Preparation method for negative ion organosilicon modified polyacrylate paper reinforcing agent

A technology of polyacrylate and paper strengthening agent, which is applied in the direction of adding strengthening agent, which can solve the problems of paper folding resistance and moisture resistance not being very good, not fully improved, paper printing dusting phenomenon, etc., to achieve monomer type Wide range of selection and composition, increased migration speed, ease of application and generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

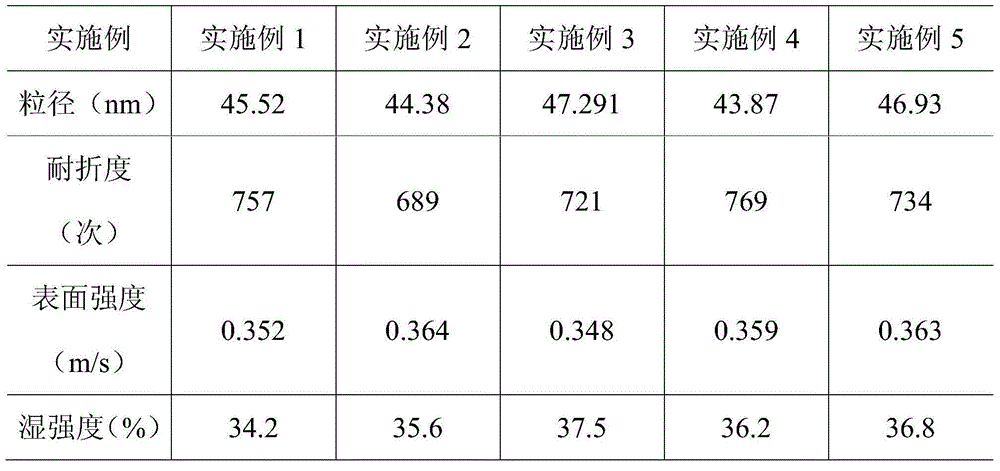

Examples

Embodiment 1

[0022] 1) In parts by mass, weigh 1 part of acrylic acid, 5 parts of hydroxyethyl methacrylate, 15 parts of butyl acrylate, 5 parts of methyl methacrylate, and 1 part of γ-methacryloyl Oxypropyltrimethoxysilane, 10 parts of isopropanol, 0.5 parts of azobisisobutyronitrile, 1.5 parts of triethylamine and 125 parts of deionized water;

[0023] 2) Add acrylic acid, hydroxyethyl methacrylate, butyl acrylate, methyl methacrylate, γ-methacryloxypropyl trimethyl to a four-necked dry flask equipped with a reflux condenser, air guide tube, and thermometer Oxysilane, isopropanol and azobisisobutyronitrile, then blowing nitrogen to raise the temperature to 70°C, reacting at 70°C for 4 hours under the protection of nitrogen to obtain system A;

[0024] 3) Cool system A to 25°C, then add triethylamine, neutralize for 30 minutes, then stir and add deionized water heated to 80°C at a speed of 1000 rpm, then increase the stirring speed and stir at a high speed Disperse for 0.5 hours to make ...

Embodiment 2

[0026] 1) In parts by mass, weigh 2 parts of acrylic acid, 7 parts of hydroxypropyl acrylate, 15 parts of propyl acrylate, 10 parts of butyl methacrylate, and 1 part of γ-methacryloyloxy Propyltrimethoxysilane, 12 parts of isopropanol, 0.7 parts of azobisisoheptanonitrile, 2.2 parts of triethylamine and 130 parts of deionized water;

[0027] 2) Add acrylic acid, hydroxypropyl acrylate, propyl acrylate, butyl methacrylate, γ-methacryloxypropyl trimethoxy to a four-necked dry flask equipped with a reflux condenser, air guide tube, and thermometer Silane, isopropanol and azobisisoheptanonitrile, then the temperature was raised to 75°C after passing through nitrogen, and reacted at 75°C for 5 hours under the protection of nitrogen to obtain system A;

[0028] 3) Cool system A to 30°C, then add triethylamine, neutralize for 30 minutes, then stir and add deionized water heated to 80°C at a speed of 1000 rpm, then increase the stirring speed and stir at a high speed Disperse for 0.5...

Embodiment 3

[0030] 1) In parts by mass, weigh 3 parts of acrylic acid, 10 parts of hydroxypropyl methacrylate, 20 parts of butyl acrylate, 10 parts of propyl methacrylate, and 2 parts of γ-methacryloyl Oxypropyltrimethoxysilane, 15 parts of isopropanol, 0.7 parts of dibenzoyl peroxide, 2.5 parts of triethylamine and 135 parts of deionized water;

[0031] 2) Add acrylic acid, hydroxypropyl methacrylate, butyl acrylate, propyl methacrylate, γ-methacryloxypropyl trimethylmethacrylate to a four-necked dry flask equipped with a reflux condenser, an air guide tube, and a thermometer Oxysilane, isopropanol and dibenzoyl peroxide, and then the temperature was raised to 85°C after passing through nitrogen, and reacted at 85°C for 5 hours under the protection of nitrogen to obtain system A;

[0032] 3) Cool system A to 35°C, then add triethylamine, neutralize for 30 minutes, then stir and add deionized water heated to 80°C at a speed of 1000 rpm, then increase the stirring speed and stir at a high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com