Water-based waterproof oil-proof agent for special paper, and preparation method thereof

A technology of waterproof and oil-proof agent and special paper, applied in the field of papermaking, can solve the problem that the comprehensive performance of fluorosilicone waterproof and oil-proof agent needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

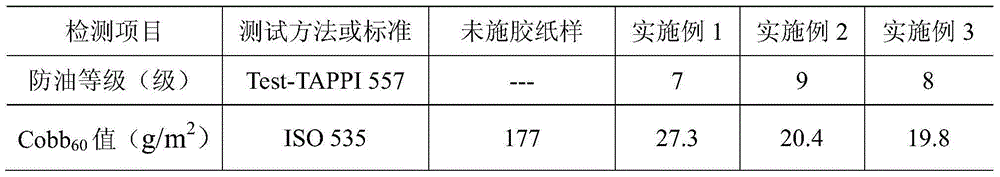

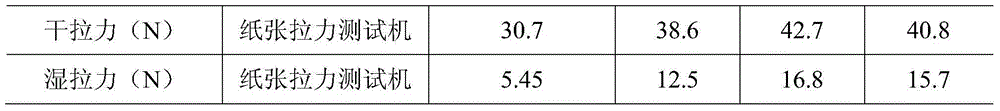

Examples

Embodiment 1

[0026] In this embodiment, the water-based water-based and oil-repellent agent for special paper, in parts by mass, includes 0.6 parts of hexamethylene diisocyanate, 105 parts of water, 20 parts of hydrogen-containing silicone oil, 20 parts of vinyl polyether, 2 parts of 1, The product obtained by reacting 1,2,2-tetrahydroperfluorohexyl methacrylate, 1 part of glycidyl methacrylate, 1 part of octadecyl acrylate and 0.38 part of chloroplatinic acid under dark conditions;

[0027] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 0.5; the molar ratio of ethylene oxide to propylene oxide in the vinyl polyether segment is 4:6; the molecular weight of the vinyl polyether is 1000.

[0028] The preparation process of the water-based water-based and oil-repellent agent for special paper in this example is as follows: add hydrogen-containing silicone oil, vinyl polyether, 1,1,2,2-tetrahydroperfluorohexyl methacrylate, methyl Glycidyl acrylate and octadecyl acryla...

Embodiment 2

[0030] The water-based water-repellent and oil-repellent agent for special paper of this embodiment, in parts by mass, includes 0.4 parts of diphenylmethane diisocyanate, 86 parts of water and 20 parts of hydrogen-containing silicone oil, 10 parts of vinyl polyether, 3 parts of 2- (Perfluorobutyl) ethyl methacrylate, 1.5 parts of glycidyl methacrylate, 1.5 parts of long-chain acrylate and 0.3 parts of chloroplatinic acid reacted under dark conditions to obtain the product;

[0031] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 0.3; the molar ratio of ethylene oxide to propylene oxide in the vinyl polyether segment is 5:5; the molecular weight of the vinyl polyether is 1000; The chain ester is a mixture of octadecyl methacrylate and lauryl acrylate with a mass ratio of 1:1.

[0032] The preparation process of the water-based water-based and oil-repellent agent for special paper in this example is as follows: add hydrogen-containing silicone oil, vinyl...

Embodiment 3

[0034] In this embodiment, the water-based water- and oil-repellent agent for special paper comprises, in parts by mass, 0.8 parts of isophorone diisocyanate, 170 parts of water, 25 parts of hydrogen-containing silicone oil, 40 parts of vinyl polyether, and 5 parts of perfluorinated The product obtained by reacting octyl ethyl methacrylate, 2 parts of glycidyl methacrylate, 1.8 parts of hexadecyl methacrylate and 0.5 part of chloroplatinic acid under dark conditions;

[0035] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 0.5; the molar ratio of ethylene oxide to propylene oxide in the vinyl polyether segment is 4:6; the molecular weight of the vinyl polyether is 2000.

[0036]The preparation process of the water-based water-based and oil-repellent agent for special paper in this example is as follows: add hydrogen-containing silicone oil, vinyl polyether, perfluorooctylethyl methacrylate, glycidyl methacrylate and formazan to a drying reactor. Hexade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com