Regenerative case paper board sludge reuse method

A technology for producing sludge and sewage, which is applied in the field of papermaking, and can solve problems such as the inability to reuse activated sludge, pollute white water of paper machines, sticky felts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

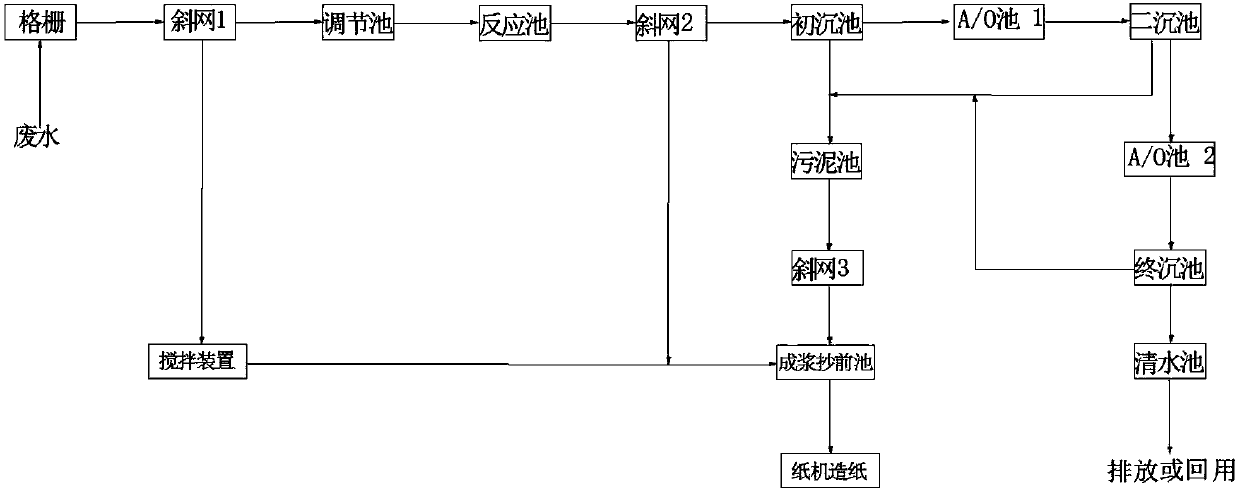

Image

Examples

Embodiment 1

[0024] Main sources of sludge: soaking waste paper pulping wastewater in the papermaking process, pulp rinsing wastewater, and wastewater discharged in the papermaking process.

[0025] Sewage water quality: pH: 6.5-7.0, COD: 2020mg / L, BOD: 1080mg / L, SS: 1640mg / L.

[0026] The waste water in the production process of the boxboard is removed by the grid to remove the suspended matter, and then the fibers filtered by the inclined screen 1 are directly transported to the pulping pre-processing pool after being passed through the stirring device. 10g / m3 of polyethyleneimine was put into the water for stirring reaction for 30 minutes, and then PAC was put into it for coagulation reaction, and the input amount of PAC was 10g / m3 of water. After being filtered by inclined screen 2, it enters the primary sedimentation tank for sedimentation for 2 hours, and the generated sludge is discharged into the sludge tank at a discharge rate of 50 tons / hour, and then discharged into the A / O tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com