Patents

Literature

83results about How to "Improve water and oil repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

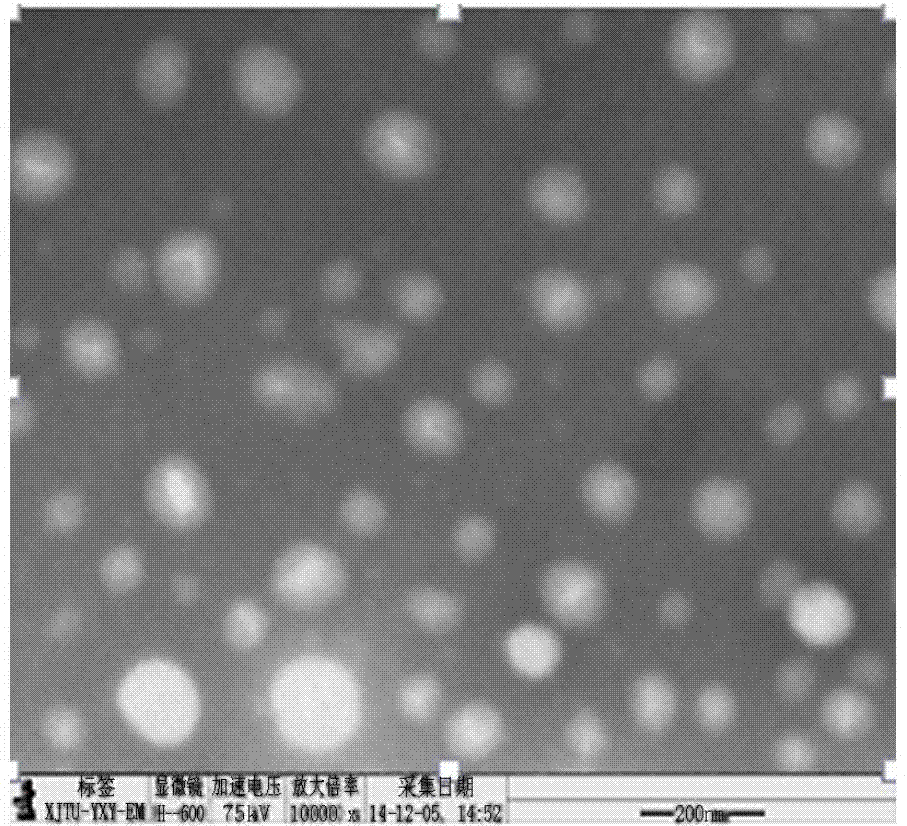

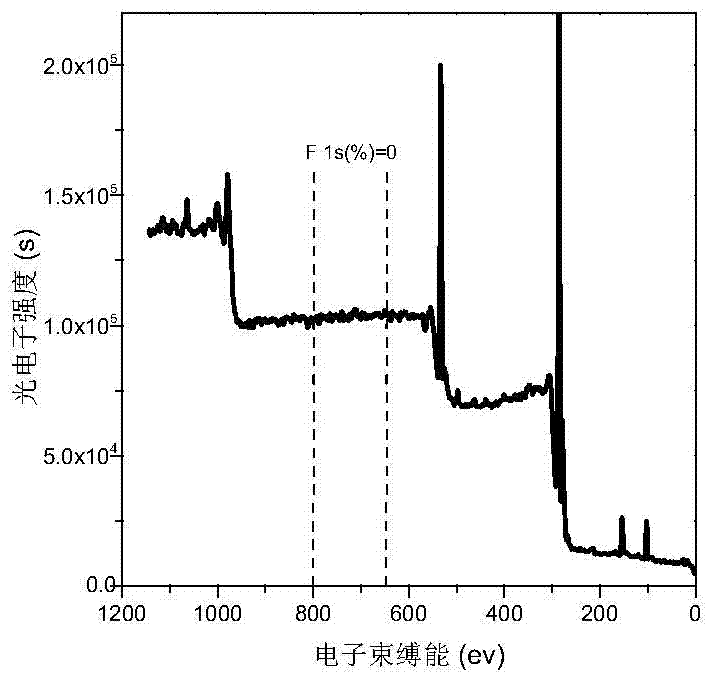

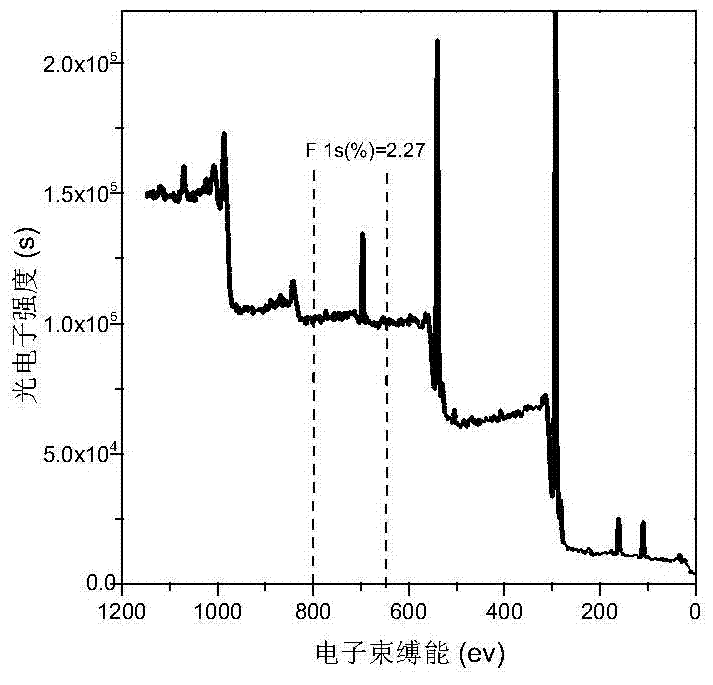

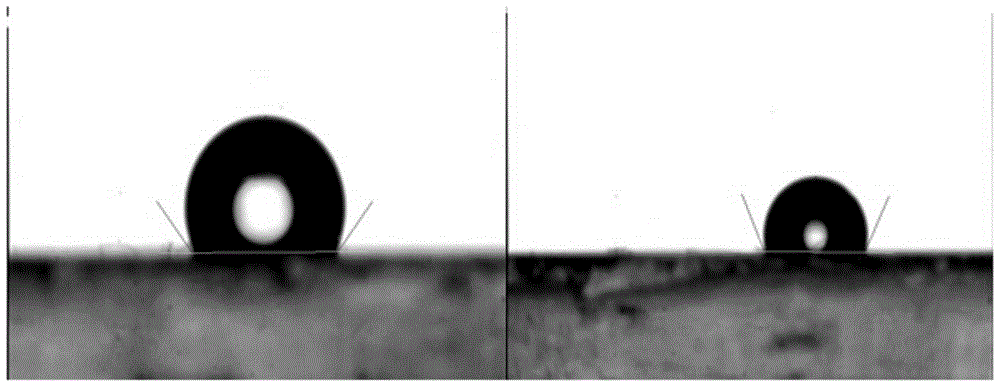

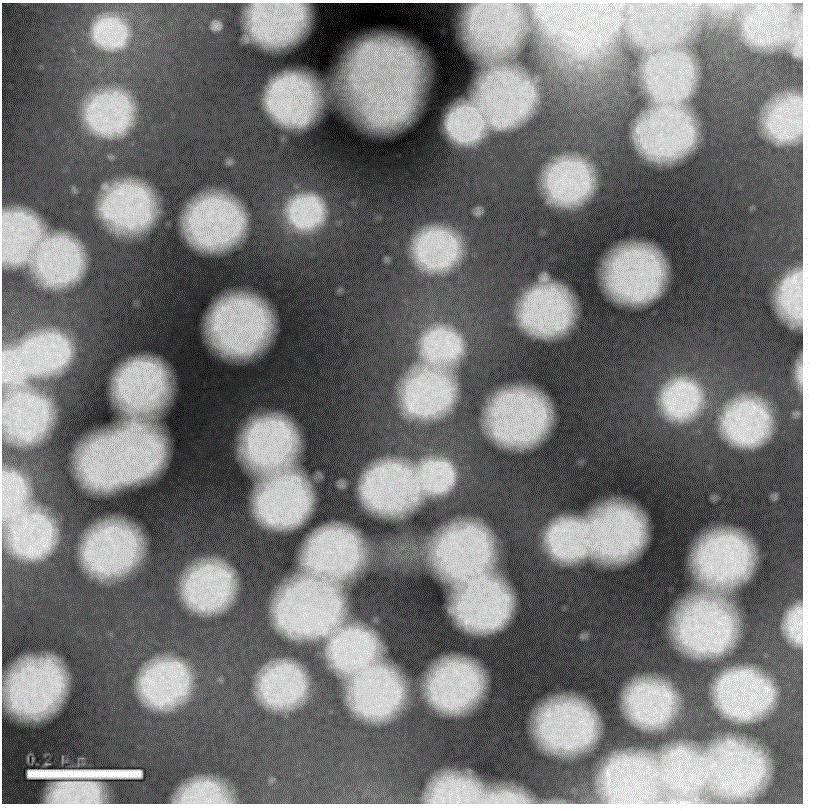

Method for preparing core-shell nano SiO2/fluorine-containing polyacrylate soap-free emulsion

ActiveCN103289010AIncreased stability and solids contentImprove water and oil repellencyFibre treatmentNano sio2Emulsion

The invention provides a method for preparing a core-shell nano SiO2 / fluorine-containing polyacrylate soap-free emulsion. The method provided by the invention can be used for synthesizing the core-shell nano SiO2 / fluorine-containing polyacrylate soap-free emulsion by introducing nano SiO2 by a sol-gel method and copolymerizing a polymerizable emulsifier, a fluorinated acrylic ester monomer and an acrylate monomer with double-bond alkoxy silane, by a soap-free emulsion polymerization technique; and the core-shell nano SiO2 / fluorine-containing polyacrylate soap-free emulsion is suitable for being used as a fabric waterproof / oilproof finishing agent. The method provided by the invention has the advantages that negative influence of a small molecular emulsifier on fluorine containing polyacrylate is eliminated, excellent properties of nano SiO2 are introduced into the fluorine-containing polyacrylate and the fluorine-containing monomer is located at the shell layer, and therefore, a fabric finishing agent with excellent water repellence and oil repellence is obtained; and compared with the similar products, the fabric finishing agent prepared by the method provided by the invention is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

Process for preparing fluorin, silicon, epoxide modified low surface energy acrylate emulsion for heavy anti-corrosion paint

InactiveCN1944476AIncrease elasticityImprove crack resistanceAnti-corrosive paintsPolymer scienceEmulsion

The present invention discloses preparation process of fluorine, silicon and epoxide modified low surface energy acrylate emulsion for heavy anti-corrosive paint. The modified acrylate emulsion is prepared with one or more of styrene, methyl methacylate, butyl acrylate, isobutyl acrylate, tert-butyl acrylate, etc as the main monomer and through introducing modifying fluorine, silicon and epoxide. The process of the present invention has simple operation and high yield, and the prepared emulsion has high water tolerance, high solvent tolerance, high acid and alkali resistance, high stability and capacity of forming film with surface energy as low as 15.5 mN / m.

