Patents

Literature

53results about How to "Increase the degree of sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

InactiveCN101168940AImprove retentionLittle impact on physical propertiesWater-repelling agents additionComplex typeParaffin wax

The invention relates to a preparation method of paraffin wax / AKD complex type neutral paper-making sizing agent. The step is as follows: firstly, AKD and paraffin wax powder are melted in AKD solution; secondly, compound emulsifying agent after being heated is added in melted AKD solution and mixed with a quick shearing mixing machine; thirdly, a rotating speed of the quick shearing blending machine is improved and preheating water is added to lead the formed AKD solution to performing emulsification nearby a W / O to O / W inversion point; quick mixing is performed and the preheating water is added and the mixing is continuously performed; fourthly, the water solution of flocculating agent PAC is added, and the mixing is continuously performed; fifthly, the mixing is stopped and the cold water is used for quickly performing cooling and cool down, and then the finished product of the paraffin wax / AKD complex-typed neutral paper-making sizing agent emulsion is produced. The complex-typed neutral sizing agent produced by the invention has the advantages that the holding rate is high, the effect on the physical property of the paper is small, and the emulsion is stable.

Owner:TIANJIN UNIV OF SCI & TECH

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

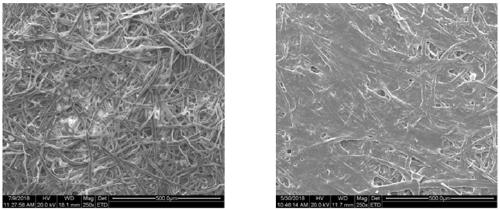

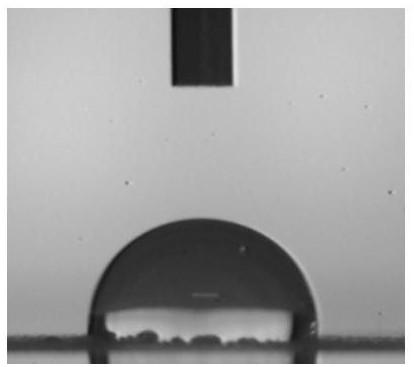

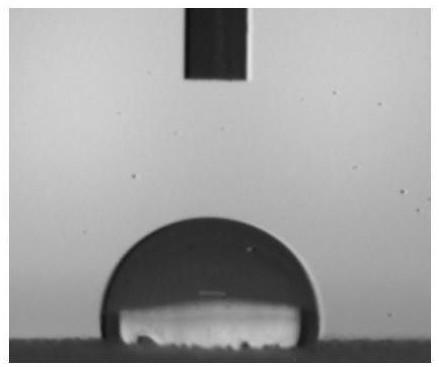

Nanocellulose film with adjustable hydrophilicity and hydrophobicity, and preparation method and application thereof

InactiveCN110577672AHigh hydrophobic contact angleImprove barrier propertiesCoatingsOxygenAccelerant

The invention provides a nanocellulose film with adjustable hydrophilicity and hydrophobicity, and further provides a preparation method and an application of the nano cellulose film. The nanocellulose film is prepared from nanocellulose, a polymer, a sizing agent and a sizing accelerant. The nanocellulose film with adjustable hydrophilicity and hydrophobicity has the advantages of high hydrophobic contact angle, high water and oxygen blocking capacity, good stability and good printability. Infrared secondary heating and sizing agent addition are adopted, so the sizing degree of the nanocellulose film is improved. The preparation method of the film has the advantages of simplicity, easiness in implementation, convenience in operation, and short preparation period; and an industrially mature tape casting process is adopted, so the nanocellulose film with adjustable hydrophilicity and hydrophobicity can be produced on a large scale.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

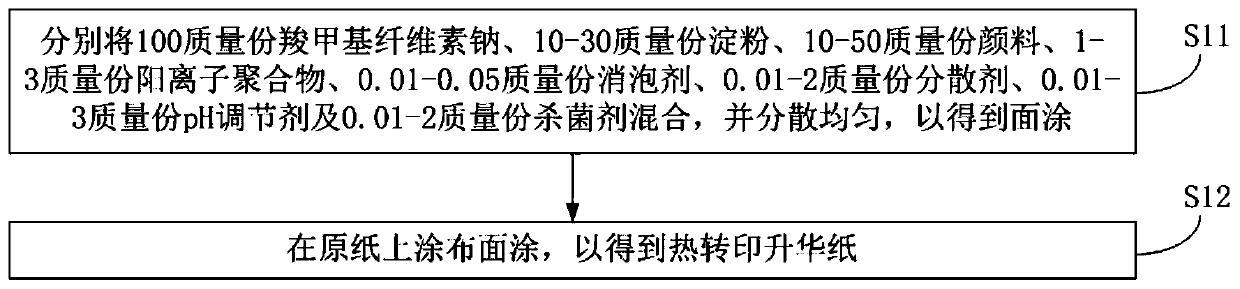

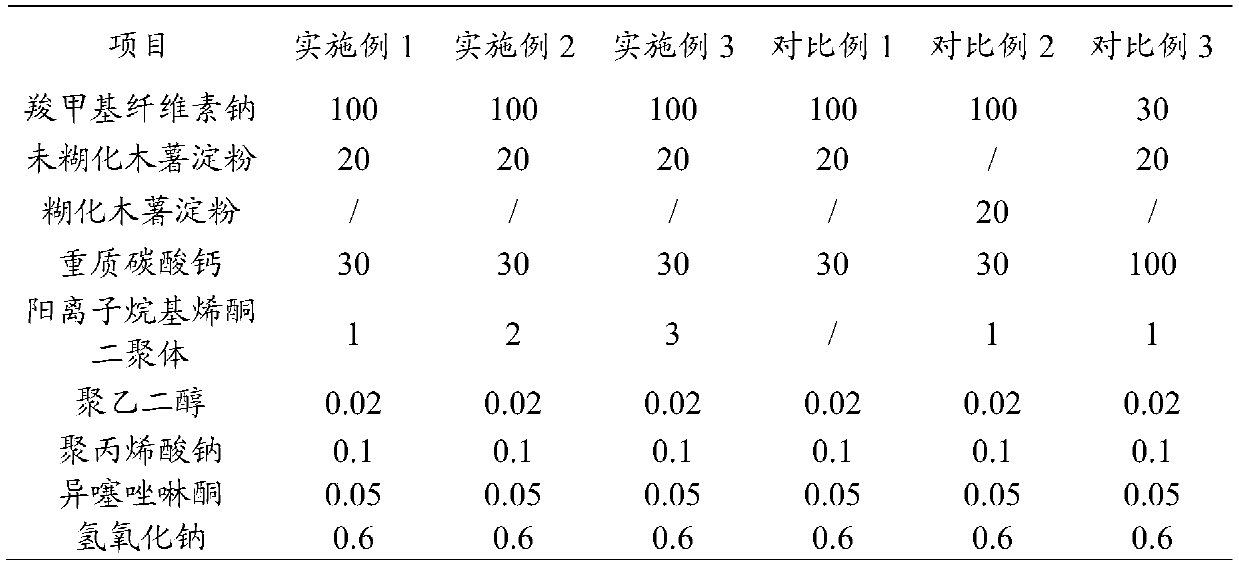

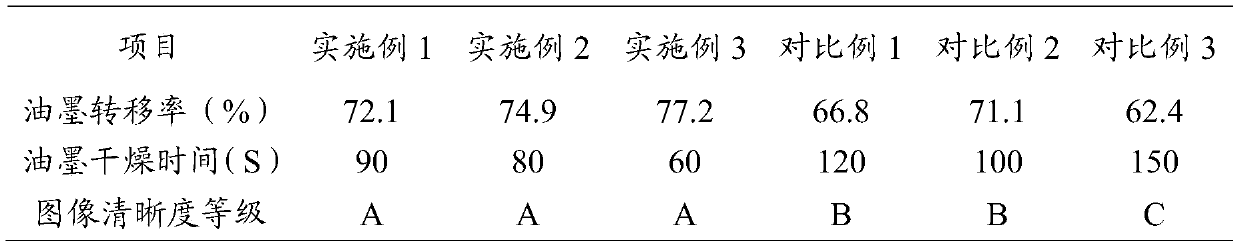

Thermal dye sublimation transfer paper coating, thermal dye sublimation transfer paper and preparation method thereof

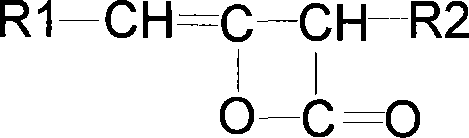

InactiveCN110485206AHigh viscosityIncrease the degree of sizingCoatings with pigmentsSpecial paperCarboxymethyl cellulosePrinting ink

