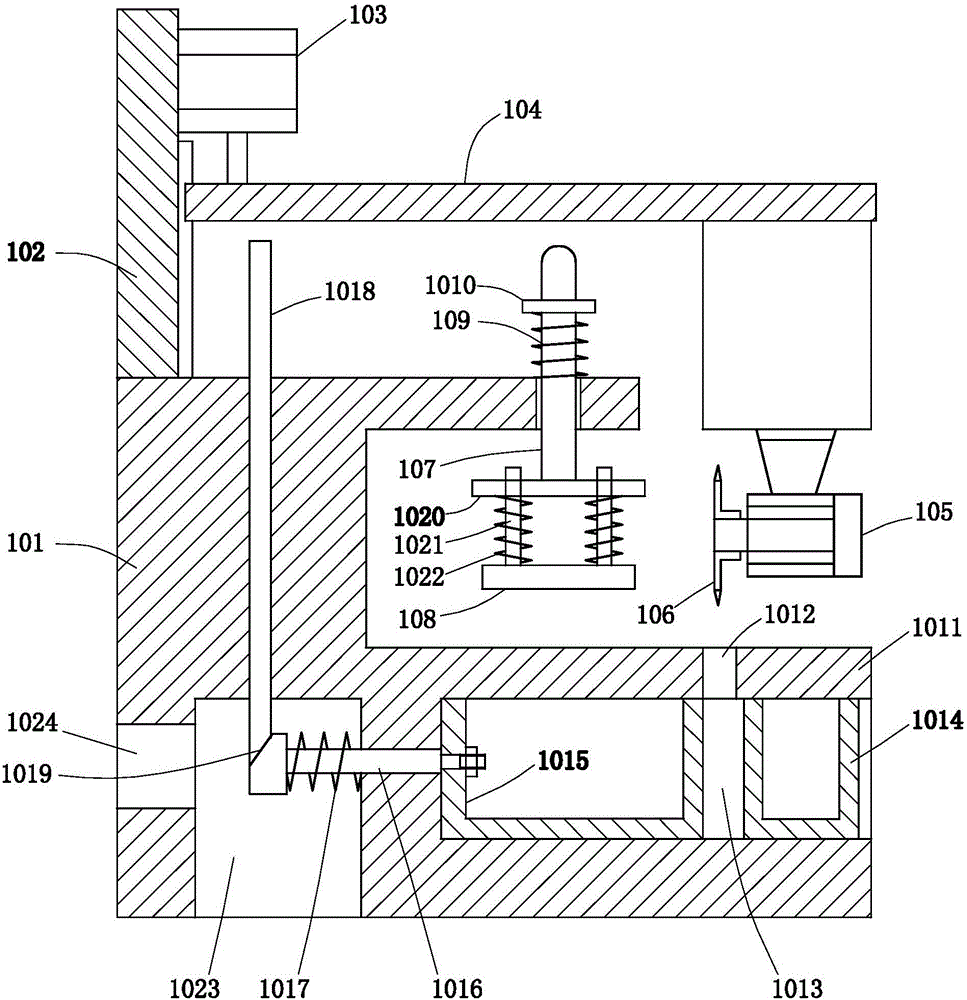

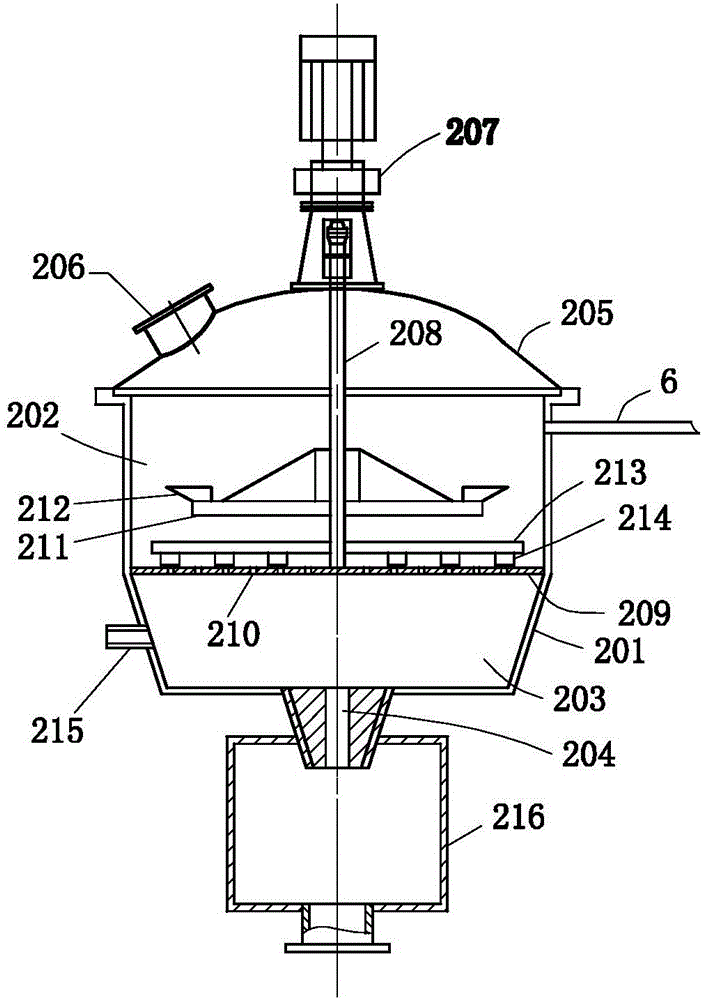

[0039] Of course, in order to make this waste book processing equipment more perfect and use better, the inventor has mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com