Owner:HUBEI UNIV

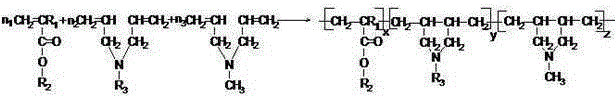

Environment-friendly fluorinated polyurethane-polyacrylate emulsion and preparation method thereof

ActiveCN104744651AGood storage stabilityImprove water resistancePolyurea/polyurethane coatingsPrepolymerFluorinated monomers

The invention discloses an environment-friendly fluorinated polyurethane-polyacrylate emulsion and a preparation method thereof. The preparation method comprises the following steps: polymerizing diisocyanate, dimethylolpropionic acid, a functional monomer and an anionic hydrophilic chain extender under the presence of a catalyst so as to obtain an isocyanate-terminated double-bond prepolymer; neutralizing with alkali and adding the water solution of a hydrophilic small-molecule chain extender for dispersing, and further initiating a fluorinated monomer and an acrylic monomer under the effect of a water-soluble initiator so as to obtain the environment-friendly fluorinated polyurethane-polyacrylate emulsion. The emulsion adopts a self-emulsifying method, and is subject to a post-chain extension method and free from any organic solvent or small-molecule emulsifier; and the emulsion is good in storage stability, and by introducing fluorine atoms, the water resistance and the solvent resistance of waterborne polyurethane are effectively improved. The emulsion is applicable to a waterborne coating, and a prepared coating film has the properties of excellent water and oil-proofing performance, heat resistance, being non-toxic, safe and highly glazed, and the like.