The invention discloses a thermal dye sublimation transfer paper coating, thermal dye sublimation transfer paper and a preparation method thereof, wherein the thermal dye sublimation transfer paper coating comprises sodium carboxymethyl cellulose, starch, a pigment, a cationic polymer and an additive, wherein the starch is non-gelatinized starch. By means of the mode, the water absorption of the thermal dye sublimation transfer paper can be improved, the drying speed of the printing ink paper is increased, and the printing ink transfer rate and the printing definition can be improved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

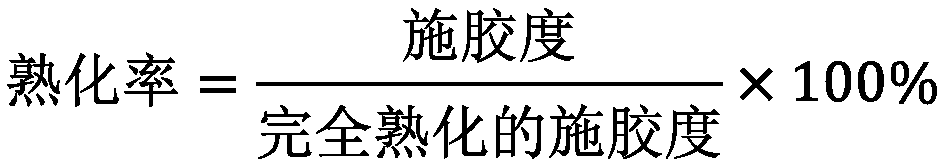

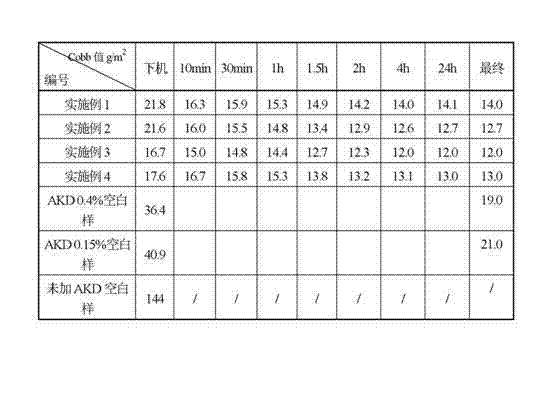

Crosslinked material capable of promoting curing of alkyl ketene dimer and preparation method thereof

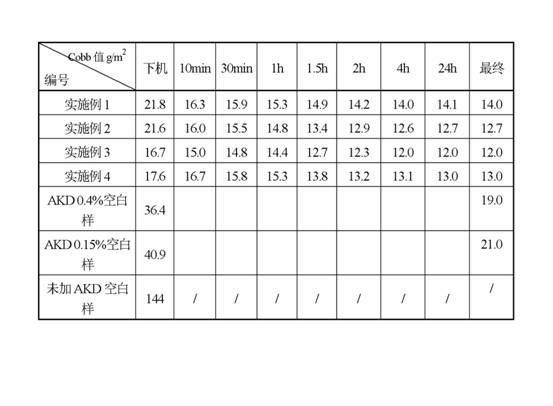

InactiveCN102101918AIncrease the degree of sizingReduce penetrationWater-repelling agents additionWater solubleGuar gum

The invention discloses a crosslinked material capable of promoting curing of alkyl ketene dimer(AKD) and a preparation method thereof. The crosslinked material is characterized by comprising guar gum, synthetic water soluble polymer, cationic assistant, crosslinking agent and water. The preparation is implemented by the following steps: dissolving the guar gum in water, adding the crosslinking agent, stirring, regulating the pH value of the mixed reaction system by using NaOH, raising the temperature to perform a cross-linking reaction, adding the synthetic water soluble polymer and the cationic assistant, cooling to obtain the crosslinked material capable of promoting the curing of the alkyl ketene dimer. The crosslinked material of the invention can improve the degree of sizing of paper, reduces infiltration capacity of liquid, and helps to produce high water resistance. The crosslinked material of the invention reduces the sizing curing time of AKD to 2 hours from the original 2 weeks, improves the utilization rate of paper machine and reduces storage time.

Owner:NANTONG TONGDI BIOTECH CO LTD +1

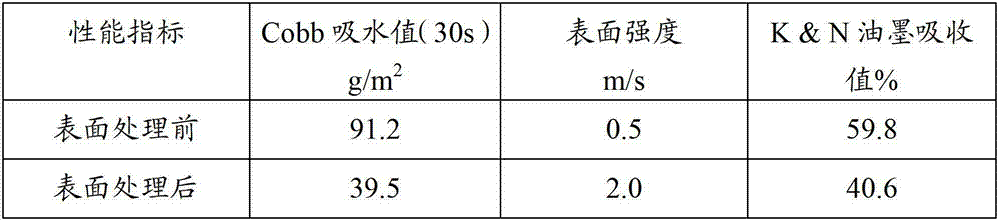

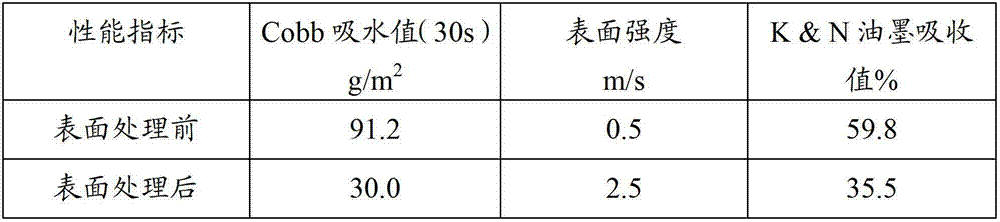

Method for treating surface of synthetic calcium silicate filled offset printing paper

ActiveCN102899960AIncrease the degree of sizingReduce absorptionPaper coatingCoatingsCalcium silicatePulp and paper industry

The invention relates to a method for treating the surface of synthetic calcium silicate filled offset printing paper. The method comprises the following steps of sizing surfaces of prepared synthetic calcium filled silicate offset printing paper sheets by using a sizing solution which at least comprises a macromolecular compound with a film-forming property and surface sizing starch. According to the method, the surfaces of the paper sheets are treated by a composite sizing agent with relatively high water resistance, so that problems that the paper is low in sizing degree and high in absorption performance can be effectively solved; and the therefore, the synthetic calcium silicate filled offset printing paper has relatively high surface strength and proper ink absorption performance.

Owner:DATANG INT POWER GENERATION +1

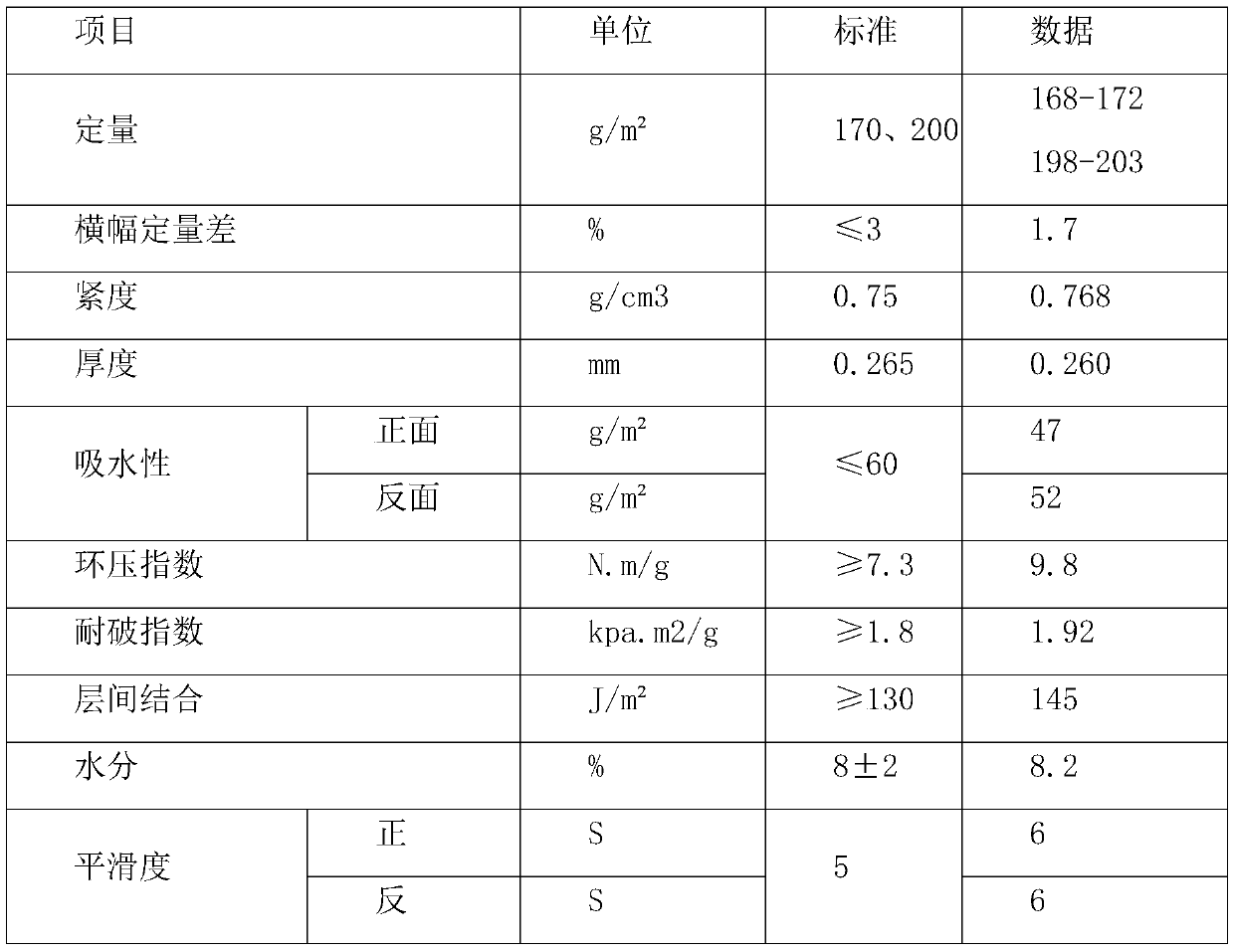

ML kraft paperboard and preparation process thereof

ActiveCN110373945AImprove tightnessHigh strengthWrappersWater-repelling agents additionCardboardPapermaking

