Waste newspaper-neutral deinking agent for waste book paper, preparation method and deinking method

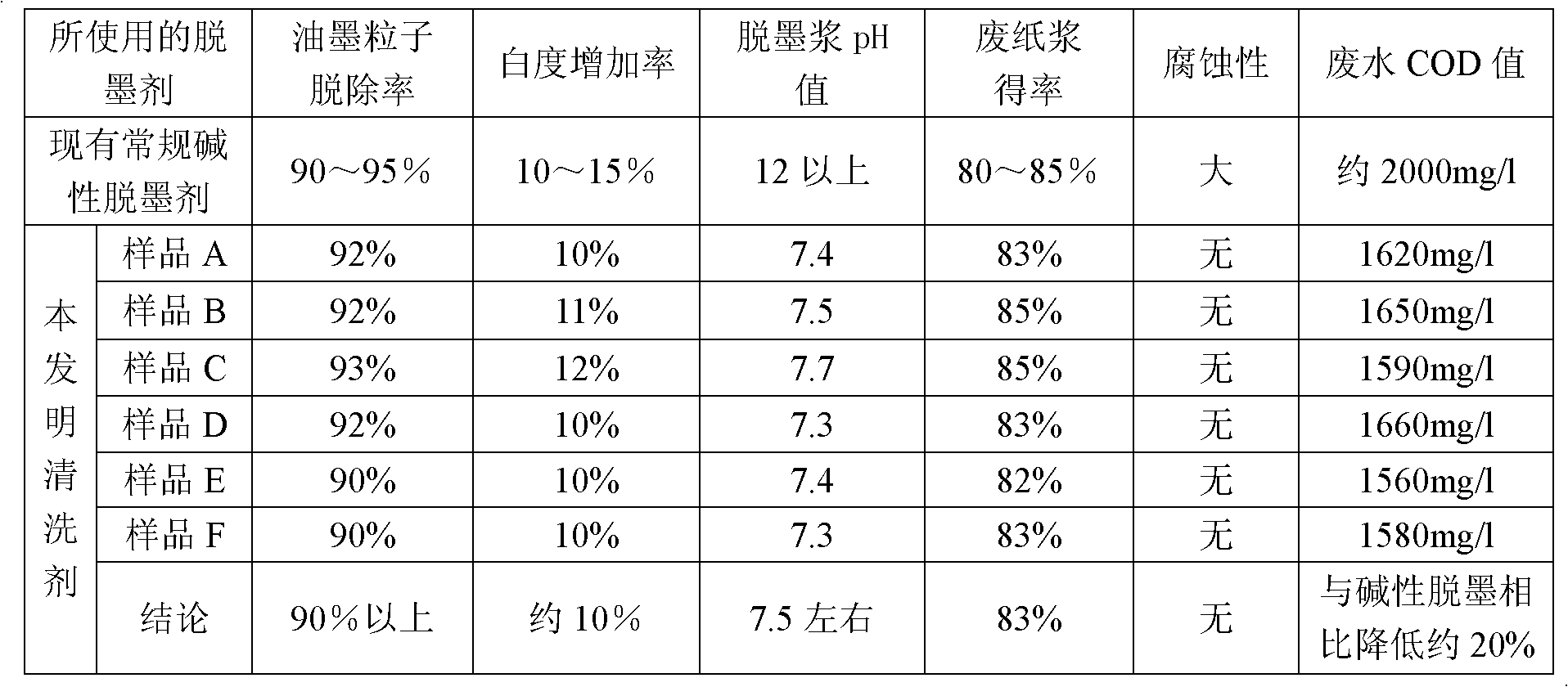

A technology of neutral deinking agent and waste newspaper, which is applied in the preparation of neutral deinking agent for waste newspaper-waste book paper, in the field of neutral deinking agent for waste newspaper-waste book paper, and can solve strong alkaline deinking wastewater High COD, increased difficulty in wastewater treatment, ecological environment pollution, etc., to achieve good deinking effect, reduce treatment difficulty, and low pollution load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the waste newspaper-waste book paper neutral deinking agent of the present invention comprises the following steps:

[0033] Step 1. Weigh the following components in parts by weight: 10-15 parts of sodium stearate, 15-20 parts of sodium lauryl sulfate, 25-35 parts of alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene 20-30 parts of vinyl ether, 20-30 parts of water;

[0034] Step 2. Pour the water weighed in step 1 into the reaction kettle, heat it to 60°C ~ 75°C, add sodium stearate, stir at a speed of 100r / min±10 until it is completely dissolved; reduce the stirring speed to 50r / min±10, sequentially add sodium lauryl sulfate, alkylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, after fully dissolved, continue to stir for 30min~50min, let it stand, and cool naturally to obtain.

[0035] The present invention uses the deinking method of waste newspaper-waste book paper neutral deinking agent, is characteri...

Embodiment 1

[0040] Waste newspapers-waste book paper neutral deinking agent, according to parts by weight, consists of the following components: 10 parts of sodium stearate, 20 parts of sodium lauryl sulfate, 30 parts of alkylphenol polyoxyethylene ether, fat 20 parts of alcohol polyoxyethylene ether, 20 parts of water.

[0041] The preparation method of this waste newspaper-waste book paper neutral deinking agent comprises the following steps:

[0042] Step 1, weighing the above-mentioned components according to parts by weight;

[0043] Step 2. Pour the water weighed in step 1 into the reactor, heat it to 65°C, add sodium stearate, and stir at a speed of 100r / min until it is completely dissolved; reduce the stirring speed to 50r / min, and then add Sodium lauryl sulfate, alkylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, after fully dissolving, continue to stir for 30min, stand still, cool naturally, obtain the neutral deinking of waste newspaper-waste book paper ...

Embodiment 2

[0049] Waste newspapers-waste book paper neutral deinking agent, according to parts by weight, consists of the following components: 10 parts of sodium stearate, 15 parts of sodium lauryl sulfate, 35 parts of alkylphenol polyoxyethylene ether, fat 20 parts of alcohol polyoxyethylene ether, 20 parts of water.

[0050] The preparation method of this waste newspaper-waste book paper neutral deinking agent comprises the following steps:

[0051] Step 1, weighing the above-mentioned components according to parts by weight;

[0052] Step 2. Pour the water weighed in step 1 into the reaction kettle, heat it to 65°C, add sodium stearate, and stir at a speed of 90r / min until it is completely dissolved; reduce the stirring speed to 50r / min, and then add Sodium lauryl sulfate, alkylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, after fully dissolving, continue to stir for 40min, let stand, cool naturally, obtain the neutral deinking of waste newspaper-waste book p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com