Crosslinked material capable of promoting curing of alkyl ketene dimer and preparation method thereof

A technology of alkyl ketene dimer and cross-linked body, applied in the field of cross-linked body, can solve the problems of insufficient sizing effect, lack of curing speed, limited sources, etc., to shorten the curing time, improve the utilization rate, The effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

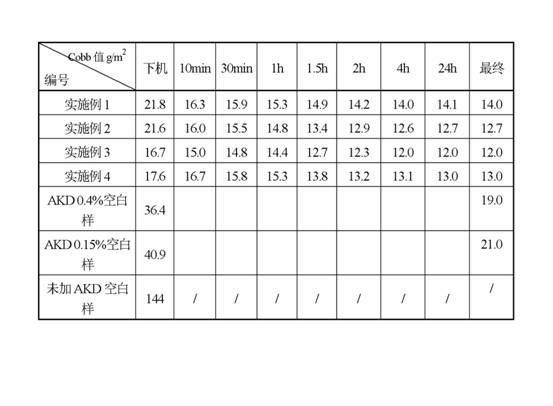

Examples

Embodiment 1

[0029] The present invention promotes the preparation method of the cross-linked body of alkyl ketene dimer ripening comprising the steps:

[0030] a, under the protection of nitrogen, 7 grams of cationic guar gum powder is added to 480 grams of deionized water, and it is evenly dispersed in deionized water under the mechanical stirring condition of 1000r / min at a rotating speed, until the cationic guar gum powder is completely When dissolving, add 2.5 grams of epichlorohydrin and stir to obtain a mixed reaction system;

[0031] b. Use NaOH to adjust the pH value of the mixed reaction system to 10. After the pH value is adjusted, the mixed reaction system is heated to a crosslinking temperature of 40° C., and the crosslinking reaction is performed for 4 hours;

[0032] c, after the cross-linking reaction finishes, then add 10 grams of weight percent concentration in the mixed reaction system and be 40% polydimethyldiallyl ammonium chloride aqueous solution, 1.8 grams of solid ...

Embodiment 2

[0035] The preparation method of the cross-linked body that promotes the curing of alkyl ketene dimer of the present invention comprises the following steps: the formula ratio is calculated in parts by weight:

[0036] a, under argon protection, add 6 grams of non-ionized guar gum powder to 490 grams of deionized water, and disperse it evenly in deionized water under the mechanical stirring condition of 900r / min at a rotating speed, and wait for the non-ionized guar gum powder When the rubber powder is completely dissolved, add 2 grams of glutaraldehyde and stir to obtain a mixed reaction system;

[0037] b. Use NaOH to adjust the pH value of the mixed reaction system to 11. After the pH value is adjusted, the mixed reaction system is heated to a crosslinking temperature of 50° C., and the crosslinking reaction is performed for 3 hours;

[0038] C, after the cross-linking reaction finishes, add the polyamide polyamine epichlorohydrin aqueous solution that contains 3.5 grams of...

Embodiment 3

[0041] The preparation method of the cross-linked body that promotes the curing of alkyl ketene dimer of the present invention comprises the following steps: the formula ratio is calculated in parts by weight:

[0042] a. Under the protection of nitrogen, 2.5 grams of anionic guar gum powder and 2.5 grams of amphoteric guar gum powder are added to 485 grams of deionized water, and they are evenly dispersed in deionized water under the condition of mechanical stirring at a speed of 1000r / min , when the guar gum powder is completely dissolved, add 0.9 gram of phosphorus oxychloride and 0.9 gram of epichlorohydrin and stir to obtain a mixed reaction system;

[0043] b. Use NaOH to adjust the pH value of the mixed reaction system to 9. After the pH value is adjusted, the temperature of the mixed reaction system is raised to a crosslinking temperature of 60° C., and the crosslinking reaction is performed for 3.5 hours;

[0044] c. After the crosslinking reaction is over, add polyvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com