The invention discloses an ML kraft paperboard and a preparation process thereof, and mainly relates to the technical field of papermaking. According to the ML kraft paperboard, basis weight is 170, 200g / m<2>, the banner quantitative difference is less than or equal to 3%, tightness is greater than or equal to 0.75 g / cm<3>, smoothness is greater than or equal to 5s, a lateral ring pressure index is greater than or equal to 7.3N.m / g, interlayer bonding strength is greater than or equal to 130J / m<2>, a bursting index is greater than or equal to 1.8kpa. M<2> / g, transverse folding strength is greater than or equal to 4 times and paper moisture is 8+ / -2%. The preparation process of the ML kraft paperboard comprise the steps that preparation, pulping, mixing, paper forming and rewinding are carried out to obtain the paperboard, and then packaging is carried out; and pulp is ground during pulping, spray starch and fillers are added during paper making, and a dyeing agent is added for dyeing.The ML kraft paperboard has the advantages of low cost, high interlayer bonding, high water resistance, high smoothness and clean front appearance. The ML kraft paperboard is mainly used in a surfacelayer and an inner layer of an industrial paper tube, the ''angle-rising'' problem does not occur when the paper tube is cut in sections due to low basis weight; and the problems of surface blisteringand paper tube layering are solved due to the fact that the interlayer bonding strength of the ML kraft paperboard is higher than that of a general kraft paperboard and cardboard paper.

Owner:汇胜集团平原纸业有限公司

Preparation method of fluorescent ASA Pickering emulsion and application thereof

ActiveCN108951280AFluorescentExcellent optical propertiesWater-repelling agents additionPaper/cardboardPickering emulsionMontmorillonite

The invention belongs to the field of chemistry and nanometer material science, and specifically discloses a preparation method of a fluorescent ASA Pickering emulsion and application thereof. The fluorescent ASA Pickering emulsion is mainly prepared by using water, carbon quantum dots, organic modified montmorillonite and ASA as raw materials. The mass ratio of the carbon quantum dots to the organic modified montmorillonite is 1: (2-4); and the mass ratio of the organic modified montmorillonite to the ASA is (2-4): 100. By using the carbon quantum dot / organic modified montmorillonite stabilization system for preparation of ASA Pickering, the adverse effects of a surfactant on water and soil can be avoided, and eco-environmental stress can be reduced. The ASA Pickering emulsion prepared bythe emulsion stabilization system has fluorescence property. By the use of the emulsion for internal sizing of paper sheet, the degree of paper sizing can be remarkably enhanced, and the internal sizing effect of the ASA Pickering emulsion is better.

Owner:SOUTH CHINA UNIV OF TECH

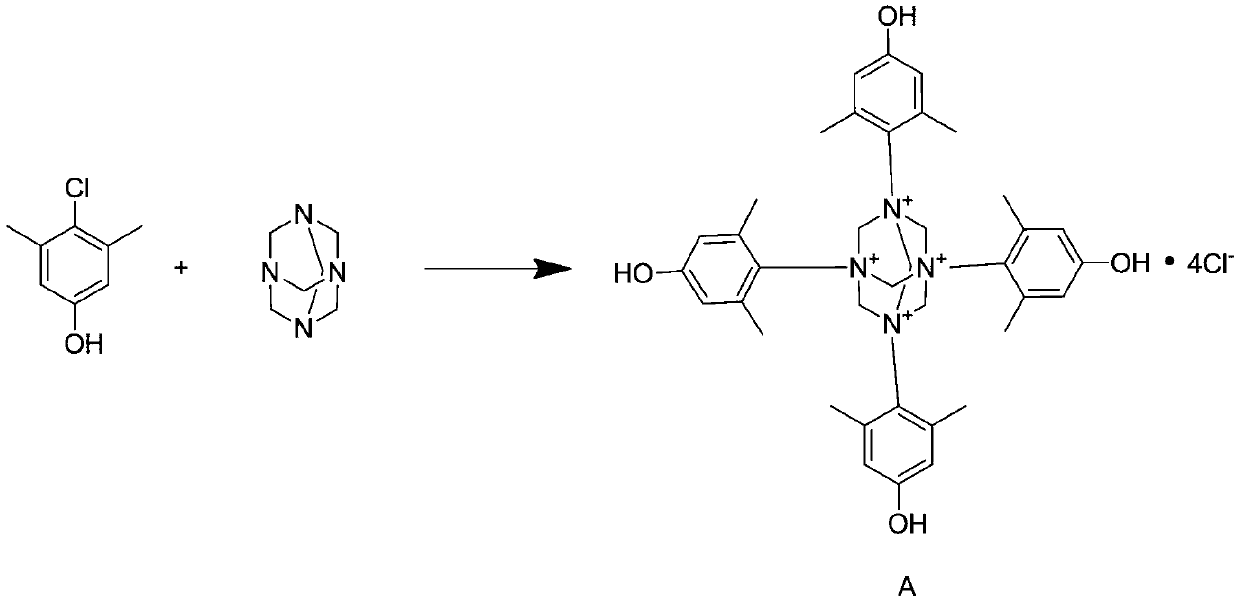

AKD neutral sizing agent prepared by cationic emulsifier and preparation method and application of AKD neutral sizing agent

InactiveCN105603818AEasy to transportEasy to storeWater-repelling agents additionPolymer scienceAnti bacteria

The invention discloses an AKD neutral sizing agent prepared by a cationic emulsifier and a preparation method and application of the AKD neutral sizing agent and relates to the field of papermaking chemicals. The method includes: mixing the solid cationic emulsifier with AKD according a certain proportion under room temperature, and melting at 80-85 DEG C; slowly adding hot water into the melt AKD / emulsifier mixture, performing shearing stirring at the speed of 1000-2000r / minute for 2-5 minutes; increasing the shearing stirring speed to 10000r / minute, and stirring at high speed for 25-30 minutes, stopping stirring, using cold water for fast cooling to obtain the sizing agent emulsion. The AKD sizing agent prepared by the method is good in water resistance, free of a curing period, good in emulsion stability, antibacterial, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Paraffin sizing agent and preparation method thereof

The invention relates to a paraffin sizing agent and a preparation method thereof. The paraffin sizing agent is prepared from the following components in parts by weight: 15-18 parts of paraffin, 4-7 parts of methyl glucose dioleate, 5-6 parts of diethylene glycol monolaurate, 3-4 parts of sodium alga acid, 2-4 parts of polyvinyl alcohol, 4-5 parts of oxidized starch and 130-134 parts of deionized water. The components of the paraffin sizing agent disclosed by the invention are dissolved, agitated and sheared to prepare the paraffin sizing agent. The prepared paraffin sizing agent has a high sizing degree, and the surface strength of paper can be improved.

