Patents

Literature

98results about How to "Reduce paper production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flyash fiber pulp and papermaking method using same as raw material

InactiveCN1580391AImprove the added value of the applicationReduce consumptionInorganic fibres/flakesNon-fibrous pulp additionSlurryFire prevention

This invention discloses fly ash fiber pulp and its use in paper making including the following components and weight percentage: emulsifier 1-10%, dispersant 1-8%, surface modifier 1-10%, powder-coal fiber 20-80%, organic fiber 20-80% and reset for water said pulp is conveyed onto a paper-making machine by conventional method to turn them into paper, which physical performance reaches to the same level as plant fiber paper and water resistance, corrosion prevention and fire prevention are tested better than plant fiber paper by related national standards.

Owner:EAST CHINA UNIV OF SCI & TECH +1

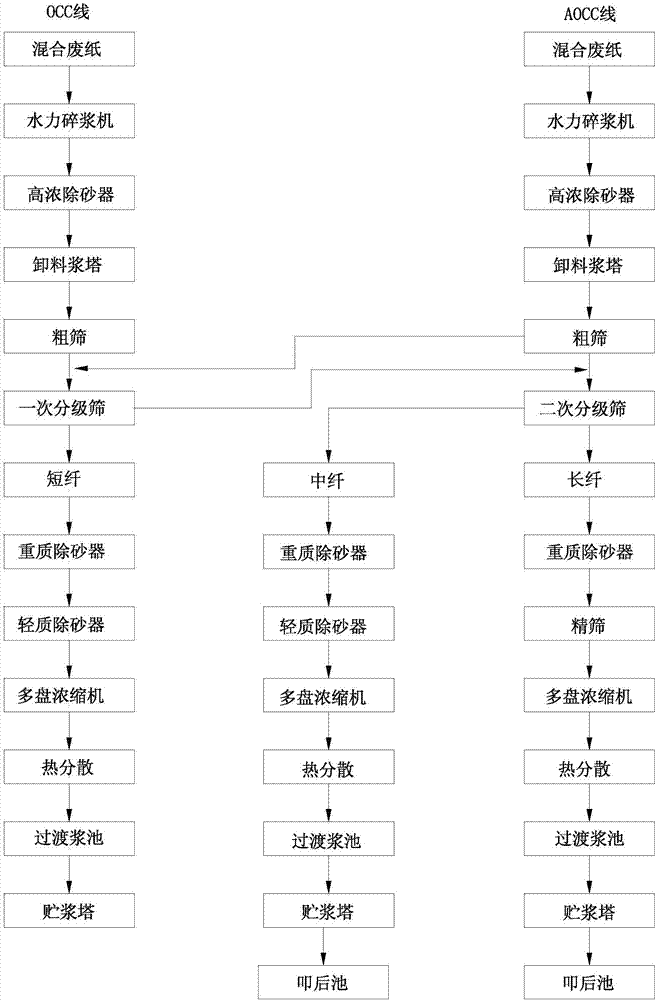

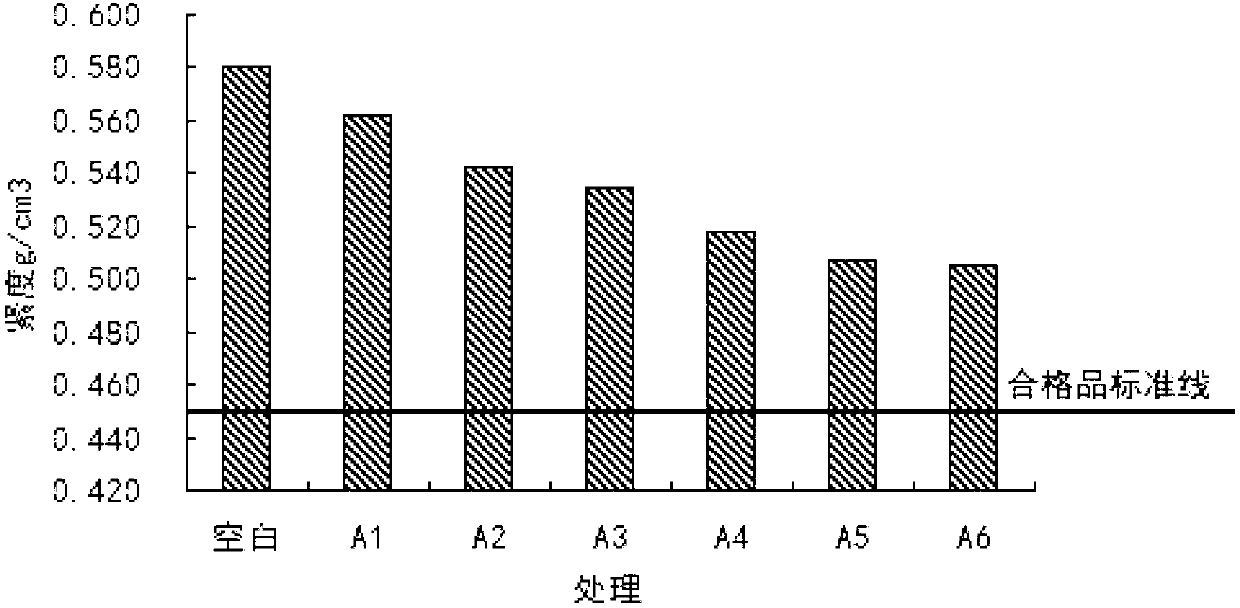

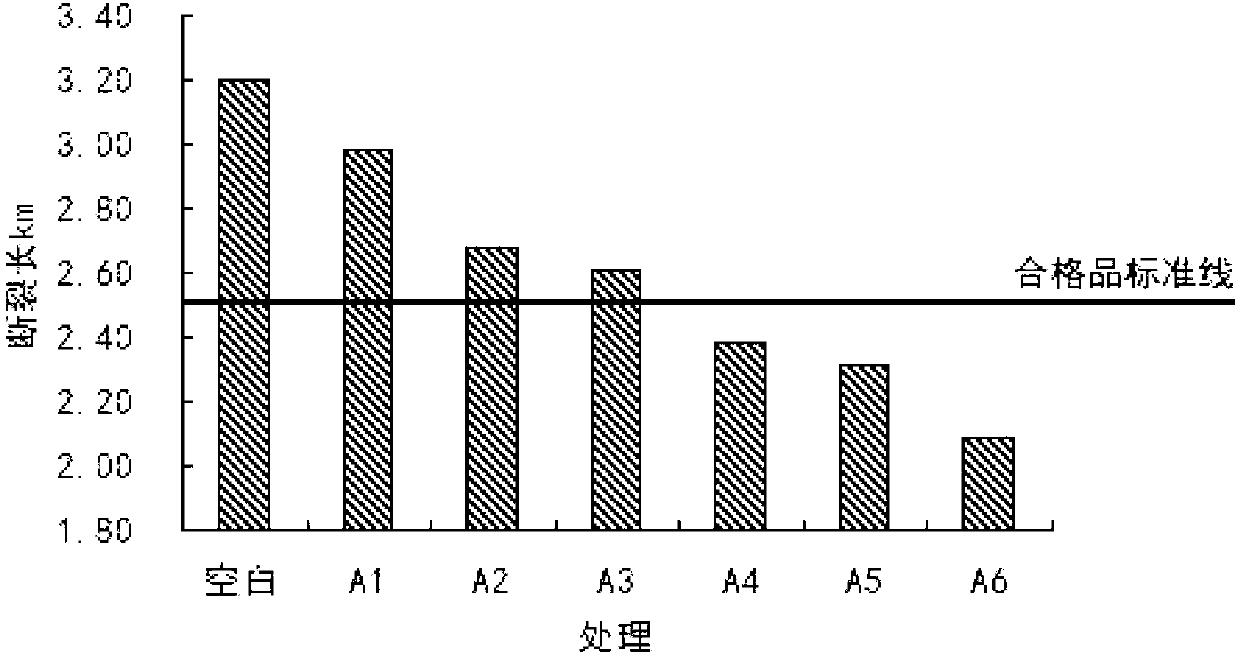

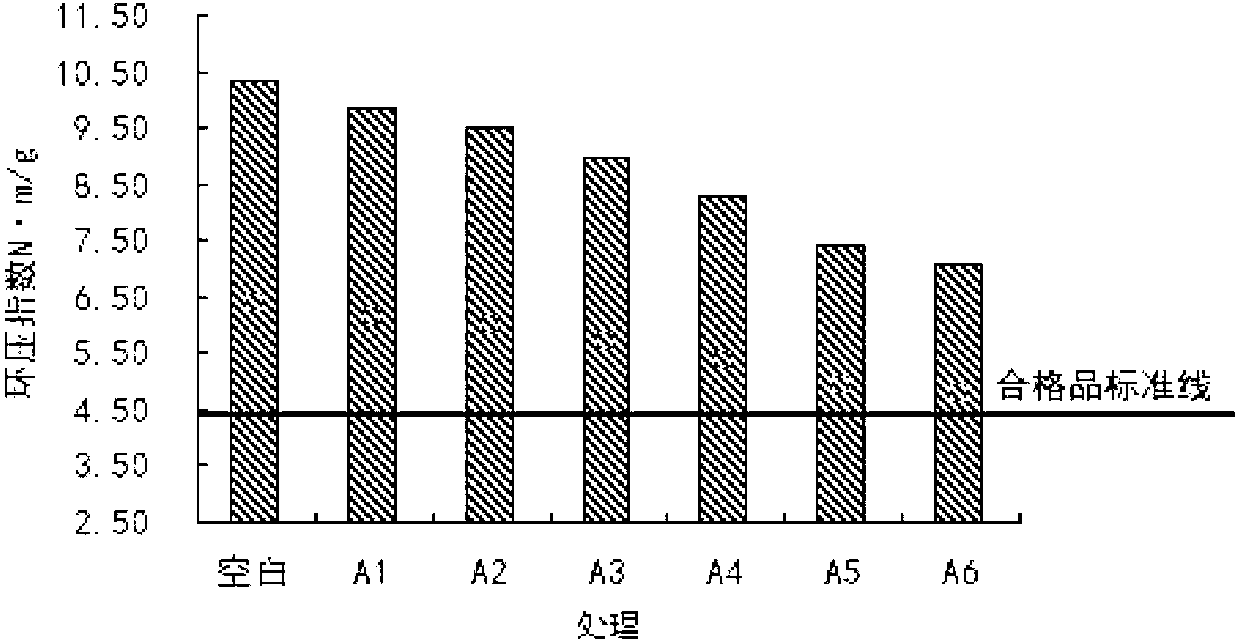

Preparation technology of environment-friendly liner board

ActiveCN106930139AQuality improvementReduce paper production costsPaper recyclingSecondary cellulose fibresFiberSlag

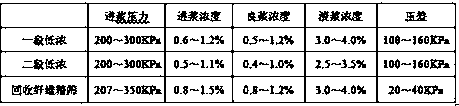

A preparation technology of an environment-friendly liner board comprises the steps of breaking waste paper into paper pulp firstly, screening the paper pulp with a coarse screening system, and conveying to a primary classifying screen system to form short fibered pulp; thenperforming secondary classifying screening on slag pulp after primary classifying screening;obatining middle fibered pulp and long fibered pulp, and using the short fibered pulp, the long fibered pulp and the middle fibered pulp for papermaking. According to the preparation technology of the environment-friendly liner board, the waste paper is recycled; the produced liner board is higher in quality; the papermaking cost of an enterprise is effectively reduced; resources are saved; and the damage to an environment is reduced.

