Method of preparing papermaking enhancer from waste paper

A papermaking enhancer and waste paper technology, applied in the field of papermaking, can solve the problem of low physical properties of paper, and achieve the effects of increasing the binding force and improving the tensile index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

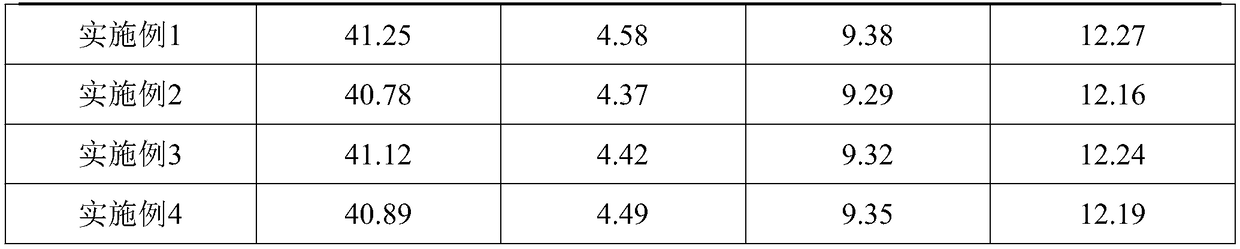

Embodiment 1

[0018] A method for preparing a paper-making reinforcing agent from waste paper, comprising the following steps:

[0019] Step 1, cutting the waste paper into small pieces, adding the pieces to the deinking aid, stirring and pulping, heat preservation and curing, to obtain deinked pulp;

[0020] Step 2: Add concentrated sulfuric acid dropwise to the deinked pulp, stir while adding, heat-preserve and seal at 45°C for 30 minutes, add deionized water to terminate the reaction, obtain a reaction solution, centrifuge the reaction solution, wash the precipitate with deionized water until the pH is Neutral to obtain nanocellulose;

[0021] Step 3, adding nanocellulose to dimethyl sulfoxide, adding sodium hydroxide under stirring conditions, heating to 60°C, adding 2,3-epoxypropyltrimethylammonium chloride dropwise, and keeping the temperature for 5 hours, Pour the reaction solution into ethanol to terminate the reaction, centrifuge the reaction solution, wash with ethanol, and dry t...

Embodiment 2

[0029] A method for preparing a paper-making reinforcing agent from waste paper, comprising the following steps:

[0030] Step 1, cutting the waste paper into small pieces, adding the pieces to the deinking aid, stirring and pulping, heat preservation and curing, to obtain deinked pulp;

[0031] Step 2: Add concentrated sulfuric acid dropwise to the deinked pulp, stir while adding, heat-preserve and seal at 55°C for 30 minutes, add deionized water to terminate the reaction, obtain a reaction solution, centrifuge the reaction solution, wash the precipitate with deionized water until the pH is Neutral to obtain nanocellulose;

[0032] Step 3, adding nanocellulose to dimethyl sulfoxide, adding sodium hydroxide under stirring conditions, heating to 65°C, adding 2,3-epoxypropyltrimethylammonium chloride dropwise, and keeping the temperature for 4 hours. Pour the reaction solution into ethanol to terminate the reaction, centrifuge the reaction solution, wash with ethanol, and dry t...

Embodiment 3

[0040] A method for preparing a paper-making reinforcing agent from waste paper, comprising the following steps:

[0041] Step 1, cutting the waste paper into small pieces, adding the pieces to the deinking aid, stirring and pulping, heat preservation and curing, to obtain deinked pulp;

[0042] Step 2: Add concentrated sulfuric acid dropwise to the deinked pulp, stir while adding, heat-preserve and seal at 70°C for 30 minutes, add deionized water to terminate the reaction, obtain a reaction solution, centrifuge the reaction solution, wash the precipitate with deionized water until the pH is Neutral to obtain nanocellulose;

[0043] Step 3, adding nanocellulose to dimethyl sulfoxide, adding sodium hydroxide under stirring conditions, heating to 70°C, adding 2,3-epoxypropyltrimethylammonium chloride dropwise, and keeping the temperature for 4 hours. Pour the reaction solution into ethanol to terminate the reaction, centrifuge the reaction solution, wash with ethanol, and dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com