Non-wood unbleached pulp food warp paper and preparation method thereof

A technology for food wrapping paper and uncolored pulp, applied in the field of paper manufacturing, can solve the problems of lack of a safe and environmentally friendly non-wood uncolored pulp food packaging paper preparation method, etc., and achieves maintenance of natural color, good biocompatibility, and increased water filtration capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The unbleached straw pulp and unbleached bamboo pulp involved in the present invention are the pulps disclosed in the Chinese patent application with the application number CN201610179306.7 and the name "non-wood pulp" submitted by the applicant on March 25, 2016. The feature is that the collected wheat straw and bamboo raw materials are pretreated separately, and then sent to the primary separation device through the conveying equipment, steamed with 0.6MPa-3.0MPa steam for 1min-5min, after cooking, multi-stage cleaning is carried out, and then solid-liquid Separation to obtain hemicellulose liquid and solid matter; adding alkali solution to the solid matter, cooking at 90°C-130°C for 0.5h-1.5h, performing a second solid-liquid separation after cooking to obtain unbleached pulp (unbleached pulp) Straw pulp and unbleached bamboo pulp). The K value of the unbleached pulp is below 5.5, the degree of percussion is 20-30°SR, the wet weight is 2-3.5g, the whiteness is below ...

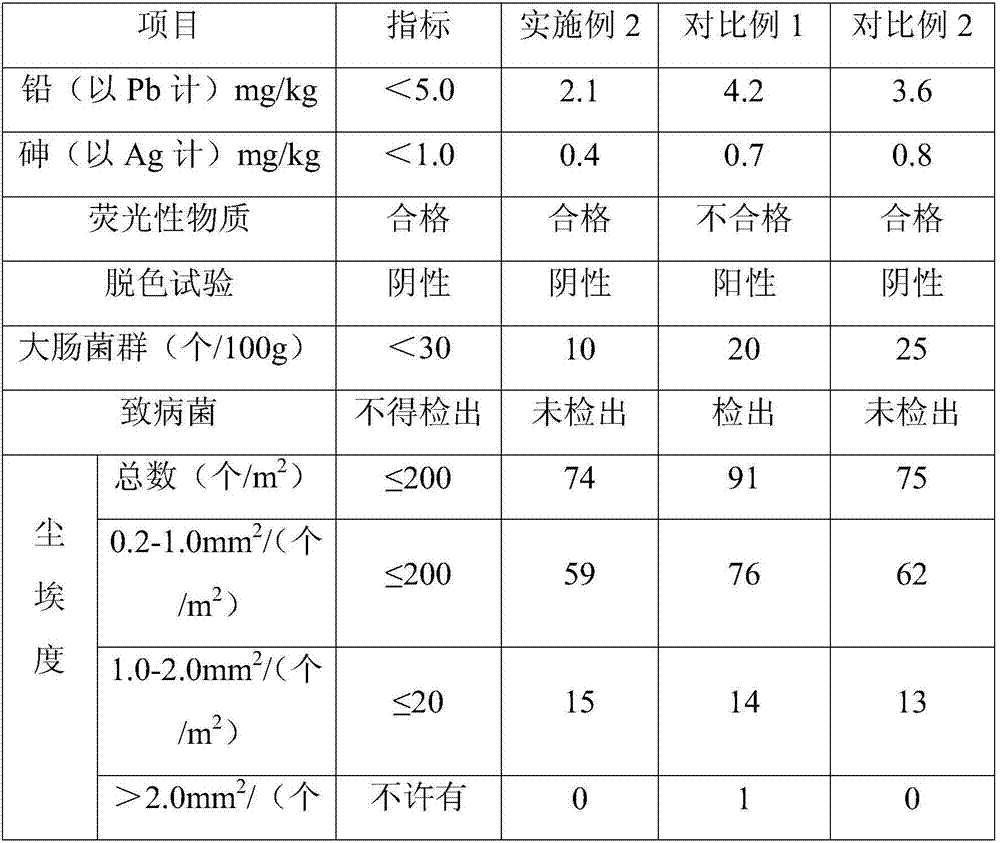

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is:

[0045] The collected wheat straw and bamboo raw materials are pretreated separately, and then sent to the first-stage separation device through the conveying equipment, steamed with 2.5MPa steam for 3min, after cooking, multi-stage cleaning is carried out, and then solid-liquid separation is carried out to obtain hemicellulose liquid and Solid matter: add alkali solution to the solid matter, cook at 120° C. for 1 hour, and perform solid-liquid separation for the second time after cooking to obtain unbleached pulp (unbleached straw pulp and unbleached bamboo pulp). The K value of the unbleached pulp is less than 5.2, the beating degree is 25°SR, the wet weight is 3.2g, the whiteness is less than 42°, the pH value is 8.5, and the cellulose content based on the total weight of solids is 96%.

[0046] The preparation steps of non-wood natural color paste food packaging paper are as follows:

[0047] In step (1), th...

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is:

[0057] A kind of non-wood type natural color paste food wrapping paper of the present invention, the slurry of described non-wood type natural color paste food wrapping paper is made by unbleached grass pulp and unbleached bamboo pulp, wherein the quantification of said wrapping paper is 65g / m 2 , the content of synthetic papermaking auxiliary agent is 2.5% of the dry pulp.

[0058] Described slurry is made up of the following components of weight percent:

[0059] Unbleached grass pulp 40%,

[0060] Unbleached bamboo pulp 60%.

[0061] The preparation method of non-wood type natural color paste food wrapping paper of the present invention, comprises the steps:

[0062] (1) Mixing 40% unbleached grass pulp and 60% unbleached bamboo pulp in a pulp tank to make the pulp uniform and obtain a 9% pulp.

[0063] In step (2), beating is performed in a low-consistency refiner, the refining speed is 20,000 rpm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com