Owner:DONGGUAN JIANHUI PAPER CO LTD

Method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge

ActiveCN103103866ASimple processEasy to operateSecondary cellulose fibresPaper-making machinesFiberResource utilization

The invention discloses a method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge, belonging to the fields of recyclable material and environmental protection. The method comprises the following steps of: by using the secondary fiber obtained after anaerobic digestion of paper mill sludge, waste paper pulp and softwood pulp as raw materials, separating and brooming the fiber through defibering and beating treatment, then dewatering, mixing, and then adding a reinforcing agent and a sizing agent to defiber; and adding paper pulp after defibering in a sheet machine so as to form uniform pages, and then pressing and drying to form corrugating base paper. The method is simple in process and high in operability, and the secondary fiber after anaerobic digestion of paper mill sludge is utilized for mixing with the waste paper pulp for papermaking, so that the energy of papermaking enterprises is saved, simultaneously efficient resource utilization of remaining secondary fiber after anaerobic digestion of paper mill sludge is realized, a new raw material source is created for papermaking factories, the cleaner production level of papermaking enterprises is improved, the resource utilization ratio of paper mill sludge is realized to the maximum, and the method has important engineering application value.

Owner:SOUTH CHINA AGRI UNIV

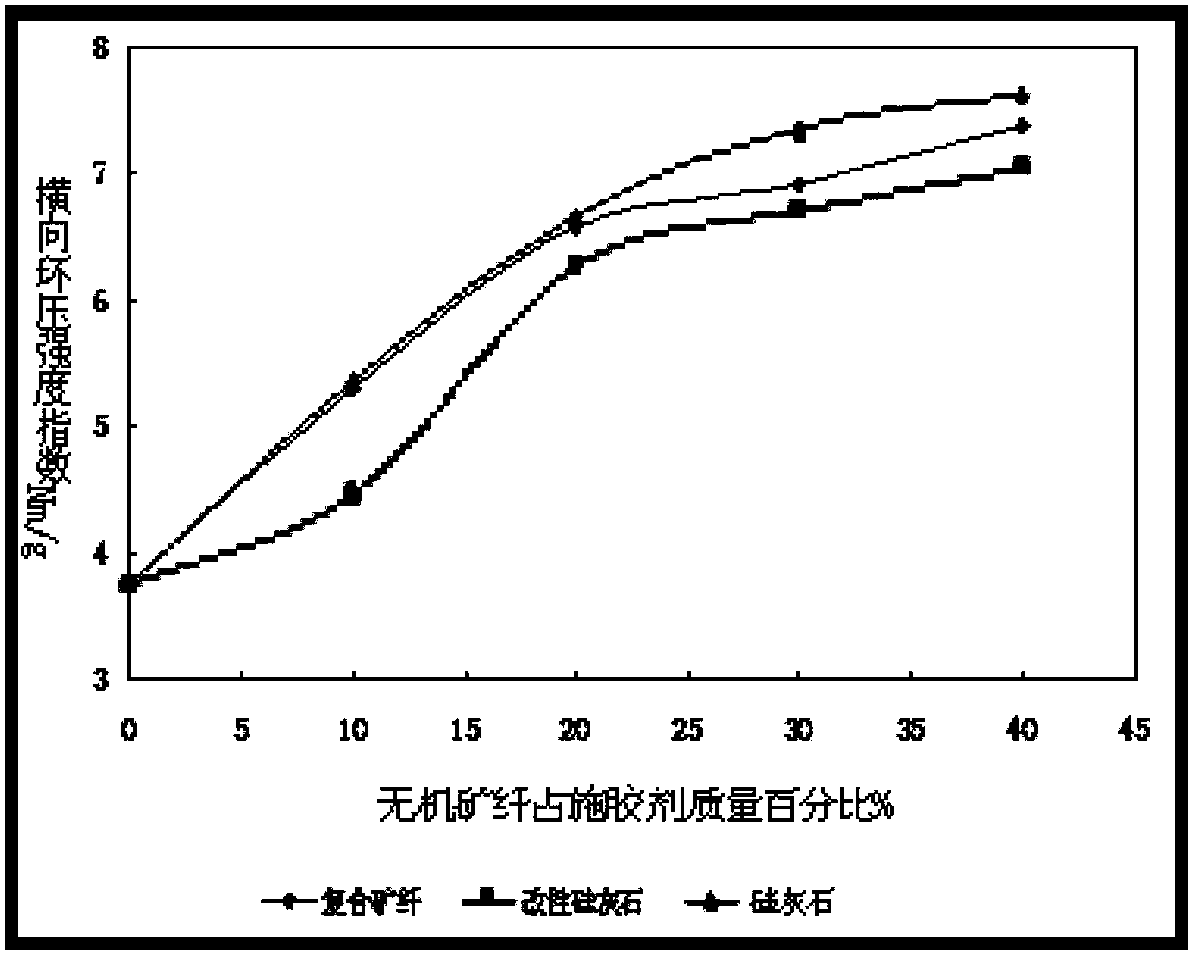

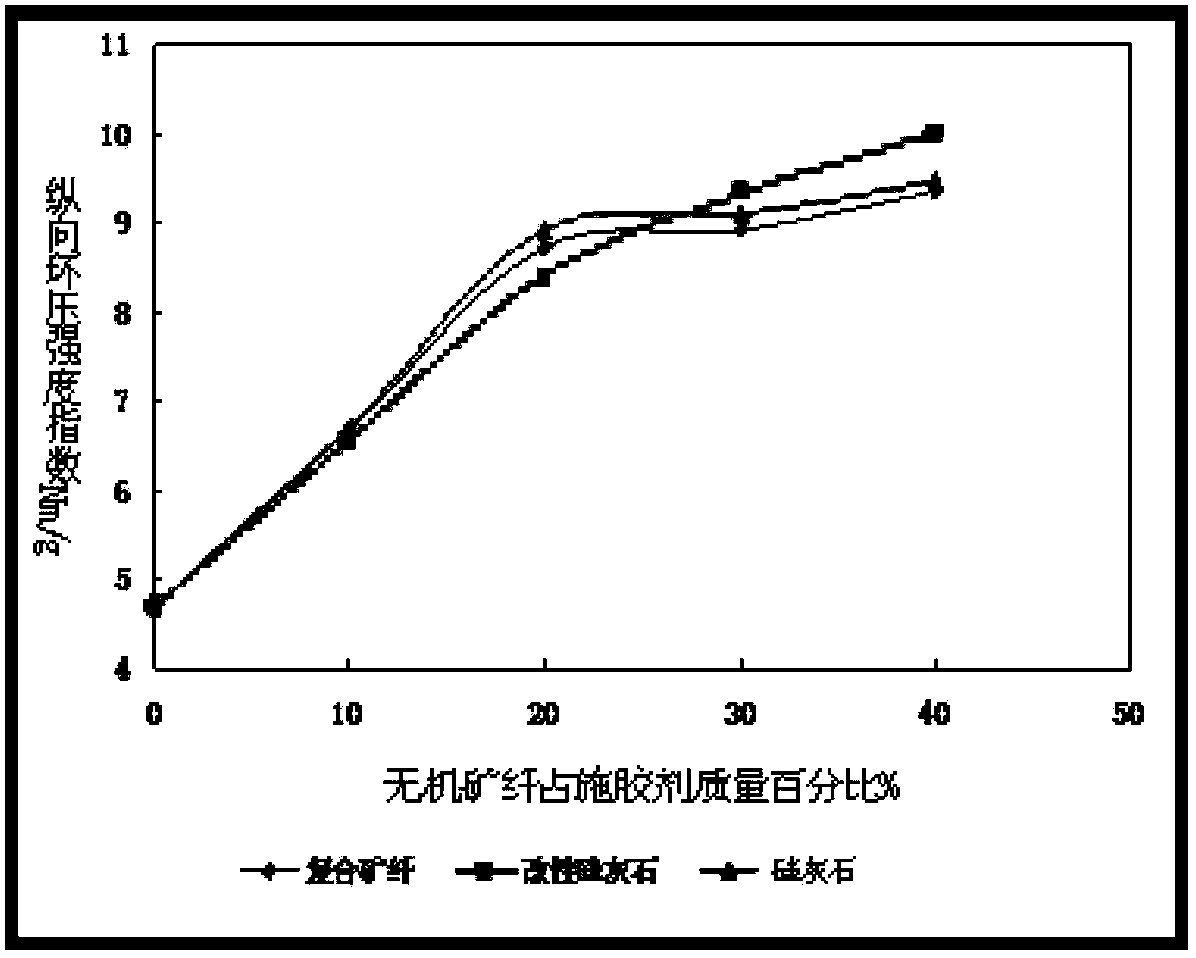

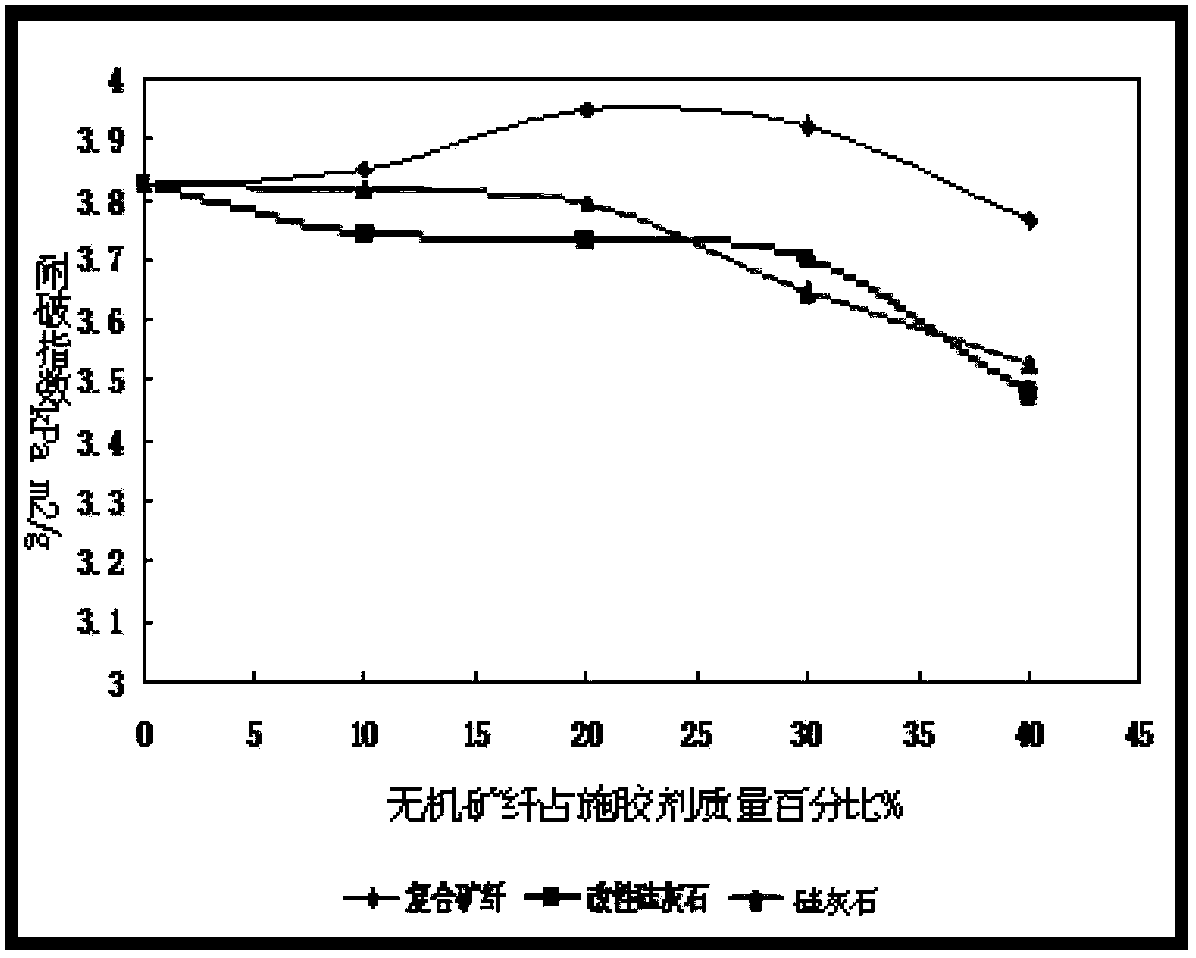

Inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and preparation method thereof

ActiveCN103388286AIncreased ring compressive strengthReduce paper production costsWater-repelling agents additionPapermakingSizing

The invention relates to an inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and a preparation method thereof. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises surface sizing starch and inorganic mineral fibers. The mineral fibers comprise composite mineral fibers, modified wollastonite or wollastonite. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises 5-40wt% of the inorganic mineral fibers. The norganic mineral fiber ring crush strength-improvement surface sizing agent can greatly improve corrugated paper ring crush strength and improve a tensile index and folding strength of a coated paper.