Owner:SUZHOU HENGKANG NEW MATERIALS

Myopia prevention paper, as well as preparation method and application

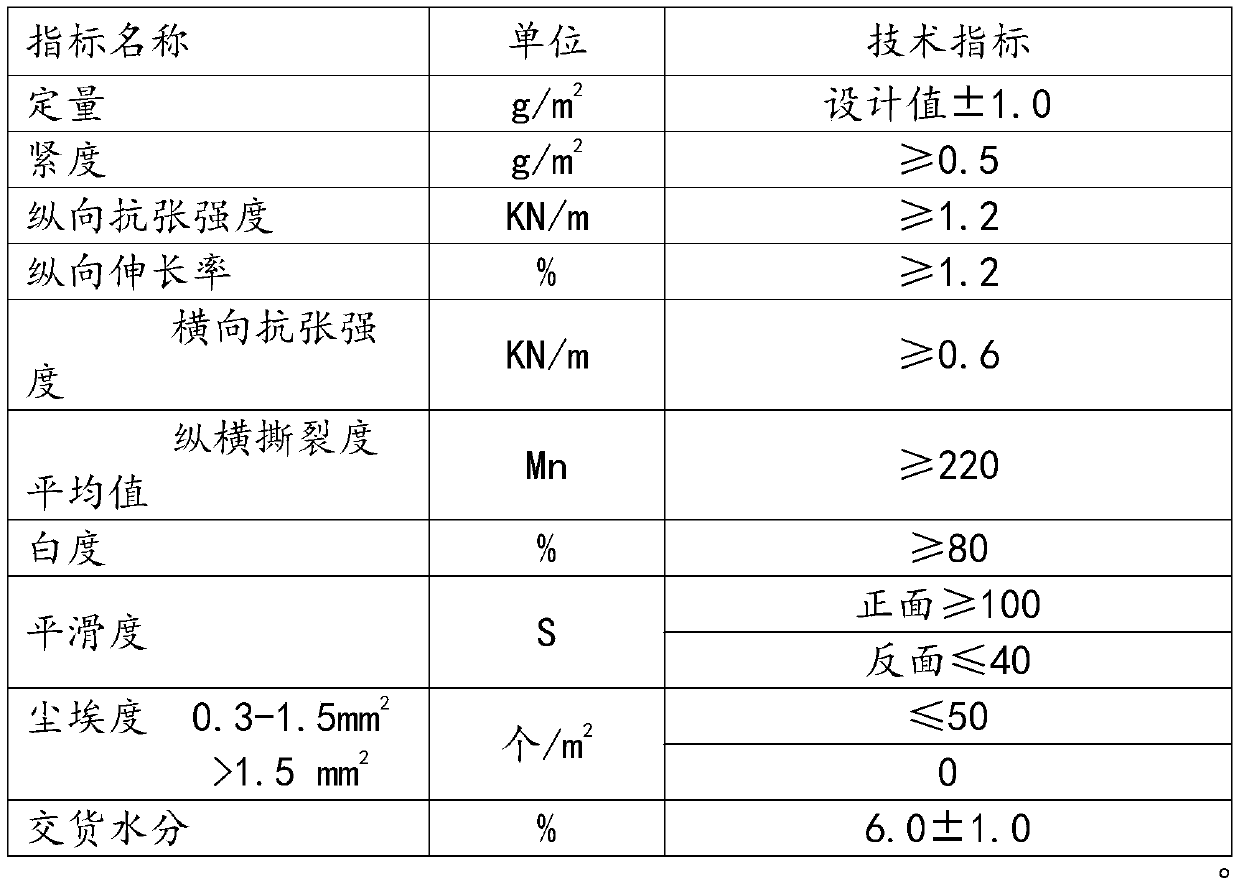

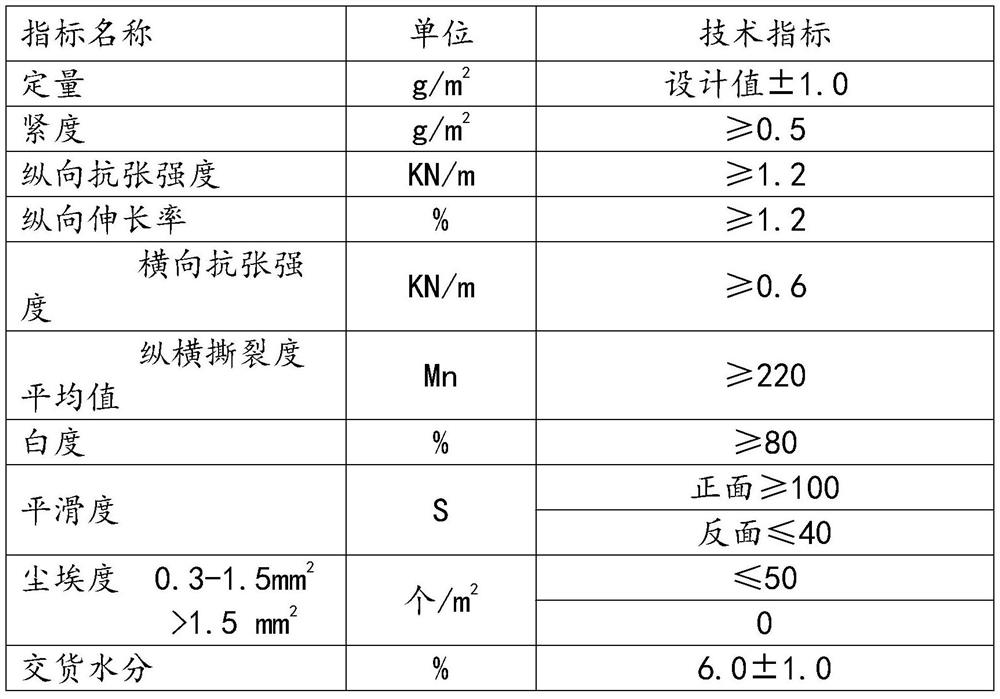

ActiveCN109403116AHigh tear indexImprove smoothnessNon-macromolecular organic additionPaper recyclingMalachite greenFiber

The invention discloses myopia prevention paper. The myopia prevention paper is prepared from pulp and pigment, wherein the pulp is prepared from the following raw materials in percentage by weight: 75 to 85 percent of waste book paper deinked pulp and 15 to 25 percent of white shavings pulp; the pigment is selected from one or more of chrysophenine G, auramine O and malachite green. The myopia prevention paper is faint yellow or faint green, and is soft in luster, so that the myopia prevention paper has low irritation to human eyes, can relieve visual fatigue, plays a certain role in protecting eyes, and plays a role in preventing myopia. Meanwhile, waste book paper and white shavings are taken as main raw materials of the myopia prevention paper, so that secondary fiber is utility fully,other additives except pigment do not need to be added, the production cost can be lowered remarkably, and the influence on the environment is lowered. Moreover, the myopia prevention paper has the advantages of high tensile index, tearing strength index, smoothness and sizing value, low surface absorption amount, and high mechanical performance, surface performance and water resistance, and is smooth for a user to write.

Owner:广州市咏润纸业科技有限公司

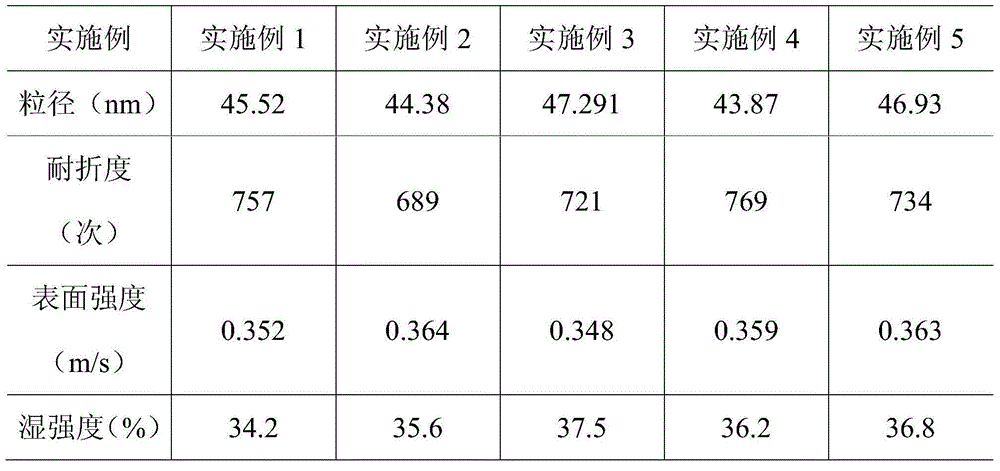

Preparation method for negative ion organosilicon modified polyacrylate paper reinforcing agent

ActiveCN103554345AImprove bindingImprove folding resistanceReinforcing agents additionFiberFolding endurance

The invention relates to a preparation method for a negative ion organosilicon modified polyacrylate paper reinforcing agent. A transparent negative ion organosilicon modified polyacrylate emulsion is obtained by solution polymerization, by using methylacrylic acid, functional vinyl monomers, lipophilic monomers and gamma-methacryloxy propyl trimethoxyl silane as comonomers and isopropanol as a solvent and a chain transfer agent to carry out free radical polymerization of acrylic monomers, and through the steps of cooling, triethylamine neutralization and water dispersion. The obtained negative ion organosilicon modified polyacrylate paper reinforcing agent can not only effectively increase paper surface strength and folding endurance but also increase waterproof property of the paper surface. Besides, due to the addition of gamma-methacryloxy propyl trimethoxyl silane, adhesion properties between fibers and inorganic fillers are increased; and defects of ash and fiber falling during a printing process of the paper. Meanwhile, the product is simple in preparation process, low in raw material cost and simple in glue-applying process and can be easily applied and popularized in real industries.

