Waste corrugated board white water treatment method

A corrugated cardboard and processing method technology, applied in the field of papermaking, can solve the problems of difficult removal of soluble substances, fluctuating product quality, increased paper breakage, etc., so as to reduce the clogging of the forming wire or the press felt, reduce the dosage, and reduce the content of soluble substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

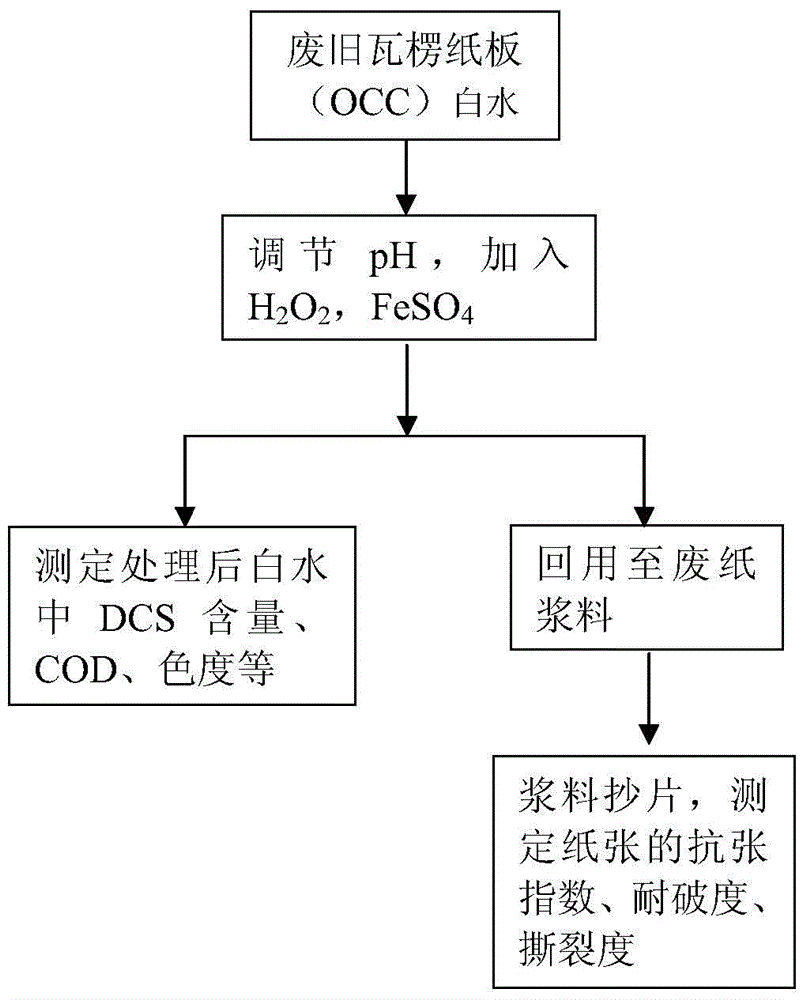

Method used

Image

Examples

Embodiment 1

[0032] Take 500mL waste corrugated white water and put it into a beaker, add concentrated sulfuric acid to adjust the pH=4, put it on a stirrer and stir at 200r / min, add FeSO to the white water first 4 , then add H 2 o 2 , adding FeSO 4 and H 2 o 2 Concentrations in white water are 400mg / L and 180mg / L respectively. After reacting for 30min, adjust the pH value of the reacting white water to 7, aerate and stir for 20min, then add polyacrylamide (PAM) for flocculation, and the added polyacrylamide ( The concentration of PAM) in white water is 2mL / L, after standing for 30min, filter with filter paper to obtain the waste corrugated paper white water water sample after treatment, add white water to waste corrugated paper pulp and carry out sheet copying in PTI sheet machine, quantification is 110g / m 2 . After testing, white water DCS removal rate = 81.2%, COD removal rate = 72.7%, chroma removal rate = 48.8%; the tensile index of waste corrugated paper increased by 13.8%, the...

Embodiment 2

[0034] Take 500mL of waste corrugated paper white water and put it into a beaker, add concentrated sulfuric acid to adjust the pH=5, place it on a stirrer and stir at 200r / min, add FeSO into the white water first 4 , then add H 2 o 2 , adding FeSO 4 and H 2 o 2 Concentrations in white water are 350mg / L and 240mg / L respectively. After reacting for 30min, adjust the pH value of reaction white water to 7, aerate and stir for 20min, then add polyacrylamide (PAM) for flocculation, and the added polyacrylamide ( The concentration of PAM) in white water is 2mL / L, after standing for 30min, filter with filter paper to obtain the treated waste corrugated paper white water water sample, add to waste corrugated paper pulp and carry out sheeting in PTI sheet machine, quantification is 110g / m 2 . After testing, white water DCS removal rate = 83.6%, COD removal rate = 74.5%, chroma removal rate = 51.2%; the tensile index of waste corrugated paper increased by 17.8%, the burst resistance...

Embodiment 3

[0036] Take 500mL waste corrugated white water and put it into a beaker, add concentrated sulfuric acid to adjust the pH=6, put it on a stirrer and stir at 200r / min, add FeSO into the white water first 4 , then add H 2 o 2 , adding FeSO 4 and H 2 o 2 Concentrations in white water are 450mg / L and 220mg / L respectively. After reacting for 30min, adjust the pH value of reaction white water to 7, aerate and stir for 20min, then add polyacrylamide (PAM) for flocculation, and the added polyacrylamide ( The concentration of PAM) in white water is 2mL / L, after standing for 30min, filter with filter paper to obtain the treated waste corrugated paper white water water sample, add to waste corrugated paper pulp and carry out sheeting in PTI sheet machine, quantification is 110g / m 2 . After testing, white water DCS removal rate = 81.8%, COD removal rate = 71.5%, chroma removal rate = 47.4%; the tensile index of waste corrugated paper increased by 15.8%, the burst resistance increased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com