Owner:大连环球矿产股份有限公司

Environment-friendly paper and preparation method thereof

InactiveCN101864691APromote absorptionGood printing adaptabilityInorganic fibres/flakesNon-fibrous pulp additionFiberPolyolefin

The invention provides environment-friendly paper and a preparation method thereof. The environment-friendly paper comprises the following components by weight percent: 65-85% of calcium carbonate fibers, 3-10% of thermoplastic starch, 10-20% of polyolefin resins and 2-5% of auxiliary components, wherein the calcium carbonate fibers are needle-like single-crystal fiber materials with average diameter of 0.5-1mu m and length diameter ratio being not less than 20 / 1; the thermoplastic starch is the micronized, plasticized and modified starch material; the polyolefin resins are polyethylene or polypropylene materials with melt index being 5-30; and the auxiliary components at least comprise surfactants with contents being not less than 1% and lubricants with contents being not less than 1%. The environment-friendly paper has the characteristics of low ration, little proportion and stable and uniform size, has good ink absorbency and printing adaptability, excellent performance indexes, such as whiteness, opacity, smoothness and tensile index and good texture and processability and can realize thermoplastic process. The environment-friendly paper accords with the present national development policy of the low carbon industry and has broad market prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

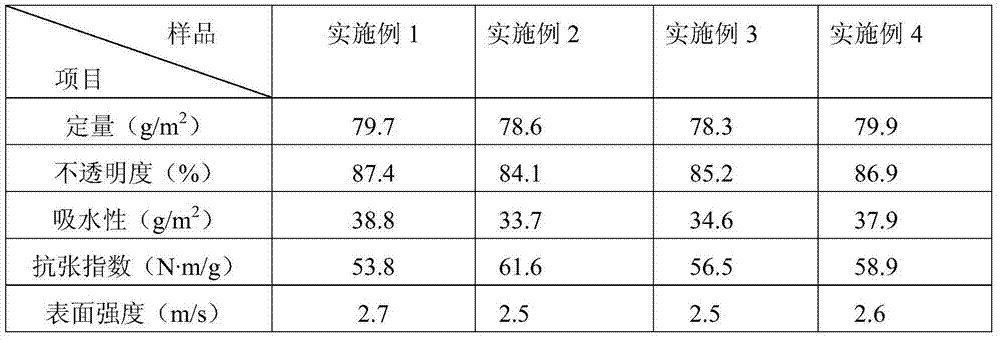

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AReduce paper production costsBroaden the field of applicationWater-repelling agents additionInorganic compound additionPapermakingSurface strength

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

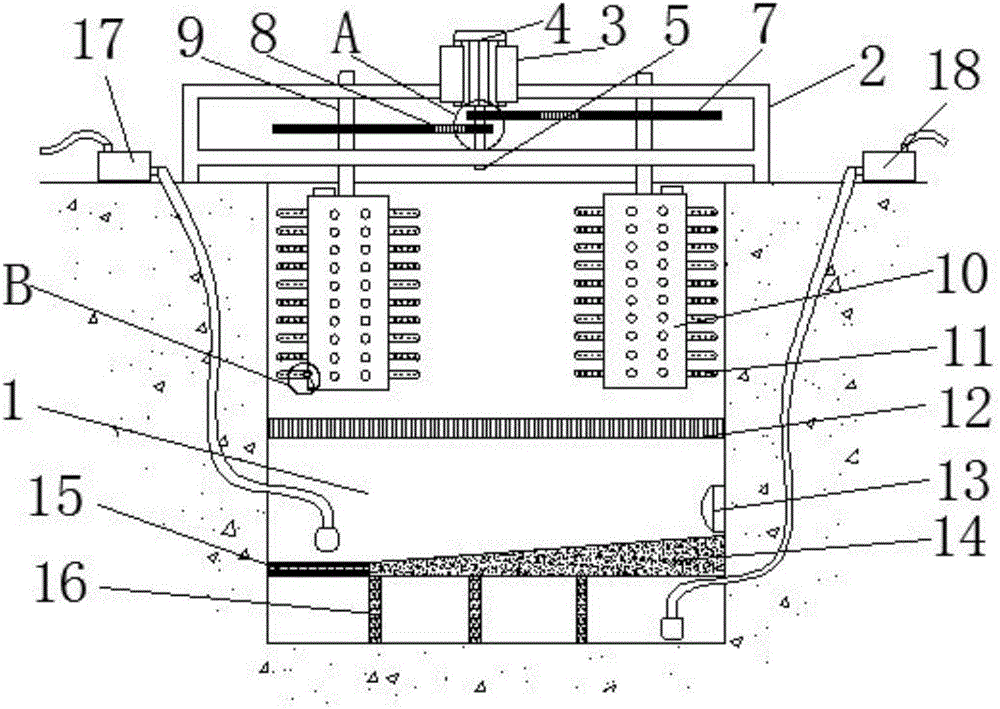

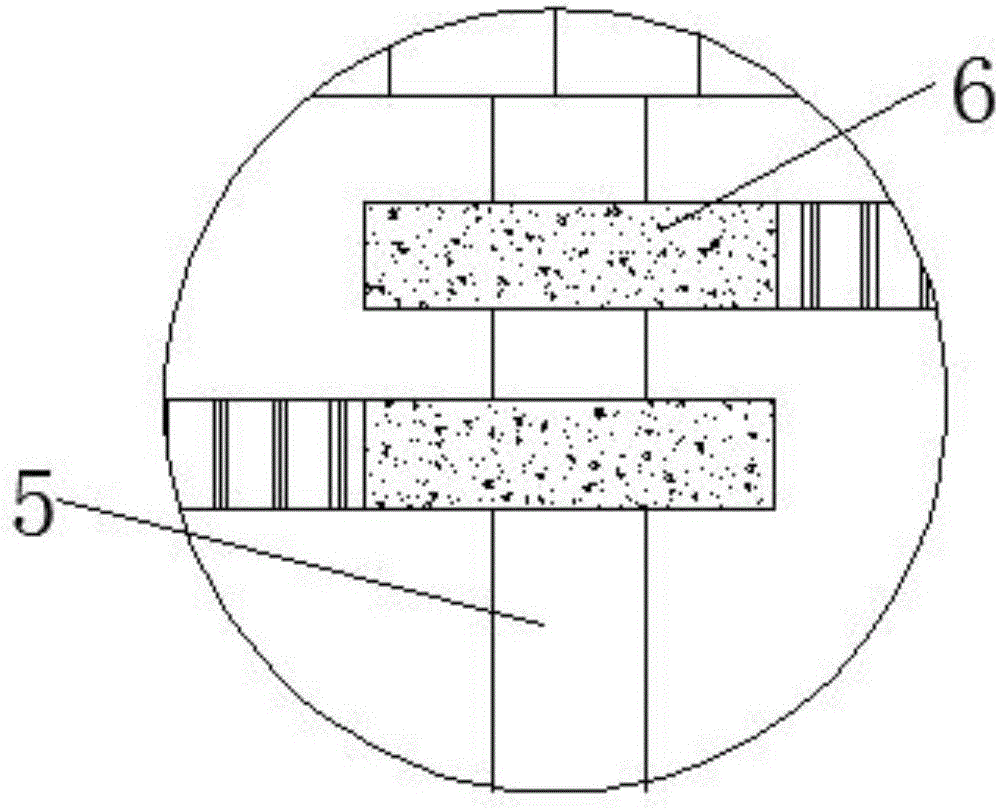

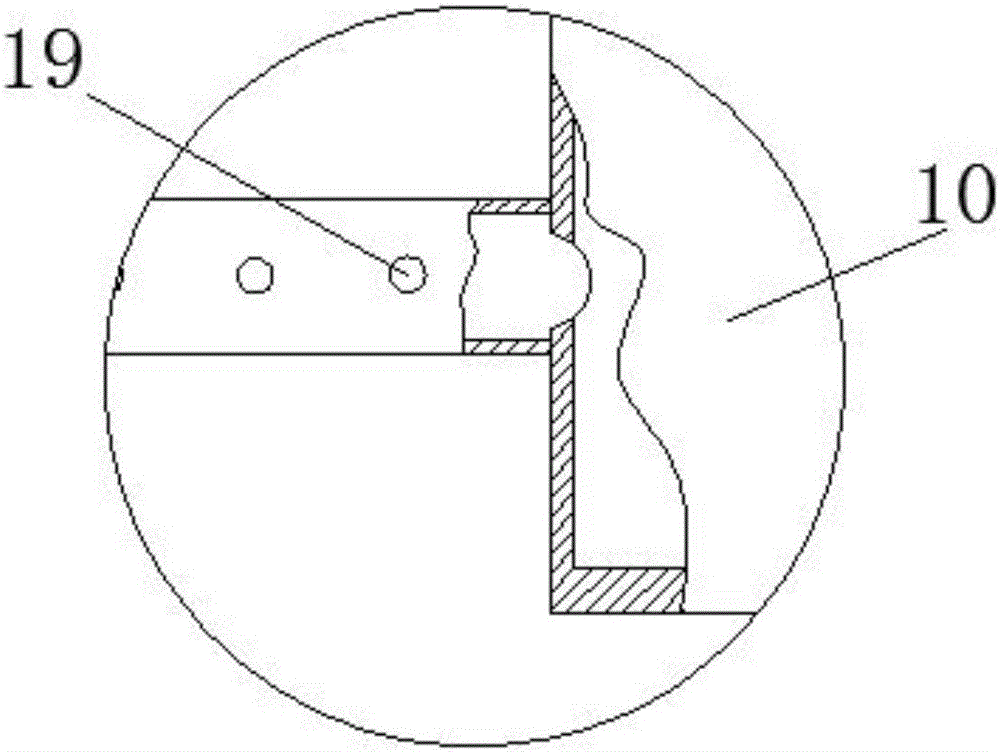

Waste water treatment device for papermaking

InactiveCN107176741AEasy to condenseEfficient recyclingTreatment involving filtrationMultistage water/sewage treatmentGear driveTreatment pond

The invention discloses a waste water treatment device for papermaking processing, which comprises a treatment pool body, a support frame is arranged above the treatment pool body, the support frame is connected with connection seats, and a motor is arranged between the connection seats. The output end of the motor is connected with a first rotating shaft, the first rotating shaft is provided with a driving gear, and both sides of the motor are provided with a second rotating shaft, and the second rotating shaft is connected to the supporting frame in rotation, and the second rotating shaft The bottom is fixedly connected to the drum. The flocculant is added to the drum through the reagent adding port, the driving gear is driven by the motor to drive the driven gear, and finally the drum is driven to rotate, and the reagent is thrown out through the small hole on the sleeve under the action of centrifugal force for stirring. After stirring The flocs fall into the bottom of the grid, and the heated flocs are more likely to coagulate. The invention can effectively recycle the fibrous solid matter in the papermaking wastewater, avoiding the waste of resources and saving the cost of papermaking.