Owner:SHAANXI UNIV OF SCI & TECH

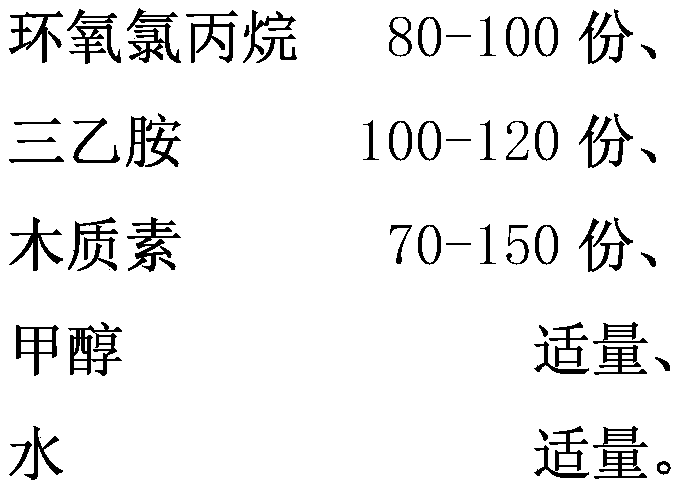

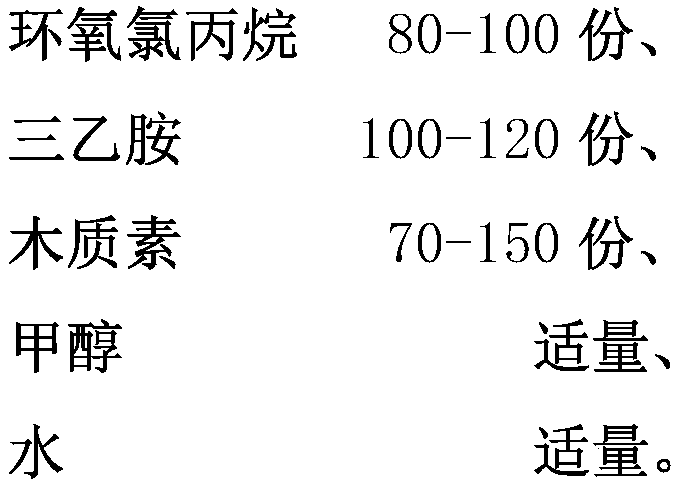

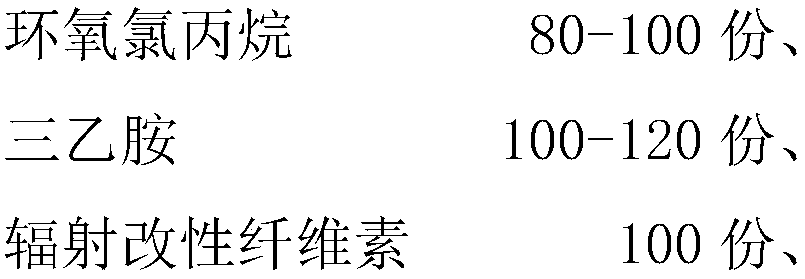

Lignin modified emulsifier and alkyl ketene dimer (AKD) emulsion prepared from same

InactiveCN110409218AImprove performanceFast agingWater-repelling agents additionPaper/cardboardEpoxyWax

The invention discloses a lignin modified emulsifier. The lignin modified emulsifier is prepared from epoxy chloropropane, triethylamine, lignin, methanol and water which react. The invention furtherdiscloses an alkyl ketene dimer (AKD) emulsion, which is prepared from AKD wax and the effective quantity of lignin modified emulsifier. The lignin modified emulsifier is successfully prepared througha series of lignin modification, then the novel AKD emulsion with excellent performance is obtained, and the AKD emulsion has the characteristics of high curing rate and high sizing degree, and has high application value in the field of papermaking.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

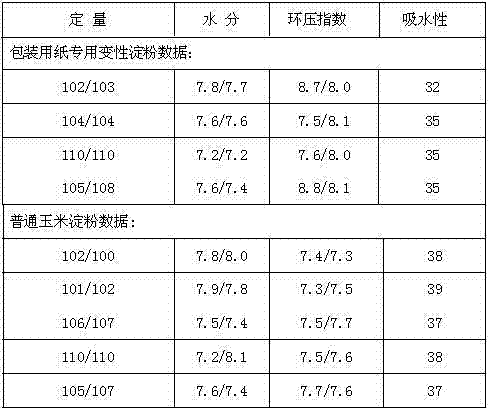

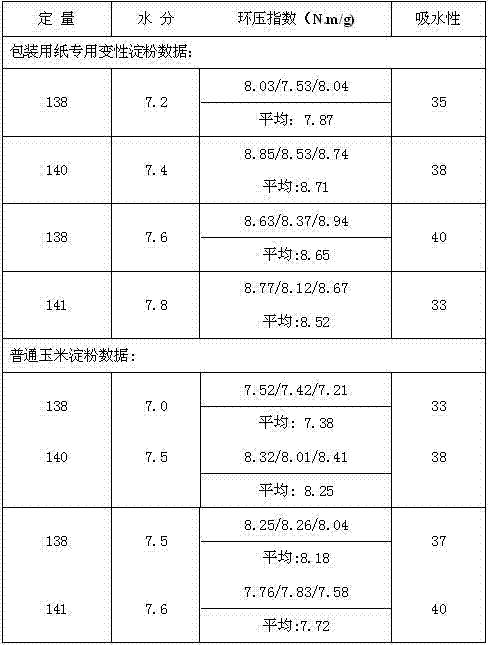

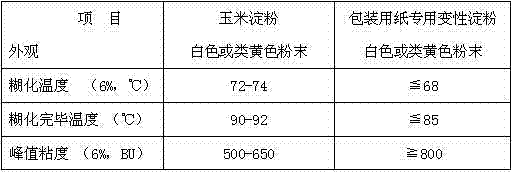

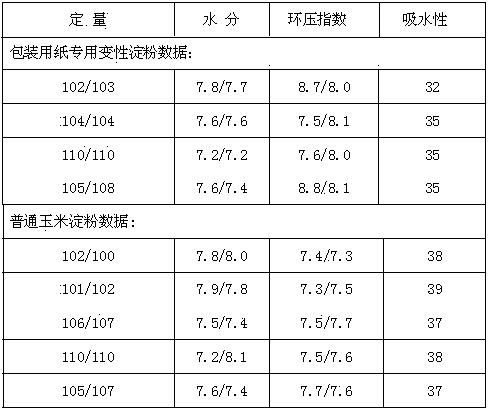

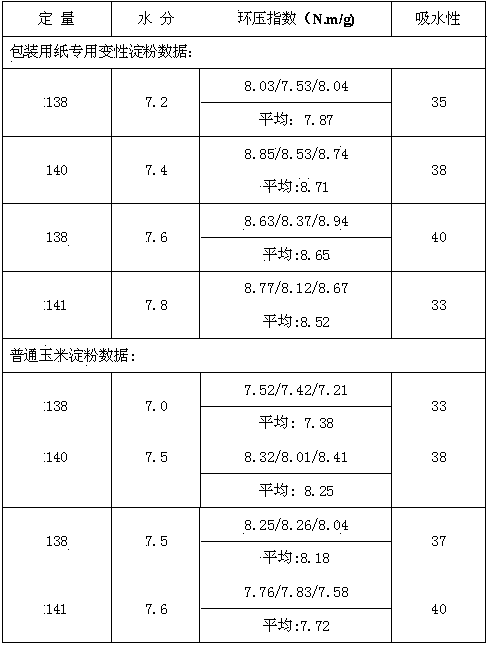

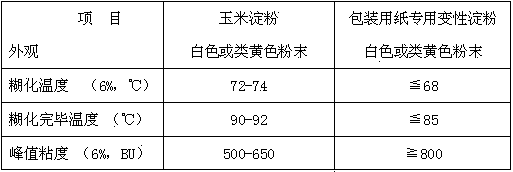

Special modified starch for wrapping paper and production method thereof

ActiveCN102731842AShorten the boil timeEasy to realize the industrialization of special modified starchBiotechnologySODIUM METAPHOSPHATE

The invention provides a special modified starch for wrapping paper and a production method thereof, belonging to the filed of deep processing of maize. The special modified starch is prepared from the following components: in a volume mass ratio, 2250 m<3> to 2750 m<3> of maize starch milk 21Be' ( equivalent to 900 to 1100 Kg of a dry basis), 18 to 22 Kg of sodium tripolyphosphate, 4.5 to 5.5 Kg of sodium trimetaphosphate, 10.8 to 13.2 Kg of urea, 4.5 to 5.5 Kg of sodium hydroxide and 36 to 44 Kg of sodium carbonate. The special modified starch for wrapping paper provided in the invention has the following advantages: the special modified starch is easy to gelatinize and has a low gelatinization temperature and a short gelatinization time; gelatinized liquid has good fluidity, transparency, film forming ability and film strength; and the special modified starch has excellent bonding performance with a variety of fibers and good compatibility with other auxiliary agents.

