Dust removal filter material finishing liquid, preparation method and application thereof

A technology for finishing liquid and filter material, which is applied in fiber treatment, liquid repellent fiber, fiber type, etc. It can solve the problem of not increasing the filter material's high temperature resistance, oxidation corrosion resistance, acid and alkali corrosion, and post-processing methods that cannot fully satisfy customers. The needs of the filter material, the loss of water resistance of the filter material, etc., to achieve excellent water resistance, anti-condensation paste bag performance, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation raw materials and mass fractions of the dust-removing filter material finishing liquid are:

[0028]

[0029] The preparation method of the finishing solution: add polytetrafluoroethylene emulsion, silicone oil emulsion, methyl siloxane, water-based epoxy resin, aminosilane, 2,6-tertiary butyl-4-methylphenol to the batching tank , under normal temperature and pressure for the first time stirring, and then add water, polyoxyethylene sorbitan monostearate and nano TiO 2 and ultrasonic treatment, making the nanoscale TiO 2 The dispersion is uniform, the viscosity of the solution is 190mPa·S, and the pH is adjusted to 7-9 to obtain a finishing solution.

[0030] The application of the above finishing liquid in finishing the dust filter material:

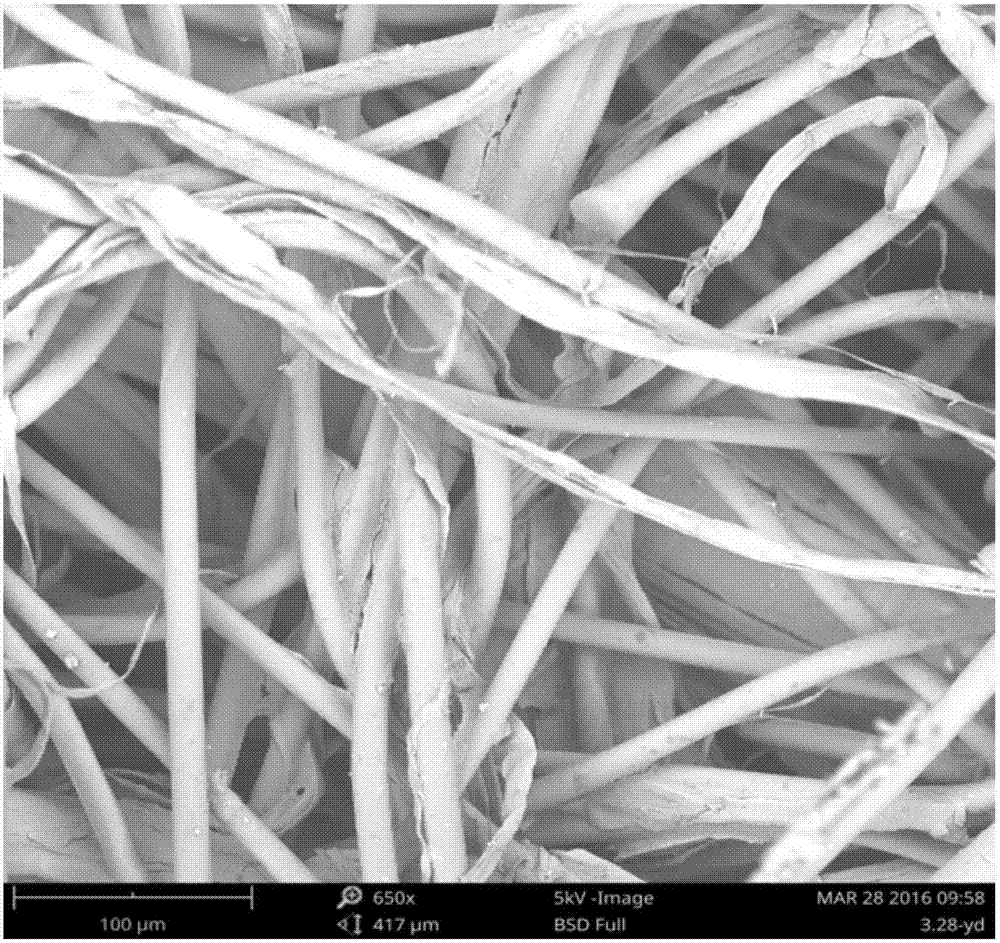

[0031] Dust removal filter material: It is needle felt, and its raw materials are polyphenylene sulfide (PPS) fiber and polytetrafluoroethylene (PTFE) fiber, among which, the proportion of PPS fiber is 50%~80%...

Embodiment 2

[0039] The preparation raw materials and mass fractions of the dust-removing filter material finishing liquid are:

[0040]

[0041]

[0042]Preparation method of finishing solution: polytetrafluoroethylene emulsion, silicone oil emulsion, methyl siloxanes, water-based epoxy resin, vinyl silane, bis(3,5-tertiary butyl-4-hydroxyphenyl) Add thioether to the batching tank, carry out initial stirring under normal temperature and pressure, then add water, polyoxyethylene sorbitan monostearate and nano TiO 2 and ultrasonic treatment, making the nanoscale TiO 2 The dispersion is uniform, the viscosity of the solution is 170mPa·S, and the pH is adjusted to 7-9 to obtain a finishing solution.

[0043] The application of the above finishing liquid in finishing the dust filter material:

[0044] Dust removal filter material: It is needle felt, and its raw materials are polyphenylene sulfide (PPS) fiber and polytetrafluoroethylene (PTFE) fiber, among which, the proportion of PPS f...

Embodiment 3

[0052] The preparation raw materials and mass fractions of the dust-removing filter material finishing liquid are:

[0053]

[0054] The preparation method of the finishing solution: polytetrafluoroethylene emulsion, silicone oil emulsion, methyl siloxanes, water-based epoxy resin, methacryloxysilane, tetrakis [β-(3,5-tertiary butyl -4-Hydroxyphenyl)propionic acid]pentaerythritol ester is added to the batching tank, and the initial stirring is carried out under normal temperature and pressure, and then water, polyoxyethylene sorbitan monostearate and nano-sized TiO are added while stirring. 2 and ultrasonic treatment, making the nanoscale TiO 2 The dispersion is uniform, the viscosity of the solution is 200mPa·S, and the pH is adjusted to 7-9 to obtain a finishing solution.

[0055] The application of the above finishing liquid in finishing the dust filter material:

[0056] Dust removal filter material: It is needle felt, and its raw materials are polyphenylene sulfide (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com