Owner:李汝和

Method for preparation of corrugated paper from straw and waste paper

InactiveCN104988790AReduce paper production costsReduce pollutionSecondary cellulose fibresNon-woody plant/crop pulpDecompositionPapermaking

The invention discloses a method for preparation of corrugated paper from straw and waste paper. The preparation steps include: 1) straw pretreatment, softening, microbial decomposition, dividing, beating and pulp screening to obtain a straw slurry; 2) waste paper breaking, slurry purification and impurity removal, slurry concentration, curing and medium concentration beating, thus obtaining a waste paper slurry; 3) mixing the straw slurry with the waste paper slurry according to a mass ratio of 1:1.1-1.5; and 4) further treating the mixed slurry to obtain a product of required specifications. The method provided by the invention changes the history that original production of high-strength corrugated paper can only use waste paper pulp and / or primary pulp, not only greatly reduces the papermaking cost, but also reduces pollution caused in the pulping process, and has very good environmental protection performance.

Owner:ZHANGJIAGANG XINFA PACKING

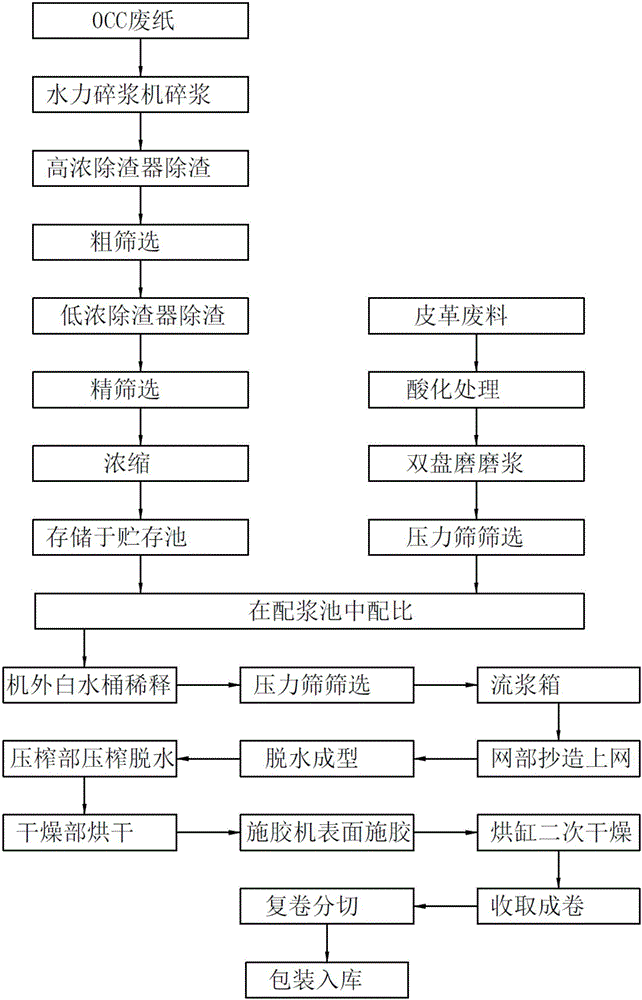

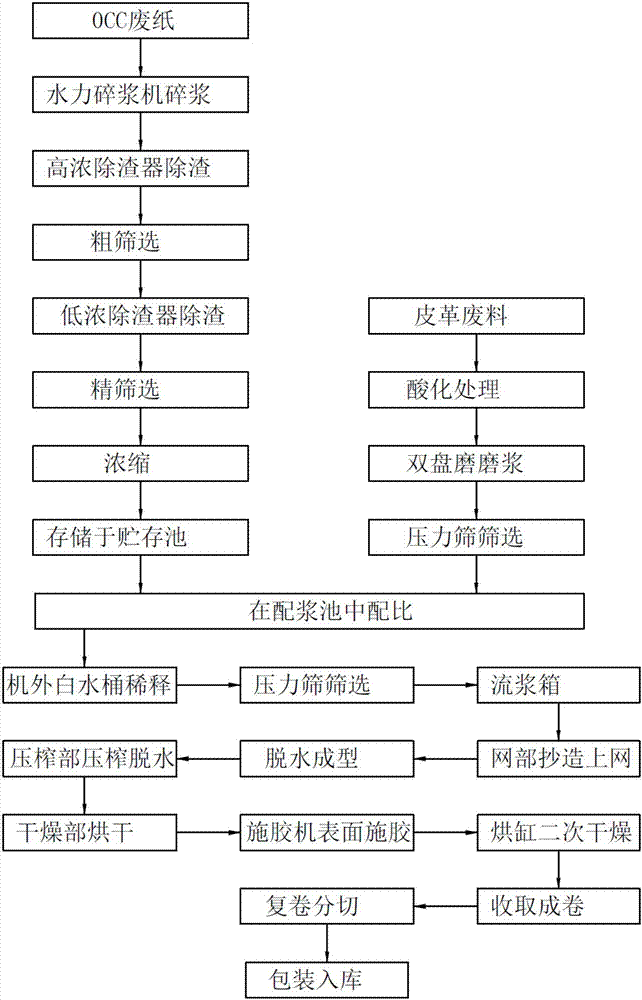

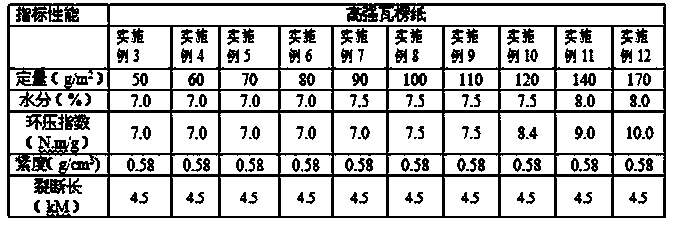

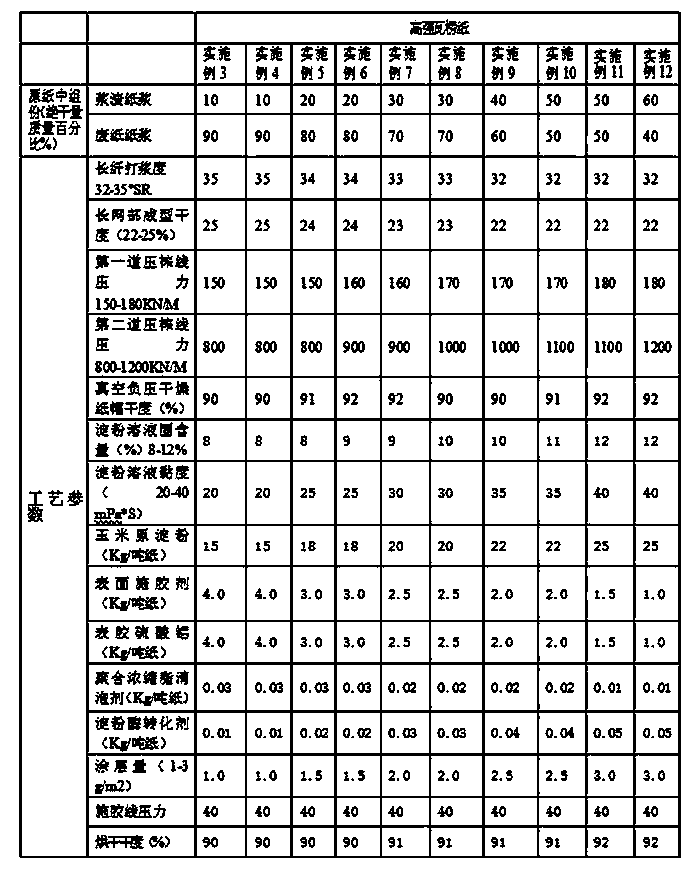

Method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper

ActiveCN106256953ARealize comprehensive utilizationReduce paper production costsMechanical working/deformationPre-tanning chemical treatmentPapermakingSingle fiber

The invention discloses a method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper. The leather waste is treated to obtain clean collagen fibers existing in a single fiber form, the OCC waste paper is pulped to be prepared into OCC pulp suitable for papermaking, 15-20% by weight of collagen fibers and 80-85% by weight of OCC pulp are matched into mixed pulp, the mixed pulp is used for papermaking, and the finished high-strength corrugating medium paper is obtained. Comprehensive utilization of resources is achieved, leather waste of shoe factories and leather factories is recycled to serve as production raw materials of the high-strength corrugating medium paper, a brand-new treating method is provided for the leather waste, and waste is turned into wealth; the production process is environmentally friendly, clean and free of pollution, environmental pollution is avoided, and the papermaking cost of the high-strength corrugating medium paper is reduced. According to the high-strength corrugating medium paper produced through the process, the collagen fibers from the leather waste and plant fibers from the OCC waste paper are interwoven and combined, and the higher-quality high-strength corrugating medium paper is obtained.

Owner:东莞顺裕纸业有限公司

Method for making degradable ground film paper from cotton stalks

ActiveCN105821699ASimple processReduce paper production costsPretreatment with water/steamPulp beating methodsNutrientPapermaking

The invention discloses a method for making degradable ground film paper from cotton stalks.The method comprises the following steps that 1, the cotton stalks are chopped into material segments; 2, the material segments are sent into a steaming bin for presteaming and then sent into a continuous cooking device for cooking; 3, the cooked materials are sent into a twin screw pulping extruder for twisting and fiber separating, and coarse pulp is obtained; 4, the coarse pulp obtained in the third step is subjected to pulp washing, beating and digestion and then sent into a papermaking machine to be made into the ground film paper.According to the method for making the degradable ground film paper from the cotton stalks, the papermaking efficiency can reach up to 90%-95%, the b / c ratio of waste water produced by the system is high, the biochemical process is easy to achieve, a biological treatment method can be adopted, the obtained ground film paper contains a large amount of nitrogen, phosphorus and potassium and provides nutrients for cotton growth after being degraded, and compared with traditional plastic film, the cost is reduced by about one third.

Owner:石河子市国力源环保制浆有限公司

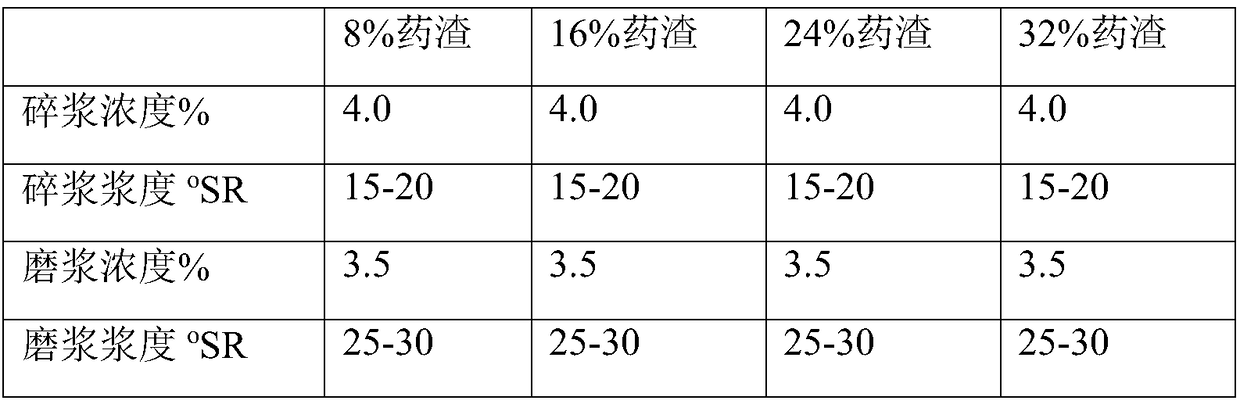

A papermaking method by using vinasse fiber pulp

InactiveCN108532337AReduce paper production costsSimple processWashing/displacing pulp-treating liquorsDigestersRice strawChemistry

The invention provides a papermaking method by using vinasse fiber pulp. The method is characterized in that the disposal vinasse from the alcohol industry is regarded as raw material, the vinasse fiber pulp mainly containing the cellulose and hemicellulose used for papermaking is prepared through the steps of crushing and slag-removing, boiling, washing and rinsing and the like, the vinasse fiberpulp is mixed with the papermaking slurry prepared by the conventional paper raw material composed of wood, bamboo wood, rice straw, straw, reed, recovery waste paper and the like to prepare mixing papermaking slurry, the mixing papermaking slurry is sent to the paper machine to produce products, or the method that the vinasse fiber pulp is prepared by the vinasse as raw material and after dilution pulping, water distribution and slurry mixing the vinasse fibre pulp is sent to the paper machine to produce paper products is completely adopted. The raw material field of papermaking industry isdeveloped, the cost of papermaking production is greatly reduced, the austere problem that the environment pollution nuisance is caused by a lot of vinasse disposed from the alcohol industry is effectively solved, the method has substantial economic benefit and social environment benefit and good popularization and use prospect.

