Patents

Literature

59results about How to "Increased tear index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing antibacterial paper on the basis of interlayer self-assembling technology

InactiveCN102587196AIncreased tensile indexHigh folding resistanceNon-fibrous pulp additionPaper/cardboardCelluloseFiber

The invention discloses a method for preparing antibacterial paper on the basis of an interlayer self-assembling technology. In the method, cationic polyelectrolyte chitosan biguanide hydrochloride (CGH) with an antibacterial function, and anionic polyelectrolyte carboxymethyl cellulose sodium (CMC) are alternately deposited on the surface of a bleached kraft hardwood fiber to prepare a layered ordered self-assembled multilayer ultrathin film, which can improve the strength property of a paper sheet while endowing the paper sheet with a good antibacterial performance. Through the change of the environment and the technical conditions of an interlayer self-assembling system, multilayer film structures with different properties can be obtained on the surface of the bleached kraft hardwood fiber, the retention of an antibacterial agent on the fiber is improved, and the antibacterial effect of the paper sheet is enhanced; a layered ordered self-assembled nano-film is prepared by taking a negatively-charged fiber as a matrix and controlling the adsorption process of a reverse-phase ion system,; the preparation method is simple in production process, less in equipment investment and high in adaptability; the prepared antibacterial paper has better antibacterial performance and strength property; and antibacterial requirements of household paper and food packaging paper can be met better.

Owner:ZHEJIANG SCI-TECH UNIV

Mixed neutral cellulase, preparation method thereof and application thereof to papermaking beating

The invention discloses a mixed neutral cellulase, and belongs to the field of enzymatic preparations. The mixed neutral cellulase comprises, in parts by weight, 10-40 parts of cellulase, 20-30 parts of acidic xylanase, 5-10 parts of pectase, 3-8 parts of mannanase and 2-8 parts of a Chinese herbal medicine powder. According to the prepared mixed neutral cellulase, the active components of the Chinese herbal medicine powder is effectively utilized, a special method is utilized to overcome the disadvantage that conventional acidic xylanase is fermented by employing a single bacterial strain; compared with unprocessed pulp, beat pulp processed by the mixed neutral cellulase is improved in beating degree by 11.76%, improved in short fiber burst index by 11.98% and improved in ring crush index by 13.99%; the beat pulp processed by the mixed neutral cellulase is improved in long fiber pulling force index by 40.17% and improved in tear index by 58.91%; the beat pulp processed by the mixed neutral cellulase has relatively smooth fiber surface and relatively soft enzyme fiber; paper made from the beat pulp processed by the mixed neutral cellulase is improved in tear index by 8.3%, improved in tensile index by 10.6% and improved in burst index by 16.5%; and paper pulp whiteness is improved by 2%-5%, sewage quality is substantially improved, and environmental pollution degree is reduced.

Owner:宁夏夏盛实业集团有限公司

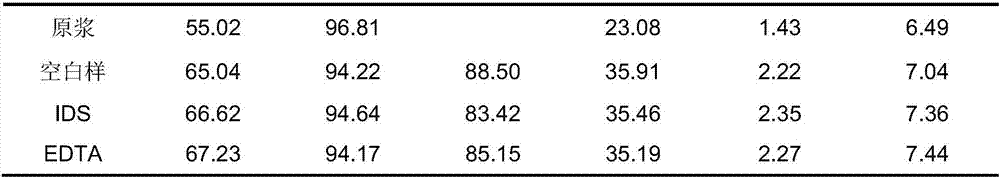

Method for removing metal ions of paper pulp and bleaching

The invention relates to a method for removing metal ions of paper pulp and bleaching and relates to a technique for removing metal ions of paper pulp and applications thereof in bleaching, belonging to the technical field of paper making. The method comprises the following steps of: (1) carrying out pretreatment for removing metal ions of the paper pulp, namely under the existence of Mg(CH(3)COO)2, Ca(CH(3)COO)2 and EDTA (disodium ethylene diamine tetraacetate), carrying out bleaching pretreatment to deoxidizing sulfate pulp; and (2) carrying out following no-pollution bleaching, carrying out following secondary bleaching treatment consisting of a peroxyacetic acid bleaching stage and a hydrogen peroxide bleaching stage on the paper pulp after the pretreatment for removing metal ions. The invention is simple and easy to operate and has obvious effect; the removal rate of the metal ions is high, and the removal rate of Mn is 80.5 percent. Compared with the conventional EDTA chelation treatment, the strength performance of the paper pulp can be improved; the Mg(CH3COO)2 and the Ca(CH3COO)2 can replace 60 percent of EDTA, consequently, the accumulative effect toxicity of the conventional chelating agent can be obviously reduced.

Owner:KUNMING UNIV OF SCI & TECH

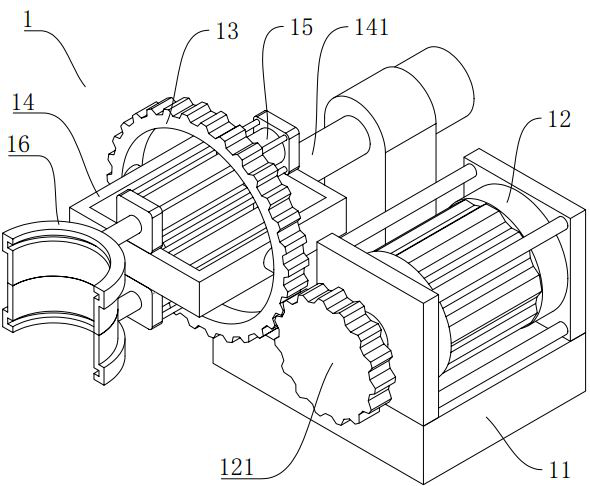

Method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp and pulping method by using same

ActiveCN103790057AReduce consumption costReduce manufacturing costPretreatment with water/steamPre treatmentWoodchips

The invention relates to a method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp. The method comprises the following steps: after soaking the wood chips, spirally extruding the wood chips; adding water into the wood chips which are spirally extruded, carrying out self-hydrolyzing pre-treatment on a mixture of the wood chips and water, and obtaining a pre-hydrolysate and the wood chips after self-hydrolyzing pre-treatment; and collecting the extruded wood chips as a raw material of chemi-mechanical pulp to obtain the wood chips after pre-treatment by hot water. The pre-treatment method provided by the invention fully uses existing part of equipment in the pulping industry without external complex equipment, and only water, small amount of dilute acids and ethanol are used without purchasing other chemicals, so that the pre-treatment process can be realized, thereby greatly saving the comprehensive production cost. Meanwhile, the method is beneficial for effectively combining pulping and papermaking with bio-refinery by existing enterprises.

