Waterproof breathable antibacterial thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polymers, can solve the problems of not having both waterproof, breathable and antibacterial properties, and achieve the effect of improving air permeability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

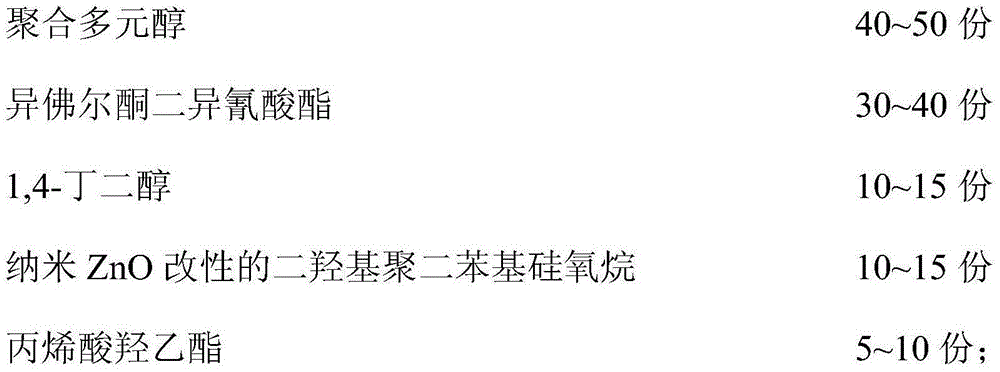

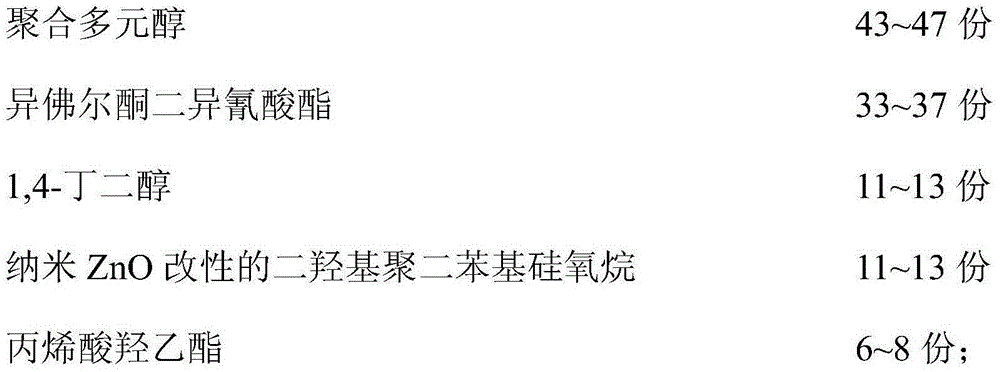

Method used

Image

Examples

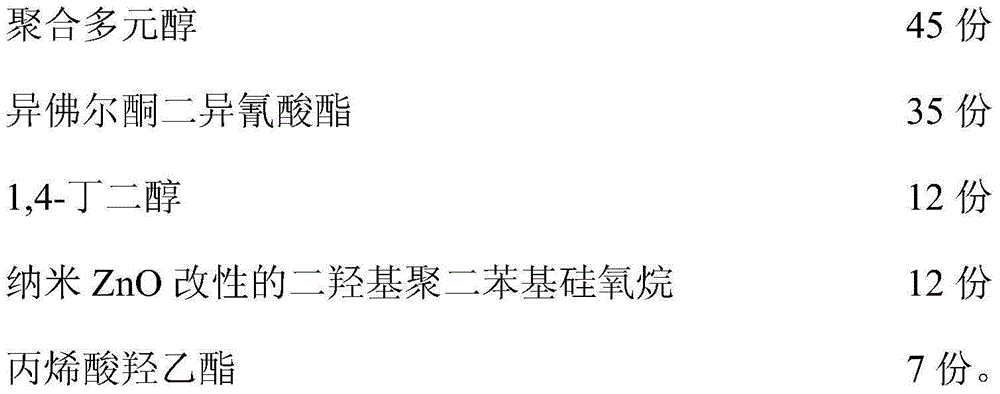

Embodiment 1

[0058] (1) Preparation of nano-ZnO modified dihydroxy polydiphenylsiloxane:

[0059] Disperse nano-ZnO in dihydroxypolydiphenylsiloxane emulsion (wherein the mass ratio of nano-ZnO and dihydroxypolydiphenylsiloxane emulsion is 1:8), and ultrasonically disperse for 1.5h to obtain a dispersion Add the dispersion liquid into a closed container with a reflux condenser and a stirrer, then raise the temperature to 45°C, stir and reflux for 6 hours, and obtain nano-ZnO modified dihydroxy polydiphenylsiloxane;

[0060] (2) Preparation of thermoplastic polyurethane elastomer:

[0061] Add 45 parts of polymer polyol, 12 parts of 1,4-butanediol and 7 parts of hydroxyethyl acrylate into the container in sequence (wherein, m=4 in the fluorine-containing polyether diol, n 1 = 4, n 2 =5,n 3 =4, the mass ratio of fluorine-containing polyether diol to 1,4-butanediol adipate diol in the polymer polyol is 4:1), vacuumize at 1100r / min at 70°C to -0.3kPa , to obtain mixture A; after heating 35...

Embodiment 2

[0064] (1) Preparation of nano-ZnO modified dihydroxy polydiphenylsiloxane:

[0065] Dispersing nano-ZnO in dihydroxypolydiphenylsiloxane emulsion (wherein, the mass ratio of nano-ZnO and dihydroxypolydiphenylsiloxane emulsion is 1:10), and ultrasonically dispersing for 2 hours, to obtain a dispersion; Add the dispersion liquid into a closed container with a reflux condenser and a stirrer, then raise the temperature to 50 ° C, stir and reflux for 5 hours, and obtain nano-ZnO modified dihydroxy polydiphenylsiloxane;

[0066] (2) Preparation of thermoplastic polyurethane elastomer:

[0067] Add 47 parts of polymeric polyol, 13 parts of 1,4-butanediol and 8 parts of hydroxyethyl acrylate into the container in sequence (wherein, m=3 in the fluorine-containing polyether diol, n 1 = 3, n 2 = 3, n 3 =3, the mass ratio of fluorine-containing polyether diol to 1,4-butanediol adipate diol in the polymer polyol is 5:1), vacuumize at 1000r / min at 80°C to -0.2kPa , to obtain mixture A;...

Embodiment 3

[0070] (1) Preparation of nano-ZnO modified dihydroxy polydiphenylsiloxane:

[0071] Disperse nano-ZnO in dihydroxypolydiphenylsiloxane emulsion (wherein, the mass ratio of nano-ZnO and dihydroxypolydiphenylsiloxane emulsion is 1:6), and ultrasonically disperse for 1 hour to obtain a dispersion; Add the dispersion into a closed container with a reflux condenser and a stirrer, then raise the temperature to 40°C, stir and reflux for 8 hours to obtain nano-ZnO-modified dihydroxypolydiphenylsiloxane;

[0072] (2) Preparation of thermoplastic polyurethane elastomer:

[0073] Add 43 parts of polymeric polyol, 11 parts of 1,4-butanediol and 6 parts of hydroxyethyl acrylate into the container successively (wherein, m=6 in the fluorine-containing polyether diol, n 1 =6,n 2 =6,n 3=6, the mass ratio of fluorine-containing polyether diol to 1,4-butanediol adipate diol in the polymer polyol is 3:1), vacuumize at 1200r / min at 60°C to -0.4kPa , to obtain mixture A; after heating 33 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com