Paper pulp preparation method

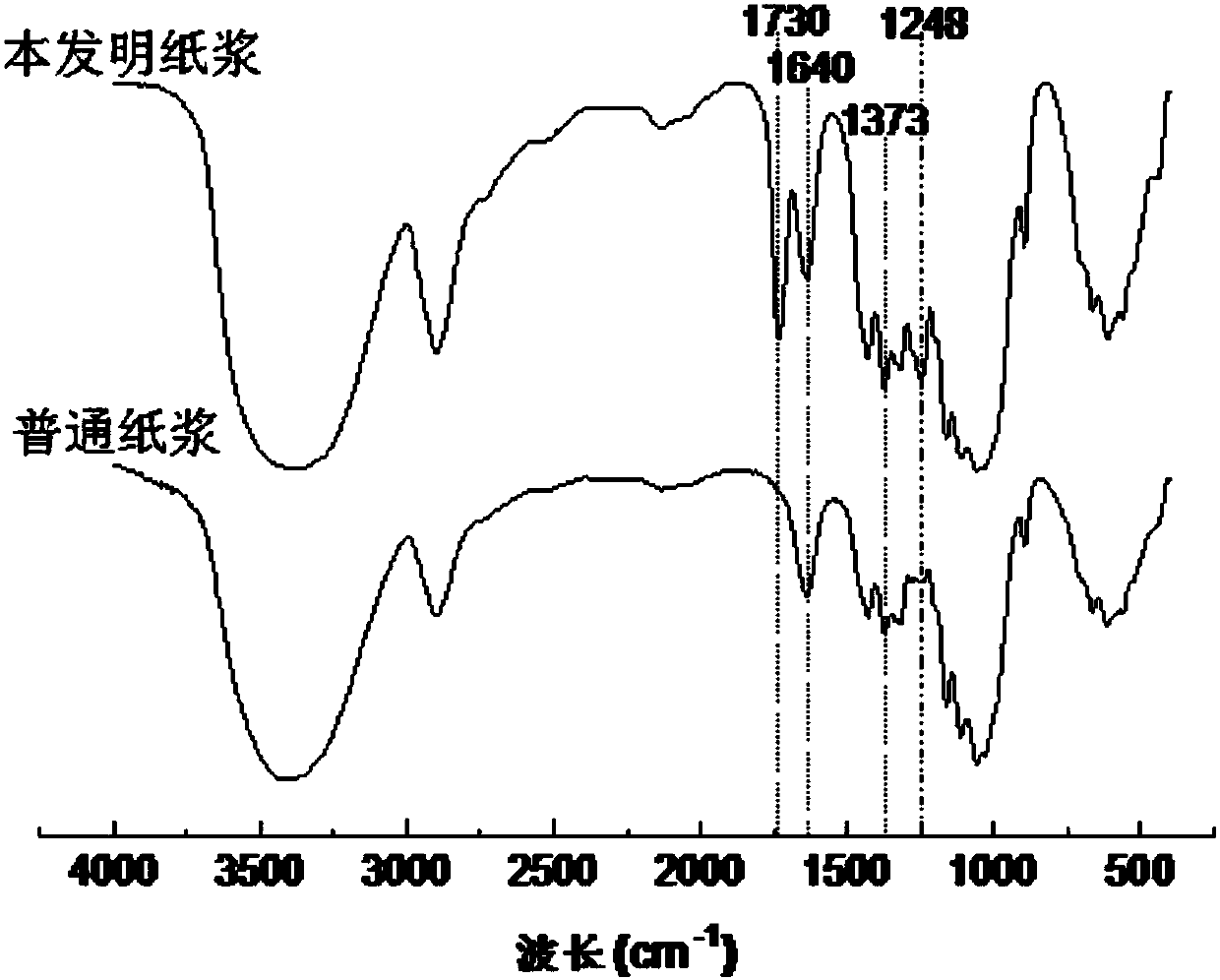

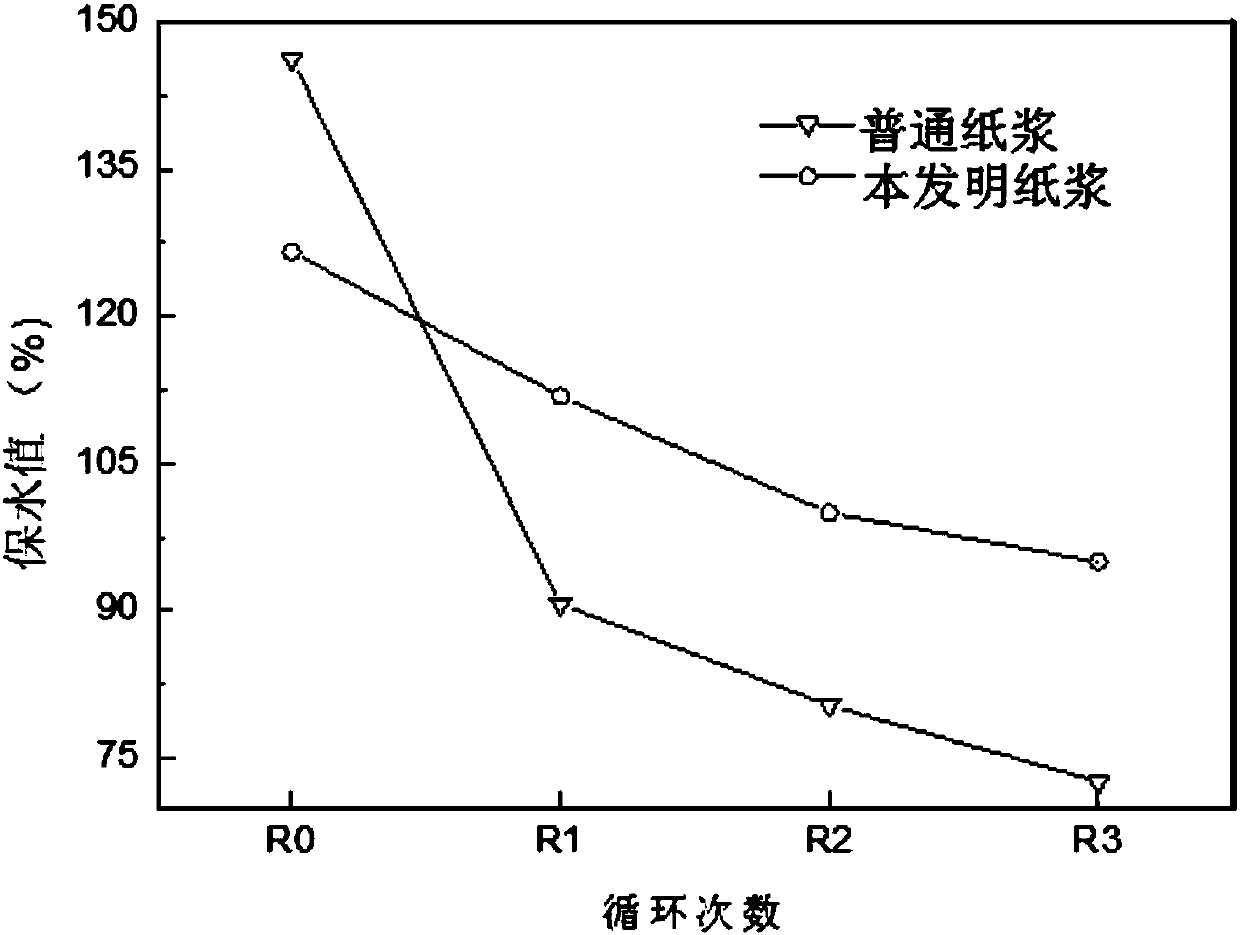

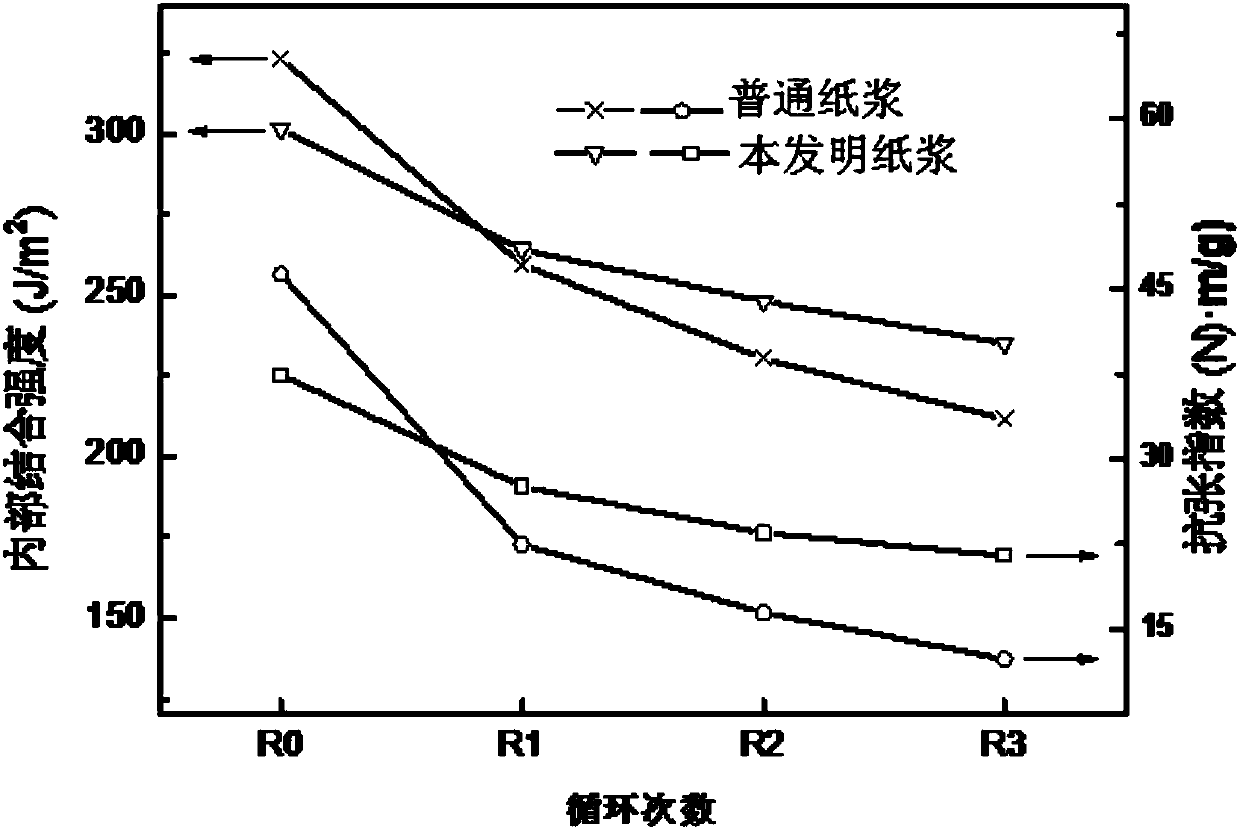

A technology of pulp and fiber pulp, which is applied in the field of industrial papermaking, can solve the problems of poor pulp quality, achieve good results, increase the tensile index, and improve the internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment provides a kind of preparation method of pulp, comprises the steps:

[0023] Step 1: Obtain cellulose, prepare fiber pulp, and adjust the water content of the obtained fiber pulp to 50-70 wt%.

[0024] The cellulose content of this step fiber pulp is 20g; The fiber pulp of this step has also carried out pretreatment: namely earlier it is diluted to mass concentration and be 1.5% fiber suspension (fiber suspension quality is 1333g), in the paper pulp disintegrating machine 10,000 revolutions for deflammation to completely separate the fibers.

[0025] In this step, after the pretreatment, the above-mentioned fiber suspension is concentrated to a cellulose concentration of 40wt% (that is, the quality of the concentrated pulp is 50g), wherein the cellulose content is 20g, and the water content is 30g (60wt%).

[0026] Step 2, adding acetic anhydride to the fiber pulp obtained in step 1, adjusting the temperature, starting hydrolysis reaction and est...

Embodiment 2

[0035] This example is a modification of Example 1. Compared with Example 1, the only change is that the mass ratio of cellulose, acetic anhydride, and acetic acid in step 1 is 1:3:8.

Embodiment 3

[0037] This example is a variation example of Example 1. Compared with Example 1, the only difference is that the temperature of the esterification reaction in Step 2 is 98°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com