A kind of preparation method of fluorine-containing polyacrylate soap-free emulsion

A technology of polyacrylate and soap-free emulsion, which is applied in the preparation of fluorine-containing polyacrylate soap-free emulsion and the preparation of cationic soap-free fluorine-containing water and oil repellent, which can solve the problems of increased production cost, low solubility, environmental pollution, etc. problem, to achieve the effect of improving waterproof and oil-proof performance and good placement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

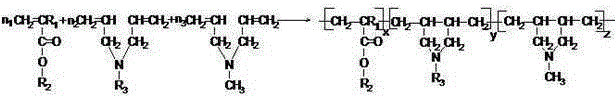

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of fluorine-containing terpolymer.

[0032] First, 40 g of dodecafluoroheptyl acrylate, 20 g of N-butyldiallylamine, and 40 g of N-methyldiallylamine were uniformly mixed to prepare mixed monomer A.

[0033] Add mixed monomer A and 200 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 65° C., and 1 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 8 hours.

[0034] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10mmHg-20mmHg.

[0035] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0036] Mix 50 g of dodecafluoroheptyl methacrylate and 50 g of methyl acrylate to prepare mixed monomer B.

[0037] The terpolymer prepared above and water were added to the mixed monomer B. Th...

Embodiment 2

[0040] 1. Preparation of fluorine-containing terpolymer.

[0041] First, 60 g of dodecafluoroheptyl methacrylate, 10 g of N-butyldiallylamine, and 30 g of N-methyldiallylamine were uniformly mixed to prepare the mixed monomer A.

[0042] Add mixed monomer A and 300 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 65° C., and 3 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 6 hours.

[0043] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10mmHg-20mmHg.

[0044] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0045] Mix 50 g of dodecafluoroheptyl acrylate and 50 g of butyl acrylate to prepare mixed monomer B.

[0046] The terpolymer prepared above and water were added to the mixed monomer B....

Embodiment 3

[0049] 1. Preparation of fluorine-containing terpolymer.

[0050] Firstly, 60 g of dodecafluoroheptyl acrylate, 10 g of N-dodecyl diallylamine, and 30 g of N-methyl diallyl amine were uniformly mixed to prepare the mixed monomer A.

[0051] Add mixed monomer A and 400 g of dioxane into a four-neck flask equipped with a stirring device, a reflux device and a thermometer. The temperature of the solution was raised to 85° C., and 5 g of azobisisobutyronitrile was added to initiate a polymerization reaction. The polymerization time was 4 hours.

[0052] After the polymerization reaction is completed, the solvent is distilled off under reduced pressure to obtain a terpolymer with a vacuum degree of 10mmHg-20mmHg.

[0053] 2. Preparation of cationic soap-free fluorine-containing emulsion.

[0054] Mix 50 g of hexafluorobutyl acrylate, 40 g of methyl acrylate, and 10 g of lauryl acrylate to prepare mixed monomer B.

[0055] The terpolymer prepared above and water were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com