Corona-resistant aramid fiber/mica insulation paper and preparation method thereof

A technology of mica insulation and corona resistance, which is applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems of poor corona resistance and achieve good corona resistance, high production efficiency, and excellent dielectric properties intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Based on the above ideas, the invention provides a method for preparing a corona-resistant aramid fiber / mica insulating paper, comprising the following steps:

[0035] Step 1, use a concentration of (1×10 -3 -1.5×10 -3 ) mol / L sodium dodecylbenzene sulfonate solution at 40-65°C for 30-90 minutes to wash aramid chopped fibers, then rinse and dry for later use. The aramid fibrids are refined through a refiner (PFI), sealed and stored for later use.

[0036]Step 2. Decompose the aramid chopped fibers in 2L of water with a fiber decomposer at a rotation speed of 10,000-25,000. Add the dispersant polyethylene oxide (PEO) when decomposing, but it is necessary to prepare 0.5706g / l PEO in advance. Ethylene solution, usually 100-1000ml solution is prepared, magnetically stirred and dispersed for 2-3 hours, placed in a volumetric flask, and a certain amount is added each time when dispersing the fibers, and then the aramid precipitated fiber obtained in step 1 is added, and the...

Embodiment 1

[0043] A kind of preparation method of corona-resistant aramid fiber / mica insulating paper of the present invention comprises the following steps,

[0044] Step 1, use a concentration of 1×10 -3 The mol / L sodium dodecylbenzenesulfonate solution washed the meta-aramid chopped fibers at 40°C for 30 minutes, then rinsed them and dried them for later use. The meta-aramid fibrids are refined through a refiner (PFI), and sealed for later use.

