Quaternary ammonium glutelin protein synthetic method

A synthesis method and gluten protein technology, applied in the field of papermaking, can solve the problems of inability to enhance fiber strength, poor binding effect of plant fibers, inability to improve protein solubility, etc. The effect of exponential increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

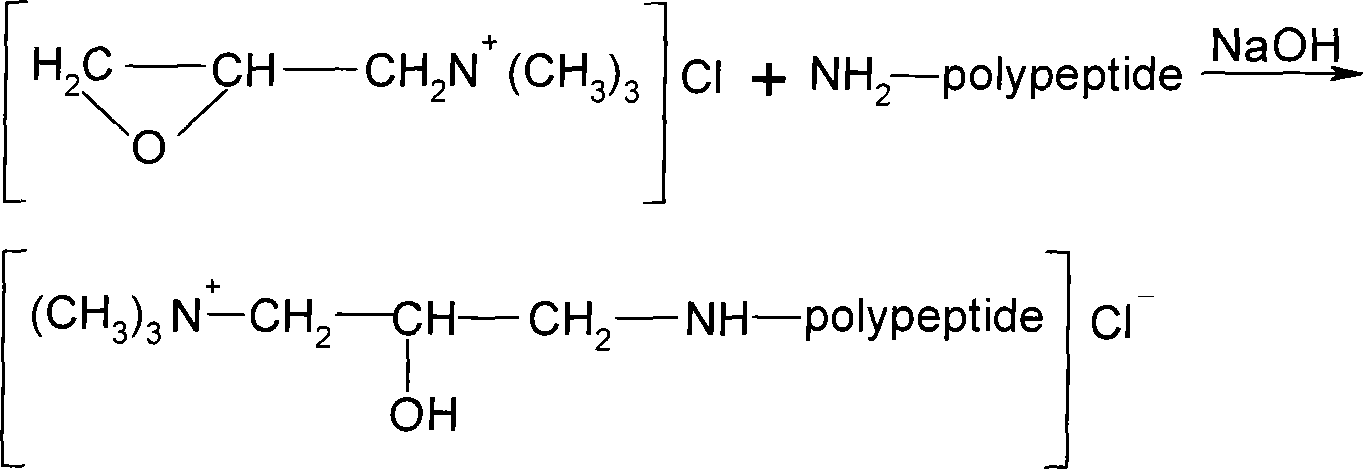

[0020] First gluten protein is dissolved in the sodium hydroxide solution of 0.1 mol / liter, then adds 30% sodium hypochlorite solution, the mass ratio of gluten protein and sodium hypochlorite (calculated by solid content) is 1: 1, and temperature is controlled at 60 ℃, React for 1 hour to obtain pre-treated gluten protein. Then react with a quaternization reagent (N,N,N-trimethylpropylene oxide chloride), the mass ratio is 1:1, the reaction temperature is 50° C., and the reaction time is 6 hours to obtain quaternized gluten protein.

Embodiment 2

[0022] First gluten protein is dissolved in the sodium hydroxide solution of 0.1 mol / liter, then adds the sodium hypobromite solution of 30%, and mass ratio is 1: 1.5, and temperature is controlled at 60 ℃, reacts 1 hour, obtains the gluten of pretreatment Prion. Then react with a quaternization reagent (N,N,N-trimethylpropylene oxide chloride), the mass ratio is 1:1.1, the reaction temperature is 30° C., and the reaction time is 6 hours to obtain quaternized gluten protein.

Embodiment 3

[0024] First gluten protein is dissolved in the sodium hydroxide solution of 0.1 mol / liter, then adds 30% ammonium hypochlorite solution, and mass ratio is 1: 1.1, and temperature is controlled at 60 ℃, reacts 1 hour, obtains the corn of pretreatment Prion. Then react with a quaternization reagent (N,N,N-trimethylpropylene oxide chloride), the mass ratio is 1:1.2, the reaction temperature is 70° C., and the reaction time is 4 hours to obtain quaternized gluten protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com