Environment-friendly heat-insulation and noise-reduction polyurea composite material and manufacturing method thereof

A composite material and environment-friendly technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of fabric thickness that cannot be thinned, poor wear resistance, and stimulation of human respiratory tract, etc., to achieve production The process has good environmental protection, good processability and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

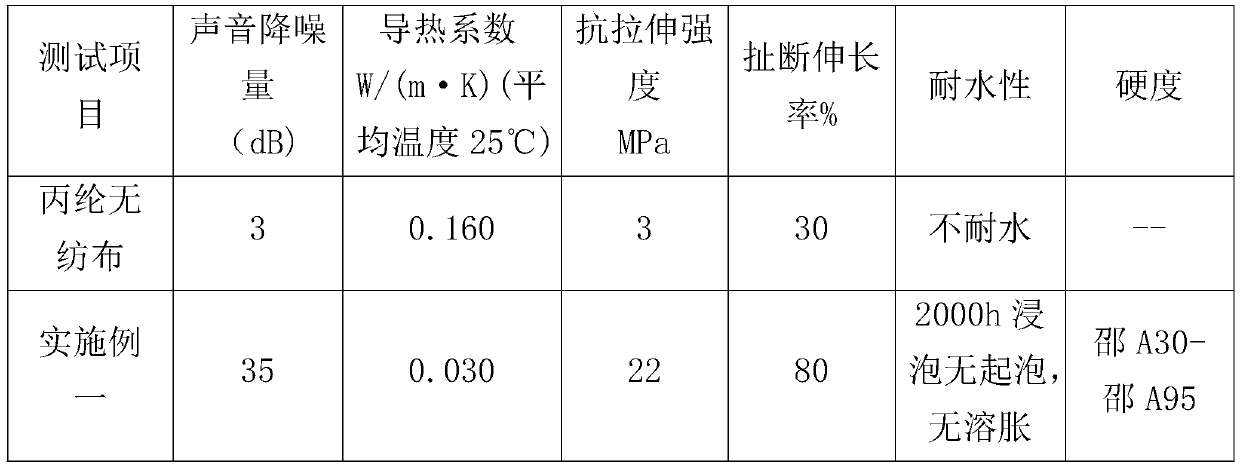

Embodiment 1

[0026] A preparation method of an environment-friendly heat-insulating and noise-reducing polyurea composite material, comprising the following steps:

[0027] (1) Preparation of component A: Put 45kg of polyether polyol, 15kg of trimethylolpropane and 10kg of butyl acetate into a reactor with a condenser, and vacuum dehydrate the reactor while keeping it stirring During 1h, turn on the condenser to lower the temperature to 35°C-50°C, keep the reaction kettle in this temperature range, add an appropriate amount of isophorone diisocyanate 75kg, when the temperature rises to 80°C-90°C, add grade A Add 3 kg of dimethyl phosphate and 0.5 kg of 2-hydroxy-4 methoxybenzophenone, continue stirring for 0.5 h, add 0.5 kg of n-butanol, stir for 0.5 h, then cool down to obtain component A;

[0028] (2) Preparation of component B: put 55 kg of polyaspartic acid resin into the dispersion tank for dispersion, then add 6 kg of cellulose acetate butyrate, and continue to disperse for 20 minute...

