Corrugating base paper enhancer and preparation method thereof

A corrugated base paper and reinforcing agent technology, which is applied in the papermaking field to achieve the effects of improving ring crush strength, reducing interference and improving evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

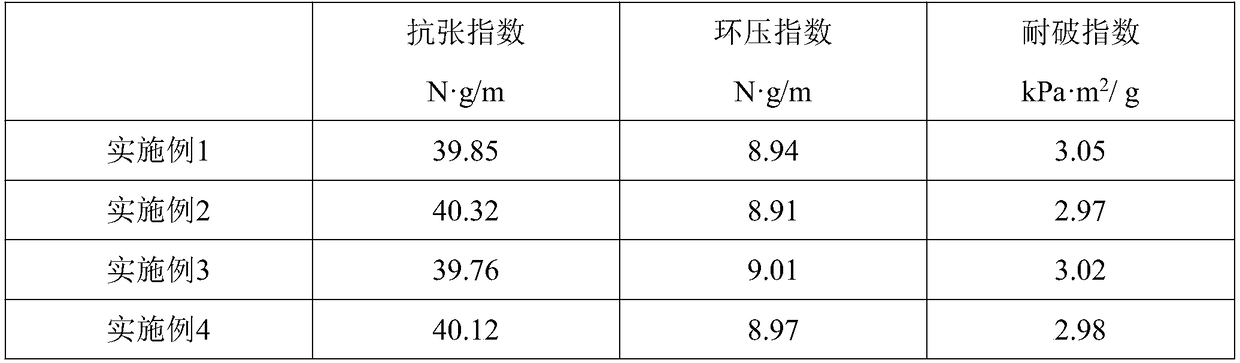

Examples

Embodiment 1

[0016] A corrugated base paper strengthening agent, comprising the following raw materials in parts by weight: 30 parts of cationic polyacrylamide, 5 parts of hydroxypropyl chitosan, 5 parts of polyamide polyamine epichlorohydrin resin, 3 parts of crosslinking agent, hydrogen 0.5 part of potassium oxide, 3 parts of layered silicate, 0.5 part of microcrystalline cellulose, 0.5 part of surfactant, 0.5 part of sodium bicarbonate, and 0.3 part of coupling agent.

[0017] Wherein, the crosslinking agent is glyoxal, the layered silicate is sodium bentonite, and the surfactant is a silicate surfactant.

[0018] The preparation method of above-mentioned corrugated raw paper strengthening agent, comprises the following steps:

[0019] Step 1, mix cationic polyacrylamide, hydroxypropyl chitosan, and polyamide polyamine epichlorohydrin resin, heat to 70°C and keep warm, add crosslinking agent and potassium hydroxide under stirring condition, keep warm for 60min, and get polymer;

[002...

Embodiment 2

[0022] A corrugated base paper strengthening agent, comprising the following raw materials in parts by weight: 33 parts of cationic polyacrylamide, 7 parts of hydroxypropyl chitosan, 6 parts of polyamide polyamine epichlorohydrin resin, 4 parts of crosslinking agent, hydrogen 0.6 parts of potassium, 4 parts of layered silicate, 0.8 parts of microcrystalline cellulose, 0.7 parts of surfactant, 0.6 parts of sodium bicarbonate, and 0.5 parts of coupling agent.

[0023] Wherein, the crosslinking agent is glyoxal, the layered silicate is sodium bentonite, and the surfactant is a silicate surfactant.

[0024] The preparation method of above-mentioned corrugated raw paper strengthening agent, comprises the following steps:

[0025] Step 1, mix cationic polyacrylamide, hydroxypropyl chitosan, and polyamide polyamine epichlorohydrin resin, heat to 70°C and keep warm, add crosslinking agent and potassium hydroxide under stirring condition, keep warm for 60min, and get polymer;

[0026...

Embodiment 3

[0028] A corrugated base paper strengthening agent, comprising the following raw materials in parts by weight: 37 parts of cationic polyacrylamide, 8 parts of hydroxypropyl chitosan, 8 parts of polyamide polyamine epichlorohydrin resin, 5 parts of crosslinking agent, hydrogen 0.8 part of potassium oxide, 6 parts of layered silicate, 0.6 part of microcrystalline cellulose, 0.7 part of surfactant, 0.6 part of sodium bicarbonate, and 0.5 part of coupling agent.

[0029] Wherein, the crosslinking agent is glyoxal, the layered silicate is sodium bentonite, and the surfactant is a silicate surfactant.

[0030] The preparation method of above-mentioned corrugated raw paper strengthening agent, comprises the following steps:

[0031] Step 1, mix cationic polyacrylamide, hydroxypropyl chitosan, and polyamide polyamine epichlorohydrin resin, heat to 70°C and keep warm, add crosslinking agent and potassium hydroxide under stirring condition, keep warm for 60min, and get polymer;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com