Owner:JILIN COFCO BIOCHEM

Preparation method of rapidly-cured water-resistant AKD sizing agent

InactiveCN106283868AStrong emulsificationGood dispersionWater-repelling agents additionWax additionFiberChemical Linkage

The invention discloses a preparation method of a rapidly-cured water-resistant AKD sizing agent, and belongs to the technical field of sizing agent preparation. The method includes the steps that firstly, guar gum is modified with cationic monomers; then, the modified guar gum and vegetable oil are blended, modification is carried out under the action of microorganisms, and a self-made synergist is obtained; finally, the synergist and other materials are compounded, and the rapidly-cured water-resistant AKD sizing agent is obtained. According to the preparation method, the characteristic that guar gum and cellulose have similar structures is utilized, the guar gum contains rich hydroxyl groups and has high affinity with fibers, and meanwhile the hydroxyl groups and fiber surface groups can form chemical bonding; besides, after modification with vegetable oil, the number of hydrophobic ester groups is increased, hydrolysis caused by contact with water can be avoided, reaction between the sizing agent and fibers is accelerated, the AKD sizing effect is improved, the problems that a common AKD sizing agent is long in curing time and delayed in sizing effect, and AKD is poor in stability in water and likely to be hydrolyzed and fail are effectively solved, and the AKD sizing agent has an excellent sizing effect.

Owner:中山市升信纸品有限公司

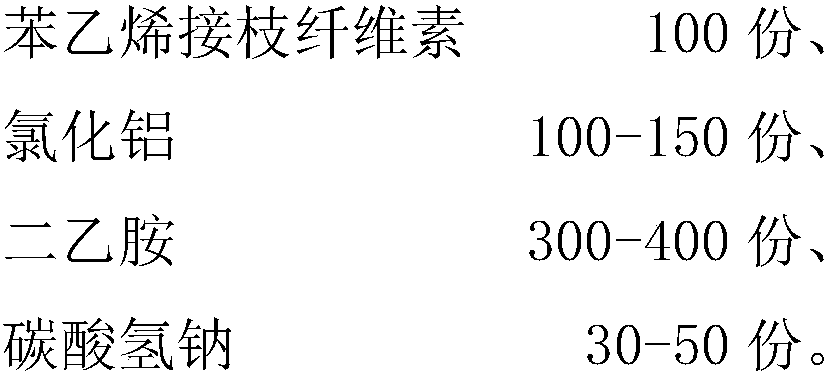

Radiation-modified cellulose emulsifier and AKD emulsion prepared utilizing the emulsifier

ActiveCN110485198AImprove performanceFast agingWater-repelling agents additionNon-macromolecular organic additionWaxEmulsion

The invention discloses a radiation-modified cellulose emulsifier which is obtained by reacting epoxy chloropropane, triethylamine, radiation-modified cellulose, methanol and water, with the radiation-modified cellulose being formed by inducing grafting of styrene to the surface of cellulose by adopting a radiation method and then performing acetylation and amination. The invention also disclosesan AKD emulsion, which comprises AKD wax and an effective amount of the radiation-modified cellulose emulsifier. The radiation-modified cellulose emulsifier is successfully prepared through a series of cellulose modification, then the novel AKD emulsion with excellent performance is obtained, and the AKD emulsion has the advantages of being high in curing rate and high in sizing degree and has wide application value in the field of papermaking.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation method of epoxy resin-modified cation waterborne polyurethane emulsion

InactiveCN102432798BIncrease the degree of sizingHigh folding resistanceWater-repelling agents additionEpoxyEmulsion

The invention provides a preparation method of an epoxy resin-modified cation waterborne polyurethane emulsion. The preparation method comprises the following steps of: firstly, pre-polymerizing: carrying out a pre-polymerizing reaction on oligomer polyalcohol, isocyanate and organic tin catalyst according to the mass fraction at the temperature of 60-80DEG C for 1-3 hours; secondly, extending a chain: adding a micromolecule hydroxyl monomer, a hydrophilic extended chain agent and epoxy resin in a reactor and carrying out a chain extension reaction at the temperature of 60-80DEG C for 0.5-2 hours; thirdly, neutralizing: adding a neutralizing agent in the reactor and finishing a salt forming reaction; and fourthly, emulsifying: adding deionized water at constant speed to obtain a modified cation waterborne polyurethane emulsion. The preparation method provided by the invention has the advantages of simpleness in operation of process, energy saving, environment friendliness and the like. According to the preparation method of the epoxy resin-modified cation waterborne polyurethane emulsion which is provided by the invention, by adding the epoxy resin and introducing a cross-linking structure, the size resistance, the fold-resisting times and the ring crash index of sized paper are improved.

Owner:SHAANXI UNIV OF SCI & TECH

Cationic rosin emulsion neutral-alkaline sizing agent and preparation method thereof

ActiveCN107630387AIncrease the degree of sizingHigh glossWater-repelling agents additionNon-macromolecular organic additionGlycerolSolvent

The invention discloses a cationic rosin emulsion neutral-alkaline sizing agent. The cationic rosin emulsion neutral-alkaline sizing agent is prepared from an emulsifier, polymerized rosin and an auxiliary material, the emulsifier is prepared from methacrylic acid, diluted sulfuric acid, ammonium acrylate, styrene, isopropanol, dodecanethiol, acrylic acid and ammonium persulfate, the polymerized rosin is prepared from rosin, a naphtha solvent, 98% sulfuric acid, anhydrous zinc sulfate and 50 DEG C deionized water, and the auxiliary materials includes lignin, sodium hydroxide and glycerin. Thecationic rosin emulsion neutral-alkaline sizing agent can improve the gloss of paper, and allows a sized surface to have a good strength and remarkably improved dry-wet strength, paper produced by using the cationic rosin emulsion neutral-alkaline sizing agent can be easily recovered and treated, and aluminum sulfate is not added in the preparation process to obtain the alkaline sizing agent handle.

Owner:龙游富田造纸精化有限公司

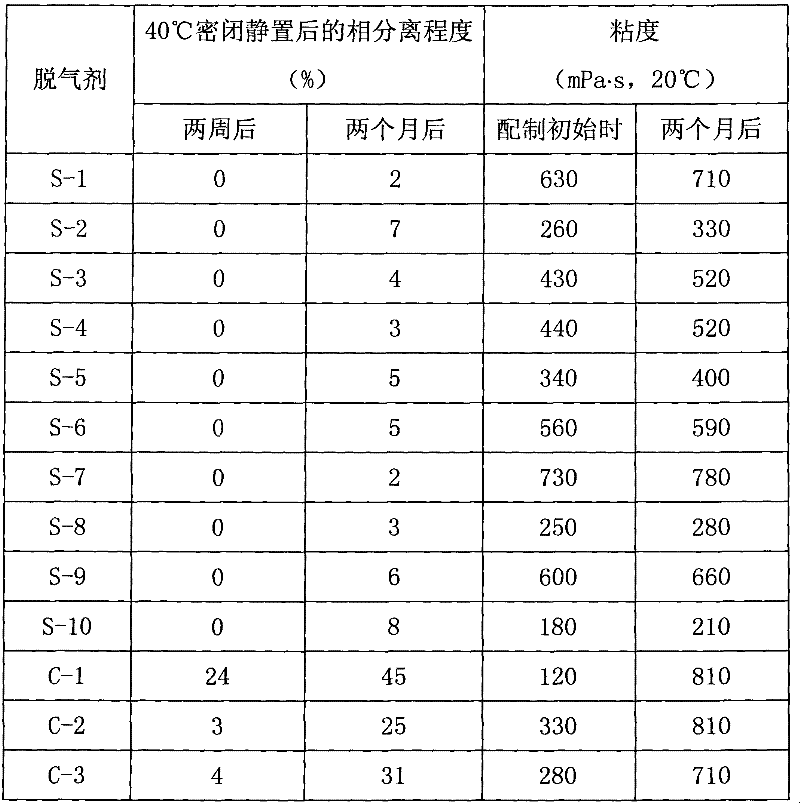

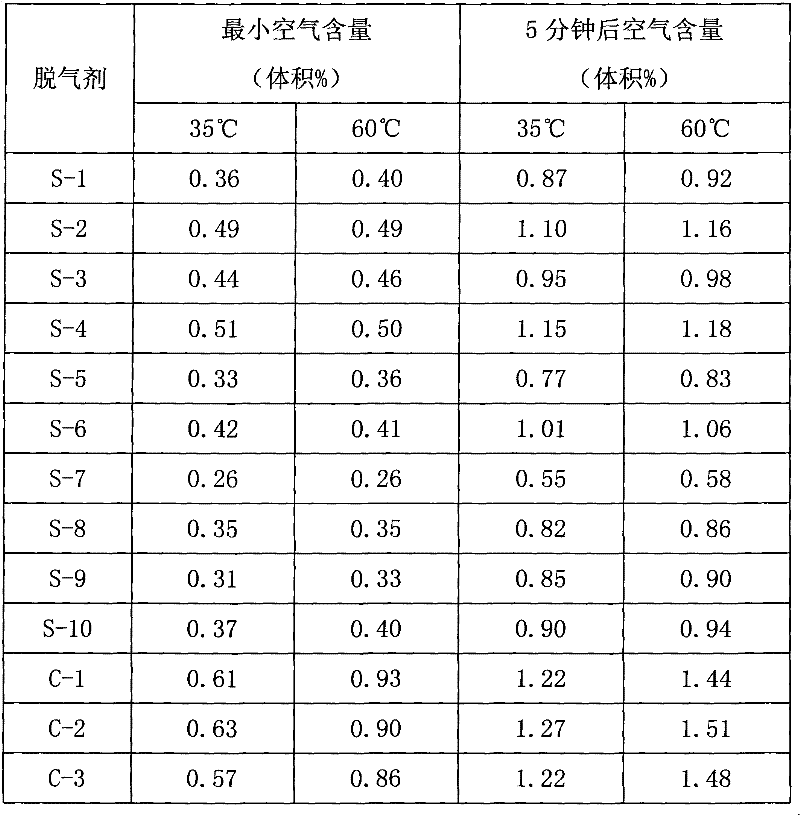

Emulsified high-alcohol degasifying agent for papermaking

ActiveCN101718055BGood storage stabilityGood high temperature degassing performanceDefoamers additionPapermakingWater soluble