Owner:广东拓普合成科技股份有限公司

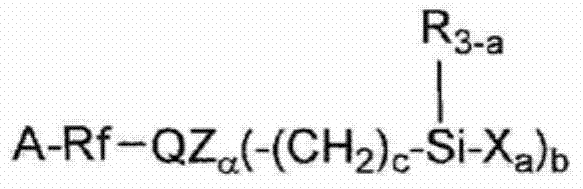

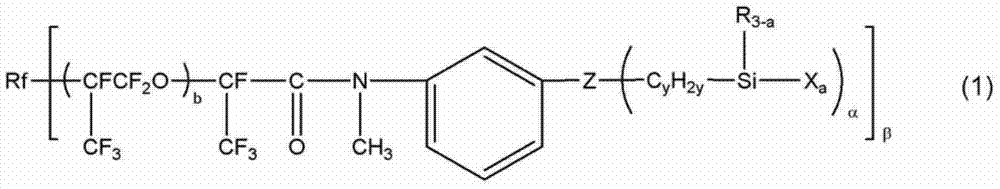

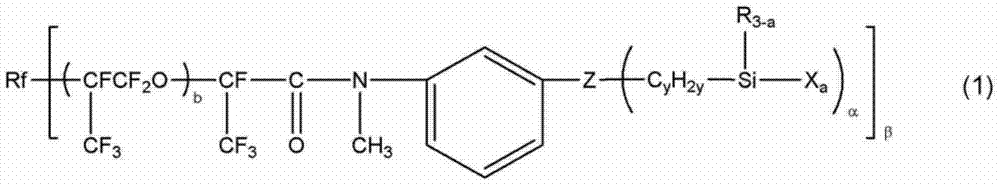

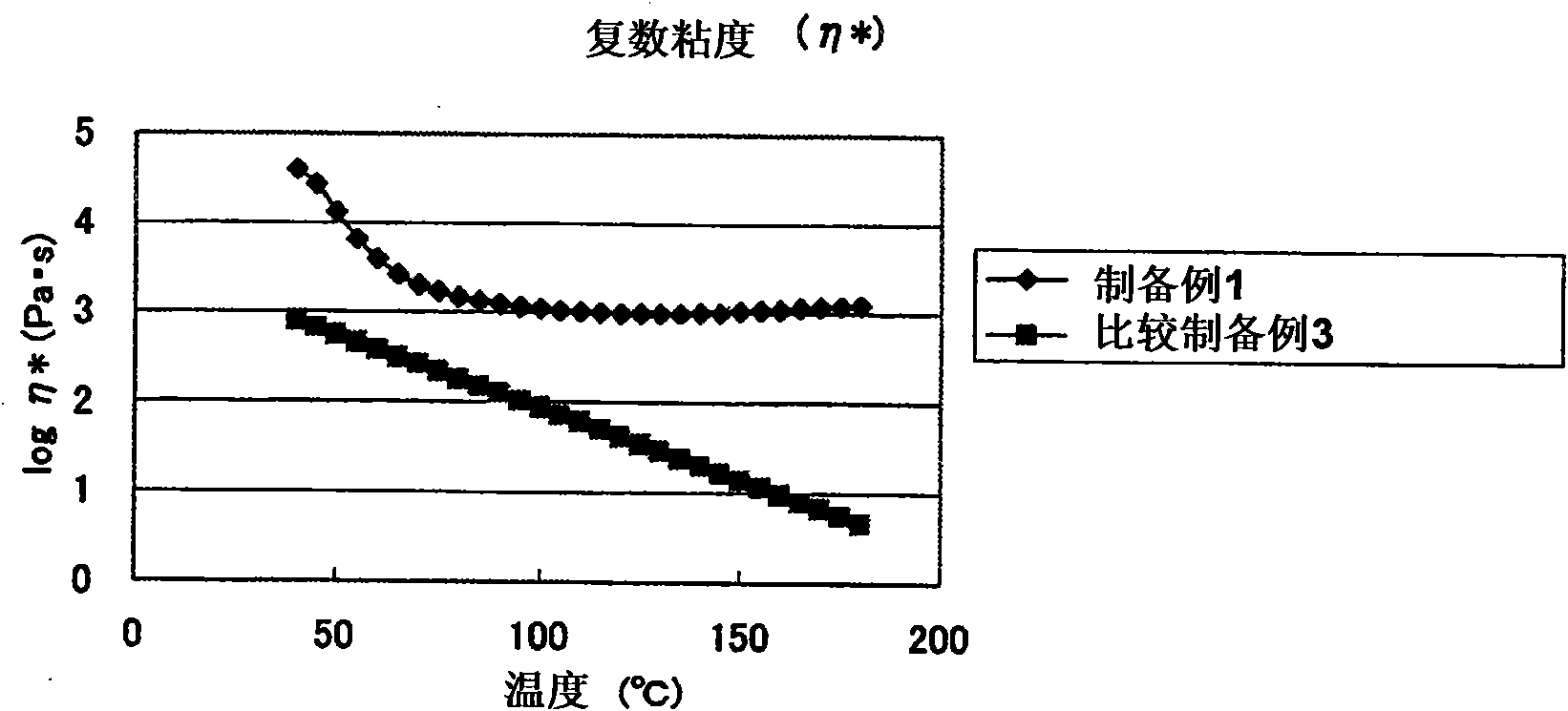

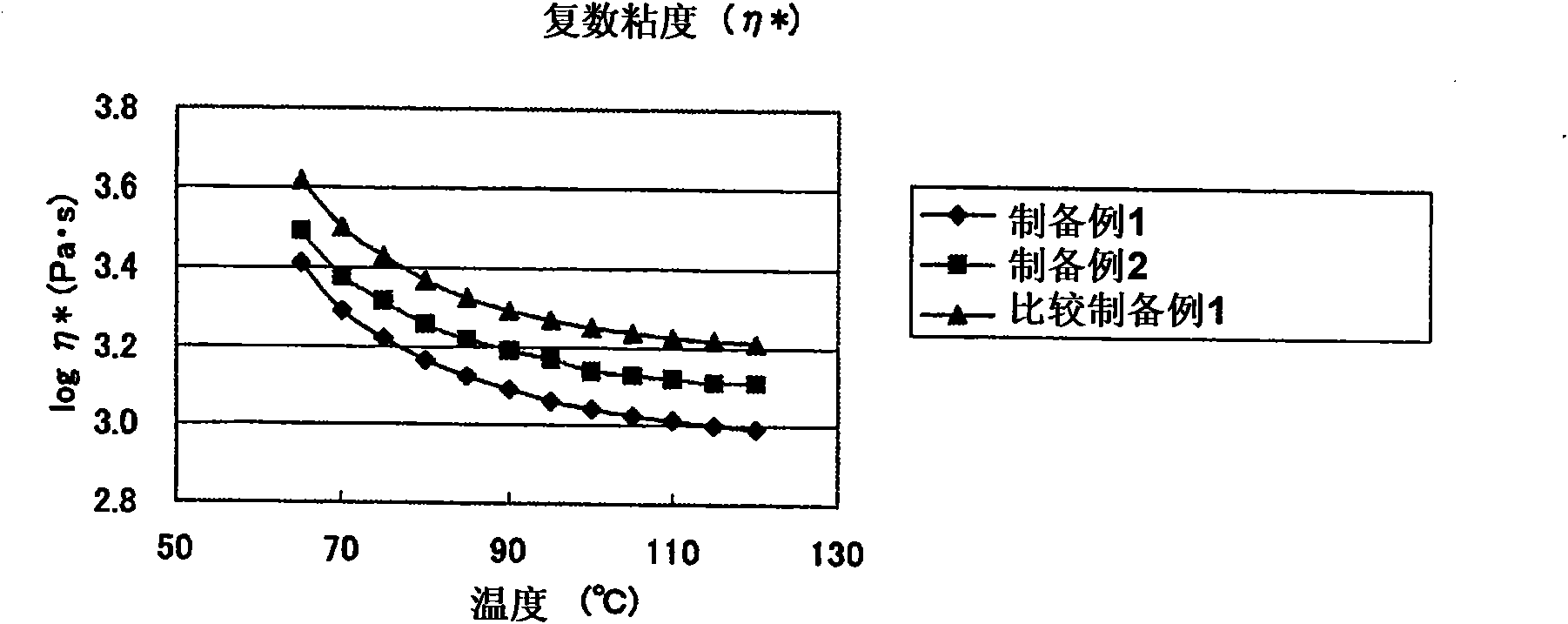

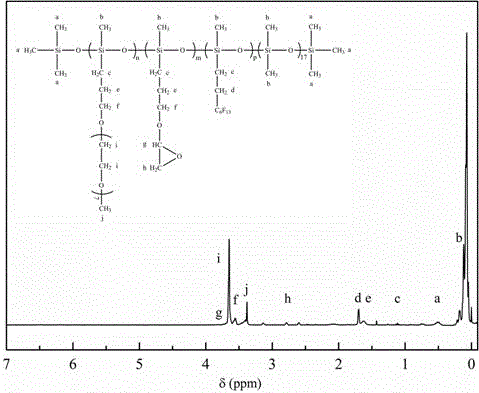

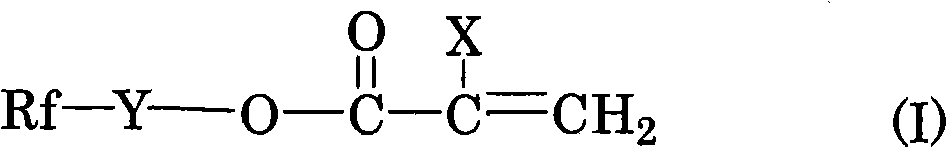

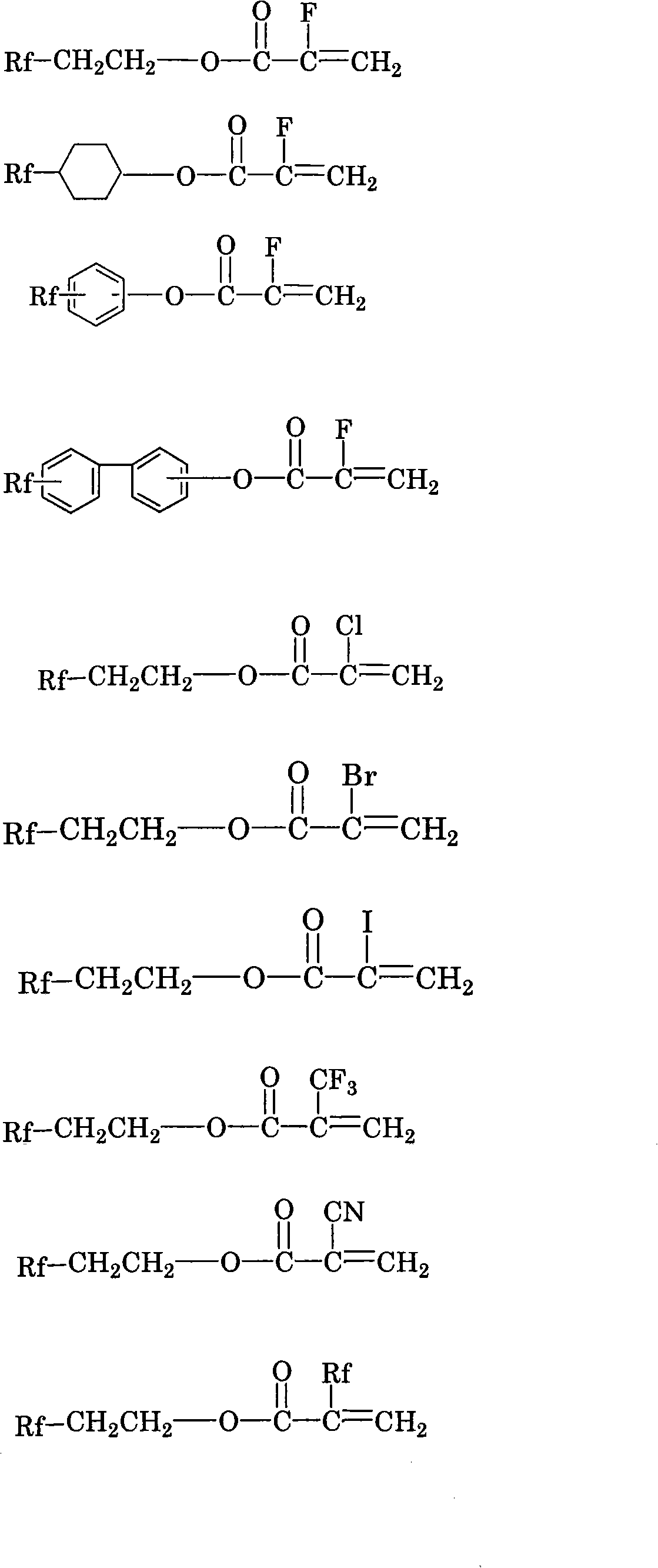

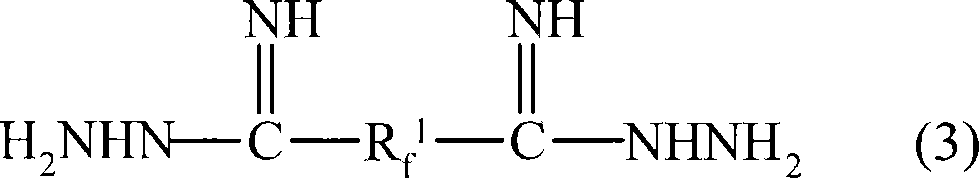

Polymer modification silane containing fluoro oxidation alkylene, surface treating agent relating same and object

ActiveCN104119524AImprove water and oil repellencyExcellent water and oil repellencyPolyether coatingsPolymer sciencePolymer modified

The invention provides a polymer modification silane containing fluoro oxidation alkylene and having a waterproof oilproof layer of excellent heat proof property, a surface treating agent having the silane and / or partial hydrolytic condensation product, and an object processed by the surface treating agent. The polymer modification silane containing fluoro oxidation alkylene is indicated by a following formula (1) (wherein, Rf refers to univalent or divalent linear link polymer residue containing fluoro oxidation alkylene, b is averagely 0-10, Z is a single 2-6valent group containing siloxane bond, R is singly alkyl or phenyl of 1-4 carbon atoms, X is a single hydrolytic group, a is a single 2 or 3, y is an integer between1-5 of each unit, alpha is an integer of 1-5, and beta is 1 or 2).

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method of washable three-proofing and easy-decontamination antibacterial fabric

InactiveCN111535026AMeet environmental protection requirementsImprove washing resistanceStain/soil resistant fibresBiochemical fibre treatmentProcess engineeringCross linker

The invention discloses a preparation method of a washable three-proofing and easy-decontamination antibacterial fabric. The preparation method is characterized by comprising the following steps of: soaping, to be specific, after desizing, scouring, bleaching and mercerizing the fabric in advance, removing impurities on the cloth cover by a soaping process, and then drying; and performing one-bathprocess washable three-proofing and easy-decontamination antibacterial finishing, to be specific, shaping and processing the soaped and dried fabric on a shaping machine, drying, baking and finishing, thereby obtaining the washable three-proofing and easy-decontamination antibacterial fabric. A working solution which simultaneously contains a C6 durable three-proofing finishing agent, a purifiedcotton durable fluorine-free waterproof agent, a durable crosslinking agent, an antibacterial agent and a special waterproof penetrant is contained in a rolling groove of the shaping machine, and thefabric is subjected to padding, then is dried and baked to obtain the washable three-proofing and easy-decontamination antibacterial fabric. The preparation method solves the contradiction between thethree-proofing and the easy decontamination, and also solves the problems between the three-proofing and the bacteria prevention; and meanwhile the fabric is endowed with the function of washing resistance, and can meet the overall actual needs for functional fabrics in actual situations.

Owner:江苏康乃馨纺织科技有限公司

Fluorine-containing polymer and water- and oil-repellent agent

ActiveCN101981070AGood film formabilityGood waterproof and oil-proofLiquid repellent fibresWoven fabricsEmulsionFluorine containing

A water- and oil-repellent agent is an aqueous emulsion containing a fluorine-containing polymer. The fluorine-containing polymer comprises (a) a fluorine-containing monomer, and (b) a crosslinkable monomer, wherein the monomers (a) and (b) are polymerized in the presence of a chain transfer agent to produce the fluorine-containing polymer.