Owner:高云

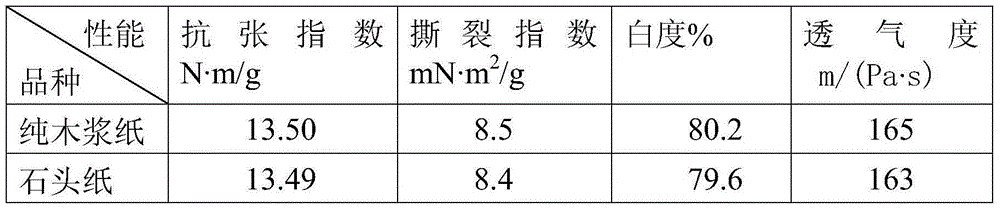

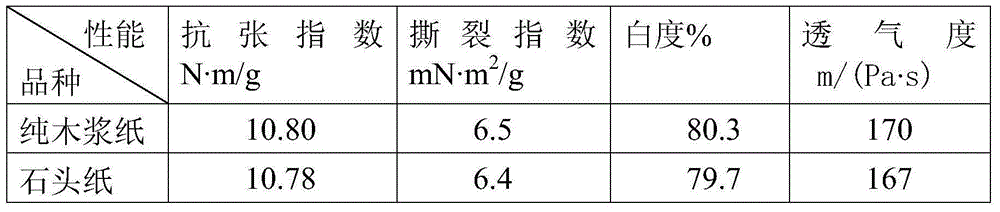

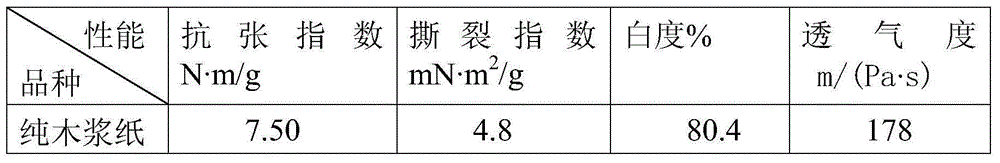

Stone paper and preparation method therefor

ActiveCN105113323AWide variety of sourcesPromote sustainable developmentReinforcing agents additionInorganic compound additionWet strengthSepiolite

The invention discloses stone paper. The stone paper comprises raw materials of sepiolite fabrics and softwood pulp plates, wherein the average particle size of the sepiolite fabrics is of 80-100 mesh grade; based on oven dry stock, the sepiolite fabrics account for 70-90% and the softwood pulp plates account for 10-30%. A preparation method for the stone paper comprises: firstly preparing a dry strength agent into a solution with the mass concentration of 3-5%; then putting the softwood pulp plates and water in a beating machine to beat; then adding the sepiolite fabrics and mechanically and uniformly stirring the mixture; screening and purifying paper materials by virtue of a vortex scummer; after purification, separately adding the dry strength agent solution, a wet strength agent and a nano enhancer, and uniformly stirring the mixture to obtain the paper pulp; adding a retention aid into the paper pulp; then draining water of the paper pulp on a silk screen to form a wet paper web; feeding the wet paper web which is dehydrated by a squeezing part into a drying part to be dried; then calendering the wet paper web by a calendering machine; and finally obtaining a finished product stone paper. The stone paper disclosed by the invention has excellent ink absorption and flame retardance, and the physical character is further superior to that of wood pulp paper.

Owner:徐州市百顺琪家具有限公司

Modification filling material and preparation method thereof, and slurry adopting modification filling material

ActiveCN103388281AReduce paper production costsImprove retention and drainageReinforcing agents additionInorganic compound additionMethyl celluloseCarboxymethyl cellulose

The invention provides a modification filling material used in the field of papermaking. The modification filling material comprises a filling material main agent which is one or more selected from diatomite, zeolite, bentonite, talc, calcium carbonate, kaolin, silk cristobalite, natural calcium metasilicate, gypsum, barite, and pyrophyllite. The modification filling material also comprises carboxymethyl cellulose, a charge neutralizing agent, and a coagulation agent. The mass of the carboxymethyl cellulose is 0.5-1% of a filling material main agent absolute mass, the mass of the charge neutralizing agent is 0.2-0.4% of the filling material main agent absolute mass, and with the addition amount of the coagulation agent, the filling material is coagulated into a coagulated filling material with a particle size of 20-80mum. The invention also provides a preparation method of the modification filling material, and a slurry adopting the modification filling material. When the modification filling material is applied in the slurry, prepared paper has good performances, and cost can be saved.

Owner:GOLD EAST PAPER JIANGSU

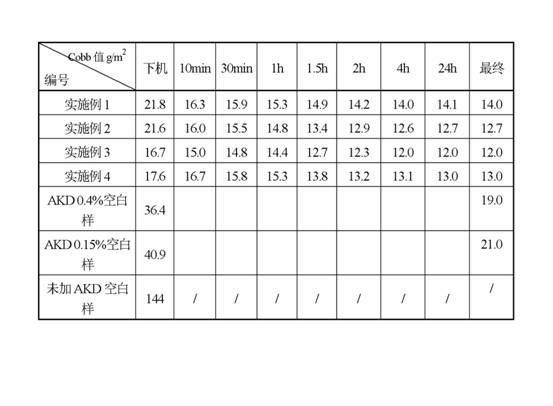

Crosslinked material capable of promoting curing of alkyl ketene dimer and preparation method thereof

InactiveCN102101918AIncrease the degree of sizingReduce penetrationWater-repelling agents additionWater solubleGuar gum

The invention discloses a crosslinked material capable of promoting curing of alkyl ketene dimer(AKD) and a preparation method thereof. The crosslinked material is characterized by comprising guar gum, synthetic water soluble polymer, cationic assistant, crosslinking agent and water. The preparation is implemented by the following steps: dissolving the guar gum in water, adding the crosslinking agent, stirring, regulating the pH value of the mixed reaction system by using NaOH, raising the temperature to perform a cross-linking reaction, adding the synthetic water soluble polymer and the cationic assistant, cooling to obtain the crosslinked material capable of promoting the curing of the alkyl ketene dimer. The crosslinked material of the invention can improve the degree of sizing of paper, reduces infiltration capacity of liquid, and helps to produce high water resistance. The crosslinked material of the invention reduces the sizing curing time of AKD to 2 hours from the original 2 weeks, improves the utilization rate of paper machine and reduces storage time.

Owner:NANTONG TONGDI BIOTECH CO LTD +1

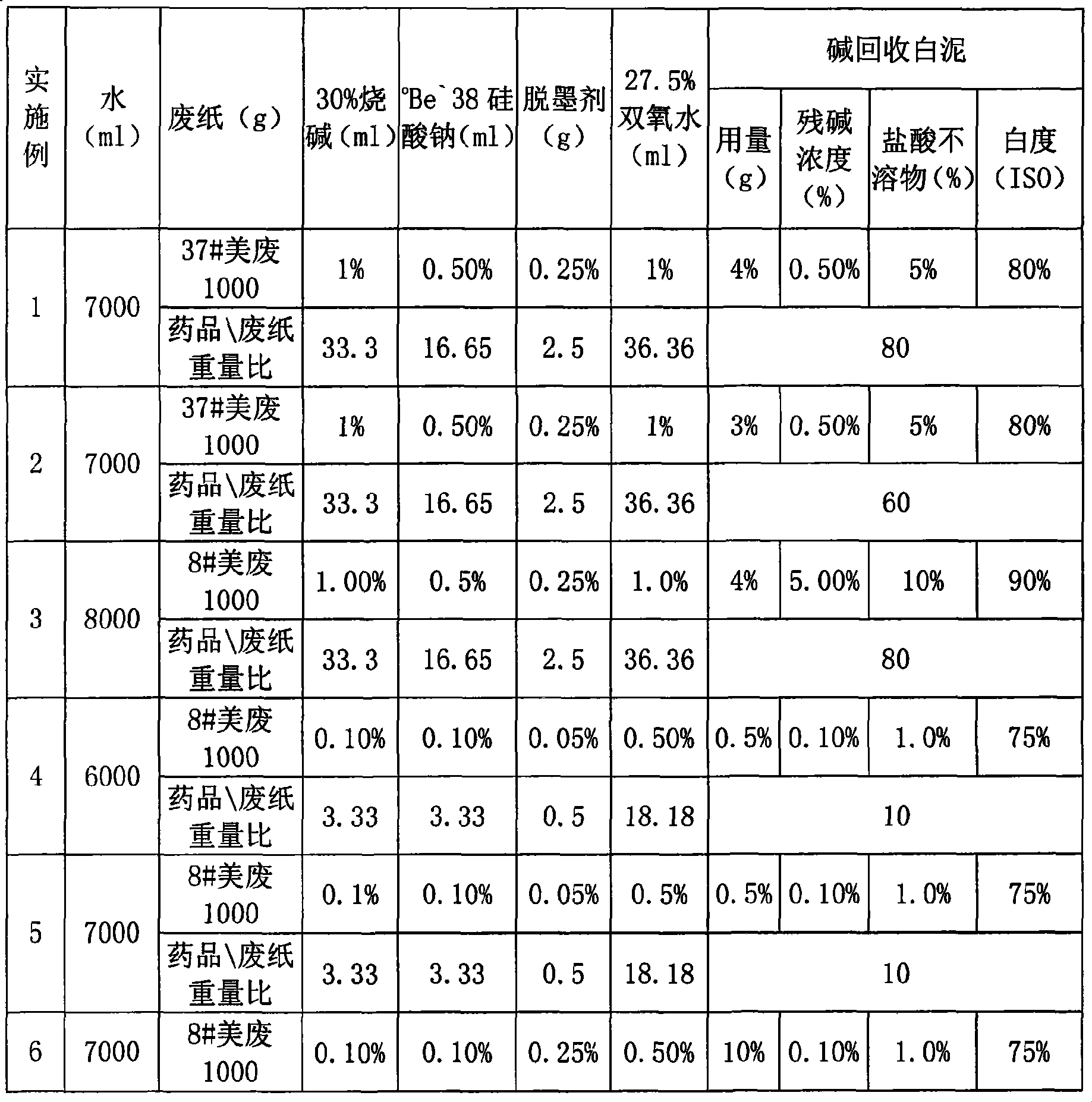

Deinking process for waste paper

InactiveCN101418527AEasy to separateGood whitening effectFats/resins/pitch/waxes removal in pulpPulp bleachingFiberSodium silicate

The invention belongs to the field of a papermaking technology and in particular relates to a method for deinking waste paper through the addition of alkali recovered white mud. The method comprises the following steps: firstly, water, the alkali recovered white mud, sodium hydrate, sodium silicate, a deinking agent and the waste paper are sequentially added, mixed and crushed for a period of time; secondly, the mixture is added with hydrogen peroxide and is crushed for a period of time; and finally, the mixture is subjected to floatation deinking through the prior floatation deinking system. The method adds the alkali recovered white mud in the process of crushing the waste paper, reduces the use amount of the hydrogen peroxide, the sodium hydrate and the sodium silicate in the deinking process, improves the ash content and fiber yield of pulp and reduces production cost and pollution of the alkali recovered white mud as industrial garbage for landfill.

