Emulsified high-alcohol degasifying agent for papermaking

A high-carbon alcohol and degassing agent technology, applied in defoamer and other directions, can solve the problems of increasing difficulty in the preparation process, thickening or gelation, affecting the process, etc., achieving good storage stability, reducing emulsification temperature, improving The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

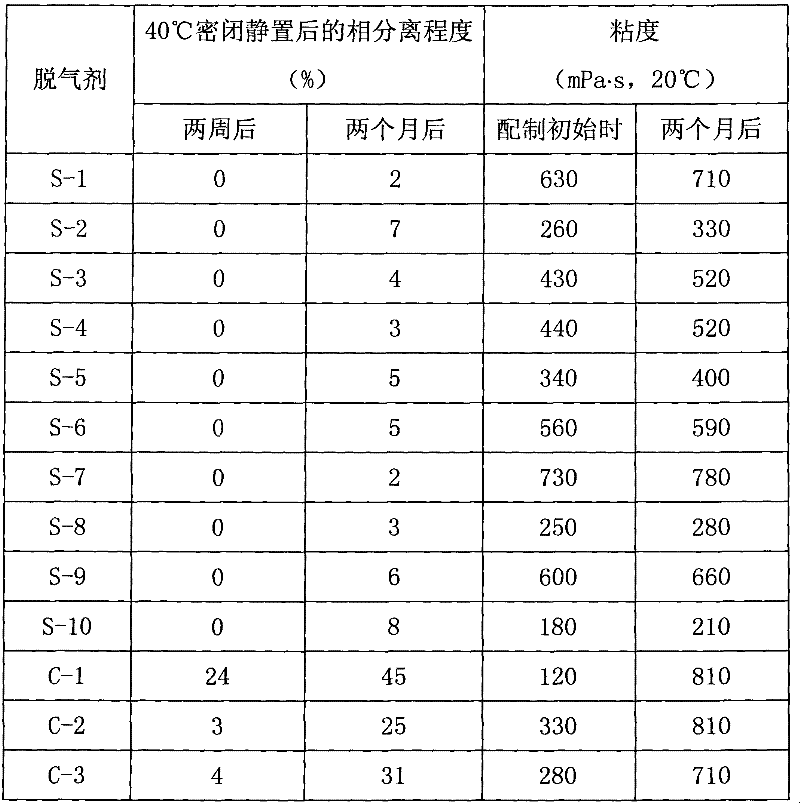

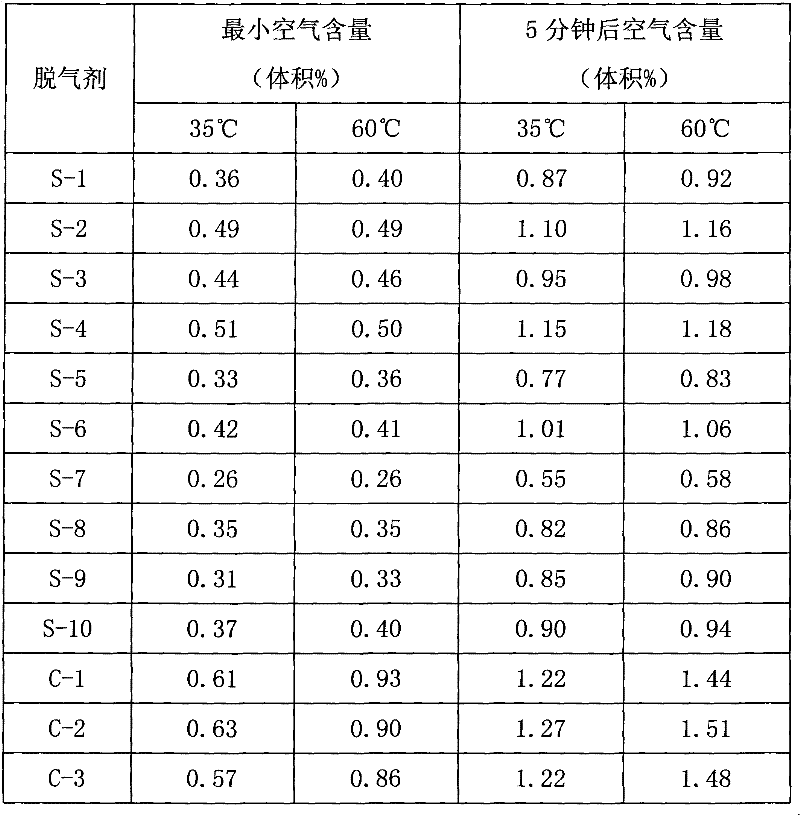

Examples

Embodiment 1

[0021] 45g lauryl alcohol (dodecyl alcohol), 36g glycerol trilaurate (glycerol-tri[dodecyl acid] ester), 54g dimethyl phthalate, 0.068g xanthan gum, 0.135 g water-soluble styrene-maleamic acid copolymer (maleamic acid mass content 30%, molecular weight 1000), 0.012g polyoxyethylene sorbitan fatty acid ester-60 and 0.012g sorbitan fatty acid ester -60 was added in the mixer, stirred at 60°C for 10 minutes, so that the components were uniformly mixed; then slowly added 94g of water to it, and continued to stir for 10 minutes to obtain emulsified high-carbon alcohol degassing agent S-1 for papermaking, which The composition is reported in Table 1.

Embodiment 2

[0023] 21g behenyl alcohol (behenyl alcohol), 40.5g behenyl behenate (behenyl alcohol behenate), 40.5g tridecane, 0.155g xanthan gum , 0.1g Brunei gum, 0.011g water-soluble styrene-maleamic acid copolymer (maleamic acid mass content 50%, molecular weight 3000), 5g sodium dodecylsulfonate, 5g octylphenol polyoxyethylene Ether-40 and 5g of nonylphenol polyoxyethylene ether-40 were added to the mixer, and stirred at 70°C for 10 minutes to make the components evenly mixed; then slowly added 216g of water to it, and continued to stir for 10 minutes to obtain the The composition of the emulsified high carbon alcohol degassing agent S-2 is recorded in Table 1.

Embodiment 3

[0025] With 30g cetyltriol, 35g glycerol trilaurate, 35g liquid paraffin, 0.15g gellan gum, 0.05g water-soluble styrene-maleamic acid copolymer (maleamic acid mass content 30%, molecular weight 1000), 1g of isooctyl alcohol polyoxyethylene ether phosphate-98 and 1g of castor oil polyoxyethylene ether-60 were added to the mixer, stirred at 70°C for 10 minutes, so that the components were mixed evenly; then slowly added 100g of water, and continue to stir for 10 minutes to obtain emulsified high-carbon alcohol degassing agent S-3 for papermaking, and its composition is recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com