Preparation method of water-based fluorine-acrylic acid-containing self-stratifying emulsion for protection of concrete surface

A concrete surface, acrylic technology, applied in the direction of coating, can solve the problems of environmental pollution, high cost of single-layer paint film, etc., and achieve the effect of reducing cost, overcoming narrow ratio range and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

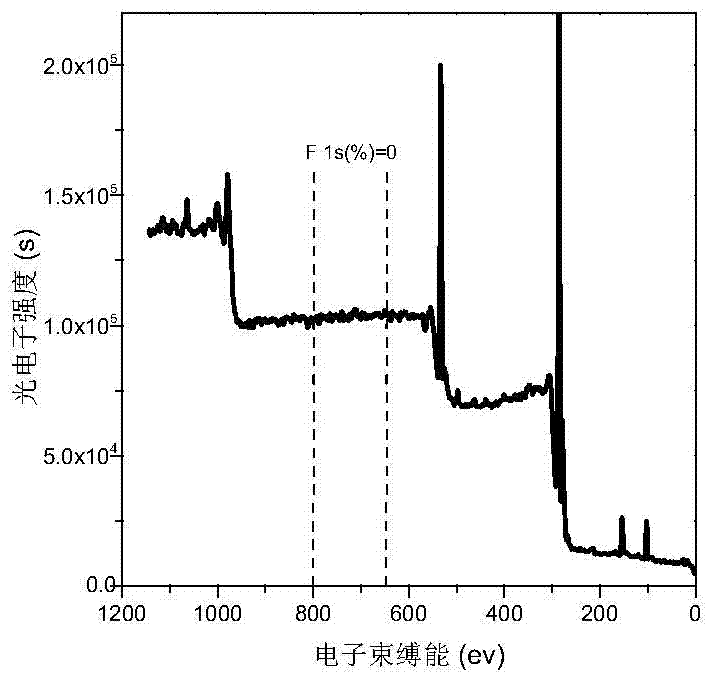

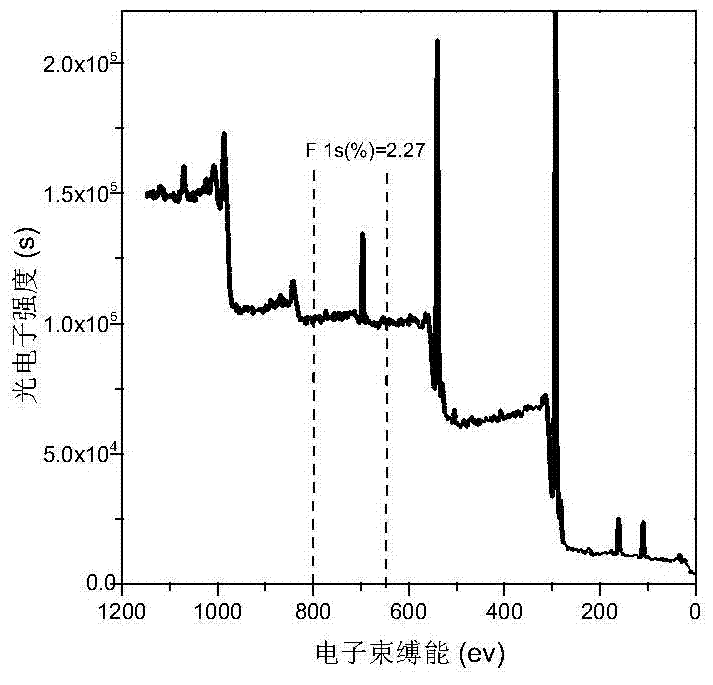

Image

Examples

Embodiment 1

[0036]1) Preparation of fluorine-modified acrylic core-shell emulsion: Weigh 30.3g of methyl methacrylate, 19.7g of butyl acrylate, and 1g of acetoacetoxyethyl methacrylate (AAEM) and stir evenly to form the core mixed monomer. Weigh 23.9g of methyl methacrylate, 26.1g of butyl acrylate, and 1g of hexafluorobutyl acrylate and stir evenly to form a shell mixed monomer. Take 10g core mixed monomer, 1g sodium dodecylsulfonate (SDS), 1g octylphenol polyoxyethylene ether-10 (OP-10), 97.4g water, 0.17g ammonium persulfate (APS), 0.3 g of sodium bicarbonate was stirred evenly, heated to 80° C. in a water bath to initiate polymerization, and kept warm for 30 minutes to obtain a seed emulsion. The remaining shell mixed monomer, 10 g aqueous solution dissolved with 0.17 g ammonium persulfate (APS) were added to the seed emulsion at a constant speed, respectively. The dropping time is 1-1.5h. After 30 minutes of heat preservation, the shell mixed monomer and 10 g of aqueous solution di...

Embodiment 2

[0040] 1) Preparation of fluorine-containing modified acrylic core-shell emulsion: Weigh 18.3g methyl methacrylate, 12g styrene, 19.7g butyl acrylate, 1g acetoacetoxyethyl methacrylate (AAEM) and stir evenly to form the core mixture monomer. Weigh 23.9g of methyl methacrylate, 26.1g of butyl acrylate, and 1g of hexafluorobutyl acrylate and stir evenly to form a shell mixed monomer. Take 10g core mixed monomer, 1g sodium dodecylsulfonate (SDS), 1g octylphenol polyoxyethylene ether-10 (OP-10), 97.4g water, 0.17g ammonium persulfate (APS), 0.3 g of sodium bicarbonate was stirred evenly, heated to 80° C. in a water bath to initiate polymerization, and kept warm for 30 minutes to obtain a seed emulsion. The remaining shell mixed monomer, 10 g aqueous solution dissolved with 0.17 g ammonium persulfate (APS) were added to the seed emulsion at a constant speed, respectively. The dropping time is 1-1.5h. After 30 minutes of heat preservation, the shell mixed monomer and 10 g of aque...

Embodiment 3

[0044] 1) Preparation of fluorine-modified acrylic core-shell emulsion: Weigh 36.1g of ethyl methacrylate, 13.9g of butyl acrylate, and 2g of acetoacetoxyethyl methacrylate (AAEM) and stir evenly to form the core mixed monomer. Weigh 28.5g of ethyl methacrylate, 21.5g of butyl acrylate, and 5g of hexafluorobutyl acrylate and stir evenly to form a shell mixed monomer. Take 10g core mixed monomer, 1g sodium dodecylsulfonate (SDS), 1g octylphenol polyoxyethylene ether-10 (OP-10), 97.4g water, 0.17g ammonium persulfate (APS), 0.3 g of sodium bicarbonate was stirred evenly, heated to 80° C. in a water bath to initiate polymerization, and kept warm for 30 minutes to obtain a seed emulsion. The remaining shell mixed monomer, 10 g aqueous solution dissolved with 0.17 g ammonium persulfate (APS) were added to the seed emulsion at a constant speed, respectively. The dropping time is 1-1.5h. After 30 minutes of heat preservation, the shell mixed monomer and 10 g of aqueous solution dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com