Owner:TIANJIN UNIV OF SCI & TECH

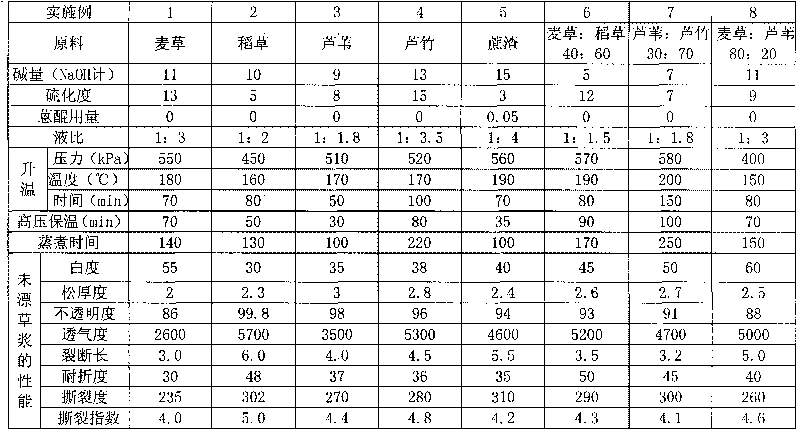

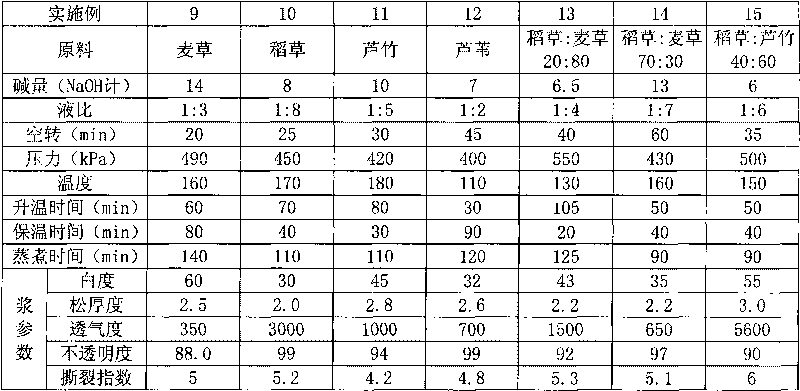

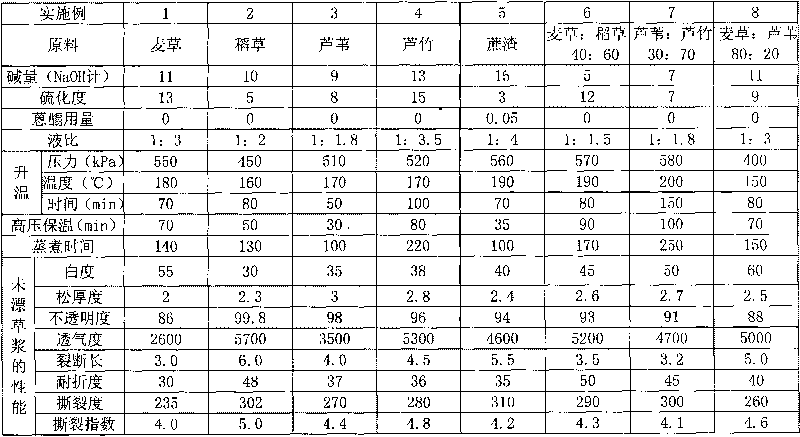

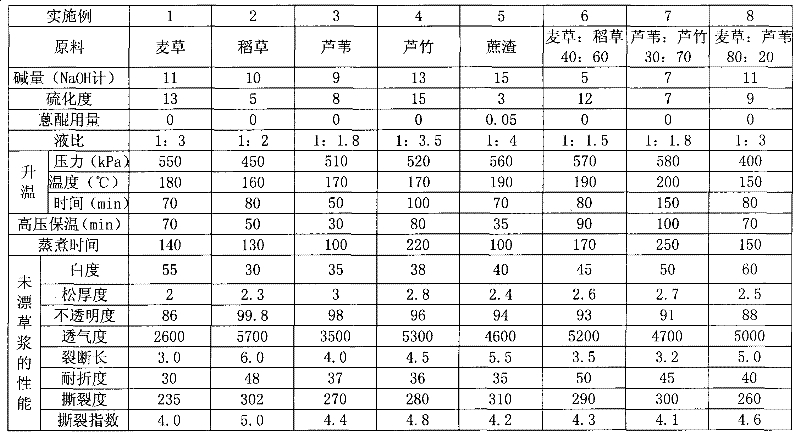

High strength mixing pulp and cultural paper made of thereof

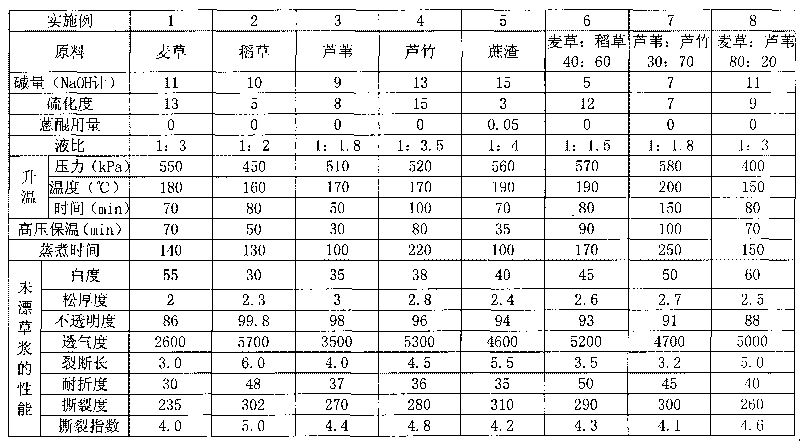

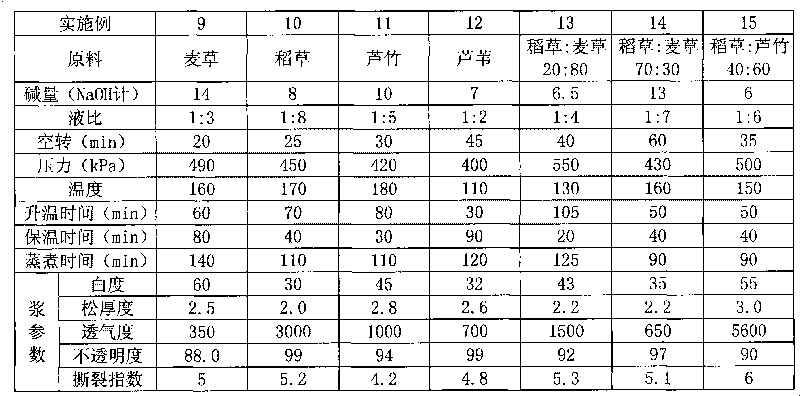

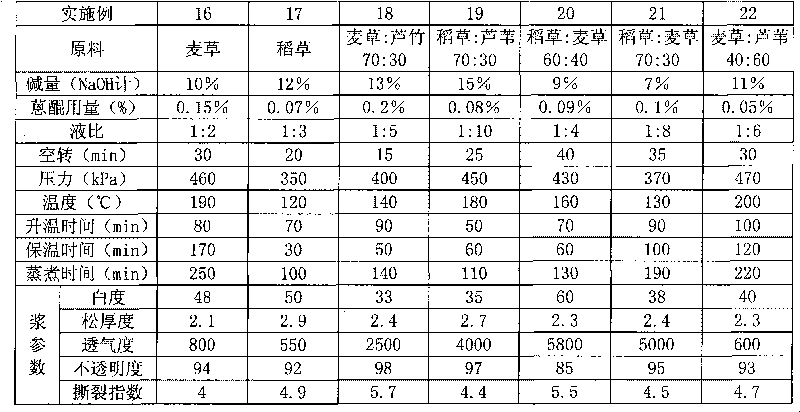

ActiveCN101760984AIncreased tear indexHigh degree of bindingNatural cellulose pulp/paperPulping with inorganic basesBleachPulp and paper industry

The invention provides mixing pulp with a large tearing index, and the weight of the high strength straw pulp is 15-95 percent of that of the mixing pulp; the paper made of the mixing pulp, including the cultural paper, also improves a cultural paper containing non-bleached straw pulp and other pulp. Because the mixing pulp is added with the non-bleached straw pulp, the amount of wood pulp and the like is reduced, thus avoiding the environmental pollution caused by bleacher during the bleaching process in technology, and avoiding generating substance harmful to the human body; and the paper product made by the method of copying hardly contains the substance harmful to the human body, thus lowering the cost of the paper production, lowering the tearing index of the paper, and lowering the aging degree of whiteness, and the paper does not return to be yellow easily.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Aramid fiber/polyimide fiber composite insulation paper with excellent breakdown resistance and preparation method thereof

InactiveCN107354808APrevent hydrolysis reactionEffective bondageAgeing prevention agents additionPlastic/resin/waxes insulatorsBreakdown strengthSurface oxidation

The invention discloses aramid fiber / polyimide fiber composite insulation paper with excellent breakdown resistance. The preparation method comprises the following steps: performing surface oxidation heat treatment on aluminum nitride, thereby enhancing the hydration resistance; performing protonation pretreatment on polyimide chopped fibers, performing pulping, putting a mixture of the polyimide short fiber pulp and chopped aramid fibers into a fiber fluffer, performing fluffing treatment, adding the aluminum nitride suspension, performing mixing, making base paper on a paper sheet former, and performing isothermal boosting hot pressing treatment to obtain the composite insulation paper. The aluminum nitride powder is subjected to heat treatment in an oxidizing atmosphere, so that a compact Al2O3 film is formed on the surface, thereby effectively preventing the hydrolysis reaction of the aluminum nitride; the aluminum nitride powder is mixed with the mixed fiber pulp, so that the small-size aluminum nitride powder is uniformly dispersed in the insulation paper, thereby filling up abundant gaps in the fiber paper structure; and interface traps are formed between the nanoparticles and fibers, thereby implementing effective binding on charges, and enhancing the breakdown strength of the insulation paper.

Owner:徐昌霞

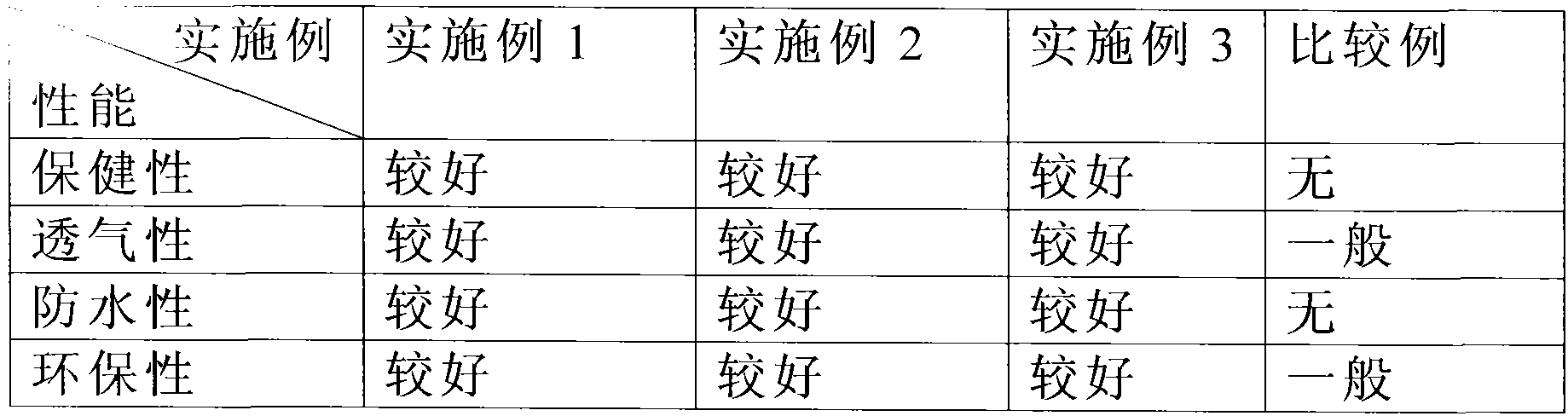

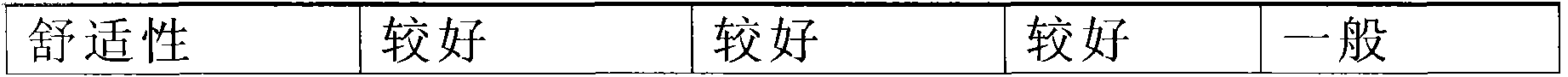

Health care mat for infants and manufacturing method thereof

InactiveCN103405088APowerful insecticidePromote circulationNervous disorderImmunological disordersTraditional medicineSemen

The invention provides a health care mat for infants and belongs to the technical field of textile processing. The health care mat for infants is of a three-layer double-side structure, a front side layer and a back side layer are both a simulation rattan mat body, and a middle health care layer is formed by evenly mixing and flattening 100 parts of Chinese herbal medicine and 5-40 parts of natural rubber cement by weight. The Chinese herbal medicine of the health care layer includes the following raw materials by weight: 1 part to 10 parts of bamboo charcoal, 1 part to 10 parts of jasmine flower, 20-35 parts of negundo chastetree fruit, 10-30 parts of semen cassiae, 10-30 parts of lavender and 10-20 parts of mint. The manufacturing method includes manufacturing the simulation rattan mat bodies, taking the Chinese herbal medicine according to the prescription, drying and breaking the Chinese herbal medicine, mixing the dried and broken Chinese herbal medicine with the natural rubber cement to obtain the health care layer, evenly coating the natural rubber cement on the bottom face of one simulation rattan mat body, laying the health care layer, then laying the other simulation rattan mat body and conducting clipping and edge wrapping to obtain a finished product of the health care mat for the infants. The health care mat is good in health care effect and low in cost.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

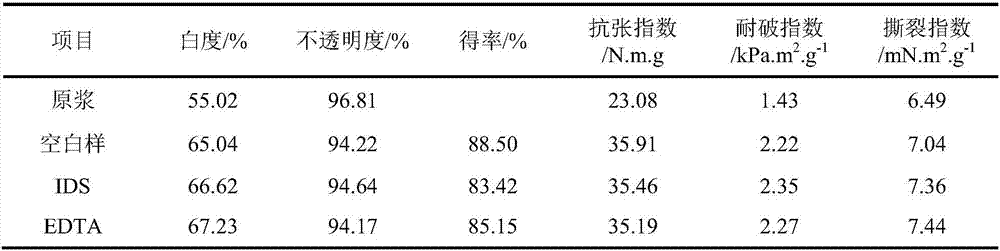

Method of applying green chelating agent in paper pulp hydrogen peroxide bleaching

The invention discloses a method of applying a green chelating agent in paper pulp hydrogen peroxide bleaching, and belongs to the technical fields of pulping and papermaking engineering. Specifically, after paper pulp is diluted to a concentration of 5%-10%, IDS with a mass percentage of 0.8%-1.2% of the absolute dry content of the paper pulp is added, mixing is performed uniformly, at the same time the chelation treatment temperature is controlled at 60-80 DEG C, and the reaction time is 50min-70min. According to the method provided by the invention, the IDS is used as the chelating agent for chelating treatment and pulp hydrogen peroxide bleaching, the bleaching effect is equivalent to that of hydrogen peroxide bleaching used conventional chelating agent EDTA, the whiteness of bagasse pulp can be improved by 2-4%, the tensile index can be improved by 5-6%, the burst resistant index can be improved by 20-23%, and the tear index can be improved by 8-10%; and the whiteness of waste paper deinking pulp can be improved by 2-4%, the burst index can be improved by 6-11%, and the tear index can be improved by 4-6%. The method provided by the invention can be used in the production process of paper pulp hydrogen peroxide bleaching.

