Vinyl chloride polymer

A vinyl chloride and polymer technology, applied in the field of vinyl chloride resin compositions and vinyl chloride polymers, can solve the problems of insufficient water repellency and oil repellency cannot be improved, and achieve the effect of improving water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Next, the present invention will be described with reference to examples, but the present invention is not limited to these examples.

[0061] In this specification, % and parts represent % by weight and parts by weight unless otherwise specified.

[0062] However, in the present invention, extrusion moldability, stain resistance, water repellency, oil repellency, color development, friction resistance, water resistance, oil resistance, and adhesiveness were evaluated by the following methods.

[0063]

[0064] The mixture was kneaded using a single-screw extruder with a diameter of 20 mm (screw CR=3.0, 60 rpm), and extruded sheets (thickness: 1.5 mm) were produced by extrusion molding using a T-die die. The sheets were evaluated according to the following criteria.

[0065] ○: The shape of the edge portion and the smoothness of the surface are good

[0066] △: The shape of the edge portion and the smoothness of the surface are slightly inferior

[0067] X: The sha...

Synthetic example 1

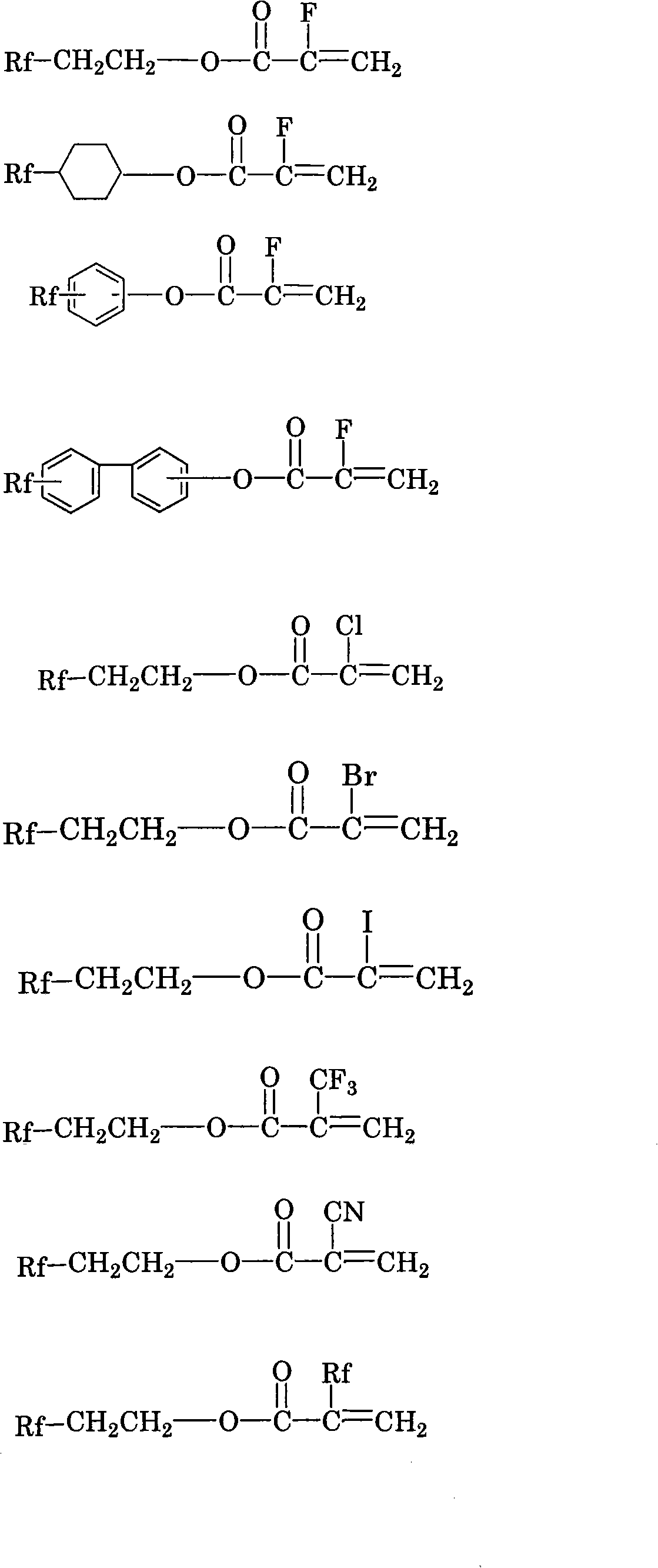

[0109] In a polymerization vessel equipped with a stirrer, a thermometer and a nitrogen inlet, after nitrogen replacement, 2400 parts by weight of deionized water, 1164 parts by weight of vinyl chloride, 36 parts by weight of C 6 f 13 -(CH 2 ) 2 OCOC (CH 3 )=CH 2 (hereinafter referred to as "C6F13MA monomer"), 2 parts by weight of bis(2-ethylhexyl) peroxydicarbonate, 1 part by weight of partially saponified polyvinyl alcohol, 2 parts by weight of hydroxypropyl methylcellulose, while stirring While raising the temperature to 56°C, the polymerization reaction was started. When the polymerization internal pressure reached 0.1 MPa, the remaining pressure was released and cooled, washed three times with 1500 parts by weight of deionized water, filtered, and dried at 50°C to obtain a copolymer. The composition of the copolymer was 3.3 parts by weight of C6F13MA monomer per 100 parts by weight of vinyl chloride.

Synthetic example 2

[0111] A copolymer was synthesized in the same manner as in Synthesis Example 1 except that the C6F13MA monomer was 120 parts by weight and the vinyl chloride was 1080 parts by weight. The composition of the copolymer was 11.9 parts by weight of C6F13MA monomer per 100 parts by weight of vinyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com