Owner:MCC PAPER YINHE

Formula and production method for low-grammage paper

InactiveCN103628349AImprove evennessImprove smoothnessCoatings with pigmentsWater-repelling agents additionFiltrationHeat treated

The invention relates to the technical field of paper making, in particular to a formula and a production method for low-grammage paper. In the formula, paper pulp, an additive and a painting are included, wherein the additive comprises 100-550 ppm of nano attapulgite crystal, 300-800 ppm of fluorescent brightener, 20-40 ppm of staining agent, 3-6 percent of filler and 1.0-1.4 percent of amylum according to proportions; the painting comprises 50-80 ppm of heavy calcium carbonate and 65-70 ppm of amylum according to proportions. The production method for the low-grammage paper adopts the formula and comprises the steps as follows: after pulping, the additive is added to the paper pulp, agitated, placed in a strong magnetic field and thermally treated for 1 hour at a high temperature; formation water filtration making, pressing dehydration, front section drying, glue coating, painting coating, smooth pressing and rolling are sequentially performed. The paper foundation paper made by adopting the formula and the production method is 80g / m<2> to 84g / m<2> in weight, can satisfy requirements of a printing machine on the hardness of the paper, and effectively improves the paper opaqueness.

Owner:福建希源纸业有限公司

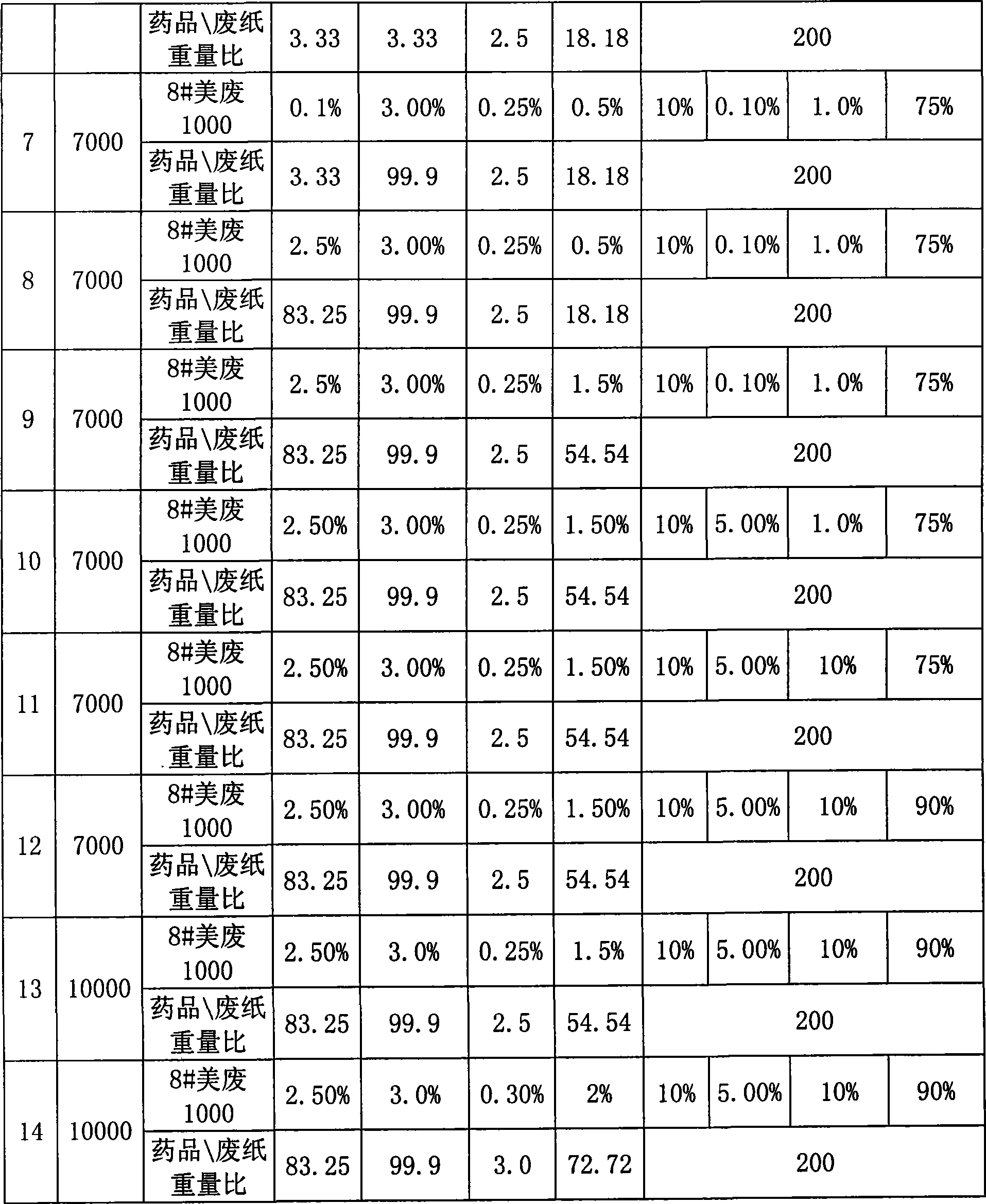

Paper with coffee flavor and preparation method and application thereof

ActiveCN110284361AHigh physical and mechanical strengthReduce usageVegetable material additionPaper/cardboardFiberSorbent

The invention belongs to the technical field of recycling and reusing of coffee grounds, and specifically relates to paper with coffee flavor and a preparation method and application thereof. The paper with the coffee flavor provided by the invention is prepared from the following raw materials in parts by mass: 50-70 parts of pulp fibers, 15-25 parts of waste paper scraps, 6-13 parts of the coffee grounds, 4-5 parts of an adsorbent and 5-15 parts of a charge balancing agent. According to the paper with the coffee flavor and the preparation method and application thereof, the coffee grounds are used as one of the raw materials of papermaking, so that the paper has the coffee flavor and has the function of removing odor; meanwhile, the use of the coffee grounds also improves the physical and mechanical strength of the paper; the use of the coffee grounds and the waste paper scraps reduces the use amount of pulp raw materials and reduces papermaking cost.

Owner:东莞市绿保纸塑制品有限公司 +1

Method for recycling tea leaf residues and tea paper for writing

ActiveCN106522019ARelieve cleaning stressHigh economic valueWaste product additionVegetable material additionGramPapermaking

The invention discloses a method for recycling tea leaf residues and tea paper for writing. The method for recycling tea leaf residues comprises the following steps that (1) the tea leaf residues are dried, grinded and smashed, and tea leaf residue powder of 60-80 meshes is obtained by screening the tea leaf residues; (2) by weight, 10-20 parts of tea leaf residue powder, 30-50 parts of wood pulp raw materials and 20-30 parts of Chinese alpine rush materials are mixed evenly to prepare paper pulp; and (3) the paper pulp is fed into a papermaking machine or traditional paper picking is conducted, and commercial paper with the gram weight being 40-200 g / m<2> is obtained. According to the method, the tea leaf residue powder and the wood pulp raw material are mixed to prepare the paper pulp, the commercial paper suitable for writing is produced, a new means and a solution are provided for recycling of the tea leaf residues, the environment cleanliness pressure caused by the tea leaf residues is relieved, and great economic value and great significance in environmental protection are achieved. The tea paper for writing has a faint fragrance of tea and has a good sensory effect, the tea leaf residues are applied by a large scale, the wood pulp raw materials are saved, and the papermaking cost is effectively reduced.

Owner:HANGZHOU JU FANG YONG HLDG

Retention method capable of improving paper making by using waste paper deinking pulp

InactiveCN101760995AImprove retentionImprove dehydration effectPulp material addition processesDeinkingTurbidity

The invention relates to a retention method capable of improving the paper making by using waste paper deinking pulp, comprising the following steps: adding concentrated sulfuric acid which is 0.4-0.7 percent by weight of the waste paper deinking pulp in an incoming waste paper deinking pulp pond, and adding the turbidity of the incoming waste paper deinking pulp bellow 1500NTU; adding fixing agent which is 0.05-0.15 percent by weight of the waste paper deinking pulp in a waste paper deinking pulp mixing system; conveying the evenly mixed material to a flow delivery system in the front of the net of a paper making machine; adding cationic polyacrylamide which is 0.03-0.05 percent by weight of the waste paper deinking pulp in the front of a pressure screen, and highly shearing the large floccules into small floccules by the pressure screen; adding bentonite which is 0.2-0.4 percent by weight of the waste paper deinking pulp; adding anionic organic particles which are 0.01-0.03 percent by weight of the waste paper deinking pulp; and making the waste paper deinking pulp into paper by the paper making machine. The retention method can obviously improve the retention rate and the dehydration effect of the net of the paper making machine and reduces the paper making cost.

Owner:WUHAN CHENMING HANYANG PAPER

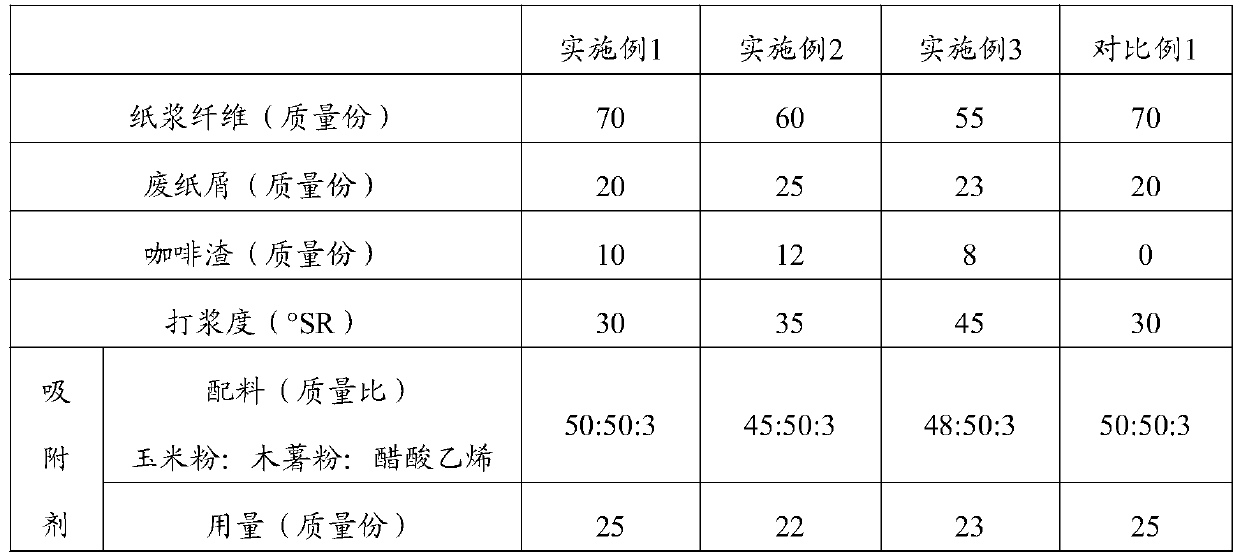

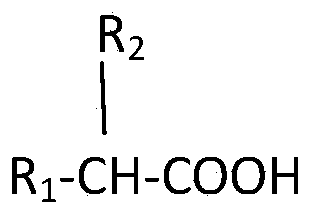

Raw material for preparing liquid branched-chain AKD as well as preparation method and application of liquid branched-chain AKD

InactiveCN104370861AImprove performanceEmission reductionOrganic chemistryWater-repelling agents additionPapermakingWastewater

The invention relates to a sizing agent for papermaking and particularly relates to a raw material for preparing liquid branched-chain AKD as well as a preparation method and application of the liquid branched-chain AKD. The raw material for preparing liquid branched-chain AKD is an alkyl fatty acid mixture of which the melting point is -15 to 35 DEG C and the degree of saturation is greater than 97%. The preparation method of the liquid branched-chain AKD comprises the following reaction steps of acylating chlorination and dimerization. The prepared liquid branched-chain AKD is used as the sizing agent for papermaking. By the liquid branched-chain AKD, the performance of the paper can be improved; the energy consumption during papermaking is decreased; the wastewater emission is decreased; the papermaking cost is reduced and the long-term running performance of the papermaking machine is improved.