Owner:SOUTH CHINA UNIV OF TECH

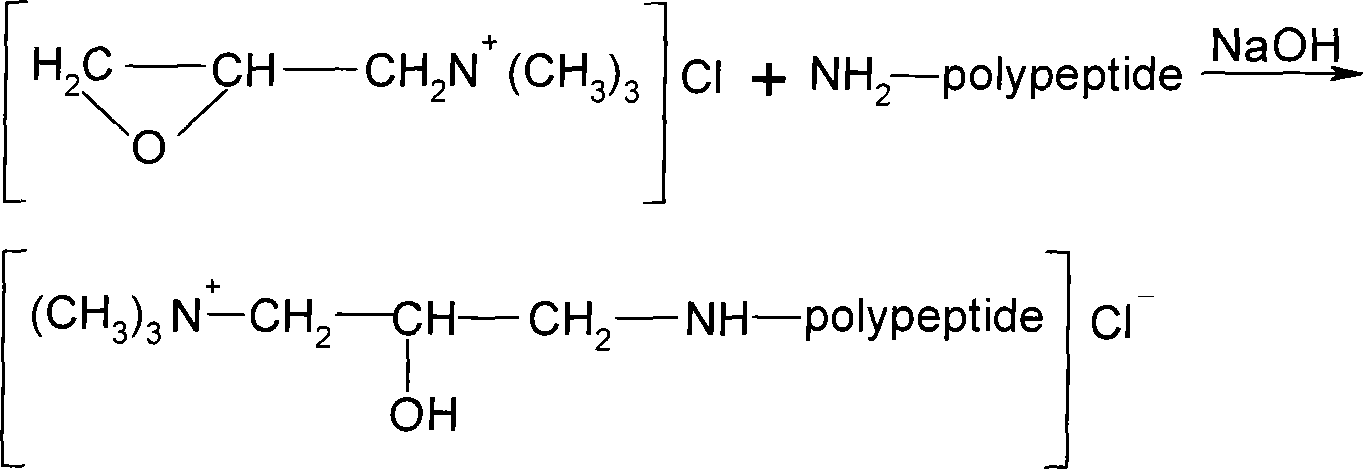

Quaternary ammonium glutelin protein synthetic method

InactiveCN101182687AImprove solubilityGood dispersionNon-fibrous pulp additionPaper/cardboardSolubilityFiber

The invention discloses a method for synthesizing quaternized gluten protein. Firstly, hypohalite is used to pretreat gluten protein. The mass ratio of gluten protein to hypohalite is 1:1-1:2. Convert the free amide groups on the gluten protein into fatty amino groups; then use cationic quaternary ammonium epoxy chloride with a mass ratio of 1:1 to 1:1.5 to carry out grafting reaction with the pretreated gluten protein to generate quaternary ammonium salts Cationic modified gluten protein. Through the pretreatment reaction of hypohalite, the content of fatty amino groups on the protein molecular chain can be increased, which is beneficial to the quaternization reaction, and the combination of protein and plant fiber can be improved; the solubility of gluten protein can be improved, and it is more suitable for plant fiber ( Pulp) for sizing.

Owner:SOUTH CHINA UNIV OF TECH

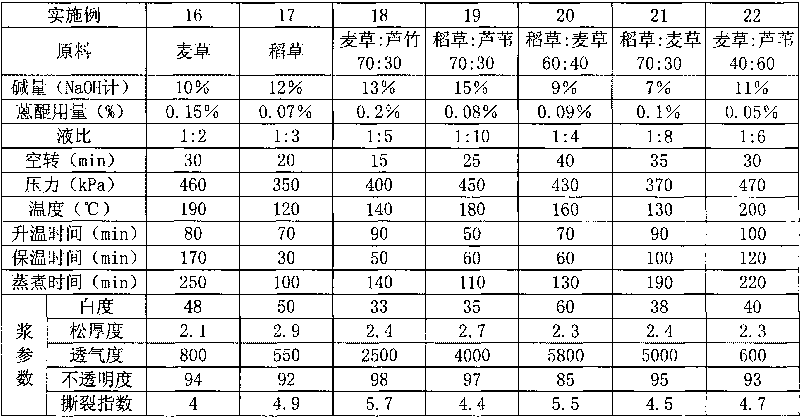

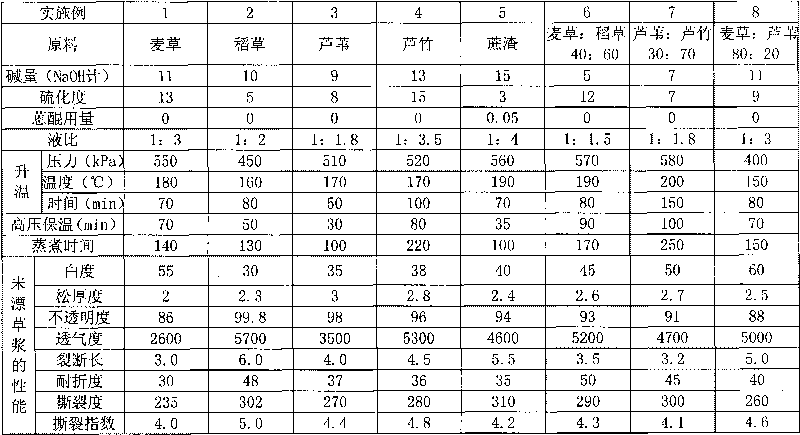

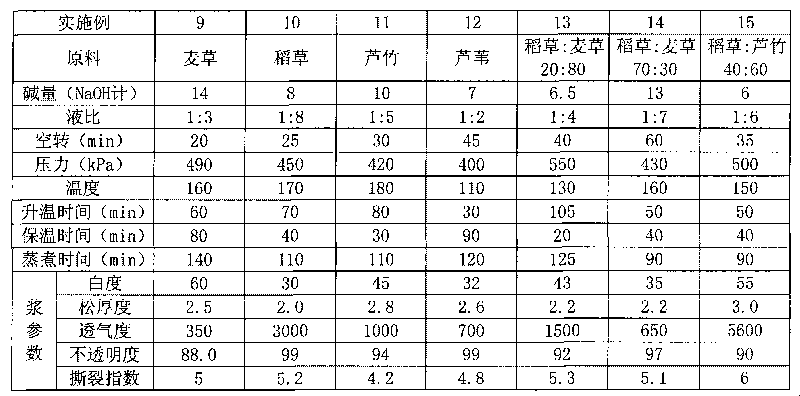

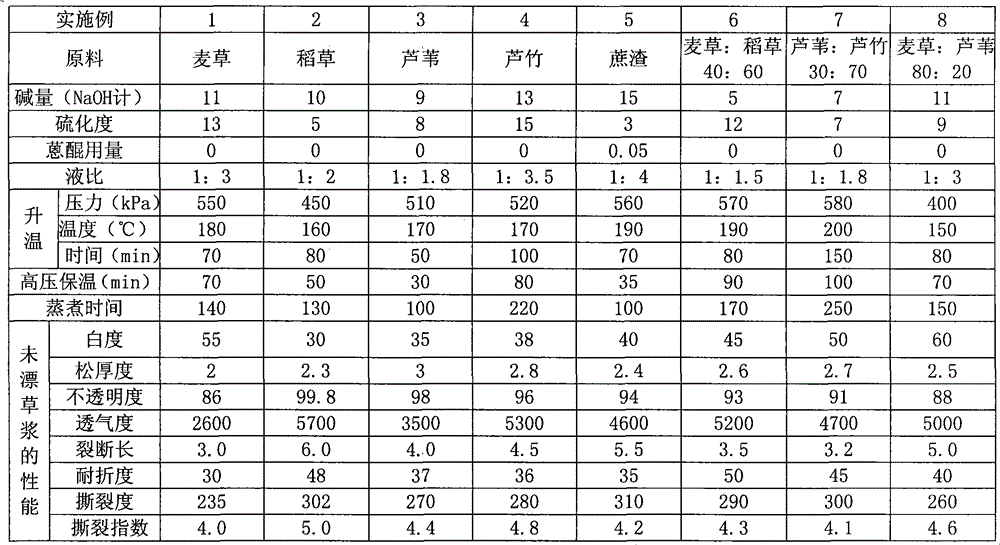

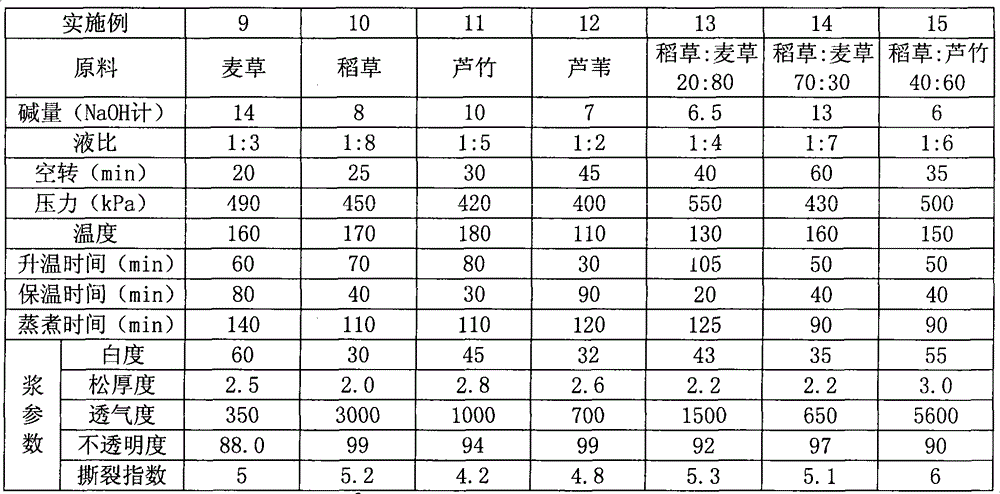

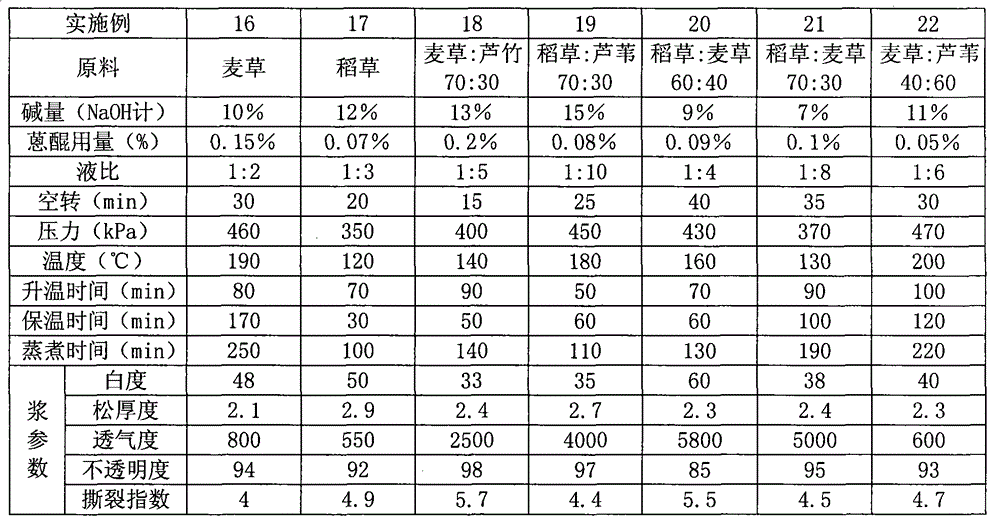

Mixed pulp material and cultural paper prepared from the same

The invention provides mixed pulp, which has high loose depth, high opacity and large tearing index. The primary color straw pulp accounts for 15 to 95 percent of the weight of the mixed pulp, the mixed pulp comprises one kind or the free combination of more than two kinds of materials of wood pulp, cotton pulp, bamboo pulp or secondary fiber, the loose depth of the primary color straw pulp is between 1.98 and 2.30 dm<3> / g, the opacity is between 89 and 99 percent, and the tearing index is between 3.5 and 6.0 mN*m<2> / g. The invention also provides cultural paper. The mixed pulp has high loosedepth, high opacity and large tearing index, a pulp material with low cost and simple pulp making process is mixed in the mixed pulp, and paper products made through the papermaking process have the characteristics of loose depth, high opacity, large tearing index of the paper products, soft color, simple and natural effect, simple manufacture process, low manufacture cost and the like.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

