Cellulose/polylactic acid fiber composite paper and preparation method thereof

A polylactic acid fiber, polylactic acid short fiber technology, applied in the direction of organic non-cellulose fiber, natural cellulose pulp/paper, fiber treatment, etc., can solve the problem of composite paper tensile index and tear index need to be improved, polylactic acid fiber Poor effect, long time and other problems, to achieve the effect of expanding the source of raw materials, reducing processing costs and processing time, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

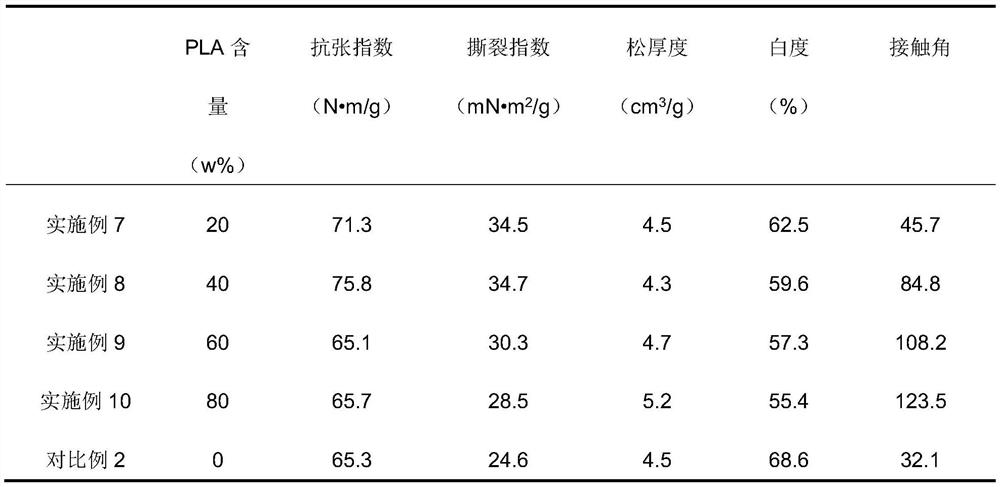

[0029] Described cellulose / polylactic acid fiber composite paper preparation method specifically comprises the following steps:

[0030] (1) The polylactic acid fiber is mechanically sheared, and the polylactic acid fiber is processed into a short fiber with a length of 0.5-2.0mm, and the polylactic acid short fiber is obtained after cleaning and drying with deionized water;

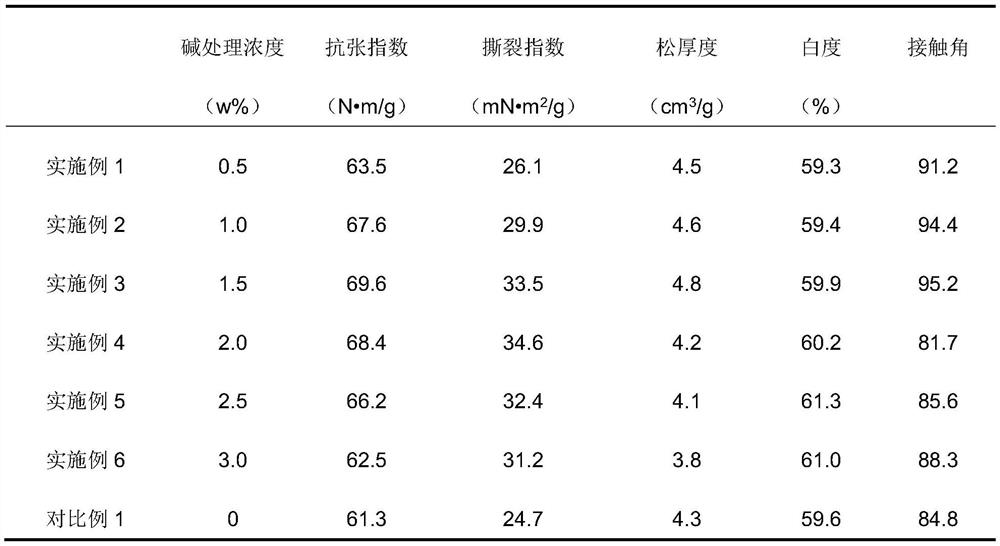

[0031] (2) The short polylactic acid fibers were soaked in absolute ethanol at room temperature for 3 hours, and then washed with water and absolute ethanol to remove impurities and pollutants. Subsequently, it is treated with 0.5% to 3.0% (w%) NaOH solution for 1 hour, and then the short polylactic acid fibers are repeatedly washed with deionized water until the washing liquid is neutral, and the modified short polylactic acid fibers are obtained after drying;

[0032] (3) Soak the natural plant fiber pulp board with deionized water for 24h, then fully decompose it with a fiber disintegrating machine (r...

Embodiment 1

[0037] (1) Cut the polylactic acid fibers on a low-speed disperser, process the polylactic acid fibers into short fibers with a length of 0.5-2.0 mm, wash with deionized water, and dry to obtain short polylactic acid fibers;

[0038] (2) Soak the shortened polylactic acid short fibers in absolute ethanol for 3 hours at room temperature, and then wash with water and absolute ethanol to remove impurities and pollutants. Then it was treated with 0.5% (w%) NaOH solution for 1h to obtain modified polylactic acid short fibers;

[0039] (3) Soak the bleached broad-leaved wood pulp board with deionized water for 24 hours, then fully decompose it with a fiber disintegrator (running at 15,000 rpm), and then pressurize the natural plant fiber pulp board in a trough beater with a beating concentration of 2% ( Hang 1kg weight) beating, beating degree is 35 ° SR, obtains cellulose pulp;

[0040] (4) The auxiliary agent sodium carboxymethyl cellulose is prepared into an auxiliary agent solu...

Embodiment 2

[0043] (1) Cut the polylactic acid fibers on a low-speed disperser, process the polylactic acid fibers into short fibers with a length of 0.5-2.0 mm, wash with deionized water, and dry to obtain short polylactic acid fibers;

[0044] (2) Soak the shortened polylactic acid short fibers in absolute ethanol for 3 hours at room temperature, and then wash with water and absolute ethanol to remove impurities and pollutants. Then it was treated with 1.0% (w%) NaOH solution for 1h to obtain modified polylactic acid short fibers;

[0045] (3) Soak the bleached hardwood pulp board and the bleached softwood pulp board with deionized water for 24 hours respectively, and then fully decompose it with a fiber disintegrating machine (running at 15000 rpm), and then the natural plant fiber pulp board is placed in the tank with a beating concentration of 2%. Pressurize (hang a 1kg weight) in a type beater to beat the pulp, and the beating degree is 40 ° SR, and then the bleached hardwood pulp a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com