Owner:DAIKIN IND LTD

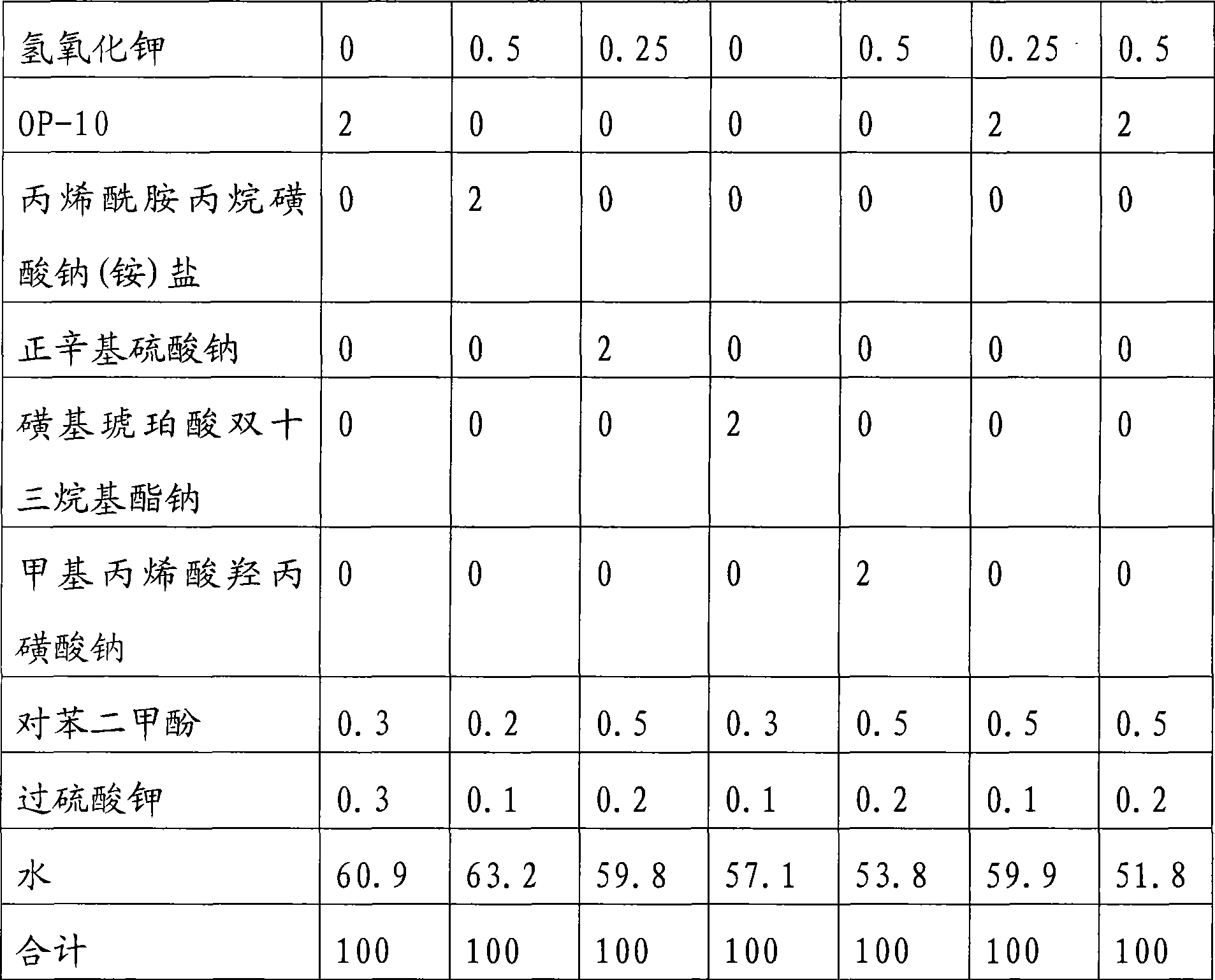

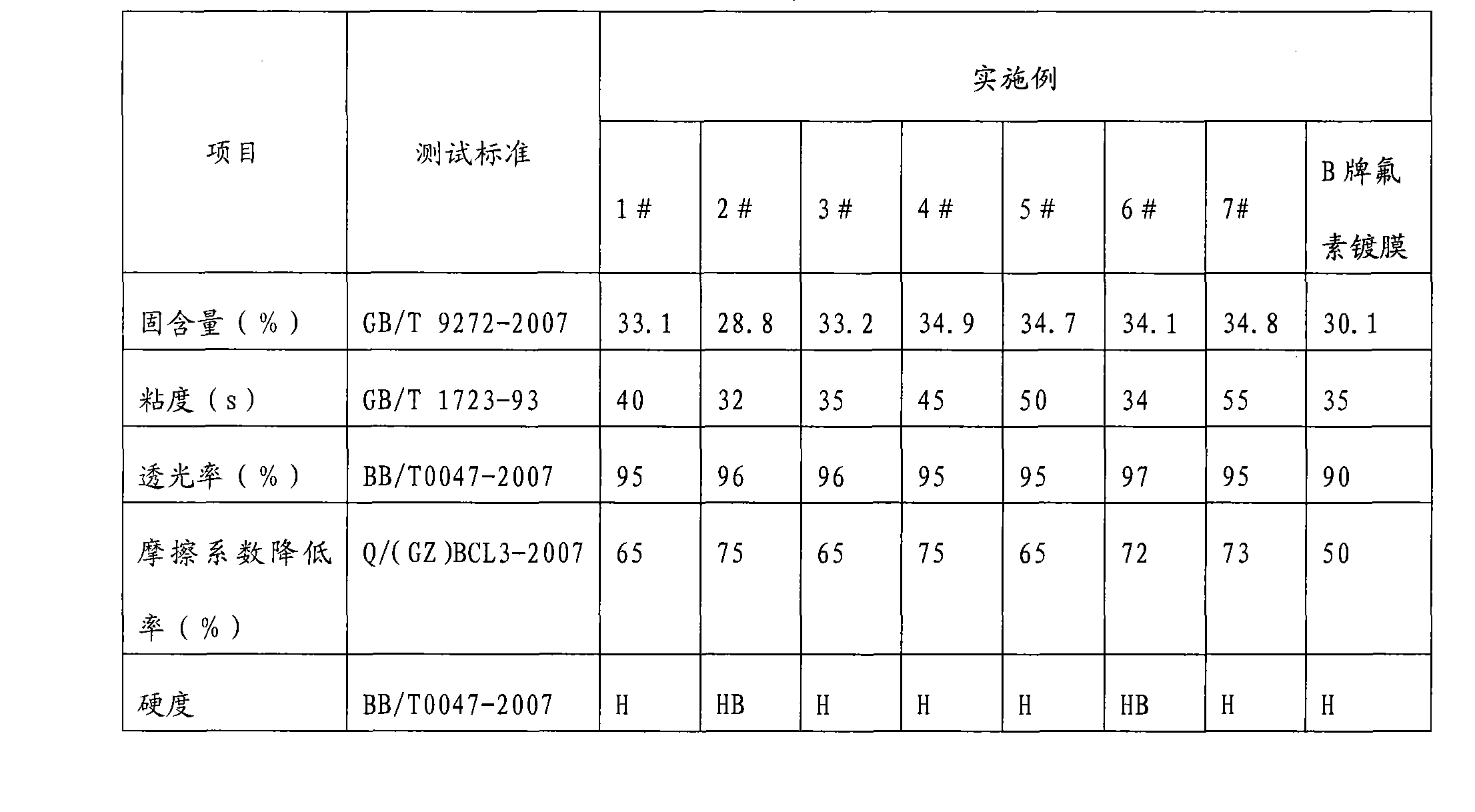

Water and oil proofing agent and preparation method thereof

ActiveCN104562684AImprove water and oil repellencyLow costFibre treatmentParaffin waxMicrocrystalline wax

The invention relates to a water and oil proofing agent and a preparation method thereof. The water and oil proofing agent comprises a fluoro-containing polymer component, a wax component, an emulsifier, a cosolvent and deionized water in a mass ratio of 1:0.1-0.4:0.05-0.15:0.1-0.3:2-4, wherein the fluoro-containing polymer component is copolymerized from a fluoro-containing monomer, an acrylate monomer and a reactive monomer with crosslinking feature in a mass ratio of 20-40:45-75:5-15; and the wax component is paraffin or microcrystalline wax or a mixture of paraffin and microcrystalline having a melting point of 50-70 DEG C. The water and oil proofing agent can be used for greatly improving the water and oil proofing performance of fabrics, and is more environment-friendly and lower in price in comparison with C8 products in the prior art especially when the fluoro-containing polymer component is a short-chain fluoroalkyl monomer having the number of carbon atoms of 1-6, and is capable of achieving the water and oil proofing performance of the C8 products.

Owner:京准化工技术(上海)有限公司

Preparation method of water-based fluorine-acrylic acid-containing self-stratifying emulsion for protection of concrete surface

The invention provides a preparation method of water-based fluorine-acrylic acid-containing self-stratifying emulsion for protection of a concrete surface. A fluorine-containing modified acrylic acid core-shell emulsion prepared by adopting an emulsion polymerization method, an acrylic acid core-shell emulsion, various auxiliaries and water are prepared into a self-stratifying emulsion for protection of concrete surface, the coating technology is simplified, the excellent weather resistance, contamination resistance, hydrophobic and oleophobic property advantages of the fluorine-containing (methyl) acrylate can be played to the greatest extent, the environment protection can be achieved, and the cost can also be lowered.

Owner:JIANGSU SOBUTE NEW MATERIALS

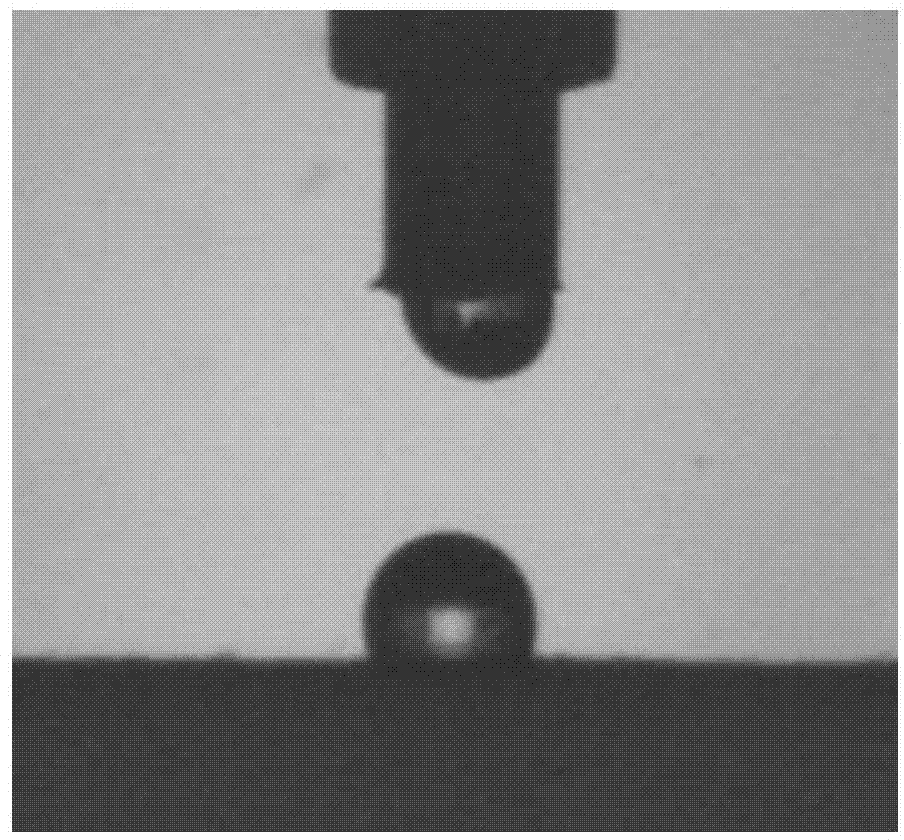

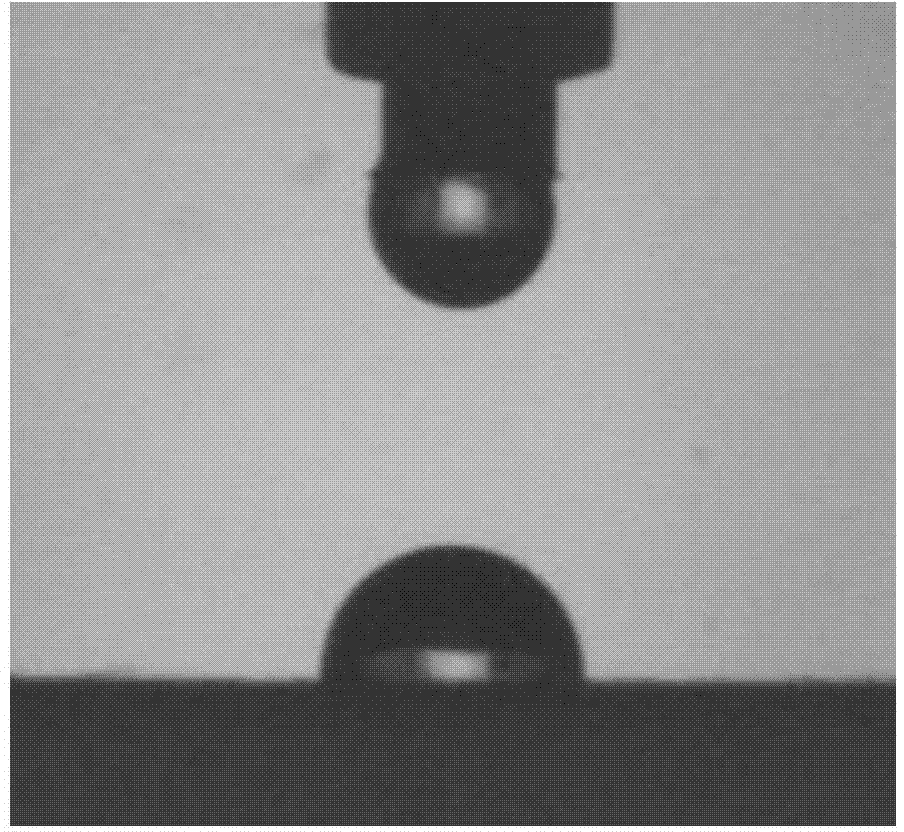

Core-shell type short-chain fluorine-containing acrylate emulsion and preparation method thereof

InactiveCN105440201ASolve the hazardHigh crystallinityCoatingsVegetal fibresFunctional monomerPolymer chemistry

The present invention discloses core-shell short-chain fluorine-containing acrylate emulsion and a preparation method thereof. A series of core-shell short-chain fluorine-containing acrylate emulsion are synthesized from methyl methacrylate (MMA) and butyl acrylate (BA) copolymer as a core and a short fluorocarbon chain 2-(perfluorohexyl) ethyl methacrylate (FMA6) and non-fluoro alkyl methacrylate copolymer as a shell by a multi-step emulsion polymerization method. The core-shell short-chain fluorine-containing acrylate emulsion solves the environmental problem caused by a C8 fluorine-containing monomer as an essential functional monomer used in a main three-control finishing agent, and meanwhile makes up the defect of shortage of product water-repellent and oil-repellent effects when an environmentally friendly C6 fluorine-containing monomer is used as an essential functional monomer. The product has a core-shell structure, the shell layer is rich in a fluorine-containing acrylate component, the amount of the fluorine monomer in the emulsion can be greatly reduced, cost is reduced, water contact angle and oil contact angle of a product latex film are large, and the core-shell short-chain fluorine-containing acrylate emulsion used in textile finishing exhibits excellent water and oil repellency.