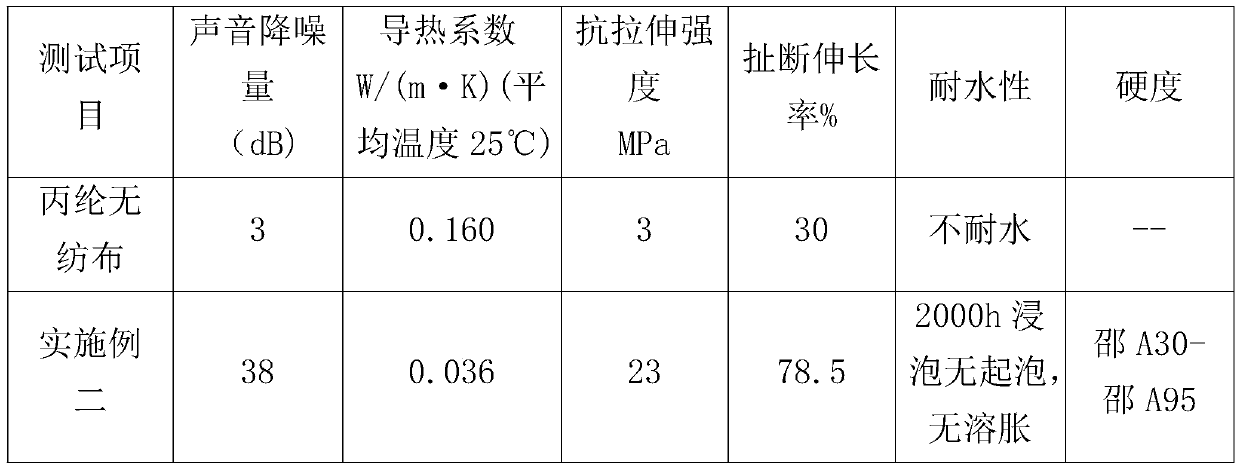

Embodiment 2

[0034] A preparation method of an environment-friendly heat-insulating and noise-reducing polyurea composite material, comprising the following steps:

[0035] (1) Preparation of component A: Put 50kg of polyether polyol, 12kg of trihydroxymethylpropane and 13kg of butyl acetate into a reactor with a condenser, and carry out vacuum dehydration while the reactor is kept stirring During 1h, turn on the condenser to lower the temperature to 35°C-50°C, keep the reaction kettle in this temperature range, add an appropriate amount of isophorone diisocyanate 78kg, when the temperature rises to 80°C-90°C, add grade A Add 4 kg of dimethyl phosphate and 0.7 kg of 2-hydroxy-4 methoxybenzophenone, continue stirring for 0.5 h, add 0.8 kg of n-butanol, stir for 0.5 h, then cool down to obtain component A;

[0036] (2) Preparation of component B: put 65 kg of polyaspartic acid resin into the dispersion tank for dispersion, then add 8 kg of cellulose acetate butyrate, and continue to disperse...

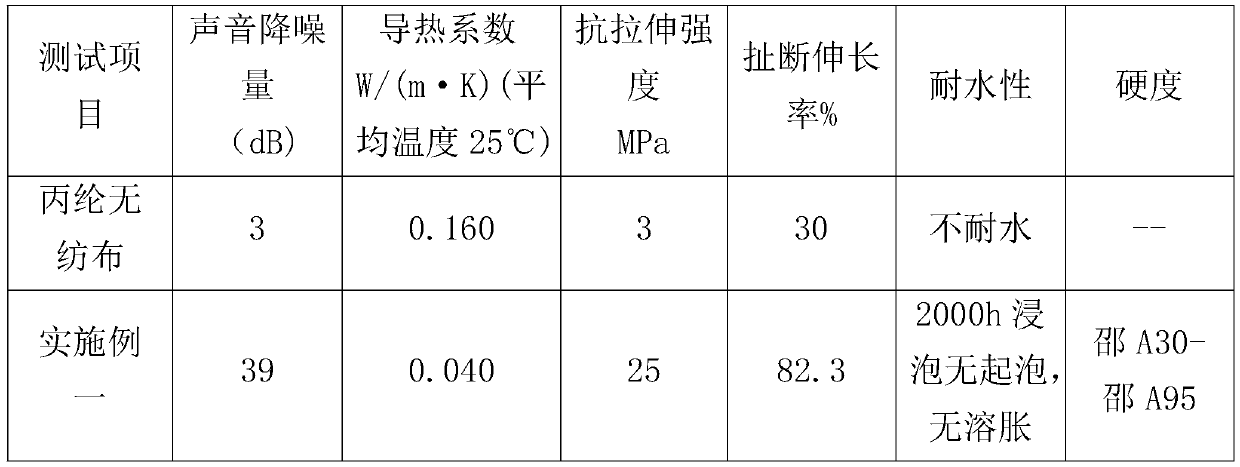

Embodiment 3

[0042] A preparation method of an environment-friendly heat-insulating and noise-reducing polyurea composite material, comprising the following steps:

[0043] (1) Preparation of component A: Put 75kg of polyether polyol, 20kg of trimethylolpropane and 20kg of butyl acetate into a reactor with a condenser, and vacuum dehydrate the reactor while it is stirring During 1h, turn on the condenser to lower the temperature to 35°C-50°C, keep the reaction kettle in this temperature range, add 80 kg of isophorone diisocyanate, and when the temperature rises to 80°C-90°C, add methyl-phosphoric acid di Add 5kg of methyl fat and 1kg of 2-hydroxy-4methoxybenzophenone, continue stirring for 0.5h, add 1kg of n-butanol, stir for 0.5h and cool down to obtain component A;

[0044] (2) Preparation of component B: Put 80 kg of polyaspartic acid resin into a dispersion tank for dispersion, then add 10 kg of cellulose acetate butyrate, and continue to disperse for 20 minutes to obtain component B; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com