Guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate, preparation method and application thereof, and paper

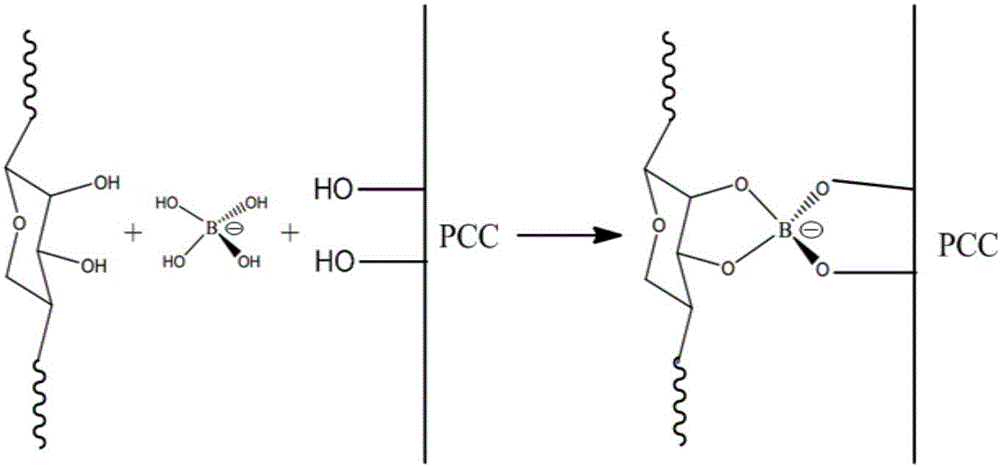

A technology for precipitating calcium carbonate and guar gum boric acid, which is applied in the direction of textiles and papermaking, papermaking, fibrous fillers, etc., and can solve the problems of reducing the application effect and not being very firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Add guar gum equivalent to 0.5% of the weight of PCC to the three-slope mouth containing 90g of water, heat up to 80°C, stir and disperse at 400rpm, and then add 10g of PCC;

[0048] Step 2: Add boric acid equivalent to 7% by weight of PCC into the reactor, and stir for 10 minutes;

[0049] Step 3: collecting the reaction product by centrifugation and washing and drying it;

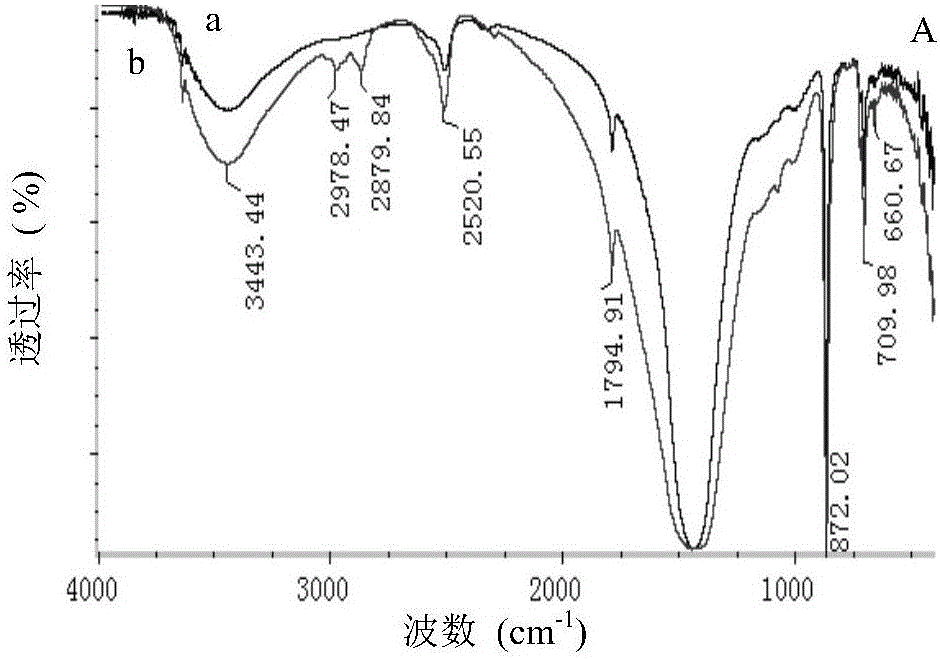

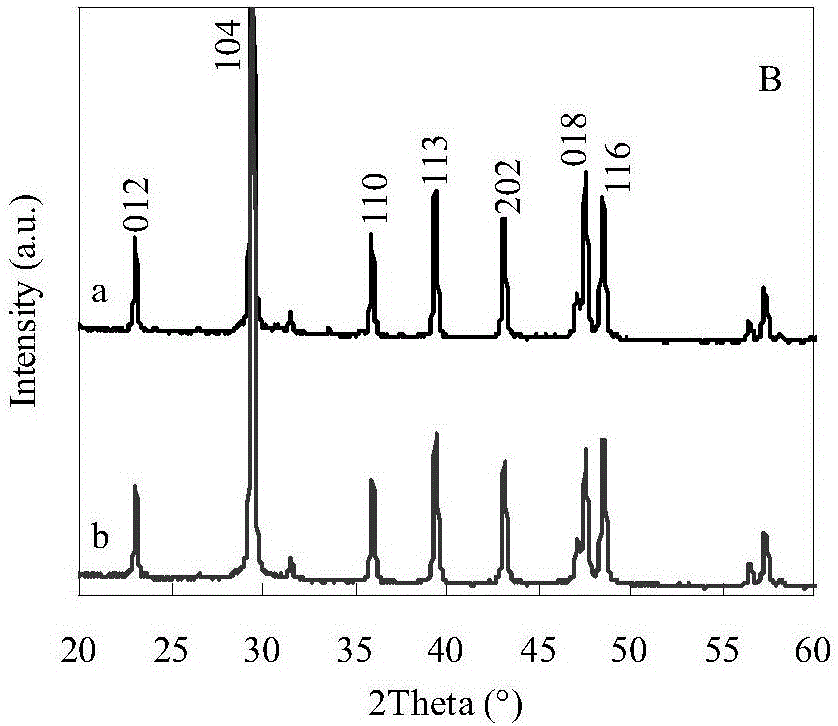

[0050] Step 4: Grind MPCC and PCC finely with a mortar, pass through a 200-mesh copper mesh, analyze and characterize them with a scanning electron microscope, Fourier transform infrared spectrometer, elemental analyzer, etc. respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com