Owner:NANJING UNIV OF SCI & TECH

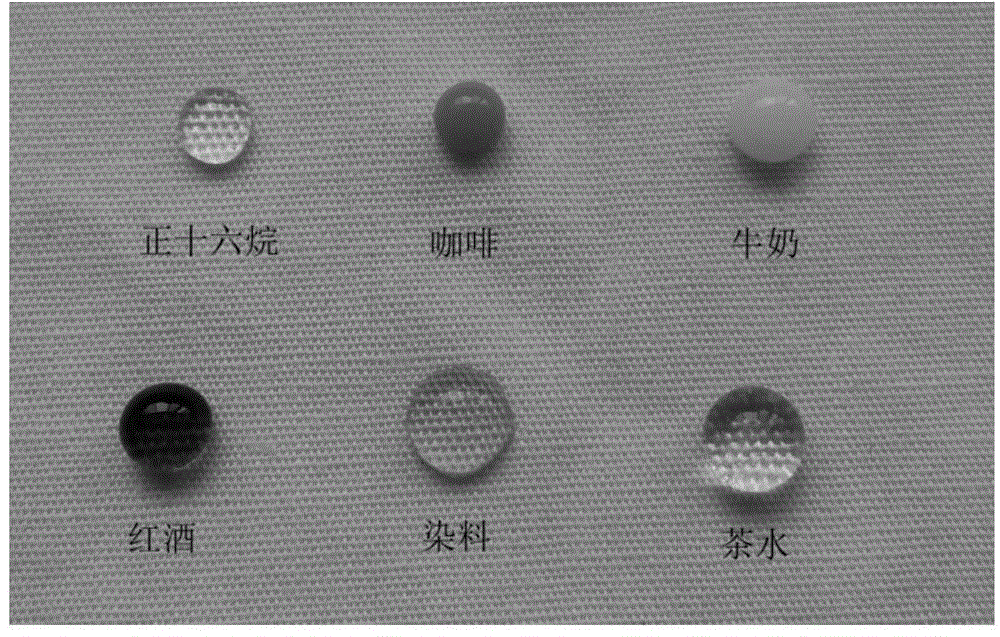

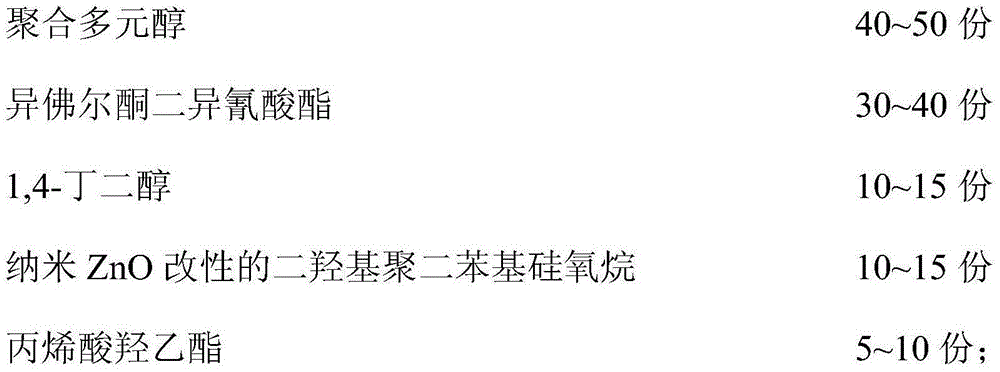

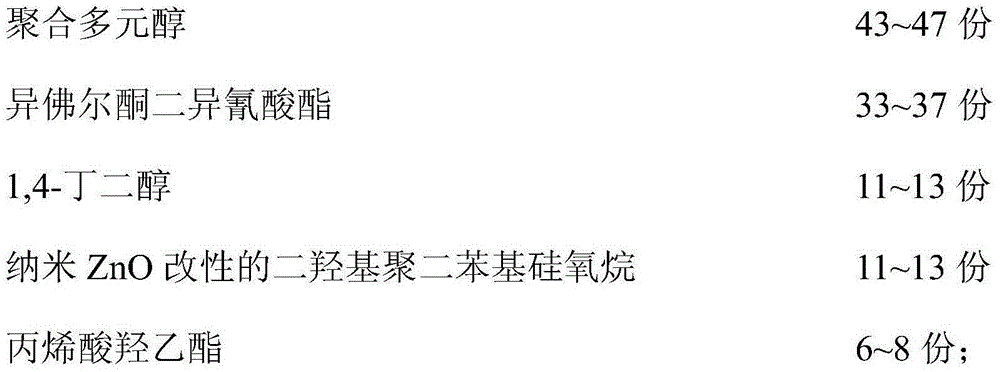

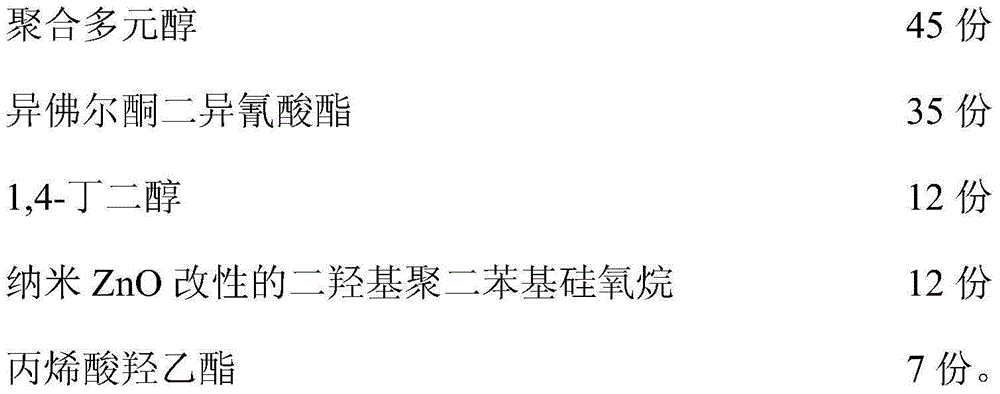

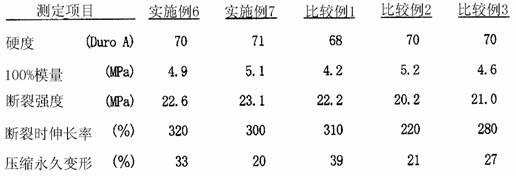

Waterproof breathable antibacterial thermoplastic polyurethane elastomer and preparation method thereof

The present invention provides a waterproof breathable antibacterial thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer is prepared from the following main components by weight: 40-50 parts of polymeric polyol, 30-40 parts of isophorone isocyanate, 10-15 parts of 1,4-butanediol, 10-15 parts of nano ZnO-modified dihydroxy polydiphenylsiloxane and 5-10 parts of hydroxyethyl acrylate. The present invention uses a mixture of fluorine-containing polyether glycol and adipic acid 1,4-butanediol adipate diol as the polymeric polyol; the synergic effect of the two improves the water and oil repellency of the target product; while dihydroxy polydiphenylsiloxane and hydroxyethyl acrylate supplemented with nano ZnO increase the antibacterial properties of the thermoplastic polyurethane elastomer, and endow the elastomer with good mechanical properties.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

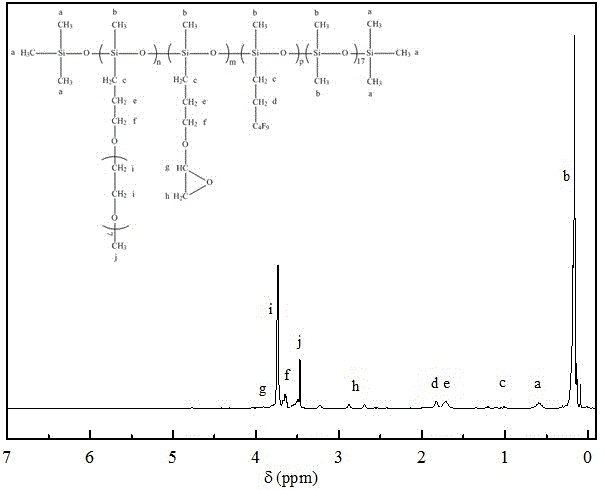

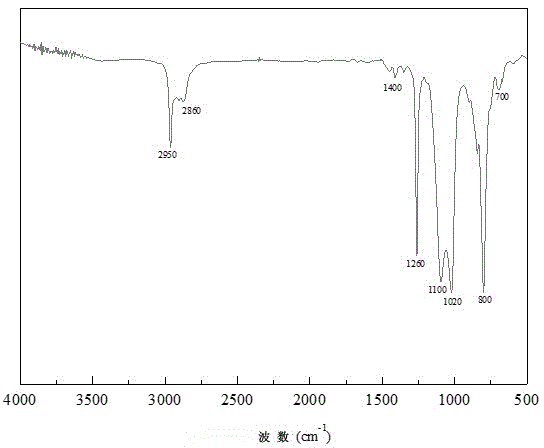

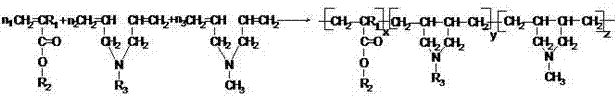

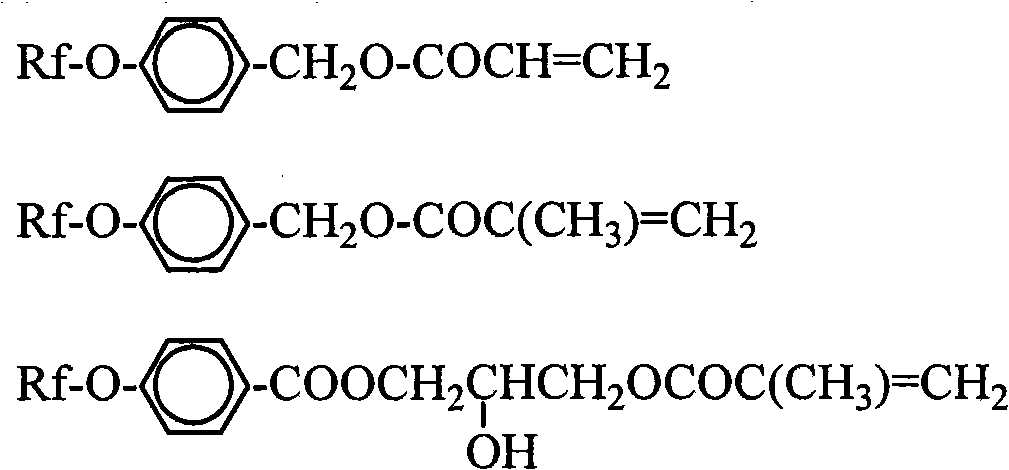

Fabric finishing agent and preparation method thereof

InactiveCN105484046AImprove water and oil repellencyImprove washabilityFibre treatmentEngineeringFluorine containing

The invention relates to a fabric finishing agent and a preparation method thereof, and belongs to the technical field of printing and dyeing auxiliary agents. The fabric finishing agent contains a polyether chain segment, an epoxy group and a fluorine-containing chain segment at the same time, and the one end of the fluorine-containing chain segment contains an alkene. the characteristics of being safe in raw materials, simple in technology and the like are provided when the fabric finishing agent is applied to printing and dyeing and the preparation method is applied to prepare the fabric finishing agent, the fabric finishing agent is capable of keeping original clothes performances and hand feeling of fabrics, and also is capable of effectively improving the water-repellent oil-repellent properties of fabrics.

