Method for improving mechanical properties and hydrophobic and oleophobic properties of aramid insulating paper

A hydrophobic and oleophobic technology with mechanical properties, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of accelerated aging of transformer insulating paper, reduced thermal stability of meta-aramid fibers, and reduced mechanical properties, and achieves excellent mechanical properties. Excellent performance, hydrophobic and oleophobic properties, and the effect of increasing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

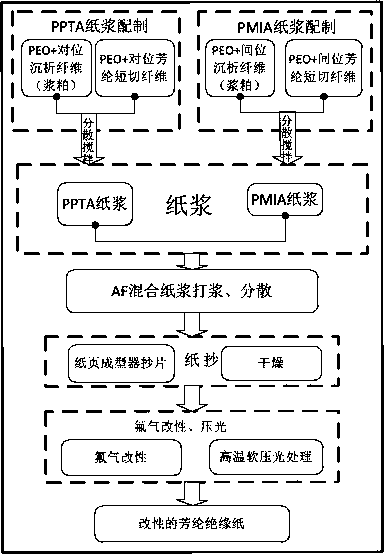

Method used

Image

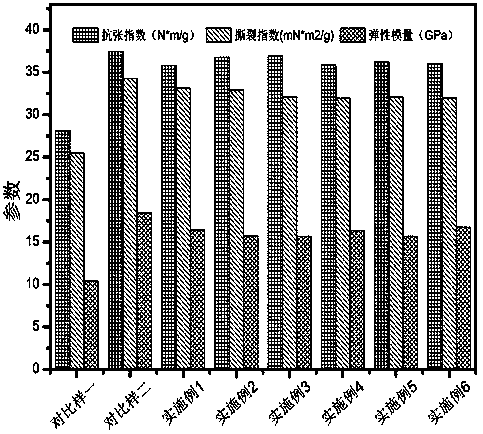

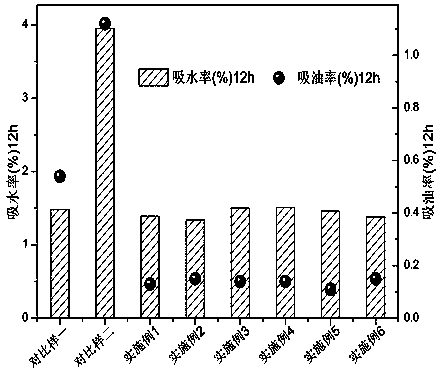

Examples

Embodiment 1

[0036] 1. Aramid fiber paper making

[0037] 1. Add the dispersant polyethylene oxide (PEO) to the meta-aramid chopped fiber solution and the meta-sedimented fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1000 r / min, and the stirring time is 10 min at a temperature of 50 °C.

[0038] 2. Add the dispersant polyethylene oxide (PEO) to the para-aramid chopped fiber solution and the para-precipitated fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1000 r / min, and the stirring time is 10 min at a temperature of 50 °C.

[0039] 3. Preparation method of meta-aramid mixed solution (PMIA): mix according to the mass ratio of precipitated fiber solution (PMIA-2) and chopped fiber solution (PMIA-1) at 1:1.2, and disperse and stir. The dispersing stirring speed was 1000 r / min, the stirring time was 40 min, and the temperature was 50 °C.

[0040] 4. Preparation method of para-aramid mixed solution (PPTA): mix according to the...

Embodiment 2

[0053] 1. Aramid fiber paper making

[0054] 1. Add the dispersant polyethylene oxide (PEO) to the meta-aramid chopped fiber solution and the meta-sedimented fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1000 r / min, and the stirring time is 15 min at a temperature of 55 °C.

[0055] 2. Add the dispersant polyethylene oxide (PEO) to the para-aramid chopped fiber solution and the para-precipitated fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1000 r / min, and the stirring time is 15 min at a temperature of 55 °C.

[0056] 3. Preparation method of meta-aramid mixed solution (PMIA): mix the precipitated fiber solution (PMIA-2) and the chopped fiber solution (PMIA-1) with a mass ratio of 1:1.3, and disperse and stir. The stirring speed was 1000 r / min, the stirring time was 40 min, and the temperature was 55 °C.

[0057] 4. Preparation method of para-aramid mixed solution (PPTA): mix the precipitated fiber solution ...

Embodiment 3

[0070] 1. Aramid fiber paper making

[0071] 1. Add the dispersant polyethylene oxide (PEO) to the meta-aramid chopped fiber solution and the meta-sedimented fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1100 r / min, and the stirring time is 15 min at 60°C.

[0072] 2. Add the dispersant polyethylene oxide (PEO) to the para-aramid chopped fiber solution and the para-precipitated fiber (pulp) respectively, and disperse and stir. The stirring speed is set to 1100 r / min, and the stirring time is 15 min at 60°C.

[0073] 3. Preparation method of meta-aramid mixed solution (PMIA): mix the precipitated fiber solution (PMIA-2) and the chopped fiber solution (PMIA-1) with a mass ratio of 1:1.3, and disperse and stir. The stirring speed was 1100 r / min, the stirring time was 40 min, and the temperature was 60 °C.

[0074] 4. Preparation method of para-aramid mixed solution (PPTA): Mix the precipitated fiber solution (PPTA-2) and the chopped fiber solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com