Preparation method of high-breakage-resistance kraft paper

A kraft paper and break-resistant technology, applied in pulp beating method, adding water repellent, adding reinforcing agent, etc., can solve the problems of complicated structure of wire part, increasing the number of production line equipment, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

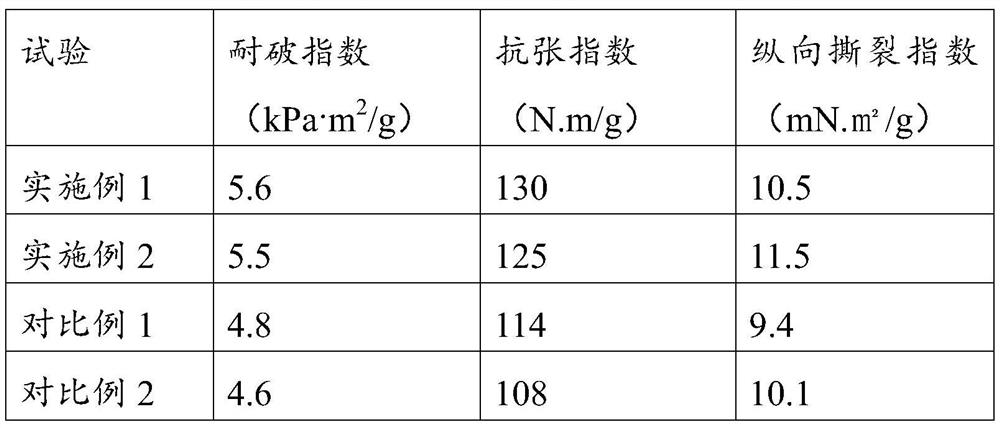

Examples

Embodiment 1

[0028] A method for preparing high-burst-resistant natural color kraft paper, comprising the steps of:

[0029] (1) Preparation materials:

[0030] Uncolored coniferous wood pulp: dry process waste paper pulp = 60:40, wherein the average fiber length of natural coniferous wood pulp is 2.15 mm, the average fiber length of dry process waste paper pulp is 1.7 mm, and the ash content is 2.6%;

[0031] The dry strength agent is 15 kg / ton air-dried pulp, the sizing agent in the pulp is 10 kg / ton air-dried pulp, the cationic starch is 13 kg / ton air-dried pulp, and the paper basis weight is 70g / m 2 ;

[0032] (2) Mixing and disintegration: the fiber raw material is entered into a hydropulper for mixing and disintegration, and the disintegration concentration is 4.5%;

[0033] (3) Sand removal: under the condition of 5% concentration, carry out high-concentration slag removal to the slurry, and use vortex motion to remove heavier impurities;

[0034] (4) High-consistency beating: th...

Embodiment 2

[0040] A preparation method of high breakage-resistant white kraft paper, comprising the steps of:

[0041] (1) Preparation materials:

[0042] Bleached softwood pulp: bleached hardwood pulp=60:40, wherein the average fiber length of bleached softwood pulp is 2.18mm, and the average fiber length of bleached hardwood pulp is 1.33mm;

[0043] The dry strength agent is 9 kg / ton air-dried pulp, the sizing agent in the pulp is 9 kg / ton air-dried pulp, the cationic starch is 11 kg / ton air-dried pulp, and the paper basis weight is 80g / m 2 ;

[0044] (2) Mixing and disintegration: the fiber raw material is entered into a hydropulper for mixing and disintegration, and the disintegration concentration is 4.5%;

[0045] (3) Sand removal: under the condition of 5% concentration, carry out high-concentration slag removal to the slurry, and use vortex motion to remove heavier impurities;

[0046] (4) High-consistency beating: the pulp enters the high-consistency disc refiner through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com