Owner:浙江七色彩虹纺织整理有限公司

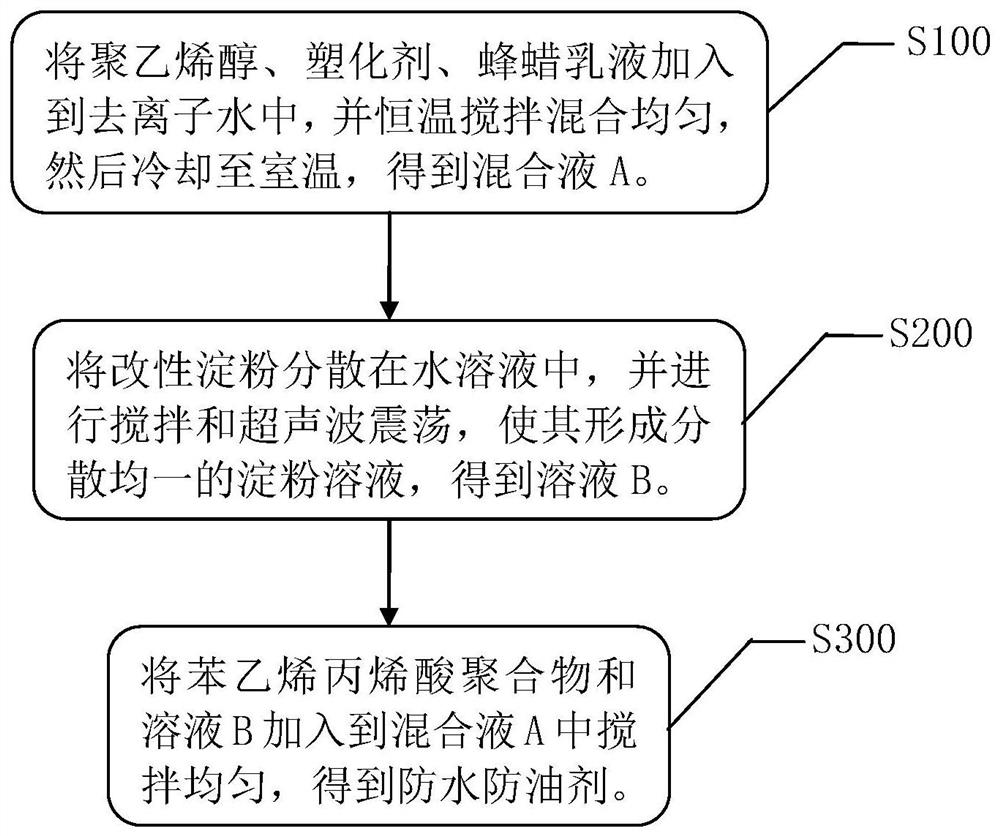

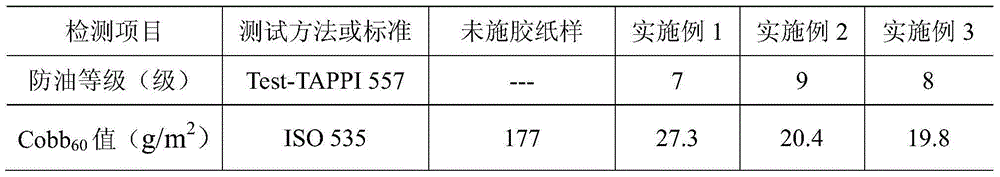

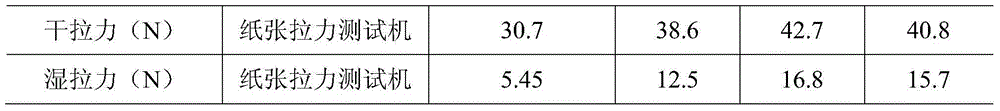

Waterproof and oilproof agent as well as preparation method and application thereof

InactiveCN111749042AGood film formingImproved water and oil repellencyNon-macromolecular organic additionPaper coatingPolymer sciencePolyvinyl alcohol

The invention relates to a waterproof and oilproof agent as well as a preparation method and application thereof. The waterproof and oilproof agent is prepared from the following components in percentage by weight: 30%-50% of styrene acrylic polymer, 5%-10% of beeswax emulsion, 2.5%-4.5% of polyvinyl alcohol, 2%-5.5% of modified starch, 0.5%-2% of plasticizer and 28%-60% of deionized water. The waterproof and oilproof agent is good in film-forming property; beeswax emulsion in a formed coating and the styrene-acrylic acid polymer are combined to form a hydrophobic and oleophobic surface layer;meanwhile, the hydrophobic and oleophobic surface layer is compounded with the modified starch, so that the waterproof and oilproof effects of the waterproof and oilproof coating on food-grade raw paper are obviously improved; the waterproof and oilproof properties of the waterproof and oilproof agent are extremely good; the waterproof and oilproof agent can completely replace traditional waxing,silicon coating and laminating processes; and the paper can directly enter a papermaking pulping system to be recycled when being recycled, the pollution of the laminated paper to the environment isreduced; and therefore, the waterproof and oilproof agent is an environment-friendly material.

Owner:ZHONGSHAN TIAN JIA PAPER PROD

UV-curable low-shrinkage environment-friendly coating

The invention discloses a UV-curable low-shrinkage environment-friendly coating, and belongs to the field of coatings, in particular to the field of UV-curable coatings. The UV-curable low-shrinkage environment-friendly coating comprises the following raw materials: cis-butenedioic anhydride, cyclohexanol methacrylate, methyl methacrylate, epoxy resin, tetraethyl orthosilicate, sodium dodecyl sulfonate, a solvent, a wetting agent, a dispersant, a leveling agent, a photoinitiator, an anti-skimming agent, white carbon black and asbestos dust. The curing product of the coating is excellent in performance, and a sample obtained after curing has excellent adhesion, scratch resistance and anti-fouling performance.

Owner:CHENGDU NASHUO TECH

Water-based waterproof oil-proof agent for special paper, and preparation method thereof

The invention relates to a water-based waterproof oil-proof agent for special paper, and a preparation method thereof. The preparation method comprises the following steps: enabling a polyisocyanate compound and water to react with hydrogen-containing silicone oil, vinyl polyether, perfluoro-acrylate, glycidyl methacrylate, long alkyl chain methacrylates and chloroplatinic acid to obtain a product under the dark condition; performing grafted polymerization reaction to the hydrogen-containing silicone oil, vinyl polyether, perfluoro-acrylate, glycidyl methacrylate and long alkyl chain methacrylates under the catalysis action of chloroplatinic acid, and then adding a polyisocyanate compound to partially close hydroxyl on a polymer chain, thus obtaining the water-based waterproof oil-proof agent for special paper, and the water-based waterproof oil-proof agent for special paper has excellent mechanical performance and waterproof and oil-proof properties. The prepared waterproof oil-proof agent can be compounded with a starch water solution and used for paper surface sizing, so that the waterproof, oil-proof, mechanical strength and softness of paper can be greatly improved.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

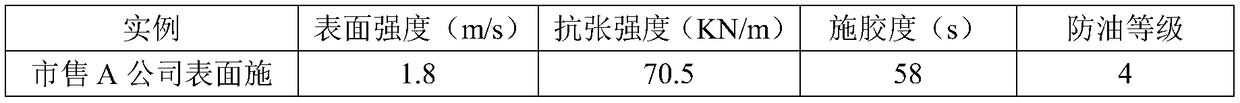

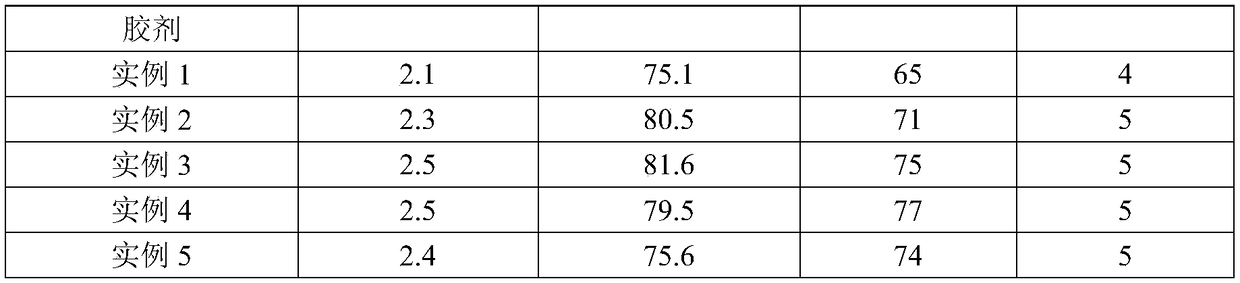

Preparation method of cationic core-shell fluorinated acrylate-alkyd resin surface sizing agent

ActiveCN108623754AImprove water and oil repellencyImprove physical strengthWater-repelling agents additionPaper coatingDouble bondSizing

The invention discloses a preparation method of a cationic core-shell fluorinated acrylate-alkyd resin surface sizing agent, and relates to the technical field of sizing for paper making. The method adopts a solution phase inversion emulsion polymerization method, ensures that acrylic monomer is grafted to alkyd resin through the adding of an initiator and double bond bonding, forms the sizing agent for a core-shell structure by taking the theoleophylic alkyd resin as a core and the hydrophilic acrylic monomer as a shell through crosslinking, and ensures that a system combines the water and oil proofing property of fluorinated acrylic resin and the high adhesive property of alkyd resin, thereby being capable of effectively improving the water and oil proofing property and physical strengthproperty of paper.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

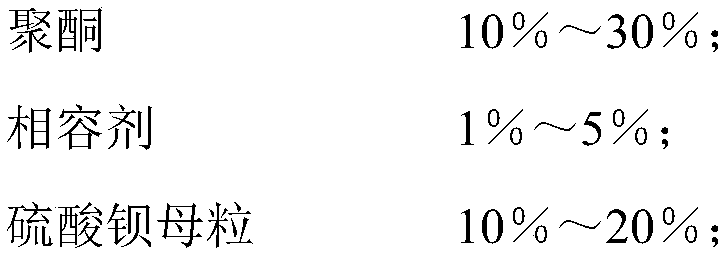

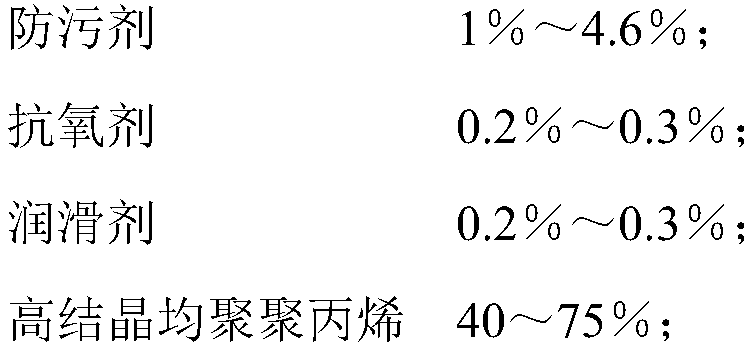

Pollution-resistance high-temperature-resistance polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer composite material modification, and particularly relates to a pollution-resistance high-temperature-resistance polypropylene material and a preparation method thereof. The polypropylene material is characterized in that high-crystallization homopolymer polypropylene is taken as a basic component, polyketone resin is added to improve the wearresistance and mechanical performance of the material, barium sulfate masterbatch is taken as a filling agent to reduce dust pollution, a compatibilizer is added to improve the bonding force betweenraw materials to improve the mechanical performance of the material, organic group modified ultrahigh molecular weight polyorganosiloxane is taken as an antifouling agent to improve the water and oilresistance and the wear resistance of the material, and the anti-ageing performance of the material is improved by adopting an antioxidant. The material has the advantages of easy processing, high glossiness, high wearing resistance, pollution resistance, easy dyeing, excellent physical mechanical performance and the like, the demands by household electrical appliance products and kitchen electrical appliances on housing materials thereof in severe environments can be completely met, and the material can be widely applied to the production of plastic spare parts which need to slide or rotate in the fields of machinery, building materials, sports and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

