Lignin modified emulsifier and alkyl ketene dimer (AKD) emulsion prepared from same

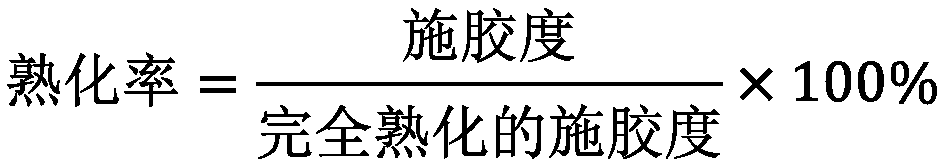

A technology of lignin and emulsifier, which is applied in the direction of water-repellent addition, textile and papermaking, and fiber raw material treatment. It can solve the problems of lack of charge and difficulty in achieving the desired effect, and achieve high sizing degree and wide application value. , fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

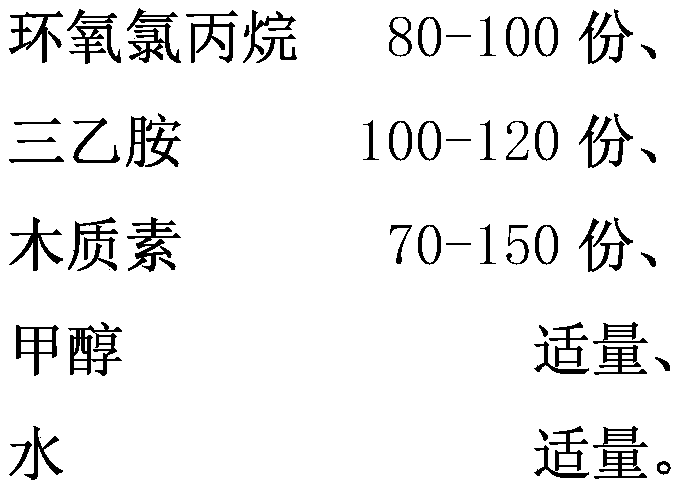

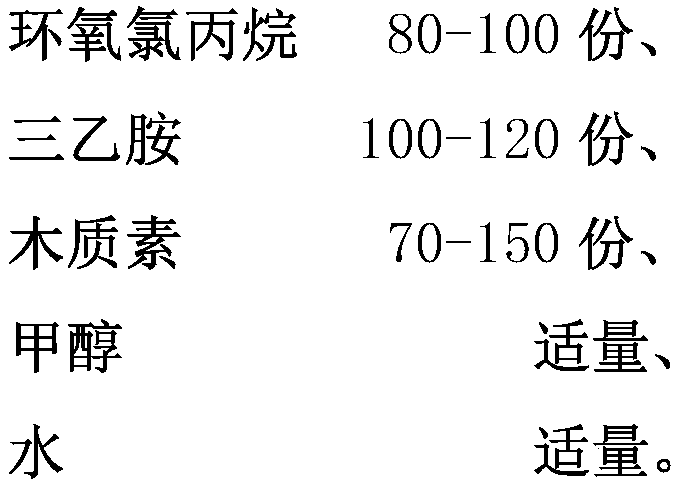

[0023] Present embodiment technical scheme is as follows:

[0024] 1. By mass, mix 100 parts of epichlorohydrin, 100 parts of methanol, 100 parts of water, and 120 parts of triethylamine, and react at 50°C for 3 hours.

[0025] 2. Then, after dispersing 100 parts of lignin in NaOH solution, add it to the above system, and continue to react for 3 hours to obtain a modified lignin emulsifier.

[0026] 3. Melt 250 parts of AKD wax in a water bath, slowly add the above modified lignin emulsifier solution, 8000r / min shear emulsification for 3 minutes, add 5 parts of stabilizing agent, 300 parts of water, continue high-speed shearing and stirring for a certain period of time After rapid cooling, discharge.

Embodiment 2

[0028] Present embodiment technical scheme is as follows:

[0029] 1. By mass, mix 80 parts of epichlorohydrin, 110 parts of methanol, 110 parts of water, and 110 parts of triethylamine, and react at 40°C for 2 hours.

[0030] 2. Then, after dispersing 100 parts of lignin in NaOH solution, add it to the above system, and continue to react for 2 hours to obtain a modified lignin emulsifier.

[0031] 3. Melt 200 parts of AKD wax in a water bath, slowly add the above-mentioned modified lignin emulsifier solution, 5000r / min shear emulsification for 2 minutes, add 3 parts of sodium bicarbonate, 200 parts of water, continue high-speed shearing and stirring for a certain period of time After rapid cooling, discharge.

Embodiment 3

[0033] Present embodiment technical scheme is as follows:

[0034] 1. By mass, mix 90 parts of epichlorohydrin, 100 parts of methanol, 100 parts of water, and 110 parts of triethylamine, and react at 45°C for 3 hours.

[0035] 2. Then, after dispersing 100 parts of lignin in NaOH solution, add it to the above system, and continue to react for 2 hours to obtain a modified lignin emulsifier.

[0036] 3. Melt 400 parts of AKD wax in a water bath, slowly add the above modified lignin emulsifier solution, 7000r / min shear emulsification for 2 minutes, add 4 parts of sodium bicarbonate, 400 parts of water, continue high-speed shearing and stirring for a certain period of time After rapid cooling, discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com