Water and oil repellent nanometer finishing agent for fabric

A water-repellent, oil-repellent, and nano-finishing technology, which is applied in fiber treatment, textiles and papermaking, and liquid-repellent fibers, can solve the problems of expensive finishing agents, biological toxicity, and non-degradability, etc. Oil effect, strong washing resistance, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

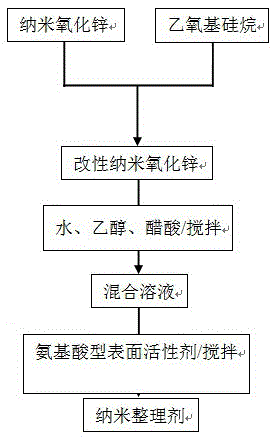

[0019] Example 1: A fabric water-repellent and oil-repellent nano-finishing agent, main components: 10 g of nano-zinc oxide with a particle size of 100 nm, 2 g of ethylsilane with a molar concentration of 0.2 mol / L, and a fatty acyl amino acid with a molar concentration of 0.4 mol / L Type surfactant 5g, absolute ethanol 2g, acetic acid 1g, deionized water 80g. The preparation process is as follows:

[0020] (1) Add nano-zinc oxide into ethylsilane and start stirring (200r / min, 60min);

[0021] (2) Add deionized water, acetic acid and ethanol in sequence and stir rapidly (800r / min, 30min);

[0022] (3) Add the fatty acyl amino acid surfactant and continue stirring until fully mixed.

[0023] The present invention uses charge transfer complexes, that is, silane coupling agents, to chemically adsorb the surface of nano-zinc oxide, thereby increasing the compatibility of nanoparticles to the matrix, improving a series of surface properties such as its wetting and dispersion, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com