High-strength hardwood pulp and preparation method thereof

A high-strength, broad-leaf technology, applied in pulp bleaching, digesters, textiles and papermaking, etc., can solve the problems that hardwood pulp cannot meet market demand, achieve the effect of optimizing wood pulp performance and improving tensile index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

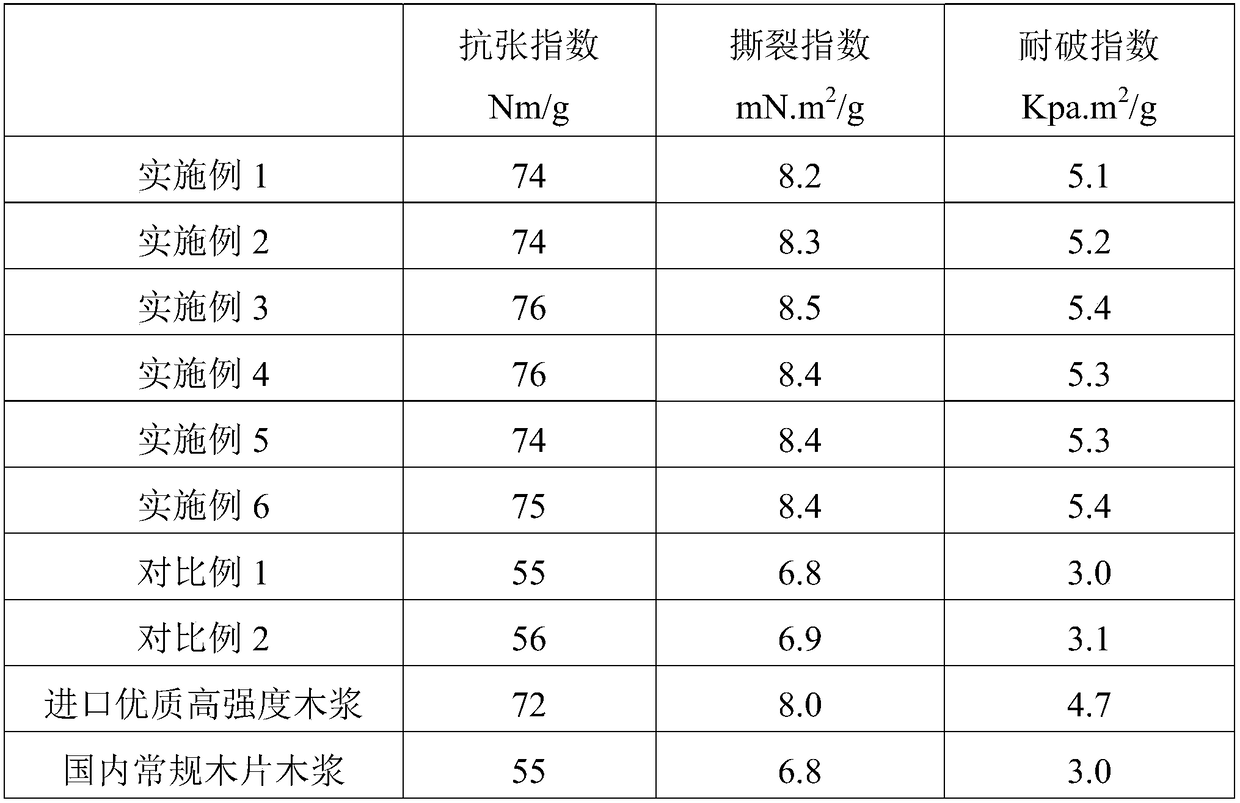

Examples

Embodiment 1

[0022] A high-strength hardwood wood pulp, the raw wood of which is composed of the following raw materials in mass percentage: 90% of blue eucalyptus and 10% of Vietnamese acacia.

[0023] The preparation method of above-mentioned high-strength hardwood wood pulp, comprises the following steps:

[0024] S1. Cooking: Cook the blue eucalyptus and Vietnamese acacia wood chips at 150°C according to the above mass percentage, the amount of alkali used is 15% of the total mass of the blue eucalyptus and acacia wood, the pressure is 5 Bar, and the cooking time is 5 hours;

[0025] S2. Screening: the combination of hole screen and slot screen, the aperture is 0.4mm;

[0026] S3. Oxygen bleaching: temperature 110°C, pressure 6Bar, NaOH dosage 20Kg / ADT, oxygen dosage 24Kg / ADT, slurry mass concentration 10%;

[0027] S4, bleaching:

[0028] ①The first chlorine dioxide bleaching: chlorine dioxide dosage 10Kg / ADT, 75°C, pH 2.5, 50min, normal pressure;

[0029] ②Alkaline extraction: NaO...

Embodiment 2

[0033] A high-strength hardwood wood pulp, the raw wood of which is composed of the following raw materials in mass percentage: 70% of blue eucalyptus and 30% of Vietnamese acacia.

[0034] The preparation method of above-mentioned high-strength hardwood wood pulp, comprises the following steps:

[0035] S1. Cooking: Cook the blue eucalyptus and Vietnamese acacia wood chips at 150°C according to the above mass percentage, the amount of alkali used is 15% of the total mass of the blue eucalyptus and acacia wood, the pressure is 5 Bar, and the cooking time is 5 hours;

[0036] S2. Screening: the combination of hole screen and slot screen, the aperture is 0.4mm;

[0037] S3. Oxygen bleaching: temperature 110°C, pressure 6Bar, NaOH dosage 21Kg / ADT, oxygen dosage 24Kg / ADT, slurry mass concentration 10%;

[0038] S4, bleaching:

[0039] ①The first chlorine dioxide bleaching: chlorine dioxide dosage 10Kg / ADT, 75°C, pH 2.5, 60min, normal pressure;

[0040] ② Alkaline extraction: Na...

Embodiment 3

[0044] A high-strength hardwood wood pulp, the raw wood of which is composed of the following raw materials in mass percentage: 80% of blue eucalyptus and 20% of Vietnamese acacia.

[0045] The preparation method of above-mentioned high-strength hardwood wood pulp, comprises the following steps:

[0046] S1. Cooking: Cook the blue eucalyptus and Vietnamese acacia wood chips at 150°C according to the above mass percentage, the amount of alkali used is 15% of the total mass of the blue eucalyptus and acacia wood, the pressure is 5 Bar, and the cooking time is 5 hours;

[0047] S2. Screening: the combination of hole screen and slot screen, the aperture is 0.4mm;

[0048] S3. Oxygen bleaching: temperature 110°C, pressure 6Bar, NaOH dosage 21Kg / ADT, oxygen dosage 24Kg / ADT, slurry mass concentration 10%;

[0049] S4, bleaching:

[0050] ①The first chlorine dioxide bleaching: chlorine dioxide dosage 10Kg / ADT, 75°C, pH 2.5, 60min, normal pressure;

[0051] ②Alkaline extraction: NaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com