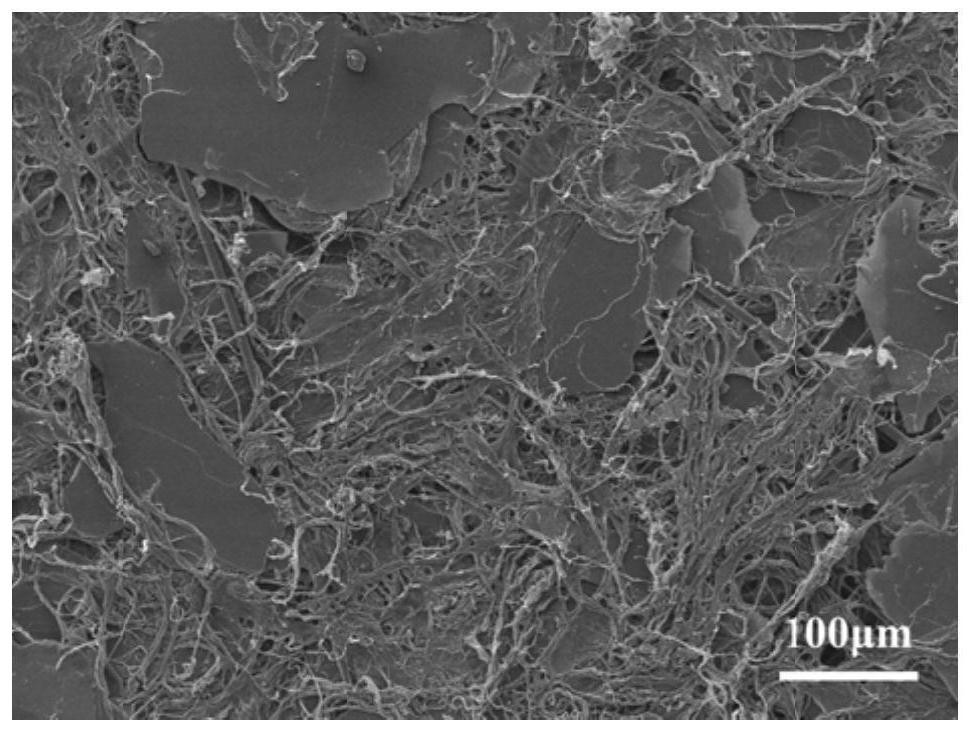

[0045] Step 2, 0.60g meta-aramid chopped fibers are decomposed in 2L of water for 25000 turns, adding muscovite sheets, aramid chopped fibers and aramid precipitated fiber gross mass 0.9% polyethylene oxide dispersant ( PEO), and then add 1.39g of meta-aramid fibrids, and disperse 8000 revolutions together with aramid chopped fibers. Then add muscovite flakes (the mass of muscovite flakes is 30% of the total mass of muscovite flakes, aramid chopped fibers and aramid fibrids), and mix and defrost for 2000 rpm to form a uniformly dispersed mi...

Embodiment 2

[0052] A kind of preparation method of corona-resistant aramid fiber / mica insulating paper of the present invention comprises the following steps,

[0053] Step 1, use a concentration of 1.2×10 -3 The mol / L sodium dodecylbenzenesulfonate solution washed the meta-aramid chopped fibers at 60°C for 40 minutes, then rinsed them and dried them for later use. The meta-aramid fibrids are refined through a refiner (PFI), and sealed for later use.

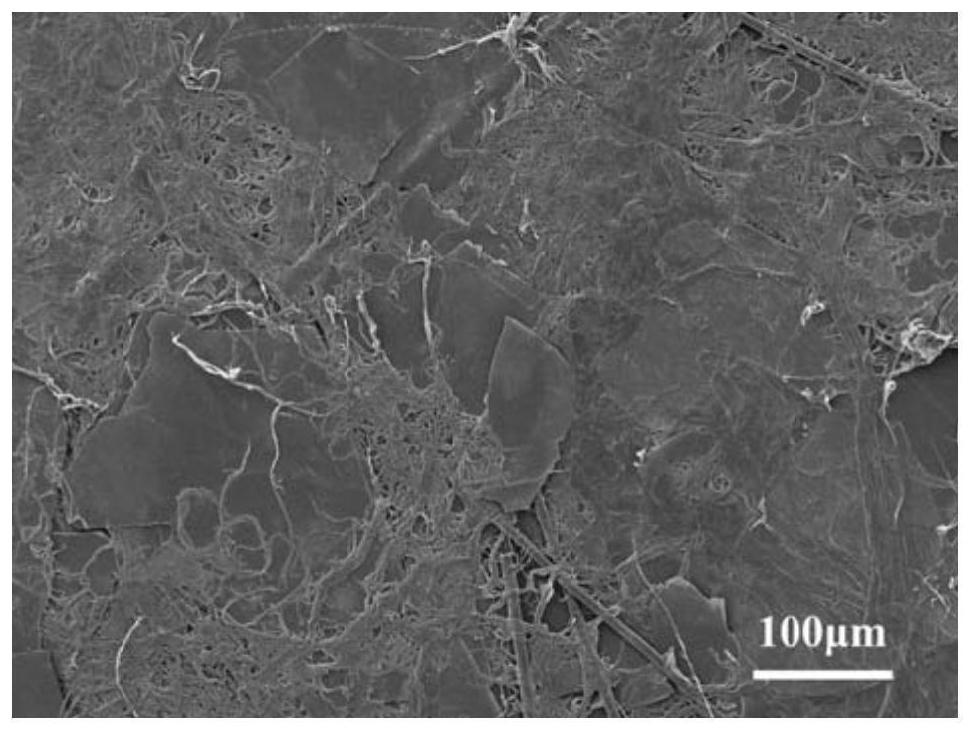

[0054] Step 2, 0.51g meta-aramid chopped fibers are decomposed in 2L of water for 15000 turns, adding muscovite sheets, aramid chopped fibers and aramid precipitated fiber gross mass 0.3% polyethylene oxide dispersant ( PEO), then add 1.19g of meta-aramid fibrids, and disperse with aramid chopped fibers for 10,000 revolutions. Then add muscovite flakes (the mass of muscovite flakes is 40% of the total mass of muscovite flakes, aramid chopped fibers and aramid fibrids), and mix and decompose at 2500 rpm to form a uniformly dispersed mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com