Water-saving, high-efficiency and environment-friendly paper machine for office and home use

A paper machine and high-efficiency technology, which is applied in the field of office and household waste paper recycling equipment, can solve the problems of limited processing structure, insufficient application and variation range, and inability to eliminate writing marks well, so as to shorten the paper-making time, The effect of improving deinking effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

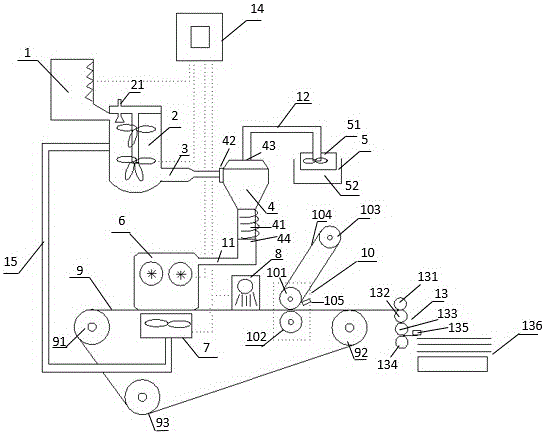

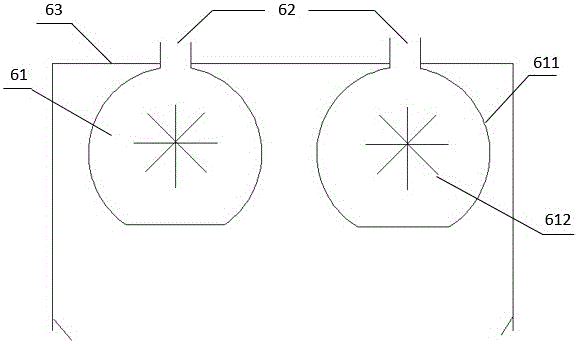

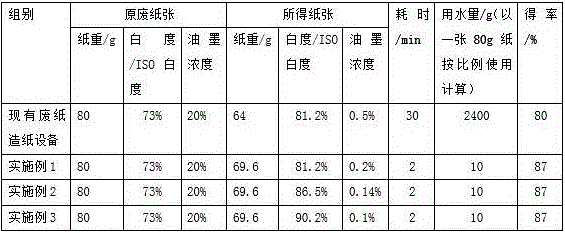

[0032] Such as figure 1 , 2 , a water-saving, high-efficiency and environmentally-friendly paper machine for office use, through the shredding unit (1), the pulping unit (2), the acceleration unit (3), the deinking unit (4), the dispersion unit (6), and the fiber distribution unit ( 7), fiber bonding unit (8), conveying unit (9) and paper forming unit (10), wherein the pulping unit (2) is a dry pulverizing pulper, and a laser tube (21) is arranged above the pulping machine , the deinking unit (4) is a pigment separator, consisting of a tangential spiral separator (41), a pulp inlet (42), an ink evaporation outlet (43) and a fiber outlet (44), the tangential spiral separator (41) The upper part is provided with a pulp inlet (42) and ink evaporation outlet (43), the lower part of the tangential spiral separator (41) is provided with a fiber outlet (44), and the outlet of the shredding unit (1) is connected to the pulping unit (2) through a pipeline The inlet, the outlet of the...

Embodiment 2

[0036] Such as figure 1 , 2, a water-saving, high-efficiency and environmentally-friendly paper machine for office use, through the shredding unit (1), the pulping unit (2), the acceleration unit (3), the deinking unit (4), the dispersion unit (6), and the fiber distribution unit ( 7), fiber bonding unit (8), conveying unit (9) and paper forming unit (10), wherein the pulping unit (2) is a dry pulverizing pulper, and a laser tube (21) is arranged above the pulping machine , the deinking unit (4) is a pigment separator, consisting of a tangential spiral separator (41), a pulp inlet (42), an ink evaporation outlet (43) and a fiber outlet (44), the tangential spiral separator (41) The upper part is provided with a pulp inlet (42) and ink evaporation outlet (43), the lower part of the tangential spiral separator (41) is provided with a fiber outlet (44), and the outlet of the shredding unit (1) is connected to the pulping unit (2) through a pipeline The inlet, the outlet of the ...

Embodiment 3

[0040] Such as figure 1 , 2 , a water-saving, high-efficiency and environmentally-friendly paper machine for office use, through the shredding unit (1), the pulping unit (2), the acceleration unit (3), the deinking unit (4), the dispersion unit (6), and the fiber distribution unit ( 7), fiber bonding unit (8), conveying unit (9) and paper forming unit (10), wherein the pulping unit (2) is a dry pulverizing pulper, and a laser tube (21) is arranged above the pulping machine , the deinking unit (4) is a pigment separator, consisting of a tangential spiral separator (41), a pulp inlet (42), an ink evaporation outlet (43) and a fiber outlet (44), the tangential spiral separator (41) The upper part is provided with a pulp inlet (42) and ink evaporation outlet (43), the lower part of the tangential spiral separator (41) is provided with a fiber outlet (44), and the outlet of the shredding unit (1) is connected to the pulping unit (2) through a pipeline The inlet, the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com