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Corn starch surface sizing agent and preparation method thereof

PendingCN109267423ALow costEasy to prepareWater-repelling agents additionPaper coatingPolyvinyl alcoholGlycerol

The invention relates to a preparation method of a corn starch surface sizing agent. The method includes the steps of adopting corn starch as a raw material, adopting sodium hypochlorite (NaClO) as anoxidant, and adopting nanometer microcrystalline cellulose as an auxiliary oxidant for preparing oxidized corn starch, wherein the available chlorine dosage of NaClO relative to absolutely dried cornstarch is 8.0-9.0 wt%, and the dosage of the nanometer microcrystalline cellulose relative to the absolutely dried corn starch is 0.5-0.8 wt%; combining the prepared oxidized corn starch with polyvinyl alcohol and glycerol to prepare the corn starch surface sizing agent. Sodium hypochlorite oxidized starch prepared by catalysis of nanometer cellulose in specific length can be used for preparing asurface sizing agent which is low in viscosity, high in glue stability, high in transparency and great in film-forming property.

Owner:QILU UNIV OF TECH

Production process of efficient kinking folding type candy packaging base paper

ActiveCN110219208AReduce consumptionHigh tear strengthDefoamers additionWrappersHigh concentrationBursting strength

The invention discloses a production process of efficient kinking folding type candy packaging base paper. The production process comprises the following procedures that bleached sulphate softwood pulp is pulped by a pulping process; then the pulp is formed by the fourdrinier multi-cylinder paper machine; and the pulp is squeezed, dried, calendered, cut, packaged and warehoused, wherein the pulping process adopts a plurality of Type 3 and Type 4 double-disc mills for mixing and pulping, and the adopted pulping mode is a high-concentration sticky pulping mode, so that the content of long fibersof the pulp can be kept to the maximum extent, and the tensile strength and the tearing strength of paper are favorably improved; and chemical auxiliary agents are added into the the pulp in the pulping process, so that compared with the traditional process, the addition of the chemical auxiliary agents saves the using amount of the auxiliary agents, has strong economic applicability, and simultaneously improves dry strength indexes such as breaking length, bursting strength, folding strength and the like and the sizing degree of paper.

Owner:WELBON SPECIAL MATERIALS CO LTD

Cation surface sizing agent and preparation method thereof

InactiveCN101649583BReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseBalance water

Owner:东莞市清正合成高新材料有限公司 +1

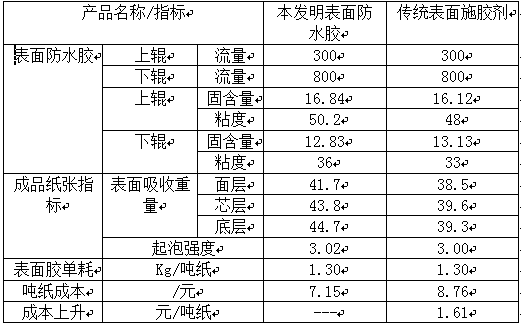

Styrene-butyl acrylate surface waterproof glue and preparation method thereof

InactiveCN109457538AImprove surface strengthIncrease the degree of sizingWater-repelling agents additionPaper coatingAmylaseDissolution

The invention discloses styrene-butyl acrylate surface waterproof glue which comprises, by weight, 100 parts of starch, 0.065 part of medium temperature amylase, 12 parts of glacial acetic acid, 0.5 part of ferrous sulfate, 25 parts of hydrogen peroxide, 125 parts of styrene, 50 parts of butyl acrylate, 15 parts of rosin, 3.5 parts of Gemini emulsifiers, 1.0 part of organic silicon defoamers and 675 parts of deionized water. The styrene and the butyl acrylate are pumped into a titration vessel, the deionized water and the starch are added into a reaction vessel, the medium temperature amylaseis added after temperature rise, the glacial acetic acid and the Gemini emulsifiers are added, the ferrous sulfate is added after dissolution, two types of titrating solution are simultaneously titrated, thermal reaction is performed for 45-50 minutes at the temperature of 85 DEG C after titration, reaction liquid is rapidly cooled, the organic silicon defoamers are added, standing is performed, and the reaction liquid is filtered and fed into a finished product packaging tank after passing chemical examination.

Owner:郑州林海环保材料有限公司

Crosslinked material capable of promoting curing of alkyl ketene dimer and preparation method thereof

InactiveCN102101918BIncrease the degree of sizingReduce penetrationWater-repelling agents additionWater solubleGuar gum

The invention discloses a crosslinked material capable of promoting curing of alkyl ketene dimer(AKD) and a preparation method thereof. The crosslinked material is characterized by comprising guar gum, synthetic water soluble polymer, cationic assistant, crosslinking agent and water. The preparation is implemented by the following steps: dissolving the guar gum in water, adding the crosslinking agent, stirring, regulating the pH value of the mixed reaction system by using NaOH, raising the temperature to perform a cross-linking reaction, adding the synthetic water soluble polymer and the cationic assistant, cooling to obtain the crosslinked material capable of promoting the curing of the alkyl ketene dimer. The crosslinked material of the invention can improve the degree of sizing of paper, reduces infiltration capacity of liquid, and helps to produce high water resistance. The crosslinked material of the invention reduces the sizing curing time of AKD to 2 hours from the original 2 weeks, improves the utilization rate of paper machine and reduces storage time.

