Water and oil proofing agent and preparation method thereof

A technology of water and oil repellent and cosolvent, used in textiles, papermaking, fiber processing, etc., which can solve the problems of high price, easy agglomeration, and difficulty in obtaining long-term stable emulsions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

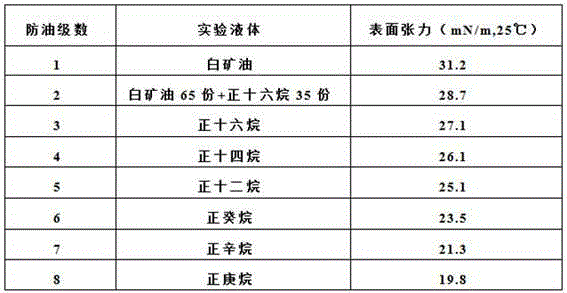

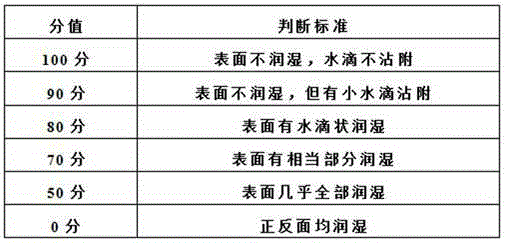

Image

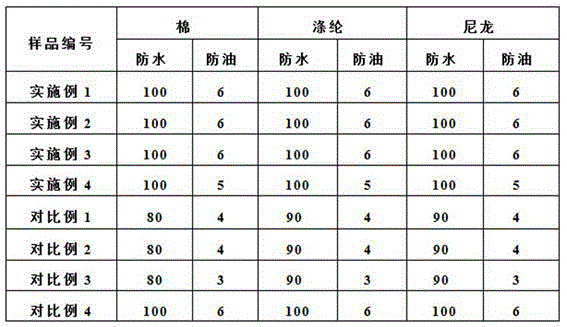

Examples

Embodiment 1

[0036] (1) exist 500ml Add the following components to the plastic bottle: CH 2 =C(CH 3 )-C(=O)-O-CH 2 CH 2 -C 6 F 13 40g , lauryl acrylate 55g 、 N- Methylolacrylamide 5g 、 58 # paraffin 20g , nonionic emulsifier C 12 H 25 O(CH 2 CH 2 O) 20 H 6g , cationic emulsifier C 18 H 37 N + (CH 3 ) 3 Cl - 4g , Tripropylene Glycol 20g ,Deionized water 400g ; put the above reaction system in 60 ° C Stirring and heating in water bath 20 Minutes later, emulsify in a high-pressure homogenizer 10 Minutes, the oil-in-water type metastable emulsion is obtained, the particle size is 150nm 。

[0037] will step ( 1 ) The resulting oil-in-water metastable emulsion is poured into a glass reactor pre-installed with a mechanical stirrer, a thermometer, a reflux condenser and nitrogen gas, and the initiator azobisisobutylamidine hydrochloride is added to the reaction system ...

Embodiment 2

[0042] (1) exist 500ml Add the following components to a plastic beaker: CH 2 =C(H)-C(=O)-O-CH 2 CH 2 -C 6 F 13 40g , cetyl acrylate 55g 、 N- Methylolacrylamide 5g 、 70 # paraffin 40g , nonionic emulsifier C 12 H 25 O(CH 2 CH 2 O) 20 H 6g , cationic emulsifier C 18 H 37 N + (CH 3 ) 3 Cl - 4g , Tripropylene Glycol 20g ,Deionized water 400g ; put the above reaction system in 70 ° C Stirring and heating in water bath 20 Minutes later, emulsify in a high-pressure homogenizer 10 Minutes, the oil-in-water type metastable emulsion is obtained, the particle size is 250nm 。

[0043] ( 2 ) will step ( 1 ) The resulting oil-in-water metastable emulsion is poured into a glass reactor pre-installed with a mechanical stirrer, a thermometer, a reflux condenser and nitrogen gas, and the initiator azobisisobutylamidine hydrochloride is added to the reaction system 0....

Embodiment 3

[0048] (1) exist 500ml Add the following components to a plastic beaker: CH 2 =C(CH 3 )-C(=O)-O-CH 2 CH 2 -C 4 F 9 40g , cetyl acrylate 55g 、 N- Methylolacrylamide 5g , microcrystalline wax 20g , nonionic emulsifier C 12 H 25 O(CH 2 CH 2 O) 20 H 6g , cationic emulsifier C 18 H 37 N + (CH 3 ) 3 Cl - 4g , Tripropylene Glycol 20g ,Deionized water 400g ; put the above reaction system in 60 ° C Stirring and heating in water bath 20 Minutes later, emulsify in a high-pressure homogenizer 10 Minutes, the oil-in-water type metastable emulsion is obtained, the particle size is 250nm 。

[0049] ( 2 ) will step ( 1 ) The resulting oil-in-water metastable emulsion is poured into a glass reactor pre-installed with a mechanical stirrer, a thermometer, a reflux condenser and nitrogen gas, and the initiator azobisisobutylamidine hydrochloride is added to the reaction system 0.5g and dodecyl mercaptan 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com