Preparation method of polyacrylate soap-free emulsion containing fluorine

A technology of polyacrylate and soap-free emulsion is applied in the preparation of fluorine-containing polyacrylate soap-free emulsion and the preparation of cationic soap-free fluorine-containing water and oil repellent, which can solve the problem of increased production cost, low solubility, environmental pollution, etc. problem, to achieve the effect of good placement stability and improved waterproof and oil-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

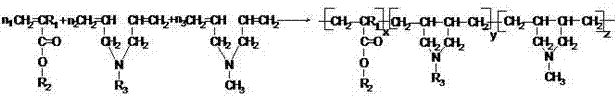

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of fluorine-containing terpolymer.

[0032] Firstly, 40 g of dodecafluoroheptyl acrylate, 20 g of N-butyldiallylamine, and 40 g of N-methyldiallylamine were uniformly mixed to prepare mixed monomer A.

[0033] Add mixed monomer A and 200 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 65° C., and 1 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 8 hours.

[0034] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10 mmHg-20 mmHg.

[0035] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0036] Mix 50 g of dodecafluoroheptyl methacrylate and 50 g of methyl acrylate to prepare mixed monomer B.

[0037] The terpolymer prepared above and water were added to the mixed monome...

Embodiment 2

[0040] 1. Preparation of fluorine-containing terpolymer.

[0041] Firstly, 60 g of dodecafluoroheptyl methacrylate, 10 g of N-butyldiallylamine, and 30 g of N-methyldiallylamine were uniformly mixed to prepare mixed monomer A.

[0042] Add mixed monomer A and 300 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 65° C., and 3 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 6 hours.

[0043] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10 mmHg-20 mmHg.

[0044] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0045] Mix 50 g of dodecafluoroheptyl acrylate and 50 g of butyl acrylate to prepare mixed monomer B.

[0046] The terpolymer prepared above and water were added to the mixed monom...

Embodiment 3

[0049] 1. Preparation of fluorine-containing terpolymer.

[0050] Firstly, 60 g of dodecafluoroheptyl acrylate, 10 g of N-dodecyl diallylamine, and 30 g of N-methyl diallyl amine were uniformly mixed to prepare the mixed monomer A.

[0051] Add mixed monomer A and 400 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 85° C., and 5 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 4 hours.

[0052] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10 mmHg-20 mmHg.

[0053] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0054] Mix 50 g of hexafluorobutyl acrylate, 40 g of methyl acrylate, and 10 g of lauryl acrylate to prepare mixed monomer B.

[0055] The terpolymer prepared above and water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com