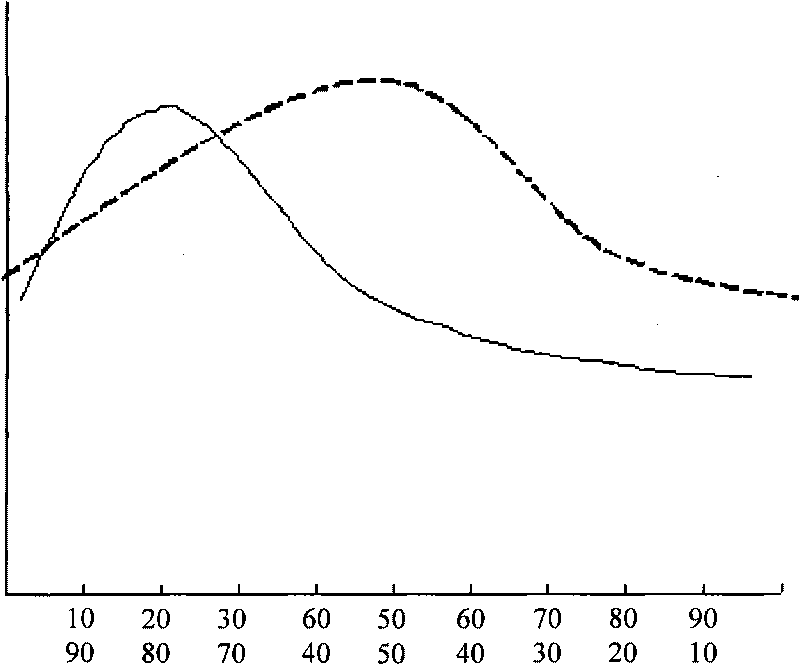

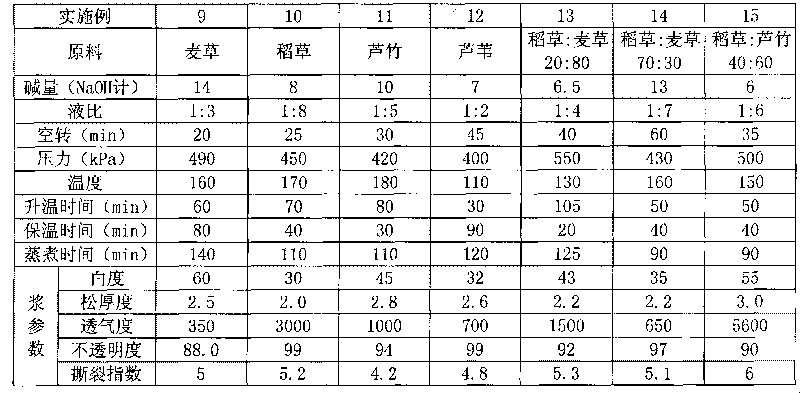

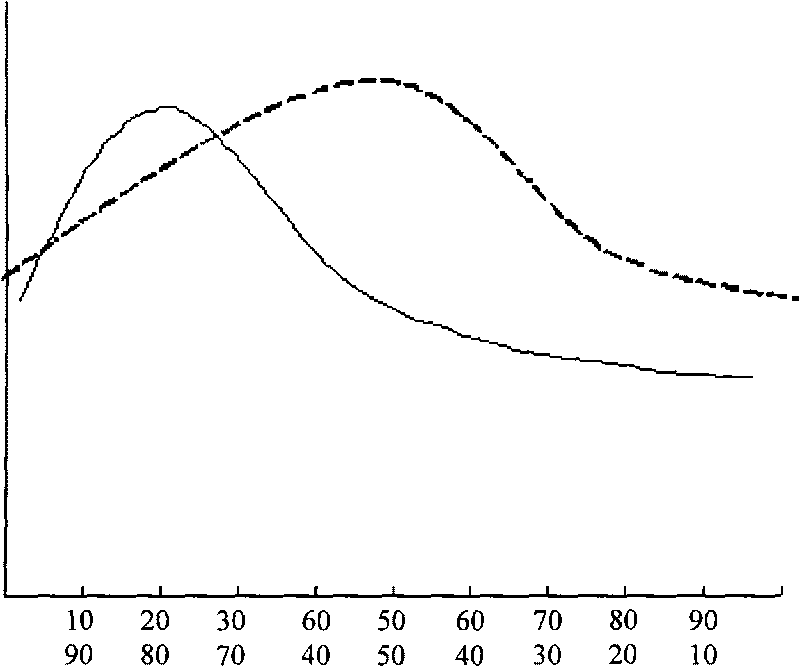

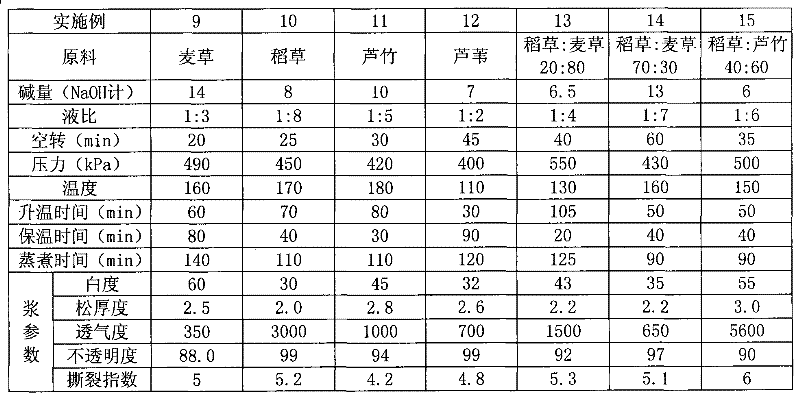

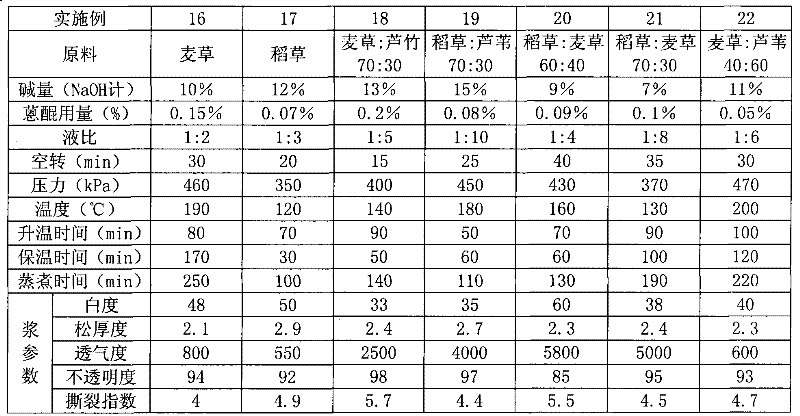

Mixed pulp with high opacity, air permeability and tearing index and cultural paper prepared from the same

ActiveCN101760989AEasy to useReduce consumptionSpecial paperPaper/cardboardPulp and paper industryChemistry

The invention relates to mixed pulp with high opacity, air permeability and tearing index and paper with the mixed pulp. The air permeability of the high-efficient straw pulp is between 300 and 6500 ml / min, the opacity is between 88 to 100 percent, and the tearing index is between 3.5 and 6 mN*m<2> / g; preferably, the air permeability is between 500 and 5500 ml / min, the opacity is between 90 and 99 percent, and the tearing index is between 4.6 and 5.6 mN*m<2> / g; more preferably, the air permeability is between 1000 and 5000 ml / min, the opacity is between 94 and 98 percent, and the tearing index is between 4.8 and 5.4 mN*m<2> / g. The mixed pulp provided by the invention has high opacity, air permeability and tearing index, so the opacity of the paper with the mixed pulp is improved, and the stiffness and the like of the paper are improved. Because of the improvement of the air permeability, the papermaking speed is greatly improved.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Mixed pulp with high bulk, air permeability and tear index and cultural paper made thereof

ActiveCN101760986AEasy to useReduce consumptionNatural cellulose pulp/paperPulping with inorganic basesPapermakingPolymer chemistry

The invention relates to mixed pulp with high bulk, air permeability and tear index and cultural paper made thereof. The air permeability of the novel straw pulp is 300-6500ml / min, the bulk is 2-3cm<3> / g and the tear index is 3.5-6mN.m<2> / g. Preferably, the air permeability is 500-5500ml / min, the bulk is 2.3-2.8cm<3> / g and the tear index is 4.6-5.6mN.m<2> / g. More preferably, the air permeability is 1000-5000ml / min, the bulk is 2.4-2.6cm<3> / g and the tear index is 4.8-5.4mN.m<2> / g. Since the bulk, the tear index and the air permeability of the mixed pulp provided by the invention are high, the bulk and the opacity of the paper made of the mixed pulp are improved, the stiffness and the like of the paper are increased, and the papermaking speed is greatly improved because the air permeability is improved.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

A method for preparing printing paper with moisture-proof function

InactiveCN108894047ALower contact angleImprove moisture resistanceSpecial paperPaper/cardboardPolyvinyl alcoholRoom temperature

The invention discloses a printing paper preparation method with moisture-proof function, which comprises the following steps: step 1, starch is dispersed into water to prepare a printing paper with aconcentration of 30 40% slurry, follow by 0.01 0.04% starch branching enzyme, raising the temperature to 35 45. Degree. C., reaction 15. Degree. C 25 min, and then adde concentrated sulfuric acidto that mixture for reaction 4 6 min, and then adde that polyvinyl alcohol, and stirring the mixture continuously for 12 16min, cool to room temperature, standby. The purpose of the invention is toprovide a method for preparing printing paper with moisture-proof function. Compared with the prior art, the printing paper has good moisture-proof effect, high use value and good application prospect.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