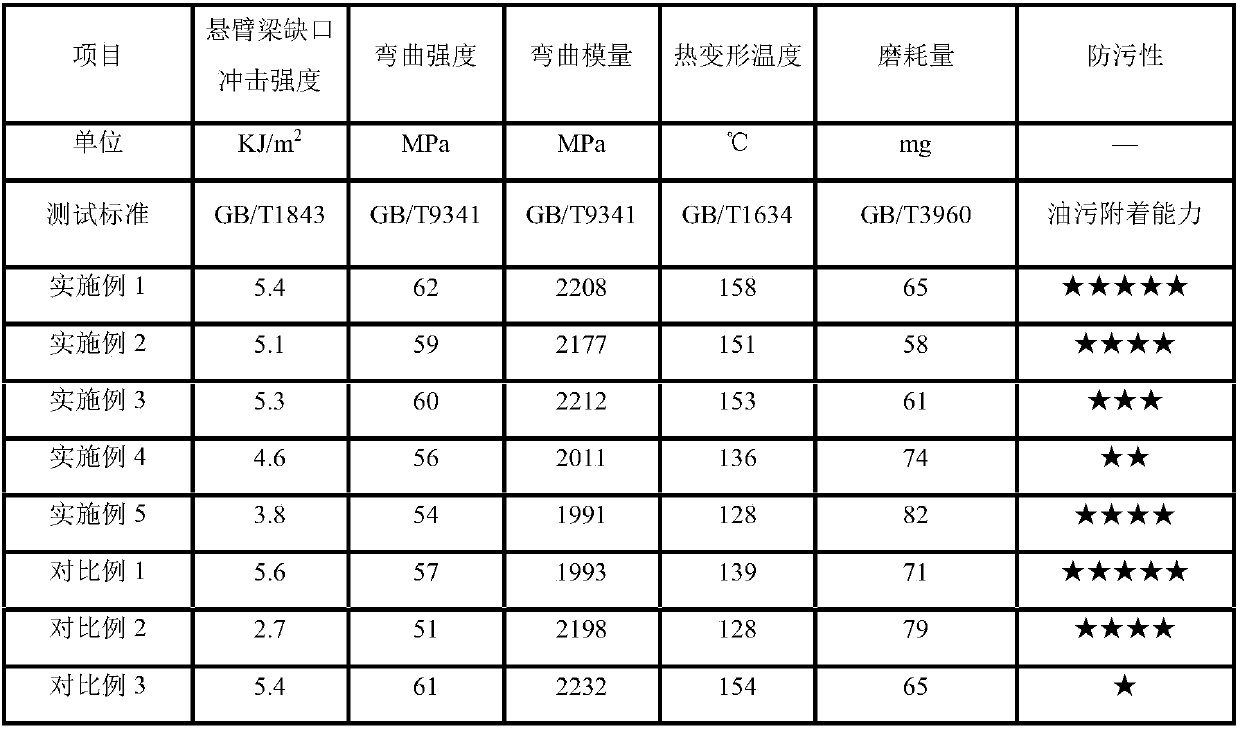

Preparation method of polyacrylate soap-free emulsion containing fluorine

InactiveCN103755879AImprove water and oil repellencyImprove placement stabilityFibre treatmentPaper coatingMethacrylateSOAP

The invention relates to a preparation method of a cation polyacrylate soap-free emulsion containing fluorine. The preparation method comprises following steps: dodecafluorhe-ptylacrylate or dodecafluoroheptyl methacrylate, N-alkyl diene propyl amine, and methyldiallylamine are mixed so as to obtain a mixed monomer A; oil soluble initiator azodiisobutyronitrile is added, an obtained mixture is heated to a certain temperature for polymerization, and a terpolymer is obtained; organic fluorine monomer and acrylate monomer are mixed so as to obtain a mixed monomer B; the terpolymer and water are added so as to obtain a monomer pre-emulsification liquid C; and water soluble initiator azobis(2-methylpropionamidine) dihydrochloride is added, and finished products are obtained via polymerization. The cation polyacrylate soap-free emulsion containing fluorine is a white emulsion; pH value ranges from 4.0 to 7.0; when the cation polyacrylate soap-free emulsion containing fluorine is mixed with water at a ratio of 9:1, no delamination is caused in 24 hours; and the cation polyacrylate soap-free emulsion containing fluorine possesses excellent storage stability, and can be stored at room temperature for 6 months without deterioration. The cation polyacrylate soap-free emulsion containing fluorine is capable of improving water resistance and oil resistance of paper or leather significantly.

Owner:QILU UNIV OF TECH

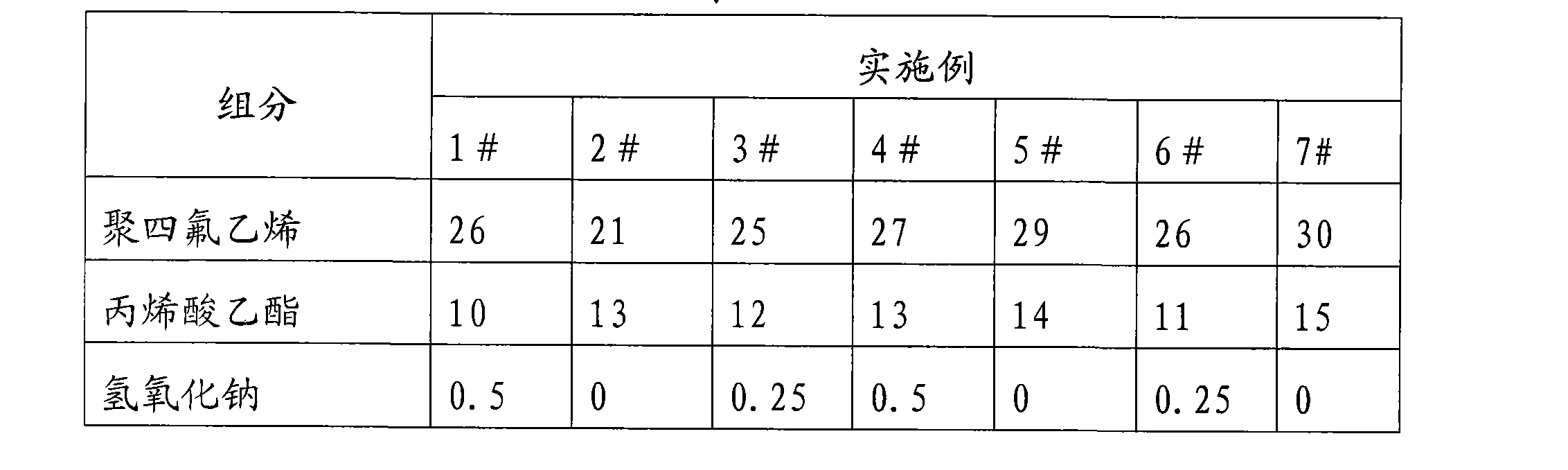

Water and oil repellent finishing method for bag type dedusting material

ActiveCN102304850ASolve the problem of unsatisfactory water and oil repellent effectImprove water and oil repellencyDispersed particle filtrationFibre treatmentPolymer scienceAdhesive

The invention discloses a water and oil repellent finishing method for a bag type dedusting material and relates to a material finishing method for high-temperature gas treatment of steel works, industrial furnaces, and industrial boilers. The finishing method comprises the following steps of: (1) preparing a finishing agent, namely weighing polytetrafluoroethylene (PTFE) emulsion, polymethylphenyl siloxane fluid emulsion, alcohol, Tween, glycerol, a hardening agent, resin HA, and adhesive and water in a mass ratio and placing in a container, stirring and mixing uniformly, and thus obtaining the finishing agent for later use; (2) padding the dedusting material by using the prepared finishing agent by a padding machine, wherein the pressure of a rotary drum of a compression roller during padding of the dedusting material is 0.5 to 0.7 MPa, and the speed of the rotary drum is 3.5 to 5.5 m / min; (3) allowing the padded dedusting material to pass through a drying oven, wherein the drying temperature is 140 to 190 DEG C, and the travel speed of the dedusting material in the drying oven is 3.5 to 5.5 m / min; and after the dedusting material is dried, winding the dried dedusting material on a fabric roller to finish the water and oil repellent finishing work of the bag type dedusting material.

Owner:江苏东方滤袋股份有限公司

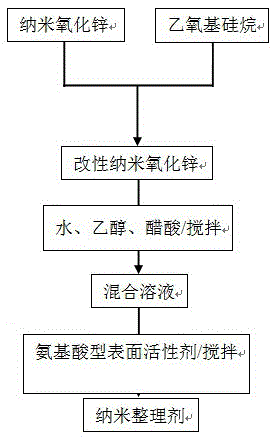

Water and oil repellent nanometer finishing agent for fabric

InactiveCN105463826AGood durabilityImprove water and oil repellencyLight resistant fibresLiquid repellent fibresChemistrySilane coupling

The invention discloses a water and oil repellent nanometer finishing agent for fabric. The water and oil repellent nanometer finishing agent comprises nanometer zinc oxide, a silane coupling agent, a surfactant, ethanol, acetic acid and deionized water. The water and oil repellent nanometer finishing agent is applicable to fabric for woven clothing and home textile fabric; the water and oil repellent effects and the stability of the fabric can be obviously improved; the preparation technology is simple and convenient; and the cost is low.

Owner:泰安市飞虹麻丝制品科技有限公司

Polyfluoroalkadiene mixture and method of manufacture therefor

ActiveCN102066296APromote decompositionLow bioaccumulationPreparation by hydrogen halide split-offIodideBULK ACTIVE INGREDIENT

Owner:UNIMATEC CO LTD

Vinyl chloride polymer

Disclosed is a vinyl chloride polymer comprising 100 parts by weight of a constituent unit (A-1) derived from vinyl chloride and 1 to 20 parts by weight of a constituent unit (A-2) derived from a fluorinated acrylate ester. Also disclosed is a vinyl chloride resin composition comprising (A) 0.2 to 20 parts by weight of the vinyl chloride polymer and (B) 100 parts by weight of a vinyl chloride resin. The vinyl chloride polymer may additionally comprise 50 parts by weight or less of a constituent unit (A-3) derived from a saturated fatty acid vinyl ester. Furthermore, the vinyl chloride polymermay additionally comprise 30 parts by weight or less of a constituent unit (A-4) derived from a vinyl ester containing an active hydrogen group. It becomes possible to improve the water-repellent / oil-repellent properties of a vinyl chloride resin.

Owner:DAIKIN IND LTD +1

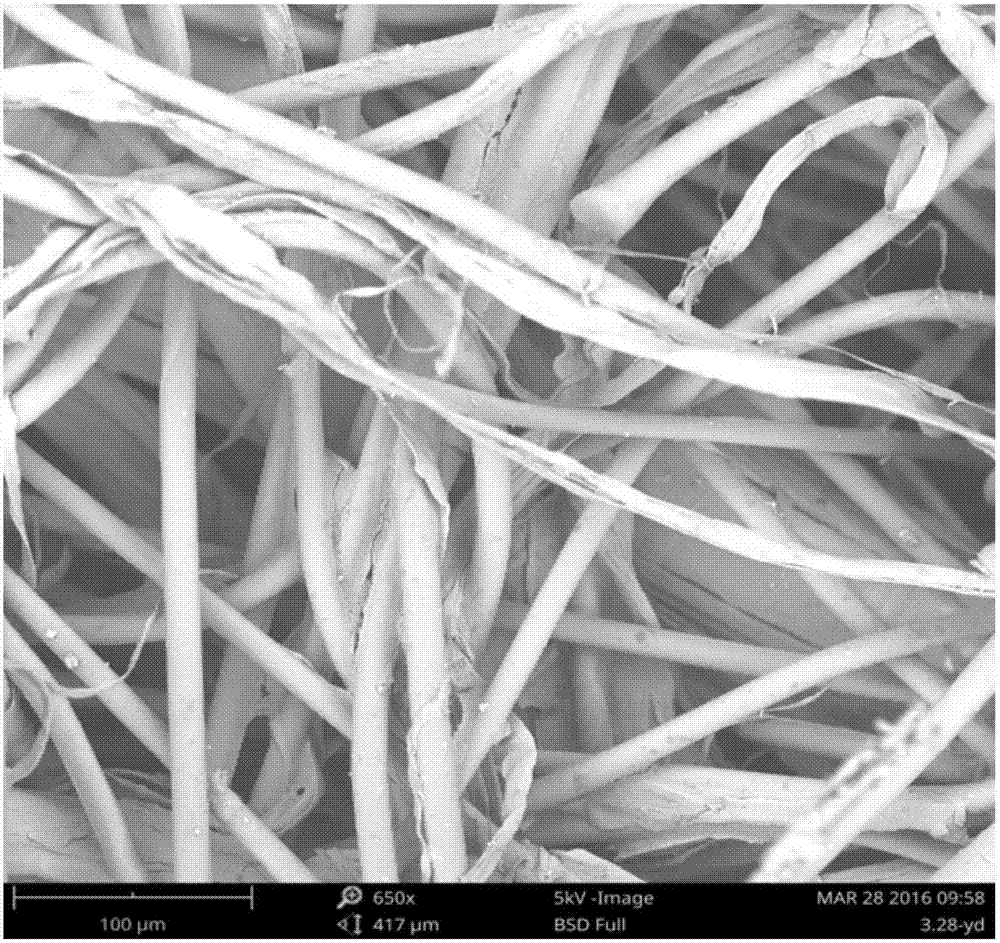

Method of coating surface of polyphenylene sulfide filter material with polytetrafluoroethylene

