Polymer modification silane containing fluoro oxidation alkylene, surface treating agent relating same and object

A technology of alkylene oxide and surface treatment agent, applied in polyether coatings, coatings, etc., can solve problems such as insufficient heat resistance, achieve antifouling performance, excellent water and oil repellency, and high heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

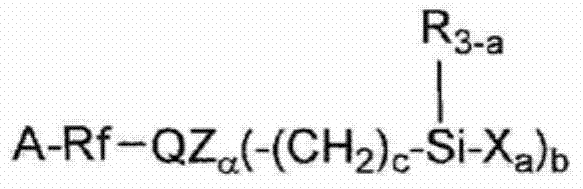

Method used

Image

Examples

Embodiment 1

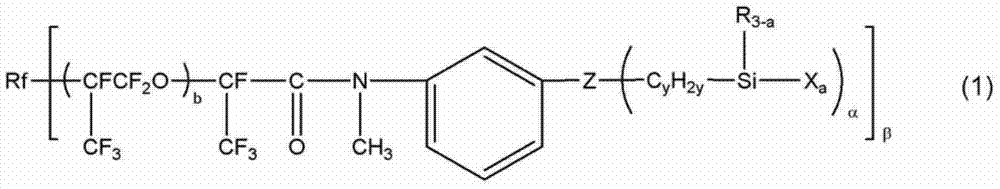

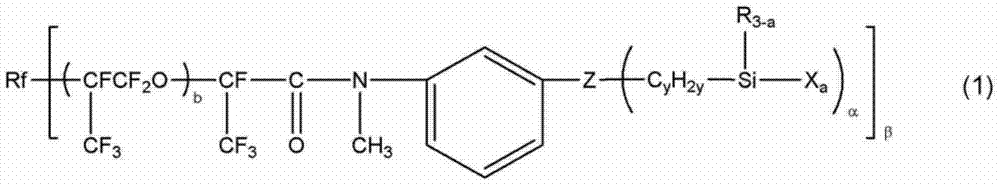

[0108] Mix the following formula (I) in the reaction vessel

[0109]

[0110] The indicated compound 100g (1.6×10 -2 mol) and 7.2 g of cesium fluoride, 44 g of tetraethylene glycol dimethyl ether, and 14 g of monoethylene glycol dimethyl ether were heated at 60° C. for 30 minutes, and aged at room temperature for 16 hours. Next, after cooling to -38° C., 29 g of hexafluoropropylene gas was supplied over 22 minutes for aging for 3 hours, and 16 g of hexafluoropropylene oxide gas was supplied over 54 minutes for aging for 3 hours. Then, 12 g of trimethylchlorosilane mixed with 30 g of heptane was added and mixed at room temperature for 1 hour. After filtering the resulting mixture, the organic solvent layer and the fluorine compound layer were separated, and the residual solvent was distilled off under reduced pressure to obtain the following formula (II):

[0111]

[0112] 106 g of perfluorooxyalkylene-containing polymers are shown.

[0113] Then, 145 g (2.3 × 10 -2 m...

Embodiment 2

[0122] Compound 40g (5.3 × 10 -3 mol) was dissolved in 10g of 1,3-trifluoromethylbenzene, and the toluene solution of chloroplatinic acid / vinylsiloxane complex 2.0×10 -2 g (as a Pt monomer containing 5.3×10 -7 mol) and 1-[1 or 2-(trimethoxysilyl) ethyl]-1,1,3,3-tetramethyldisiloxane (HDTMS) 1.8g (1.1×10 -2 mol), aged at 80°C for 4 hours, and the solvent and unreacted substances were distilled off under reduced pressure. Next, residual high boiling point components were removed by a molecular distillation apparatus to obtain 25 g of a liquid product.

[0123] The compound obtained in Example 2 was confirmed to have a structure of the following formula (VI) by NMR.

[0124]

Embodiment 3

[0126] Compound 40g (5.3 × 10 -3 mol) and tetramethylcyclotetrasiloxane (cyclosiloxane H4) 6.4g (2.7×10 -2 mol) was dissolved in 40 g of 1,3-trifluoromethylbenzene and heated to 90°C. Then, 2.0×10 toluene solution of chloroplatinic acid / vinylsiloxane complex was added dropwise -2 g (contains 5.0×10 as a Pt monomer -7 mol), aged at 90°C for 3 hours, and distilled off the solvent and unreacted substances under reduced pressure. The obtained product was mixed with 20 g of fluorine-based inert solvent PF5060 (manufactured by Sumitomo 3M Co., Ltd., Japan), 0.80 g of SHIRASAGI AS (manufactured by Japan Enviro Chemicals Co., Ltd.) was added as activated carbon, and stirred at room temperature for 1 hour. Then, SHIRASAGI AS was removed by filtration, and the solvent was distilled off to obtain 38 g of a liquid product represented by the following formula (VII).

[0127]

[0128] Next, 38 g (5.3 × 10 -3 mol) was dissolved in 21g of 1,3-trifluoromethylbenzene, and vinyltrimethox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com