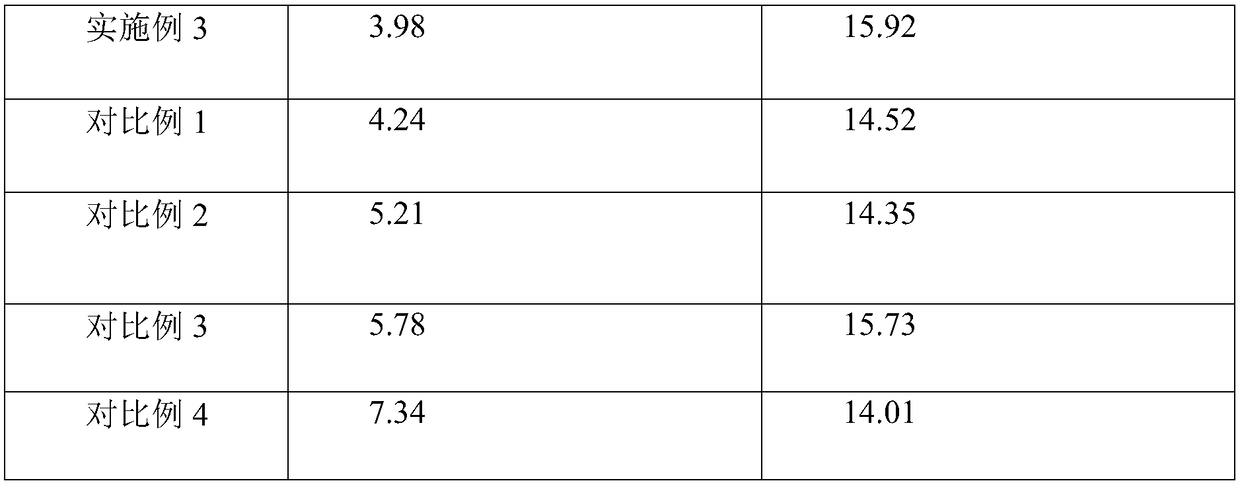

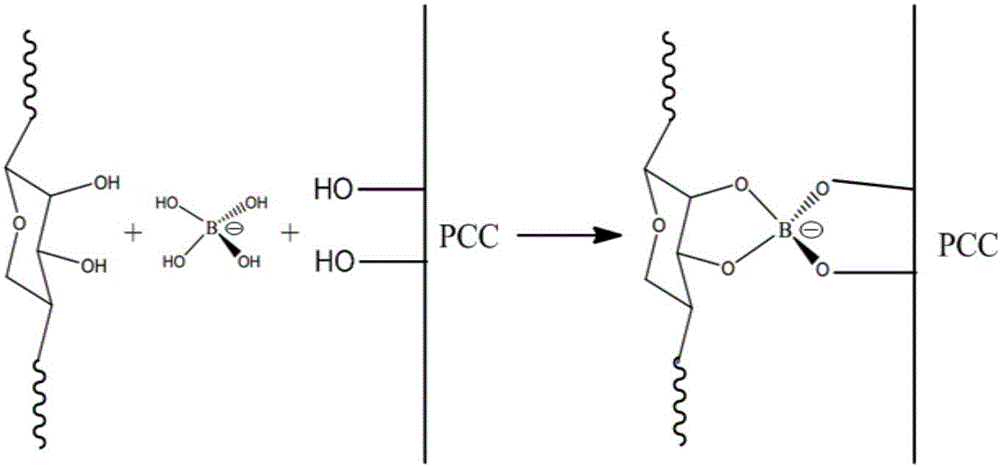

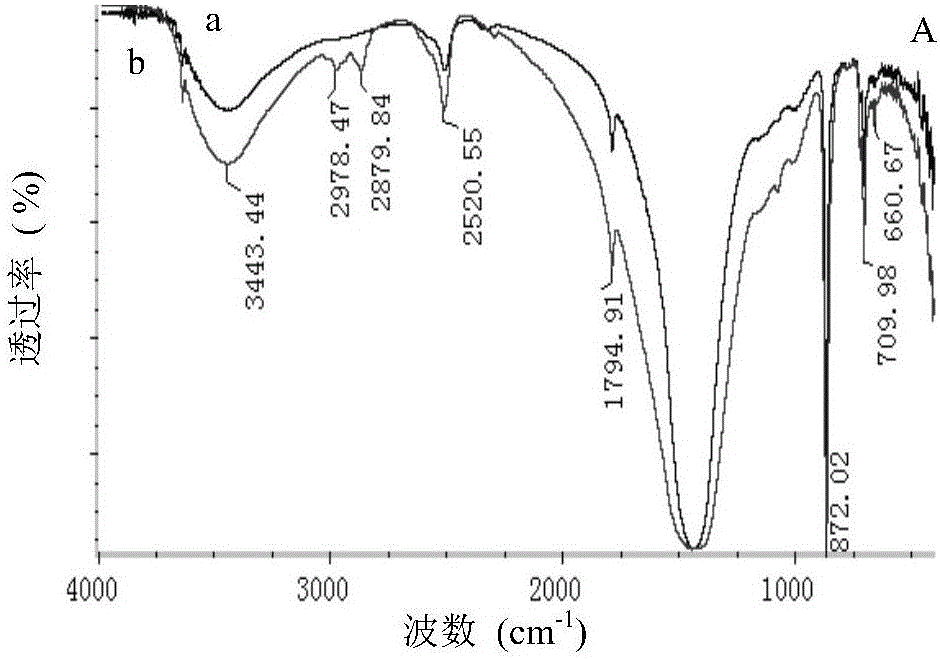

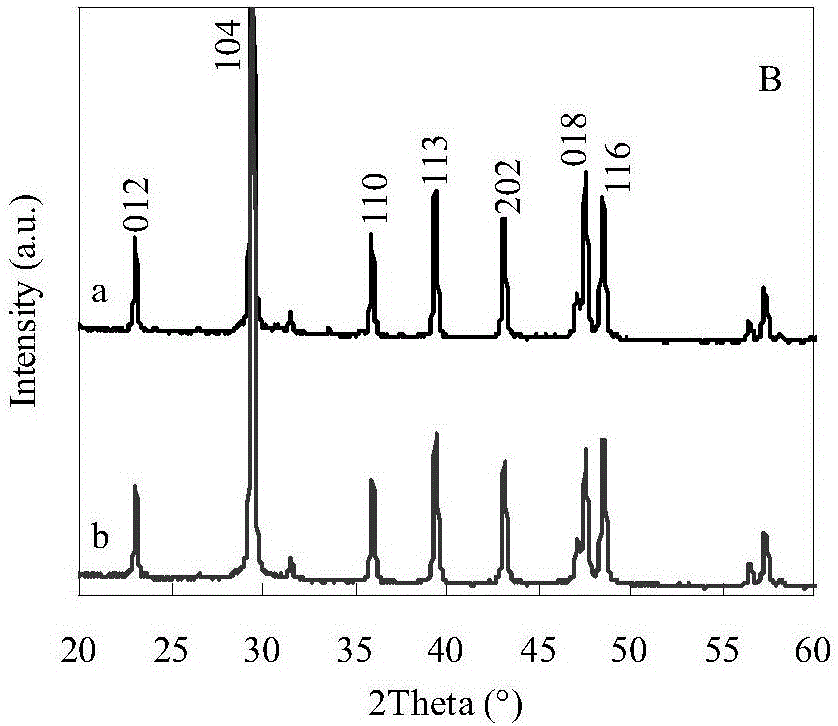

Guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate, preparation method and application thereof, and paper

ActiveCN106702811AIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsPrecipitated calcium carbonateBoric acid

The invention provides a guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate. Guar gum is crosslinked on the surface of the modified precipitated calcium carbonate through boric acid. The invention aims to provide a modified precipitated calcium carbonate which can obviously enhance the tensile index, burst index and tear index of paper and the single-pass retention rate of the filler when being used in the filler of the paper. The invention also provides a preparation method and application of the modified precipitated calcium carbonate. Besides, the invention also provides a paper containing the modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Preparation method of high-strength structural color fibers

InactiveCN110528285AImprove mechanical propertiesImprove anti-aging propertiesCarbon fibresFiberEpoxy

The invention relates to a preparation method of high-strength structural color fibers, and belongs to the technical field of textile materials. Poly N-isopropyl acrylamide is used for grafting polystyrene to prepare a nanosphere emulsion, by adopting an alternating deposition technology, the surfaces of carbon fibers are alternately spin-coated with and deposited with a mixed emulsion compoundedof the emulsion, silicon dioxide microspheres and epoxy resin layer upon layer, and bragg grating-shaped structural color fibers with good mechanical performance are prepared; the silicon dioxide microspheres have optical performance for resisting ultraviolet light, when the silicon dioxide microspheres are doped in materials, the anti-ageing performance and chemical resistance performance of thematerials can be improved, and the strength and intensity of the materials can also be improved; according to the preparation method, by adopting the alternating deposition technology, the surfaces ofthe carbon fibers are alternately spin-coated with and deposited with the mixed emulsion layer upon layer, and fracture length and tearing indexes, a bursting index and folding resistance degree of afabric are greatly improved; the fracture length and bursting strength of the fabric are closely related to the binding intensity among the fibers, and after the surfaces of the fibers are subjectedto alternating deposition, the binding force among the fibers of the fabric is greatly improved.

Owner:曹运福

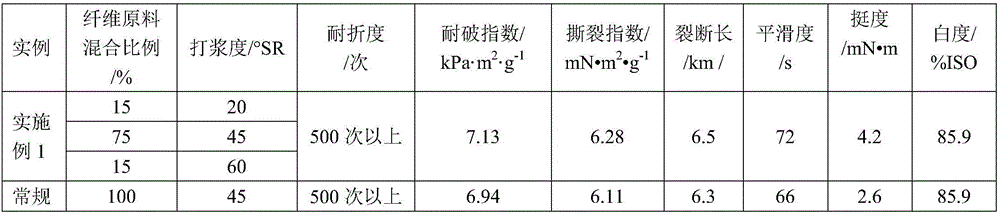

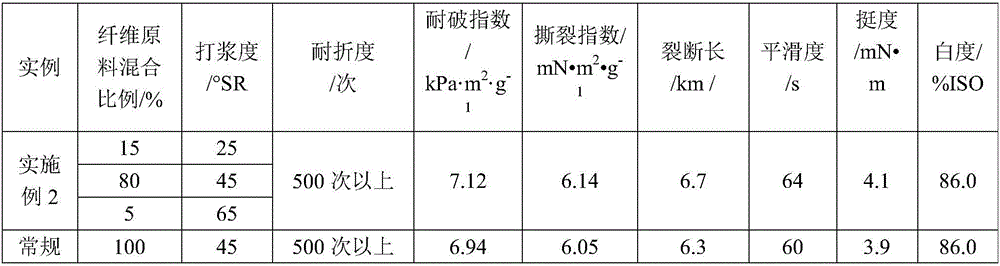

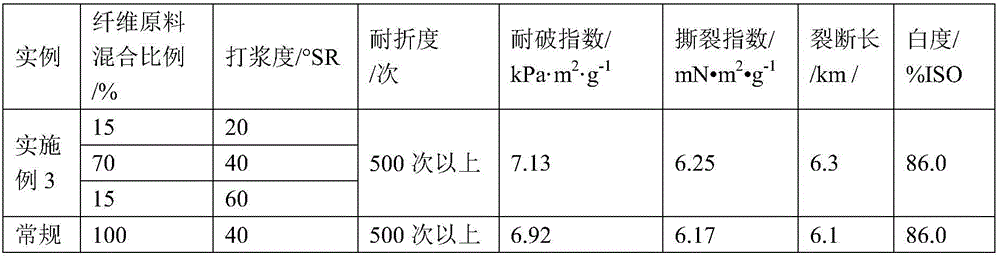

Method for preparing paper-based material from biochemical technology ECF bleached sulfate pulp of fast-growing poplar

ActiveCN106592321AReduce energy consumptionBeating energy savingPulp beating methodsChemical/chemomechanical pulpCardboardBursting strength

The invention discloses a method for preparing a paper-based material from a biochemical technology ECF bleached sulfate pulp of fast-growing poplar. The method comprises the following steps: 1, preparing a paper pulp through a biochemical technology ECF bleaching technology of sulfate pulp of the fast-growing poplar; and 2, carrying out gradient beating on the prepared paper pulp to obtain paper pulp with three beating degrees, wherein the beating degree of first paper pulp is 10-30 DEG SR, the beating degree of second paper pulp is 30-55 DEG SR, and the beating degree of third paper pulp is 55-70 DEG SR; and 3, carrying out making molding or compaction molding on the mixed pulp to obtain the paper-based material. The method adopting a gradient beating technology and a self-adding technology solves the disadvantages of single beating technologies in the prior art, and avoids use of extra additives, and the produced paper-based material has the advantages of high folding strength, high bursting strength and high tearing resistance index, is suitable for producing various types of paper bases, and is especially for producing white cardboard raw paper-based materials.

