Polyfluoroalkadiene mixture and method of manufacture therefor

A technology of polyfluorinated alkadiene and manufacturing method, which is applied in the fields of dehydrohalogenation preparation, organic chemistry, etc., can solve the problems of large influence, reduced surface orientation of treated substrate, unable to obtain sufficient performance, etc., and achieves bioaccumulation. low sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

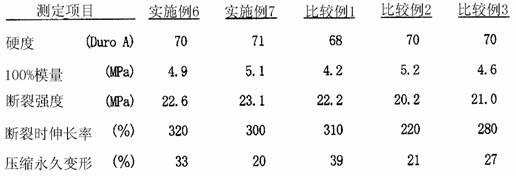

[0108] Next, the present invention will be described by way of examples.

reference example 1

[0110] In an autoclave with a capacity of 1200ml equipped with a stirrer and a thermometer, put

[0111] CF 3 (CF 2 ) 3 (CH 2 CF 2 )(CF 2 CF 2 ) 2 I (99GC%)

[0112] 603 g (0.99 mol) and 7 g (0.05 mol) of di-tert-butyl peroxide, and the autoclave was degassed with a vacuum pump. After heating the internal temperature to 80°C, ethylene was sequentially introduced to make the internal pressure 0.5 MPa. After the internal pressure was reduced to 0.2 MPa, ethylene was introduced again to be 0.5 MPa, and this operation was repeated. While maintaining the internal temperature at 80 to 115°C, 41 g (1.45 mol) of ethylene was introduced over about 3 hours. The contents are recovered under the condition that the internal temperature is 50°C or lower to obtain

[0113] CF 3 (CF 2 ) 3 (CH 2 CF 2 )(CF 2 CF 2 ) 2 (CH 2 CH 2 )I (98GC%)

[0114] which is

[0115] C 4 F 9 CH 2 (CF 2 ) 5 CH 2 CH 2 I

[0116] 637g (98.8% yield).

Embodiment 1

[0118] The 3, 3, 4, 4, 5, 5, 6, 6, 3, 3, 4, 4, 5, 5, 6, 6, 7,7,9,9,10,10,11,11,12,12,12-Nadetafluoro-1-iodododecane C 4 F 9 CH 2 (CF 2 ) 5 CH 2 CH 2 I 5 g (7.8 mmol) was dissolved in 15 ml of a fluorinated organic solvent (Asahi Glass Co., Ltd. AK-225). After cooling with ice, 1,8 - Diazabicyclo[5.4.0]-7-undecene [DBU] 2.6 g (17.2 mmol). After the dropwise addition was completed, stirring was carried out at about 0° C. for about 1 hour, and then stirring was continued at room temperature for about 23 hours (total reaction time was 24 hours).

[0119] After the completion of the reaction, washing with 20 ml of water was performed twice, and then washing with saturated brine was performed once, and the resulting reaction product solution was dehydrated and dried with anhydrous magnesium sulfate. After the reaction solvent was distilled off under reduced pressure, the residue was purified by reduced pressure distillation to obtain 2.8 g (yield: 77%) of a fraction having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com