Owner:周元幸 +2

Preparation method of ferro-nickel slag inorganic fiber pulp

ActiveCN110373935AResilientSolve pollutionInorganic fibres/flakesWaste product additionSlagAluminum silicate

The invention provides a preparation method of ferro-nickel slag inorganic fiber pulp. The method includes the steps that 1, ferro-nickel slag slurry is mixed with lime, lead oxide and zinc oxide through conveying equipment; 2, the evenly-mixed raw materials are calcined at a high temperature in a high-temperature electric melting furnace to form slurry; 3, aluminum silicate is added into the slurry obtained through calcination, when the slurry becomes flocculent cotton, the flocculent cotton is pulled out in time, and ferro-nickel slag inorganic fibers are collected through a cotton collecting machine; 4, the prepared ferro-nickel slag inorganic fibers are chopped and subjected to slag removal through a grit settling tank, and then a softener, pulp fibers, a thickener, a modifier, a modified thickener, a binder and water are added for pulping; and 5, an obtained solution is heated and continuously stirred, then slag is further removed through a grit catcher, and after cooling to the room temperature, the uniform ferro-nickel slag inorganic fiber pulp is obtained. The ferro-nickel slag inorganic fiber pulp obtained through the method has the advantages of being super fine, super soft and tough.

Owner:张文生

Stencil tissue paper production method

The invention discloses a stencil tissue paper production method. Paper mulberry branches are collected to serve as the raw material, the paper mulberry branches are ignited with open fire to 30-50 DEG C and baked for 5-12 min, and then paper mulberry bast is peeled off; outer bark is cut off and dried in the sun, dried paper mulberry fiber skin is placed in water to be soaked for 5-10 days, quick lime is added to water to enable paper mulberry fiber skin to be continued to be soaked, lime is washed off with flowing water, and rub-peeling and beating are conducted; carambola water and beaten paper mulberry fiber skin are mixed and stirred to enable paper pulp to be in an evenly suspended cotton shape in water, well blended mixed materials are placed in a pericarpium citri reticulatae box to be evenly blended, papermaking and paper pressing are conducted to obtain wet paper, and then wet paper is dried in the air to obtain stencil tissue paper. The prepared stencil tissue paper has the advantages of being fine and flexible in texture, soft and smooth in hand feeling, high in elasticity, high in fiber amount, plain in color, resistant to wearing, not prone to wrinkling, durable, long in service life, high in practicality and the like. No chemical component is added during production, environment friendliness is realized, pollution is avoided, and health of users can not be endangered.

Owner:GUIZHOU LIPING ZHULVKANG AGRI DEV TRADE CO LTD

Papermaking sterilizing preservative

InactiveCN103015266ARapid sterilizationDelay drug resistanceNon-fibrous pulp additionPaper/cardboardWater qualityPapermaking

The invention discloses a papermaking sterilizing preservative which comprises the following components in percentage by weight: 40-80% of 2, 2-dibromo-3-nitrilo-propanamide, 10-30% of ethylene glycol system organic solvent, 1-10% of polyhydric alcohols, 1-10% of cyclic nitrogen system sulfur system chemical compound, and 1-10% of organic nitrogen system sulfur system chemical compound. According to the papermaking sterilizing preservative provided by the invention, the bacterium can be quickly killed, the papermaking sterilizing preservative is low in drug resistance and wide in application range, the accumulation of dissolved matter and colloid in a white water system can be reduced, the cleanness of water quality can be kept, the use of the other chemical substances in the process of papermaking can be used, the papermaking cost can be reduced, and the quality of finished paper can be improved.

Owner:姜建明

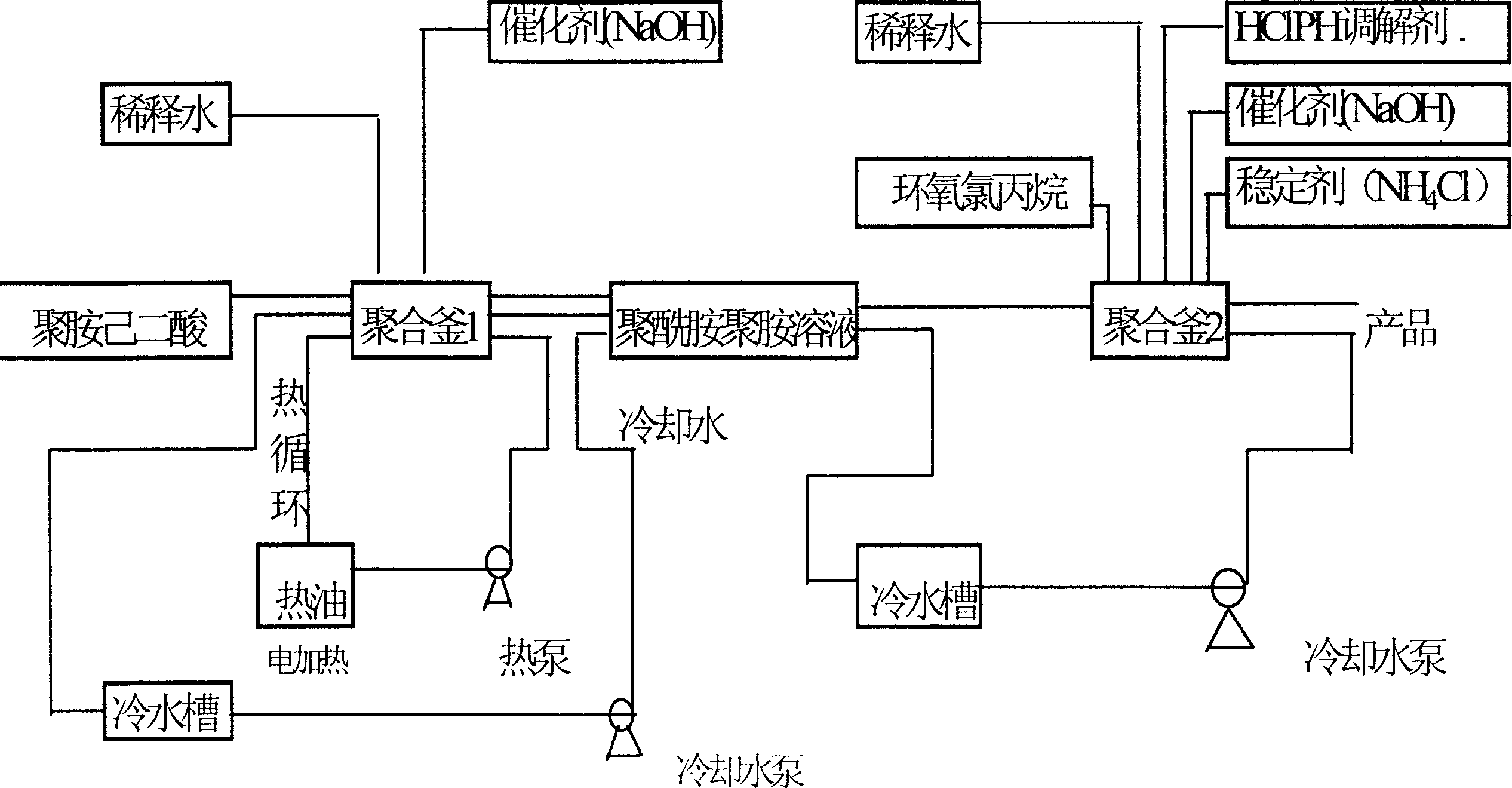

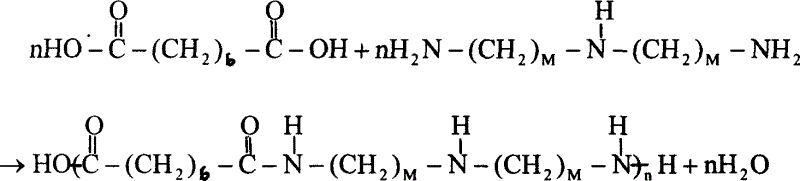

Prepn process of epichlorohydrin wet strength agent for polyamide and polyamine

InactiveCN1548650AReasonable workmanshipRaw materials are easy to getReinforcing agents additionPapermakingPolyamide

The preparation process of polyamide-polyamine epichlorohydrin wet strength agent for papermaking includes two steps of synthesizing polyamide-polyamine and synthesizing ultimate product. The preparation process of polyamide-polyamine epichlorohydrin includes adding polyamine into the first reactor, heating, adding adipic acid and catalyst through stirring, adding water for diluting and other steps to obtain polyamide-polyamine; adding polyamide-polyamine solution into the second reactor, dropping epichlorohydrin while stirring, heating, reflux, adding catalyst, adding water for diluting, and adding HCl to regulate pH value to 7-8 while stirring to obtain product.

Owner:费会林

A method for producing high-strength corrugated medium paper by mixing leather waste with OCC waste paper

ActiveCN106256953BRealize comprehensive utilizationReduce paper production costsNon-fibrous pulp additionMechanical working/deformationPlant fibreSingle fiber

The invention discloses a method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper. The leather waste is treated to obtain clean collagen fibers existing in a single fiber form, the OCC waste paper is pulped to be prepared into OCC pulp suitable for papermaking, 15-20% by weight of collagen fibers and 80-85% by weight of OCC pulp are matched into mixed pulp, the mixed pulp is used for papermaking, and the finished high-strength corrugating medium paper is obtained. Comprehensive utilization of resources is achieved, leather waste of shoe factories and leather factories is recycled to serve as production raw materials of the high-strength corrugating medium paper, a brand-new treating method is provided for the leather waste, and waste is turned into wealth; the production process is environmentally friendly, clean and free of pollution, environmental pollution is avoided, and the papermaking cost of the high-strength corrugating medium paper is reduced. According to the high-strength corrugating medium paper produced through the process, the collagen fibers from the leather waste and plant fibers from the OCC waste paper are interwoven and combined, and the higher-quality high-strength corrugating medium paper is obtained.

Owner:东莞顺裕纸业有限公司

Renewable high-strength corrugated medium and its production method

ActiveCN103321088BReduce paper production costsPromote environmental protectionWaste product additionPaper recyclingPapermakingSizing

The invention relates to a renewable high-strength corrugated medium and its manufacturing method. The raw paper is prepared from 40-90% of old paper stock and 10-60% of dreg paper pulp. The invention also provides a high-strength corrugated paper and its production method. The right side and back side of the corrugated medium are respectively provided with sizing layers. According to the renewable high-strength corrugated medium, waste paper and dregs are used as raw materials. Therefore, the renewable high-strength corrugated medium has good environmental protection property and requires low papermaking cost. According to the renewable high-strength corrugated paper, the raw paper layer is prepared from waste paper and dregs which are used as raw materials. The right side and the back side are both provided with the sizing layers. The production method requires low papermaking cost and is beneficial to environmental protection. Key technical indexes of the production method all reach national standard (GB / T13023-2008) superior product AA grade.