Owner:QILU UNIV OF TECH

Wet strengthening agent and preparation method thereof

InactiveCN105507076AAvoid enteringStop festeringReinforcing agents additionPolymer scienceDiethylenetriamine

The present invention provides a wet strengthening agent preparation process, wherein the wet strengthening agent is a PAE resin and comprises the raw materials such as adipic acid, diethylenetriamine, p-toluenesulfonic acid and epichlorohydrin. The invention relates to a process for preparing the wet strengthening agent by using the raw materials, wherein the process is characterized in that the process is divided into two stages, the first stage comprises synthesizing a prepolymer polyamide polyamine (PPC), and the second stage comprises synthesizing the final product PAE resin. According to the present invention, with the addition of the PAE wet strengthening agent, the tear index of the corrugated paper is improved and is increased by 59%, the bursting strength is increased by 33%, the transverse ring crush strength is increased by 28%, and the folding resistance is increased by 240% so as to substantially enhance the comprehensive performance of the corrugated paper.

Owner:丹阳市华兴纸箱有限公司

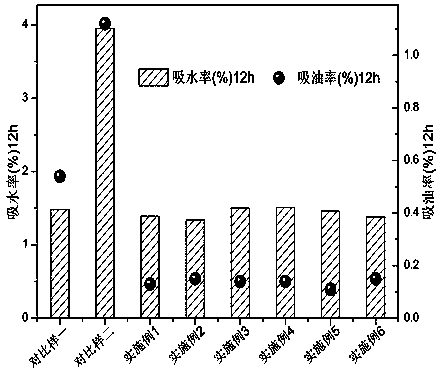

Cellulose/polylactic acid fiber composite paper and preparation method thereof

ActiveCN114481681AReduce processing costsReduce processing timeNon-fibrous pulp additionNatural cellulose pulp/paperCellulosePolymer science

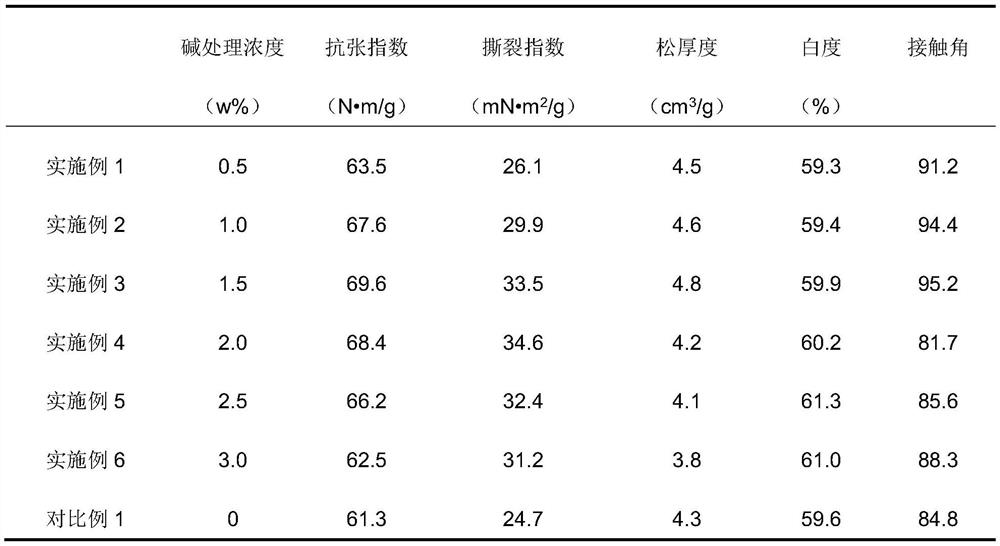

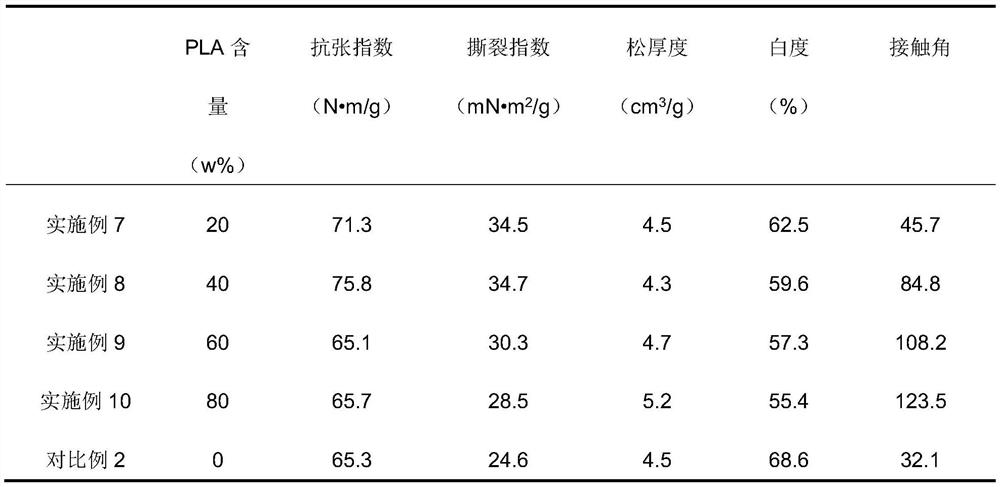

The invention provides cellulose / polylactic acid fiber composite paper and a preparation method thereof, and the preparation method comprises the following steps: (1) cutting polylactic acid fibers into short fibers, cleaning and drying to obtain polylactic acid short fibers; (2) soaking and cleaning polylactic acid short fibers with absolute ethyl alcohol, performing alkali etching treatment with a 0.5%-3.0% strong alkali solution, washing until the washing liquid is neutral after the alkali etching treatment is completed, and drying to obtain modified polylactic acid short fibers; (3) soaking and defibering the natural plant fiber pulp board with water, and then pulping to obtain plant fiber pulp; (4) preparing an auxiliary agent into an auxiliary agent solution; and (5) mixing, defibering and dispersing the modified polylactic acid short fibers, the plant fiber pulp and an auxiliary solution to obtain mixed pulp, performing papermaking by adopting a wet forming technology, and performing squeezing and drying to obtain the cellulose / polylactic acid fiber composite paper. The tensile index and the tearing index of the composite paper are improved, and the treatment cost and the processing time of the polylactic acid fibers are reduced.

Owner:SHAANXI UNIV OF SCI & TECH

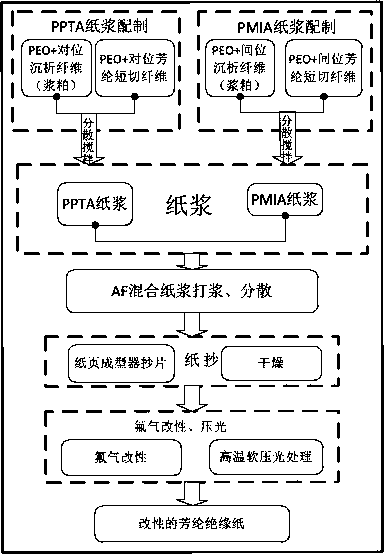

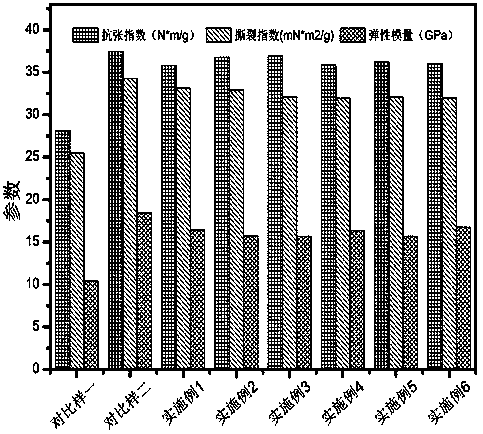

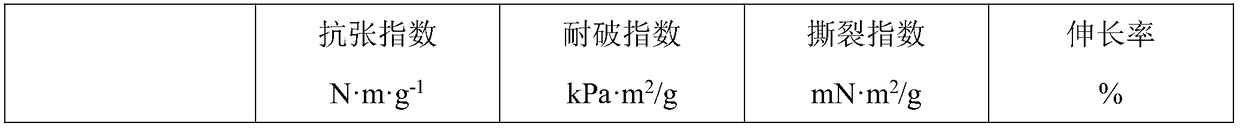

Method for improving mechanical properties and hydrophobic and oleophobic properties of aramid insulating paper

InactiveCN107663807AImprove mechanical propertiesIncreased tensile indexPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPapermakingAramid

The invention relates to a method for improving mechanical properties and hydrophobic and oleophobic properties of aramid insulating paper. Para-position aramid fibers are added in a papermaking process of meta-position aramid insulating paper. Compared with meta-position aramid fibers, the para-position aramid fibers have better mechanical properties, so that the mechanical properties of the meta-position aramid insulating paper are further improved. The aramid insulating paper is modified by utilizing fluorine gas; after modification, a new group is introduced into the surface of the aramidinsulating paper so that the contact angle of the surface of the aramid insulating paper is enlarged and the hydrophobic and oleophobic properties of the aramid insulating paper are increased. A high-temperature soft calendering method is utilized so that the structure of the aramid insulating paper is not damaged and the crystallization degree of the aramid fibers can be greatly improved; meanwhile, the acting force between aramid cellulose chains is enhanced through a hot pressing manner, the combination is tighter and the linear density is increased; the tearing index and the tensile indexof the aramid insulating paper are greatly improved. The preparation method of the aramid insulating paper, provided by the invention, has the characteristics of simple technology, practicability andthe like.

