Inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and preparation method thereof

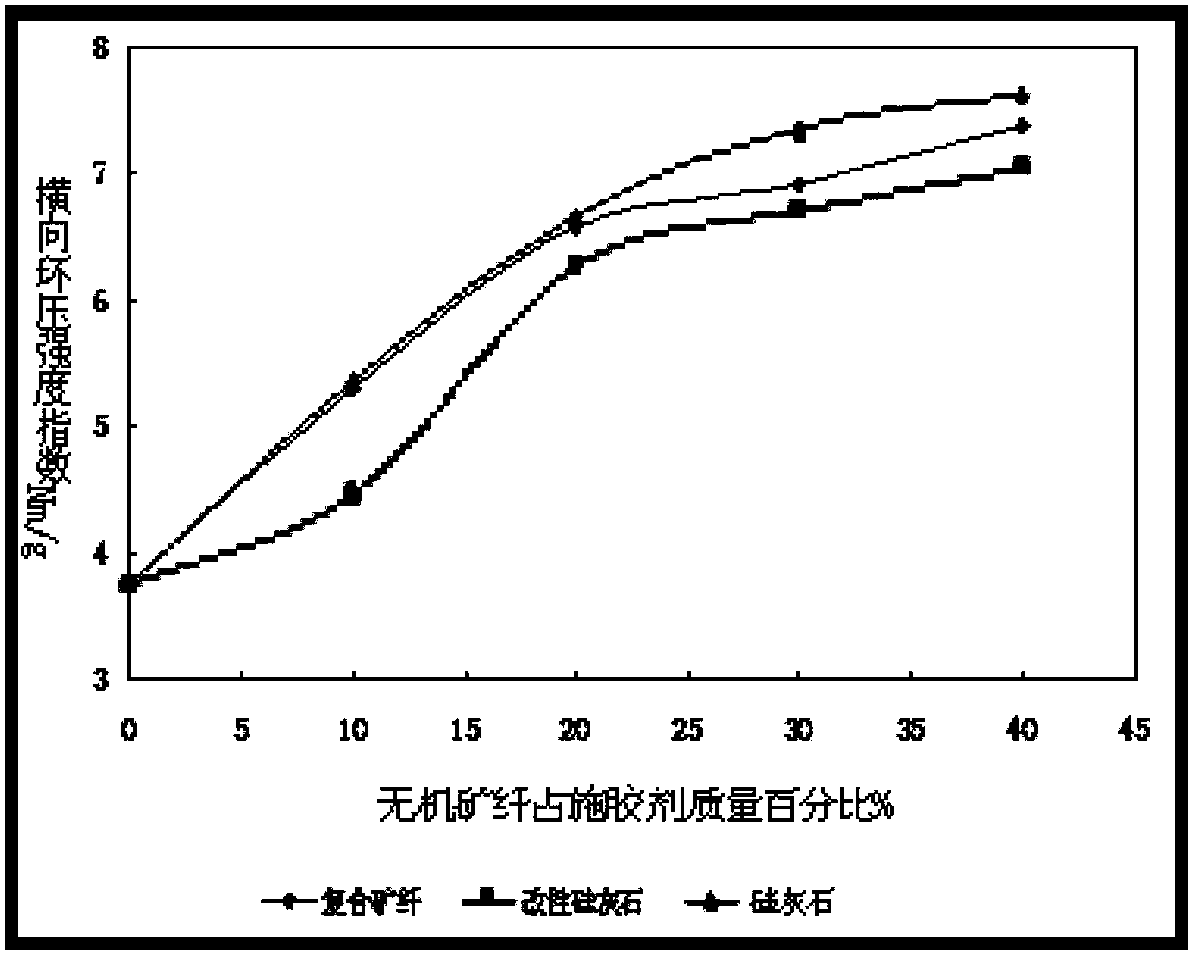

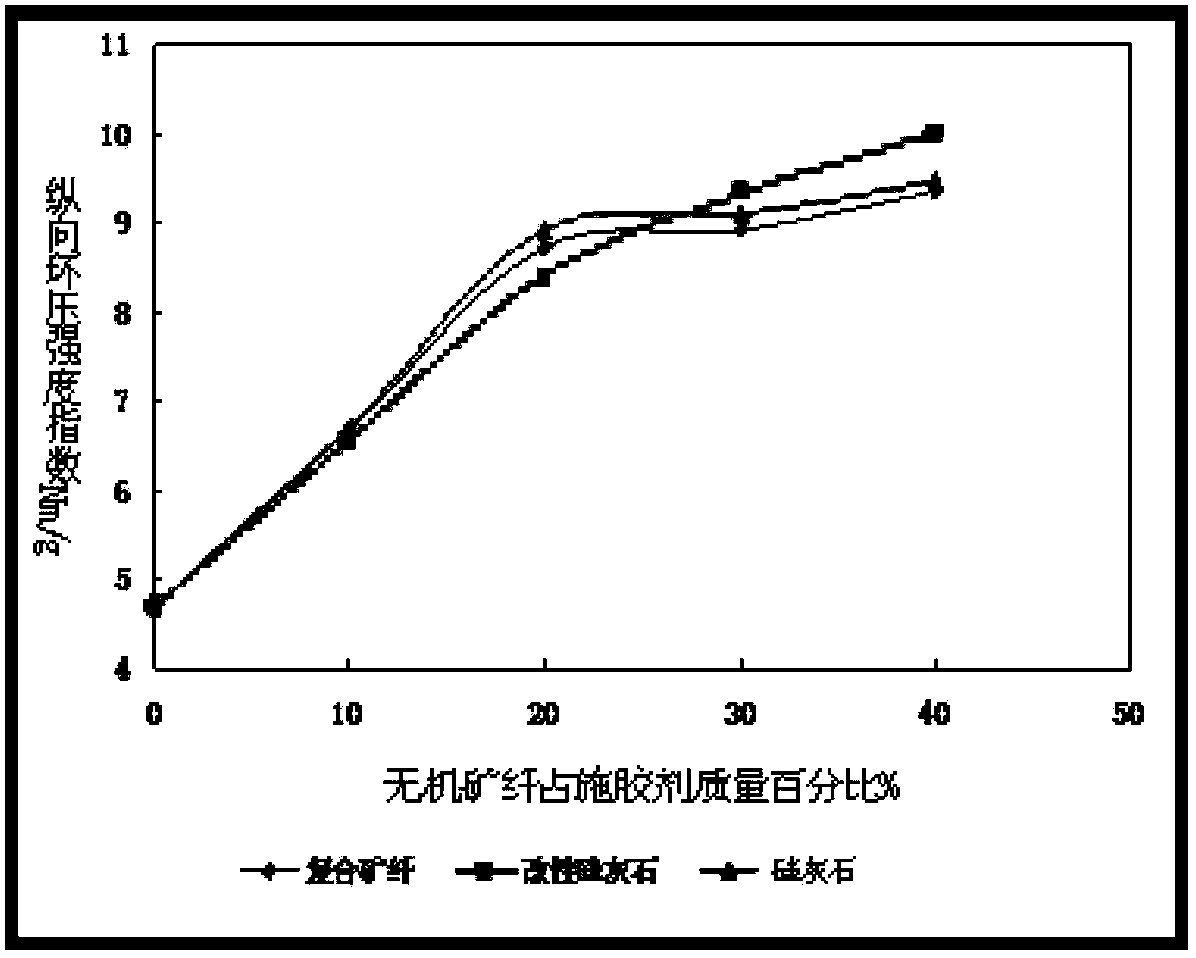

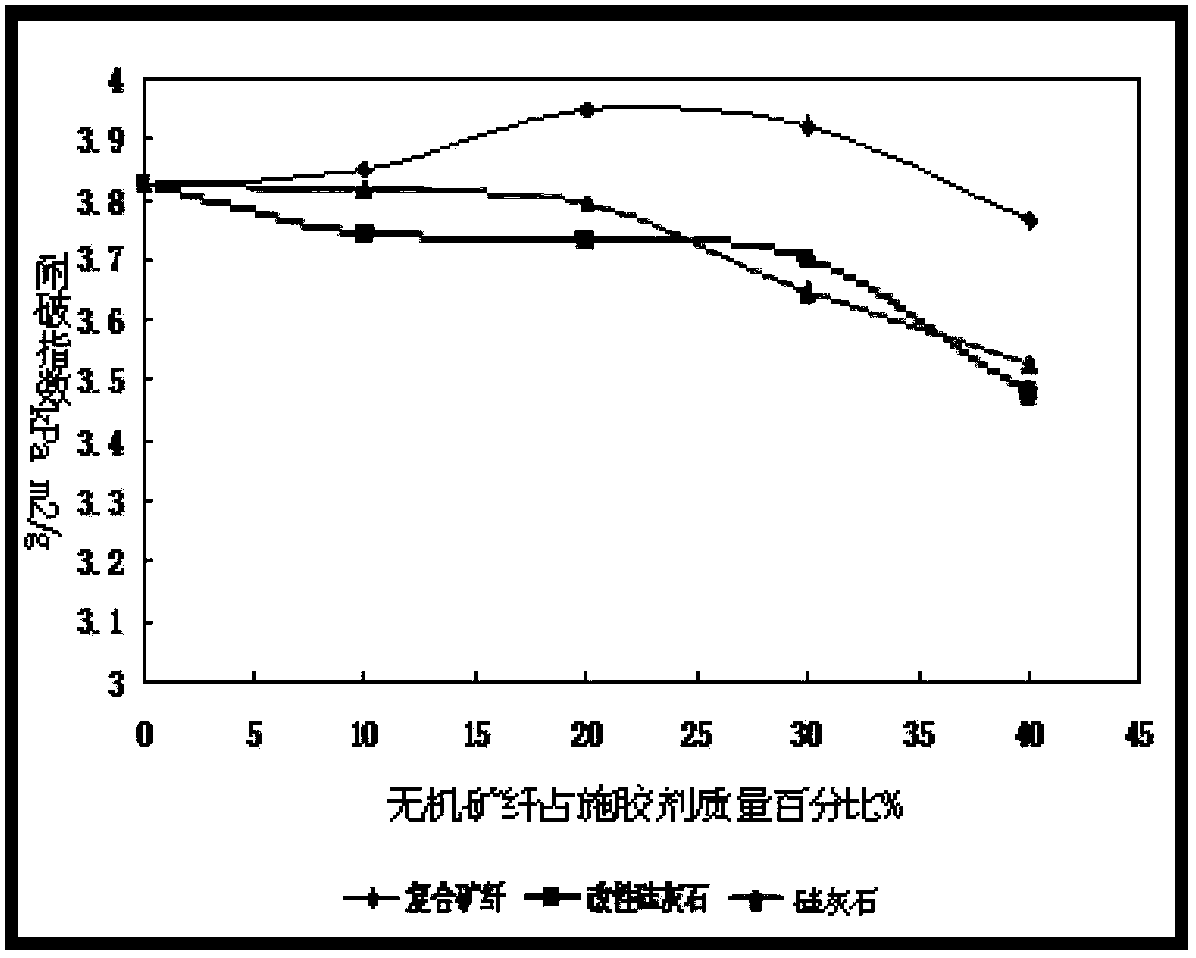

A technology of surface sizing agent and inorganic mineral fiber, applied in the direction of water repellent addition, etc., can solve the problems of high production cost and prohibitive enterprises, and achieve the effect of reducing papermaking cost, improving ring compressive strength, and reducing papermaking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An inorganic mineral fiber ring pressure-reinforced surface sizing agent for papermaking, the sizing agent is composed of surface sizing starch and composite mineral fiber, and the percentage of the composite mineral fiber accounting for the mass of the sizing agent is 5%, so The above-mentioned composite mineral fiber is wollastonite fiber and attapulgite clay, and its mass ratio is 7:3.

[0039] The preparation method of the sizing agent is to mix the composite mineral fiber and the surface sizing starch to prepare an aqueous solution with a mass concentration of 8%, stir evenly, heat up to 90°C, gelatinize for 30 minutes, and cool down to 60°C.

Embodiment 2

[0041] The difference with embodiment 1 is:

[0042] The mass percentage of the composite mineral fiber in the sizing agent is 10%.

Embodiment 3

[0044] The difference with embodiment 1 is:

[0045] The mass percentage of the composite mineral fiber in the sizing agent is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com