Owner:JIAN GRP

Papermaking bactericidal preservative

The invention discloses a papermaking bactericidal preservative, which belongs to the technical field of papermaking industry. According to the technical scheme, the papermaking bactericidal preservative is composed of the following raw materials in parts by weight: 23-45 parts of 2,2-dibromo-3-nitrilo propionamide, 5-12 parts of an ethylene glycol organic solvent, 1-10 parts of polyhydric alcohol, 1-10 parts of cyclic nitrogen sulfur compounds, 1-10 parts of organic nitrogen sulfur compounds, 5-25 parts of 2-sulfhydryl methylthio benzothiazole, 1-10 parts of methylene bisthiocyanate, 2-8 parts of an emulsifier and 5-25 parts of polyhexamethylene guanidine hydrochloride. Compared with the prior art, the papermaking bactericidal preservative disclosed by the invention has a quick sterilization function, low resistance to drugs and a wide application range, and is capable of reducing dissolved matters and colloidal substances accumulated in a white water system, maintaining the cleanness of water, reducing the used amount of other chemical substances in a papermaking process, reducing the papermaking cost and improving the quality of paper.

Owner:WEIFANG OUSEN OUDE PULP & PAPER

Method for producing recycled paper from wax-containing waste paper

InactiveCN106320044AReduce pollutionReduce paper production costsPaper recyclingInorganic compound additionWaxSlag

The invention discloses a method for producing recycled paper from wax-containing waste paper, and belongs to the waste paper recovery and processing technology field. <{EN2}>The method comprises the steps of 1) preparing ingredients, namely blending a raw material whose average paraffin content is between 17-22%; 2) crushing; 3) friction cleaning; 4) slurry beating, and adding 0.1-0.3% nanometer titanium dioxide in the beating process; 5) slurry squeezing; 6) slurry washing; 7) slurry polishing, and adding 1-4% wax virgin material in the slurry polishing process; and 8) screening to remove slag. <{EN3}>According to the method, dirt adhered to the waste paper can be removed thoroughly by secondary cleaning, making the surface of the new wax paper clean and having no impurities or different color.

Owner:谭凌晖

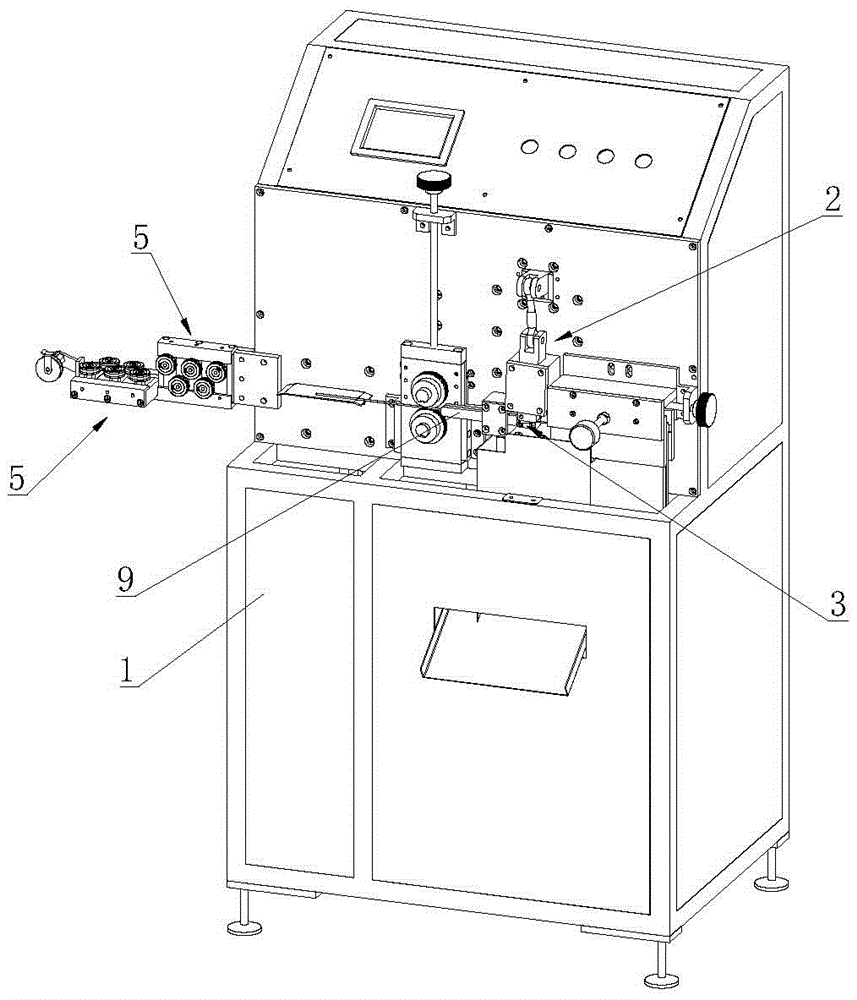

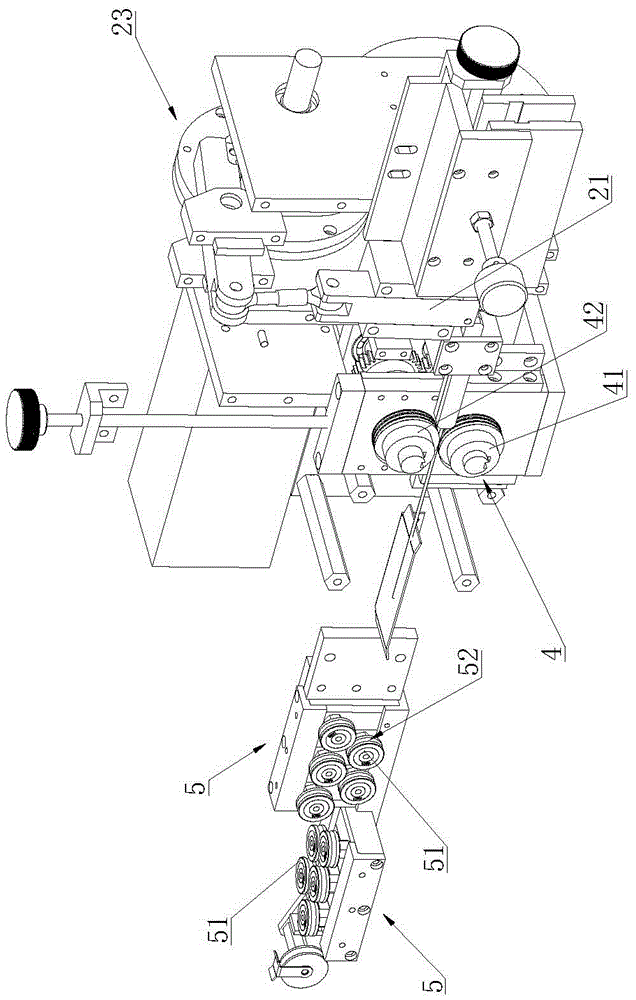

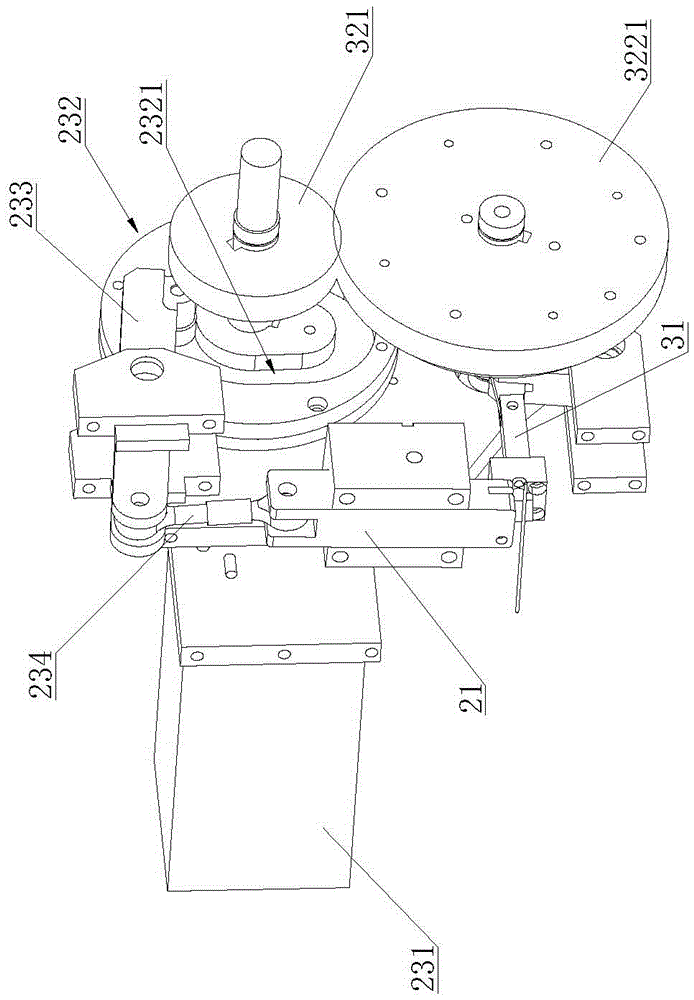

Jumper forming machine and forming method thereof

ActiveCN105478633ASimple structureCompact structureLine/current collector detailsHot stampingPatch cable

The invention relates to the technical field of hot stamping, in particular to a jumper forming machine and a forming method thereof. The method comprises the following steps: a feeding mechanism shifts a wire before a forming mold by a needed pin length; the forming mold is used for punching a middle wire to obtain a first pin part; the feeding mechanism sends the middle wire in front of the forming mold by a needed connecting length; the forming mold is used for punching the middle wire to obtain a connecting part; the feeding mechanism shifts the wire in front of a cutter by a needed pin length; and a cutter is used for cutting off the middle wire to obtain a second pin part so as to finish the forming of a part. The forming machine comprises a frame, a forming mechanism arranged on the frame, and a cutting mechanism; the forming mechanism includes a forming slide block, a forming mold and a forming driving mechanism; and the cutting mechanism includes a cutter and the cutting driving mechanism. The jumper forming machine and the forming method thereof enable the jumper forming to become easy, simplify the structure of the forming equipment, reduce the manufacturing cost, are easy to realize the production automation, and reduce the labor cost.

Owner:东莞市捷瑞自动化科技有限公司

Medicine residue envelope paper and preparation method thereof

PendingCN108071048AMeet product quality standardsRich appearanceSpecial paperMicroorganism/enzyme additionFiberMedicine

The invention discloses medicine residue envelope paper. The gram weight is 80 to 200gsm; a main fiber raw material is prepared from traditional Chinese medicine residue slurry, softwood pulp and hardwood pulp with the grain diameter being less than or equal to 3mm and the fiber length less than or equal to 10mm, wherein the weight content of the traditional Chinese medicine residue slurry is 8 percent to 35 percent, the weight content of the softwood pulp is 45 percent to 65 percent and the weight content of the hardwood pulp is 0 to 30 percent. According to the medicine residue envelope paper disclosed by the invention, traditional Chinese medicine residues are used as paper pulp raw materials and are recycled; a treatment step of the traditional Chinese medicine residues is a normal plant fiber raw material pulping process and additional special equipment and treatment technology are not needed; wastes are directly changed into valuable things and resources and cost are saved, so that the treatment difficulty of the medicine residues of a traditional Chinese medicine factory is radically solved. An actual papermaking experiment shows that the envelope paper prepared by doping common wood pulp into the slurry prepared from the traditional Chinese medicine residues meets product quality standards.

Owner:HANGZHOU YONGSEN SPECIAL PAPER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com