Owner:SOUTHWEST UNIVERSITY

Method of preparing papermaking enhancer from waste paper

InactiveCN108611900AImprove bindingIncreased tensile indexPaper recyclingWaste paper working-upSulfuric acidHydrogen bond

The invention discloses a method of preparing papermaking enhancer from waste paper, which includes the steps of: shearing waste paper into small chips and performing deinking treatment; processing the paper chips into nano-cellulose with concentrated sulfuric acid; modifying the nano-cellulose with 2,3-epoxypropyltrimethylammonium chloride to obtain cation nano-cellulose; finally mixing and grinding the cation nano-cellulose, chitosan and a surfactant to prepare an enhancer. In the invention, the nano-cellulose is small in diameter and can fill the gap between fibers; meanwhile, the nano-cellulose is rich in hydroxyl groups, which can be combined with hydroxyl groups on the surface of cellulose to form a hydrogen bond, thus enhancing combining force between the fibers, and further improving tensile index, burst index, tearing index and elongation rate of paper.

Owner:JURONG MAOYUAN WEAVING FACTORY

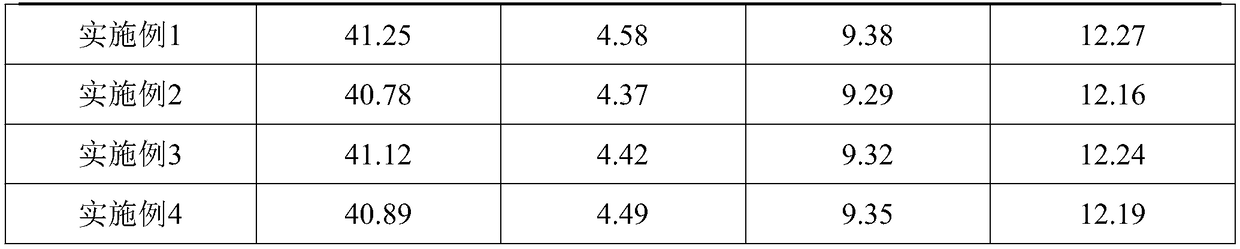

Regenerative case paper board sludge reuse method

InactiveCN107698104AGuaranteed concentrationImprove retentionSludge treatment by de-watering/drying/thickeningWaste product additionSludgePapermaking

The invention belongs to the field of papermaking, and particularly relates to a regenerative case paper board sludge reuse method, which comprises the following steps that step 1, carton production sewage is drained into a regulating pool through a grid and an inclined wire 1 sequentially, then sequentially passes through a reaction pool, an inclined wire 2, a primary sedimentation pool, an A / O pool 1, a secondary sedimentation pool, an A / O pool 2 and a final sedimentation pool and is drained into a clear water pool, wherein various indexes of the treated sewage are normal, and the treated sewage can be recycled; and step 2, sludge in the primary sedimentation pool, the secondary sedimentation pool and the final sedimentation pool is discharged into a sludge pool, and the sludge in the sludge pool sequentially passes through an inclined wire 3, enters a machine chest and enters a paper machine with accepts according to a proportion for paper making. By utilizing the technical scheme of the invention, the sludge can be wholly reused and realizes zero emission.

Owner:嘉兴市博莱特纸业股份有限公司

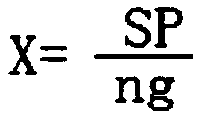

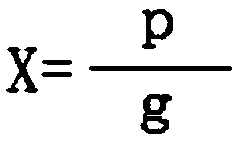

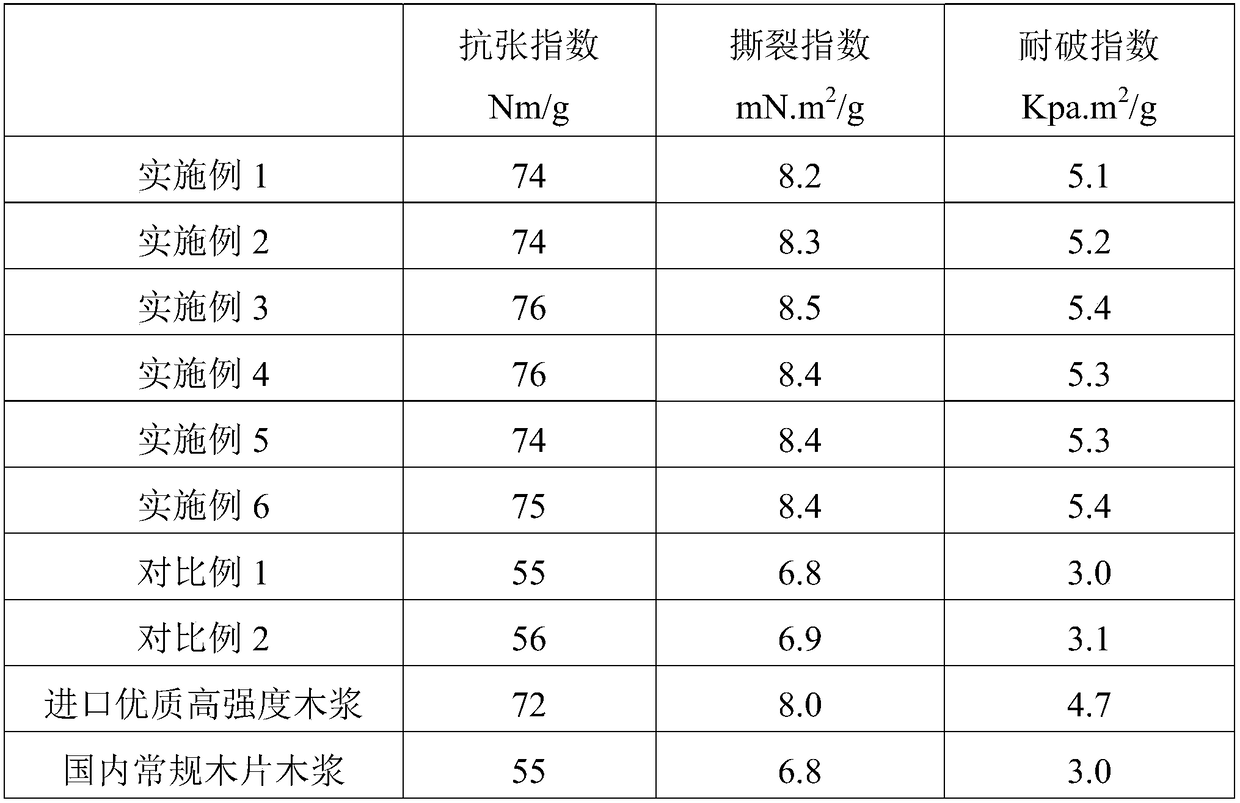

High-strength hardwood pulp and preparation method thereof

InactiveCN108978307AIncreased tensile indexOptimizing Pulp PropertiesDigestersPulp bleachingHardwoodAcacia mangium

The invention provides high-strength hardwood pulp and a preparation method thereof. Raw material wood of the hardwood pulp comprises the following raw materials in percentage by mass: 70-90% of bluegum and 10-30% of acacia mangium. According to the high-strength hardwood pulp and the preparation method thereof, the blue gum and the acacia mangium are combined, a ratio of the blue gum to the acacia mangium is optimized, a tensile index, a tearing index and a burst index of the prepared hardwood pulp are greatly improved, and the hardwood pulp performance is significantly optimized, exceeds those of domestic conventional wood chip pulp, is above superior product standards in bleached hardwood pulp industry standards and is better than those of imported high-quality high-strength wood pulp.

Owner:HAINAN JINHAI PULP & PAPER

Mixed pulp material and cultural paper prepared from the same

The invention provides mixed pulp, which has high loose depth, high opacity and large tearing index. The primary color straw pulp accounts for 15 to 95 percent of the weight of the mixed pulp, the mixed pulp comprises one kind or the free combination of more than two kinds of materials of wood pulp, cotton pulp, bamboo pulp or secondary fiber, the loose depth of the primary color straw pulp is between 1.98 and 2.30 dm<3> / g, the opacity is between 89 and 99 percent, and the tearing index is between 3.5 and 6.0 mN*m<2> / g. The invention also provides cultural paper. The mixed pulp has high loosedepth, high opacity and large tearing index, a pulp material with low cost and simple pulp making process is mixed in the mixed pulp, and paper products made through the papermaking process have the characteristics of loose depth, high opacity, large tearing index of the paper products, soft color, simple and natural effect, simple manufacture process, low manufacture cost and the like.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

High strength mixing pulp and cultural paper made of thereof

ActiveCN101760984BReduce dosageLow costNatural cellulose pulp/paperPulping with inorganic basesBleachPulp and paper industry

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

3-vinylamino-2-hydroxypropyltrimethylammonium chloride copolymer and its preparation and application

ActiveCN105754022BDifficult to breedImprove retentionWater-repelling agents additionSpecific water treatment objectivesAminationSodium hydroxide

The invention discloses 3-vinylamino-2-hydroxypropyltrimethylammonium chloride copolymer and preparation and application thereof.The preparation includes: placing acrylamide monomer and distilled water in a N2 protected reactor, adding a chain transfer agent, a complexing agent and an initiator, stirring at 30-70 DEG C for 10-30 min, standing for 10-30 min, cooling to 10-15 DEG C, adding sodium hydroxide, stirring well and then adding sodium hydrochloride slowly, reacting for 1-3 h, adding sodium hydroxide, reacting for 2-4 h, dropwise adding epichlorohydrin, reacting for 0.1-0.5 h, heating to 50-90 DEG C, reacting for 1-3 h, dropwise adding trimethylamine aqueous solution slowly, and reacting for 2-5 h and then cooling to normal temperature to obtain the 3-vinylamino-2-hydroxypropyltrimethylammonium chloride copolymer; the copolymer is light yellow thick liquid, > / =13% in solid content, 9-10 in pH, 80-100 in degree of polymerization and higher than 60% in amination degree, and is useful as a paper enhancer, a paper sizing agent, a water treating agent and the like.The preparation process is simple, production materials are easy to obtain, a production cycle is short, reacting is mild, and invention is convenient for industrial large-scale production and has a promising application prospect.