InactiveCN106884325ASimple methodGood film formingLiquid repellent fibresFiltration separationCorrosion resistantOrganosilicon

The invention discloses a method of coating the surface of a polyphenylene sulfide filter material with polytetrafluoroethylene. The method comprises the following steps: (1) preparing a polytetrafluoroethylene composite coating agent from a PTFE dispersion liquid, an acrylate adhesive and waterborne epoxy resin according to the mass ratio of 82 to 15 to 3; (2) preparing a composite finishing liquid from the polytetrafluoroethylene composite coating agent, silicone oil, an organosilicon waterproofing agent, a penetrating agent and distilled water according to the mass ratio of (10 to 12) to (1 to 2) to (3 to 6) to (1 to 2) to 200; and (3) soaking the polyphenylene sulfide filter material into the composite finishing liquid, drying and roasting the soaked polyphenylene sulfide filter material at high temperature to prepare the polyphenylene sulfide filter material of which the surface is coated with the polytetrafluoroethylene. Compared with the prior art, the method has the advantages that the filter material has little possibility of being oxidized and is good in corrosion resistance and film-forming property and adhesive force of the polytetrafluoroethylene, has the water resistance and oil resistance and can be widely used in the polyphenylene sulfide filter material in coal fired high-temperature flue gas.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Raw material formula for automotive glass surface protective film and method of producing the same

ActiveCN101429405ADoes not affect visible light transmittanceGood weather resistanceCoatingsTectorial membraneEnd-group

The invention relates to a raw material formulation of a surface protective film for automobile glass and a preparation method thereof. The raw material formulation of the surface protective film for the automobile glass comprises the following components: polyfluortetraethylene, ethyl acrylate, a catalyst, an emulsifying agent and water, wherein the polyfluortetraethylene has an iodic active end group, the polymerization degree of the polyfluortetraethylene is 4 to 6, and the molecular weight of the polyfluortetraethylene is 200 to 600 thousand. The preparation method for the surface protective film for the automobile glass comprises the following steps: (1) weighing the raw materials according to a proportion; (2) making the polyfluortetraethylene and the water react for 2 to 4 hours at a temperature of between 120 and 140 DEG C in the presence of a catalyst; (3) and then adding the ethyl acrylate into the mixture to react for 1 to 2 hours at a temperature of between 110 and 118 DEG C; and (4) adding the emulsifying agent into the mixture to homogenize and emulsify the mixture to obtain the final product. The prepared surface protective film for the automobile glass has strong binding force with glass, can reduce surface tension and surface friction factor of the glass, and improve oil resistance and water resistance of the glass; and a coating is not easy to damage.

Owner:广州保赐利化工有限公司

Crosslinkable polytetrafluoroethylene composition, cross-linked polytetrafluoroethylene powder, polytetrafluoro-ethylene moldings, resin blend compositions, and resin blend moldings

The invention aims at providing a PTFE resin which can be molded by a conventional process such as compression molding without expensive equipment or hot-coining of low productivity and little generates toxic substance during the molding and which retains the strength, crystallinity and surface characteristics inherent in conventional PTFE resins and exhibits isotropy, uniformity, and less deformation than those of conventional PTFE resins. The crosslinkable polytetrafluoroethylene composition comprises a polytetrafluoroethylene and a crosslinking agent. The polytetrafluoroethylene has at least one reactive functional group selected from the group consisting of cyano (-CN), carboxyl (-COOH), alkoxycarbonyl (-COOR (wherein R is a monovalent organic group)), and acid halide groups (-COX (wherein X is halogen)) at the end of at least either of the backbone chain and the side chain. The crosslinking agent can react with one or more of the reactive functional groups to form a ring structure.

Owner:DAIKIN IND LTD

Anti-icing UV (ultraviolet) curing fluorine coating

InactiveCN104946130AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesWater basedUV curing

The invention discloses an anti-icing UV (ultraviolet) curing fluorine coating, and belongs to the field of coatings, in particular to the field of UV curing water-based coatings. The water-based UV curing fluorine-containing coating comprises the following raw materials: a film forming matter, a solvent, a dispersing agent, a defoaming agent, a flatting agent, a photoinitiator, white carbon black, nano silica and nano aluminum oxide. A curing product of the fluorine-containing coating has good property; and a sample prepared by curing has excellent adhesion, scratch resistance, antifouling property and anti-icing capacity.

Owner:CHENGDU NASHUO TECH

Preparation process of grey cotton cloth

InactiveCN110172838AImprove water and oil repellencyGood flexibilityDyeing processTextile shapingAfter treatmentCotton cloth

The invention discloses a preparation process of grey cotton cloth. The preparation process sequentially comprises the following steps: singeing treatment: carrying out singeing treatment on cotton fabric to obtain singed cotton cloth; desizing, scouring, bleaching and cold batching: putting the singed cotton cloth into a cold batching liquid for cold batching treatment so as to obtain cold batched cotton cloth; broad washing: carrying out broad washing on the cold batched cotton cloth so as to obtain broad washed cotton cloth; mercerizing: carrying out mercerizing treatment on the broad washed cotton cloth so as to obtain mercerized cotton cloth; dyeing: carrying out dyeing treatment on the mercerized cotton cloth so as to obtain dyed cotton cloth; shaping: shaping the dyed cotton cloth so as to obtain the shaped cotton cloth; and coating a waterproof and oil proof layer: coating one side of the shaped cotton cloth with waterproof and oil proof glue so as to obtain a single-side waterproof and oil proof cotton cloth. According to the preparation process provided by the invention, innovation is carried out on an aspect of after-treatment processing, a process of combining waterproof and oil proof coating and calendaring is adopted, and the grey cotton cloth prepared by using the preparation process has the advantages that the grey cotton cloth is soft, water-proof and oil proof, is prevented from environment pollution caused by bleaching, and conform to the concept of going green and environmental protection, and sustainable development.

Owner:孝感安华纺织有限公司

Dust removal filter material finishing liquid, preparation method and application thereof

The invention discloses a dust removal filter material finishing liquid, which includes, by mass, 10-20% of a polytetrafluoroethylene emulsion, 2-8% of a silicone oil emulsion, 2-8% of an organic silicon waterproofing agent, 0.2-0.4% of an antioxidant, 1-3% of aqueous epoxidized resin, 3-10% of a silane coupling agent, 4% of nano TiO2, 0.5-2% of a non-ionic penetrating agent, and the balanced being water. The invention also discloses a preparation method and an application of the dust removal filter material finishing liquid. A filter material treated with the finishing liquid has excellent waterproofing property and film-forming performance, so that the filter material has anti-oxidizing, anti-corrosion, water-repellent and oil-preventing, anti-static, anti-condensation and anti-bag-sticking performances. Meanwhile, the service life of the filter material is prolonged, and further filter efficiency of the punched felt filter material is increased.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

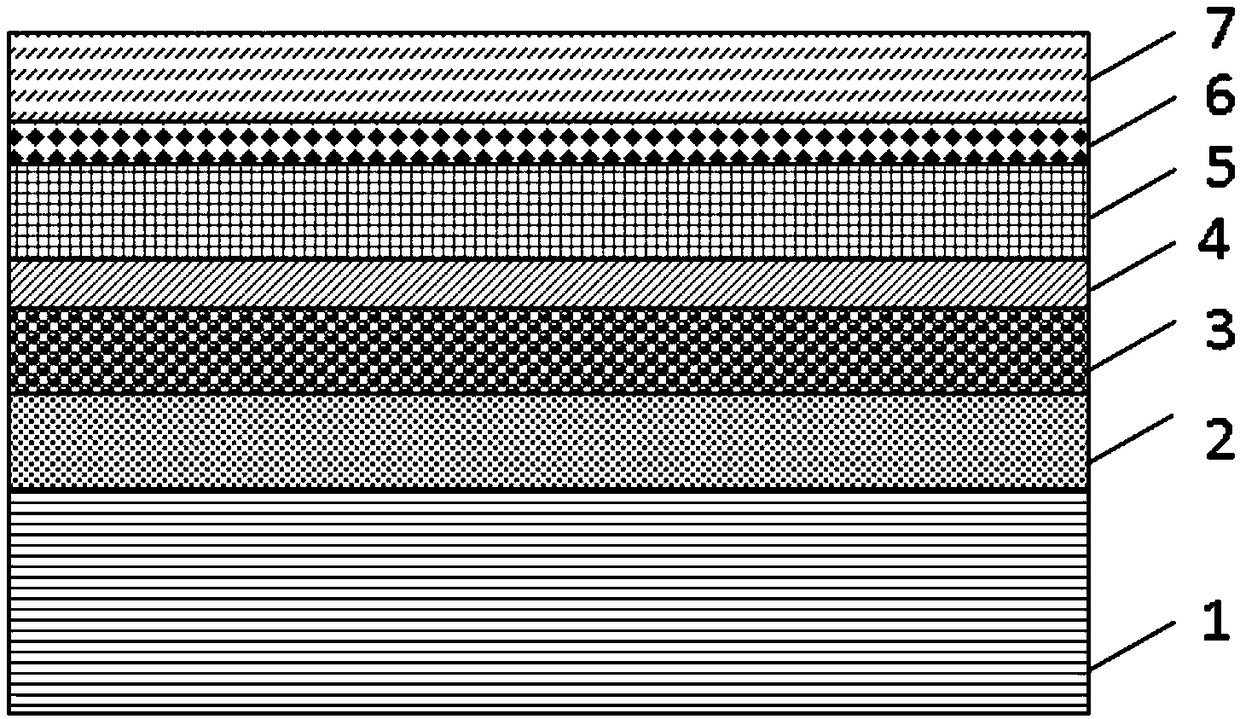

Low-migration and high-barrier local positioning anti-counterfeiting laser food packaging board and production method thereof

PendingCN109016755AImprove barrier propertiesEffective moisture-proofSynthetic resin layered productsDomestic containersCardboardBiochemical engineering

The invention relates to a low-migration and high-barrier local positioning anti-counterfeiting laser food packaging board and a production method thereof. The packaging board comprises a base paper layer, and a PE lamination layer, a vacuum aluminized layer, a local positioning anti-counterfeiting laser layer, a laminating coating layer and a plasma corona PET film layer which are sequentially compounded on the upper surface of the base paper layer from bottom to top. Compared with packaging materials in the prior art, the packaging food integrates the holographic laser anti-counterfeiting effect of a local positioning cat eye lens and the dual-protection ultrahigh-barrier property of the PE lamination layer and the plasma corona PET film in order to prevent effective migration of the aluminized layer, achieves the multiple effects of beauty, counterfeiting resistance and ultrahigh barrier, and promotes the development and innovation of the packaging industry.

Owner:ANHUI ZIJIANG METALLIZATION ENVIRONMENTAL PROTECTION MATERIAL CO LTD +1

Water and oil repellent finishing method for bag type dedusting material

ActiveCN102304850BSolve the problem of unsatisfactory water and oil repellent effectImprove water and oil repellencyDispersed particle filtrationFibre treatmentPolymer scienceAdhesive

Owner:江苏东方滤袋股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com