Owner:NANTONG TONGDI BIOTECH CO LTD +1

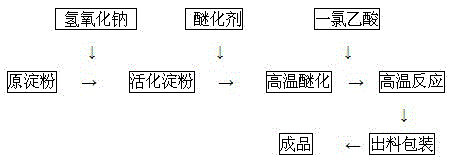

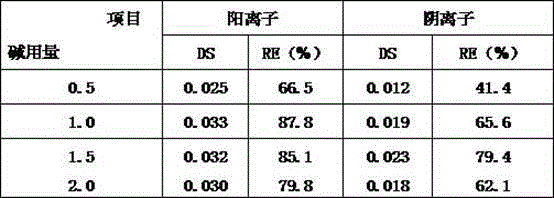

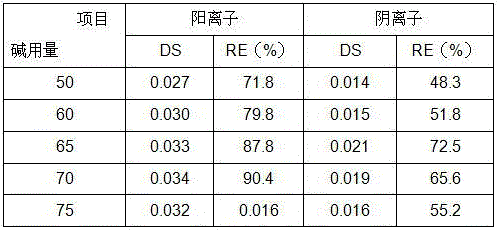

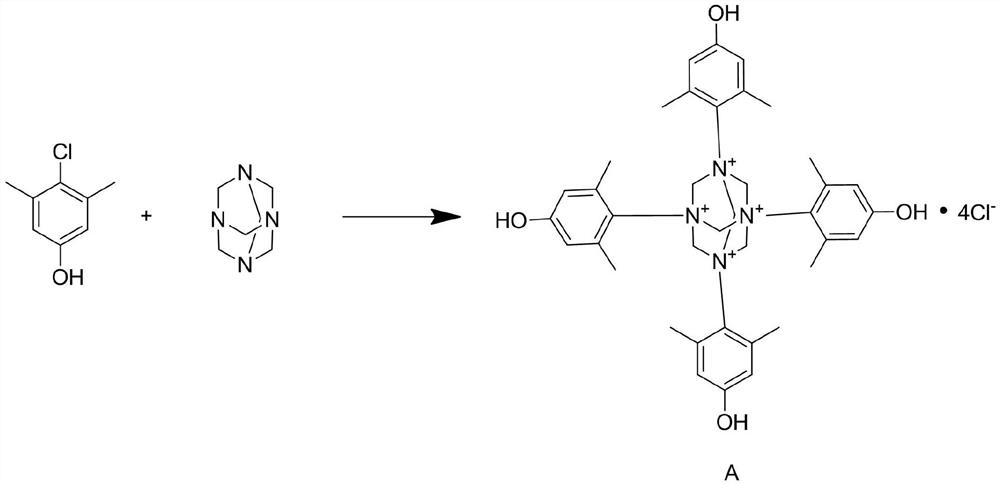

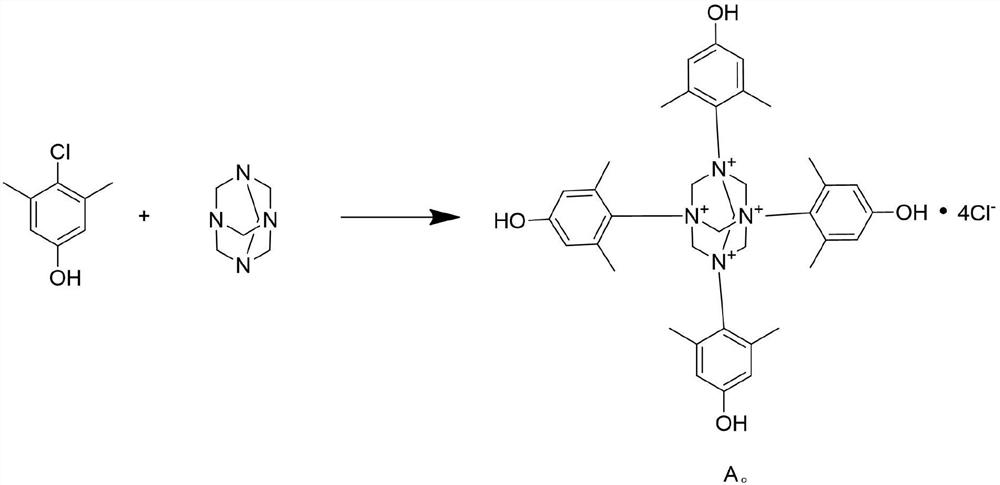

Method for preparing carboxy-type amphoteric starch in one step by semi-dry process

The invention discloses a method for preparing carboxyl-type amphoteric starch in one step by a semi-dry process, which is characterized in that: firstly adding a cationic reagent 3-chloro-2-hydroxypropyl-trimethylammonium chloride to carry out etherification reaction on the original starch, After the etherification reaction, directly add the anionizing reagent monochloroacetic acid to carry out the carboxymethylation reaction. Both anionization and cationization reactions are carried out in one kettle to prepare carboxy-type amphoteric starch in one step, and the production process is uninterrupted. The invention can effectively solve the shortcomings of wet process and dry process. Cationic and anionic groups are connected in the same starch chain, so that the product has the characteristics of cationic starch and anionic starch, and various performances are improved; the reaction time can be shortened from 8 hours to 6 hours; due to the shortened process, energy saving and consumption reduction, so that The product cost can be saved by about 12%.

Owner:抚州新天下知识产权咨询管理有限公司

Special modified starch for wrapping paper and production method thereof

ActiveCN102731842BShorten the boil timeEasy to realize the industrialization of special modified starchBiotechnologySODIUM METAPHOSPHATE

The invention provides a special modified starch for wrapping paper and a production method thereof, belonging to the filed of deep processing of maize. The special modified starch is prepared from the following components: in a volume mass ratio, 2250 m<3> to 2750 m<3> of maize starch milk 21Be' ( equivalent to 900 to 1100 Kg of a dry basis), 18 to 22 Kg of sodium tripolyphosphate, 4.5 to 5.5 Kg of sodium trimetaphosphate, 10.8 to 13.2 Kg of urea, 4.5 to 5.5 Kg of sodium hydroxide and 36 to 44 Kg of sodium carbonate. The special modified starch for wrapping paper provided in the invention has the following advantages: the special modified starch is easy to gelatinize and has a low gelatinization temperature and a short gelatinization time; gelatinized liquid has good fluidity, transparency, film forming ability and film strength; and the special modified starch has excellent bonding performance with a variety of fibers and good compatibility with other auxiliary agents.

Owner:JILIN COFCO BIOCHEM

Paper or paperboard amphoteric ion emulsion agent and production method thereof

ActiveCN103132367BImprove the folding indexIncrease the degree of sizingNon-macromolecular organic additionPaper/cardboardPolyesterWarm water

Provided is a paper or paperboard amphoteric ion emulsion agent and a production method thereof. The paper or paperboard amphoteric ion emulsion agent comprises the main raw material components of , by weight, 7.5-10.5 parts of polyvinyl alcohol, 11.5-14 parts of amylum, 1.5-2.2 parts of polyacrylamide, 1.0-2.0 parts of urea-formaldehyde resin, 2-3 parts of polymine, 0.3-0.4 part of lisothiazolinone, and 60 parts of water. The production method of the paper or paperboard amphoteric ion emulsion agent comprises that all the raw materials are weighed and obtained according to the formula, 10-30 parts of clean water are added to each electric heating reaction kettle, the polyvinyl alcohol, the amylum, and the urea-formaldehyde resin are respectively heated to the temperature of 80-90 DEG C for 50-80 minutes with the rotating speed of 50-70 revolutions per minute, the polymine is heated to 50-60 DEG C for 40-50 minutes, the polyacrylamide is dissolved at room temperature for 2-2.5 hours with the rotating speed of 30-40 revolutions per minute, the lisothiazolinone is soaked in warm water for 40 minutes and filtered by a screen of 80 meshes for further using, then the solutions of all reaction kettles are mixed, power of hydrogen (PH) value is adjusted to 6.8-8.0 by using a natrium hydroxydatum (NaOH) solution with the concentration of 2-2.5%, the mixed solution is evenly stirred after cooling down and then filtered by a polyester wire of with 800meshes, and a finished product is obtained after the qualified detection. The finished product can be added in a paper pulp pool, and can also be used in the process of paper machine wet part interlayer spraying. The paper or paperboard amphoteric ion emulsion agent and the production method thereof are energy conserving, environment friendly, clear in production, no toxic, no palliative and high in paper pass rate.

Owner:湖南鑫鸿盛达生物科技有限公司

Styrene-acrylic emulsion, preparation method thereof, and application thereof

ActiveCN102775542BGood film formingImprove hydrophobicityWater-repelling agents additionPaper coating(Hydroxyethyl)methacrylateEmulsion

The invention relates to a styrene-acrylic emulsion, a preparation method thereof, and an application thereof. The styrene-acrylic emulsion provided by the invention comprises the components of: starch, amylases, a cationic monomer, an acrylate monomer, a crosslinking monomer, styrene, a dispersing agent, hydroxyethyl methacrylate, an initiator aqueous solution with a concentration of 20wt%, and deionized water. A surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention and biological latex has better film-forming performance and good hydrophobicity. With the surface sizing emulsion, paper can be provided with better surface strength, better printing performance, and certain water resistance. The styrene-acrylic emulsion is environment-friendly. When in use, the surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention is directly coated on the surface of paper, and surface sizing starch is no longer used during the surface sizing process. Therefore, a fine paper surface sizing operation process is simplified, and surface sizing process stability in fine paper production is improved.

Owner:广州市迪笙生物科技有限公司

AKD neutral sizing agent prepared by cationic emulsifier and its method and application

InactiveCN105603818BEasy to transportEasy to storeWater-repelling agents additionPolymer scienceAnti bacteria

The invention discloses an AKD neutral sizing agent prepared by a cationic emulsifier and a preparation method and application of the AKD neutral sizing agent and relates to the field of papermaking chemicals. The method includes: mixing the solid cationic emulsifier with AKD according a certain proportion under room temperature, and melting at 80-85 DEG C; slowly adding hot water into the melt AKD / emulsifier mixture, performing shearing stirring at the speed of 1000-2000r / minute for 2-5 minutes; increasing the shearing stirring speed to 10000r / minute, and stirring at high speed for 25-30 minutes, stopping stirring, using cold water for fast cooling to obtain the sizing agent emulsion. The AKD sizing agent prepared by the method is good in water resistance, free of a curing period, good in emulsion stability, antibacterial, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

A production process of high-efficiency twisted and folded candy packaging base paper

The invention discloses a production process of high-efficiency twisted and folded candy packaging base paper, which includes the following steps: pulping bleached kraft softwood pulp through a beating process → then making the pulp into a fourdrinier multi-cylinder paper machine → pressing → Drying→calendering→slitting→packing and storage; Among them, the beating process uses several 3-type and 4-type double-disc mills for mixing and beating, and the beating method adopted is a high-concentration viscous beating method, which can retain the long fibers of the pulp to the greatest extent content, which helps to improve the tensile strength and tear strength of the paper; chemical additives are added to the pulp in the beating process. Compared with the traditional process, the addition of chemical additives saves the amount of additives, and has strong economic applicability. At the same time, the dry strength indicators such as the breaking length, bursting strength and folding strength of the paper and the degree of sizing are improved.

Owner:WELBON SPECIAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com