Owner:FUZHOU UNIV

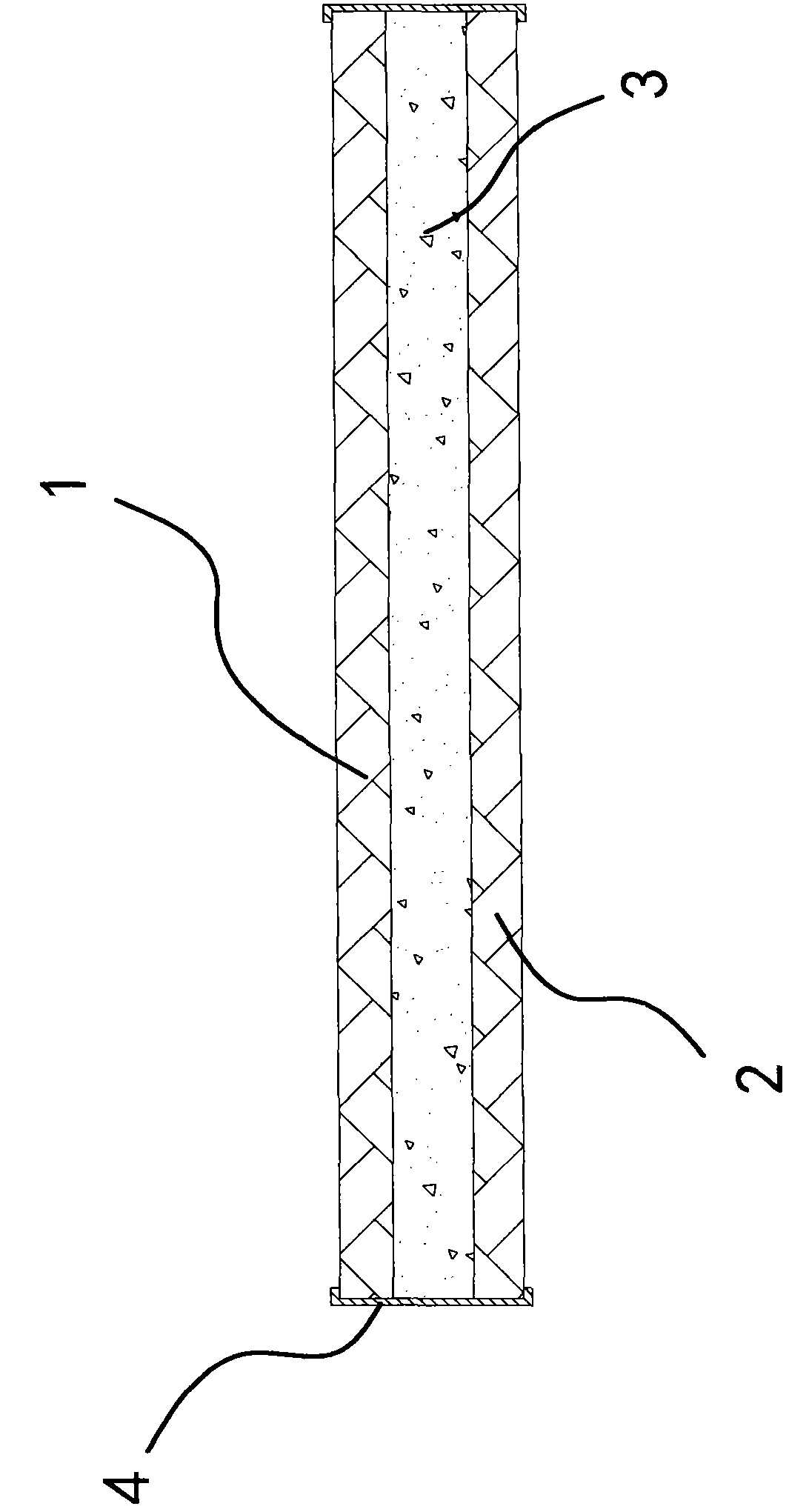

Paper cushion package

PendingCN114351494AAvoid squeezingSimple preparation processPulp beating methodsPulp bleachingPlant fibreMontmorillonite

The invention relates to a paper cushion package. The paper cushion package is formed by stretching kraft paper on which tearing lines or cutting marks are distributed; the tearing lines or the cutting marks are distributed in a matrix manner, two adjacent columns of longitudinal tearing lines or cutting marks are staggered, the kraft paper is stretched, the tearing lines or the cutting marks are torn to form rhombic meshes, and four edges of all the rhombic meshes are twisted under stretching to form a corrugated shape, a honeycomb shape, a grid shape or a network shape; and the two adjacent rows of tearing lines or cutting marks are staggered by 1 / 2 length of the tearing lines or cutting marks. The manufacturing process of the kraft paper is further optimized, the montmorillonite is added, and the montmorillonite is fully dispersed and interwoven with the plant fibers to form a stable three-dimensional network structure with high bonding strength, so that the toughness of the kraft paper is improved, and the buffering performance of the buffering package made of the kraft paper is better.

Owner:杨介思

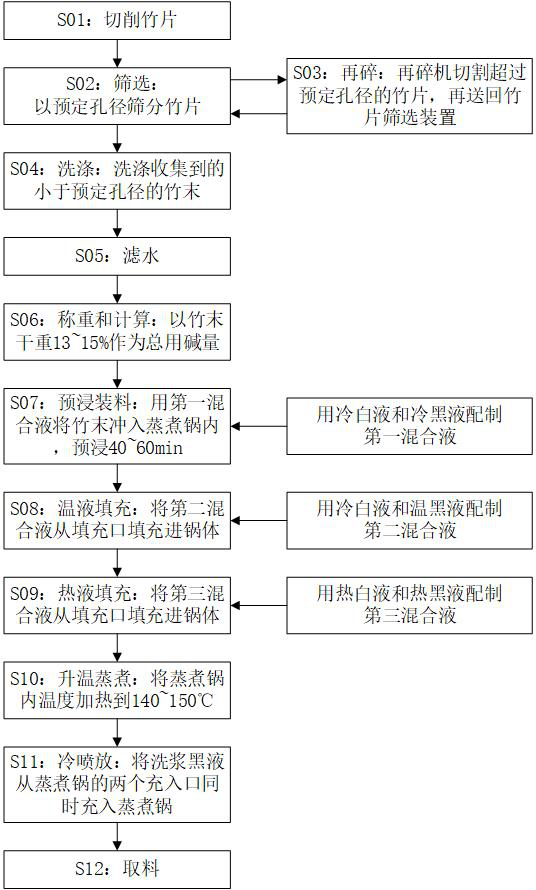

Low-temperature replacement cooking method for bamboo kraft pulp

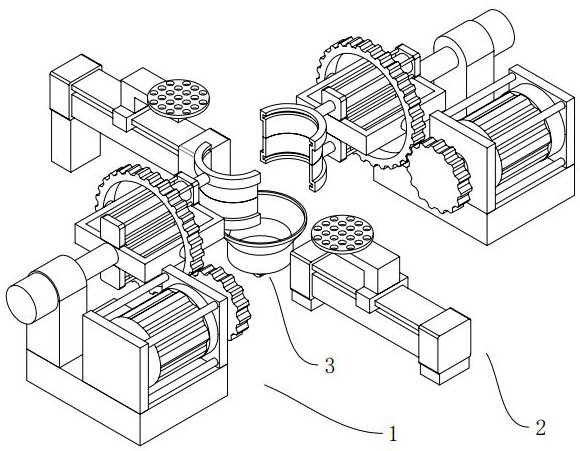

ActiveCN113882180AEasy to operateLow undistilled matter contentDigestersRaw material divisionCooking methodsSieve

The invention relates to a low-temperature replacement cooking method of bamboo kraft pulp. The method comprises the steps of bamboo chip cutting, screening, re-crushing, washing, water filtering, weighing and calculating, presoaking and charging, warm liquid filling, hot liquid filling, heating and cooking, cold blowing, material taking and the like. A bamboo chip screening device used in the screening step comprises a pair of overturning units, a pair of screening tray conveying units and a receiving unit. The sieve tray conveying units are arranged between the two overturning units, and the receiving unit is arranged between the two sieve tray conveying units. The method is easy to operate and high in product yield, the prepared kraft pulp is low in content of unsteamed products, low in kappa number, good in uniformity, high in strength, high in intrinsic viscosity, high in burst index, high in tensile index, high in tear index, high in mitt folding strength, low in steam unit consumption and low in alkali unit consumption, and the bamboo kraft pulp produced through the method is high in quality and can replace needlebush kraft pulp. The bamboo chip screening device can fully screen out bamboo powder smaller than the preset aperture of the screening tray, and the working efficiency is improved.

Owner:四川天竹竹资源开发有限公司

Process for integrating pulping and bleaching by using ultrasonic wave

ActiveCN101781862BEmission reductionSimple processWashing/displacing pulp-treating liquorsNon-macromolecular organic additionFiberUltrasound - action

The invention discloses a process for integrating pulping and bleaching by using ultrasonic wave, which relates to the technical field of papermaking and pulping. The process comprises the following steps: adding water to raw materials to obtain a raw material liquid which has a concentration of 3%-30%, and adding an ultrasonic wave assistant enhanced additive which is 0.1%-1.0% of the raw material liquid weight; then heating the raw material liquid to 50 DEG C-180 DEG C and turning on an ultrasonic generator, wherein the ultrasonic power is 0.25-1 kilowatt per cubic meter of the raw materialliquid; the frequency is 15-80KHz; and the ultrasonic wave acts on the raw material liquid intermittently for 1-5 hours. With the action of ultrasonic wave, fiber and lignin in the raw material are separated to form bleached slurry; and carrying out processes such as selecting, purifying, solvent extracting and the like after discharging. The invention has the beneficial effects that: carrying out pulping and bleaching simultaneously; greatly decreasing the number of equipment and the energy consumption, saving investment and having lower production cost; obtaining high yield of paper pulp and bleaching efficiency and having good product quality; having less working sections of pulp washing and using less water; discharging less waste water and having lower chemical oxygen demand (COD) and chroma; not containing persistent toxic pollutants such as AOX and the like; and having smaller pollution load and being friendly to the environment.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

A kind of method of pulp metal ion removal and bleaching

A method for removing and bleaching pulp metal ions. The invention relates to a paper pulp metal ion removal process and its application in bleaching, belonging to the technical field of papermaking. The present invention mainly comprises the following steps: 1. paper pulp is carried out to remove metal ion pretreatment, promptly under the condition that Mg(CH3COO) 2, Ca(CH3COO) 2 and EDTA (disodium ethylenediaminetetraacetic acid) exist, oxygen desulfurization Bleaching pretreatment of salt pulp; ② Subsequent non-polluting bleaching, the pulp after the above-mentioned metal ion removal pretreatment is then subjected to a subsequent two-stage bleaching treatment consisting of a peracetic acid bleaching section and a hydrogen peroxide bleaching section. The invention is simple and easy to implement, and the effect is remarkable; the removal rate of metal ions is high, and the removal rate of Mn is 80.50%. Compared with conventional EDTA chelating treatment, the strength performance of pulp can be improved; Mg(CH3COO)2, Ca(CH3COO)2 can replace 60% of EDTA, and the cumulative effect toxicity of conventional chelating agents can be significantly reduced.

Owner:KUNMING UNIV OF SCI & TECH

Mixed neutral cellulase and its preparation method and application in papermaking beating

InactiveCN103642774BFull typeWide range of conditionsHydrolasesCellulose treatment using microorganisms/enzymesFiberPull force

The invention discloses a mixed neutral cellulase, and belongs to the field of enzymatic preparations. The mixed neutral cellulase comprises, in parts by weight, 10-40 parts of cellulase, 20-30 parts of acidic xylanase, 5-10 parts of pectase, 3-8 parts of mannanase and 2-8 parts of a Chinese herbal medicine powder. According to the prepared mixed neutral cellulase, the active components of the Chinese herbal medicine powder is effectively utilized, a special method is utilized to overcome the disadvantage that conventional acidic xylanase is fermented by employing a single bacterial strain; compared with unprocessed pulp, beat pulp processed by the mixed neutral cellulase is improved in beating degree by 11.76%, improved in short fiber burst index by 11.98% and improved in ring crush index by 13.99%; the beat pulp processed by the mixed neutral cellulase is improved in long fiber pulling force index by 40.17% and improved in tear index by 58.91%; the beat pulp processed by the mixed neutral cellulase has relatively smooth fiber surface and relatively soft enzyme fiber; paper made from the beat pulp processed by the mixed neutral cellulase is improved in tear index by 8.3%, improved in tensile index by 10.6% and improved in burst index by 16.5%; and paper pulp whiteness is improved by 2%-5%, sewage quality is substantially improved, and environmental pollution degree is reduced.

Owner:宁夏夏盛实业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com