Low-temperature replacement cooking method for bamboo kraft pulp

A kraft pulp and displacement cooking technology, which is applied in the direction of digester, papermaking, and raw material separation, can solve the problems of low mechanical strength, high chemical consumption, and large bamboo chip transportation, and achieve the purpose of retaining cellulose strength and undigested matter The effect of low content and low Kappa value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

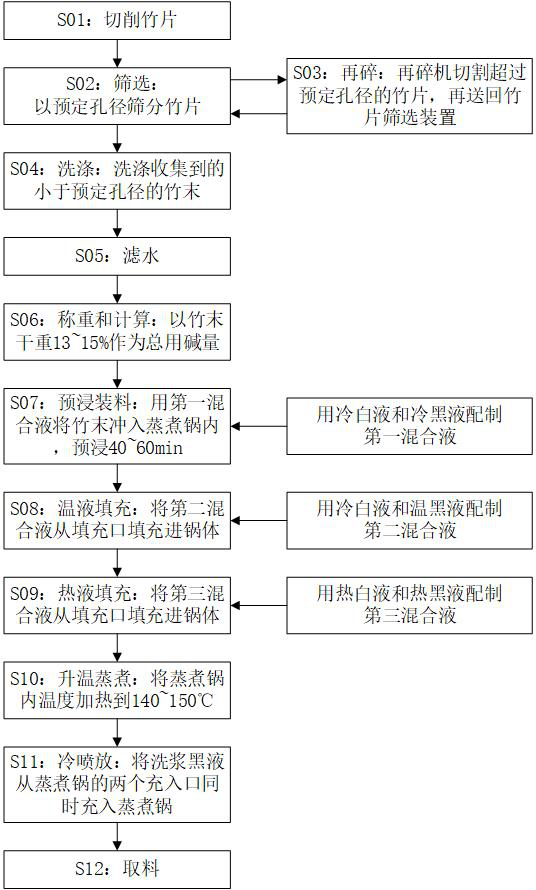

[0050] Bamboo cryogenic displacement kraft pulp cooking process, the implementation of the following steps:

[0051] S01: cutting bamboo: bamboo cut into the bamboo;

[0052] S02 is: Screening: The step of S01 obtained bamboo bamboo belt conveyor conveyed to the screening device for screening a predetermined aperture, bamboo extraction is performed over a predetermined aperture step S03, is smaller than the predetermined aperture bamboo collecting the last step performed by S04;

[0053] S03: broken again: the bamboo step S02 exceeds a predetermined aperture and then delivered to the mill by a belt conveyor, crusher and then cutting the bamboo, a bamboo strip cut from step S02 is repeated sieving steps;

[0054] S04: washing: the step S02 the end of the bamboo collected by washing 2H washing machine;

[0055] S05: drainage: The wash step S04 bamboo end by belt conveyor to the conveyor is provided with drainage and storage silo filter to a moisture of 49.5%;

[0056] S06: weighing ...

Embodiment 2

[0065] Bamboo cryogenic displacement kraft pulp cooking process, the implementation of the following steps:

[0066] S01: cutting bamboo: bamboo cut into the bamboo;

[0067] S02 is: Screening: The step of S01 obtained bamboo bamboo belt conveyor conveyed to the screening device for screening a predetermined aperture, bamboo extraction is performed over a predetermined aperture step S03, is smaller than the predetermined aperture bamboo collecting the last step performed by S04;

[0068] S03: broken again: the bamboo step S02 exceeds a predetermined aperture and then delivered to the mill by a belt conveyor, crusher and then cutting the bamboo, a bamboo strip cut from step S02 is repeated sieving steps;

[0069] S04: washing: the step S02 bamboo collected by the end of the washing machine washing for 2.5 h;

[0070] S05: drainage: The wash step S04 bamboo end by belt conveyor to the conveyor is provided with drainage and storage silo filter to a moisture of 48.5%;

[0071] S06: we...

Embodiment 3

[0080] Bamboo cryogenic displacement kraft pulp cooking process, the implementation of the following steps:

[0081] S01: cutting bamboo: bamboo cut into the bamboo;

[0082] S02 is: Screening: The step of S01 obtained bamboo bamboo belt conveyor conveyed to the screening device for screening a predetermined aperture, bamboo extraction is performed over a predetermined aperture step S03, is smaller than the predetermined aperture bamboo collecting the last step performed by S04;

[0083] S03: broken again: the bamboo step S02 exceeds a predetermined aperture and then delivered to the mill by a belt conveyor, crusher and then cutting the bamboo, a bamboo strip cut from step S02 is repeated sieving steps;

[0084] S04: washing: the step S02 the end of the bamboo collected by washing 3H washing machine;

[0085] S05: drainage: The wash step S04 bamboo end by belt conveyor to the conveyor is provided with drainage and storage silo filter to a moisture of 48.9%;

[0086] S06: weighing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com