Patents

Literature

42results about How to "Less prone to phase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose-based flexible heat storage composite material and preparation method thereof

ActiveCN113337252AStabilize cross-linking defectsLess cross-linking defectsHeat-exchange elementsCellulosePtru catalyst

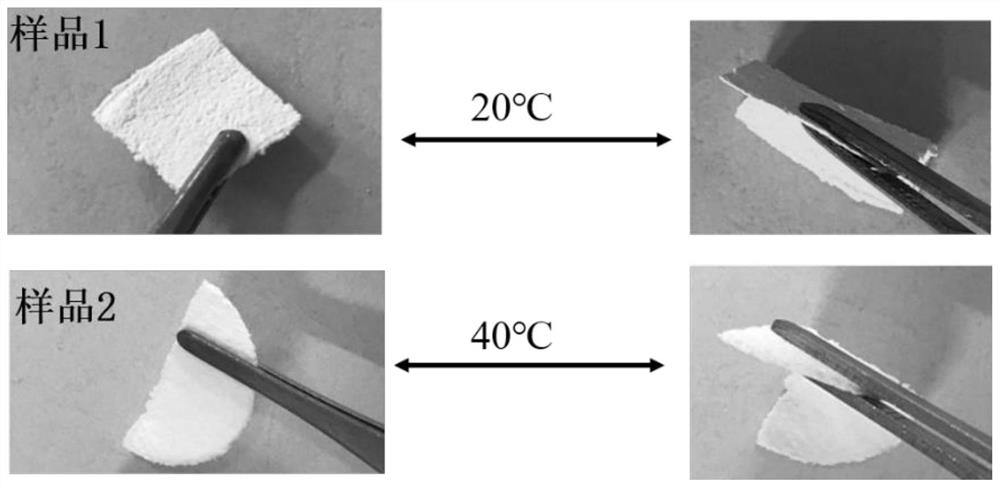

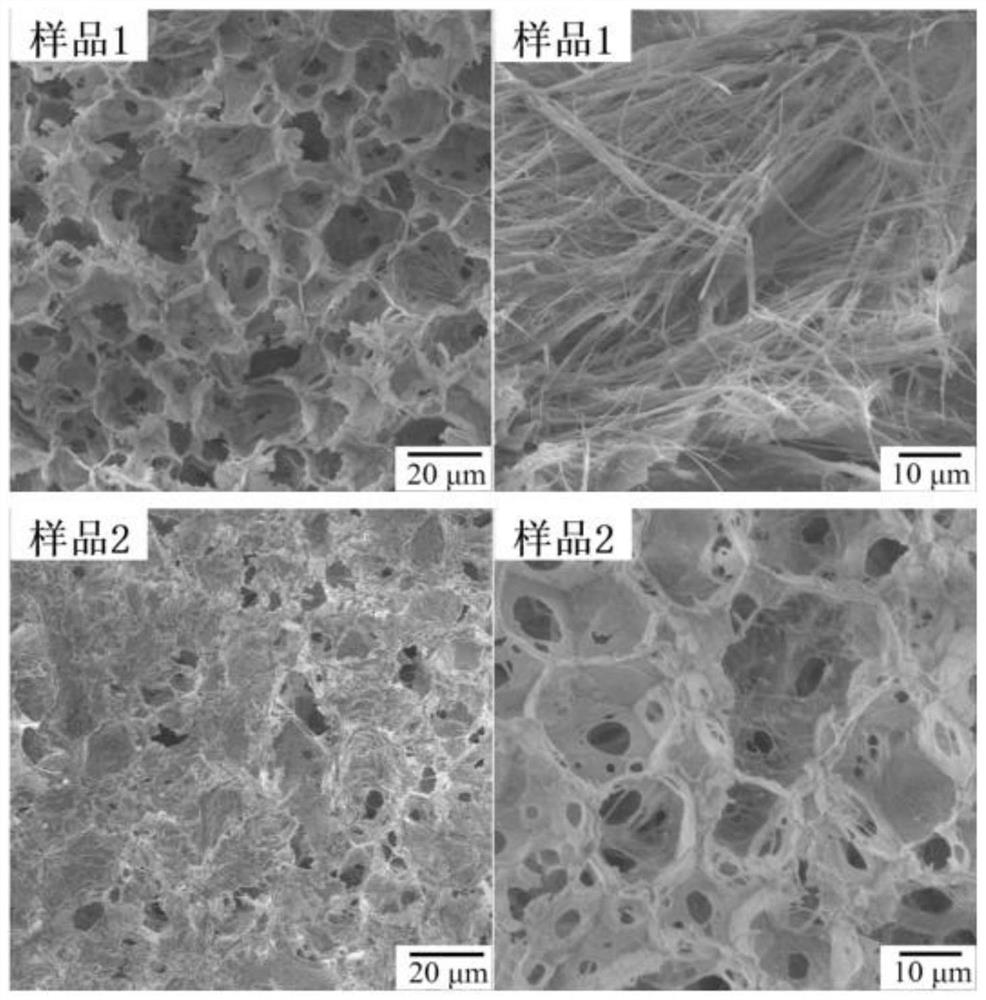

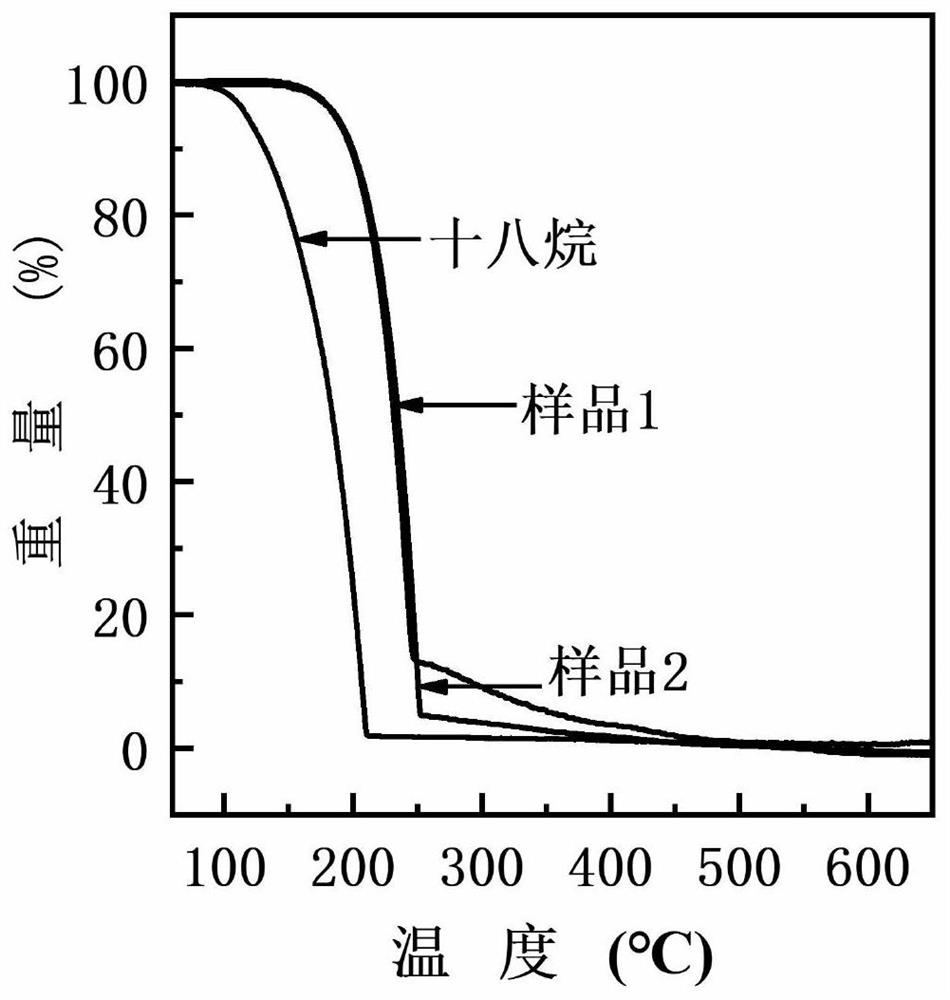

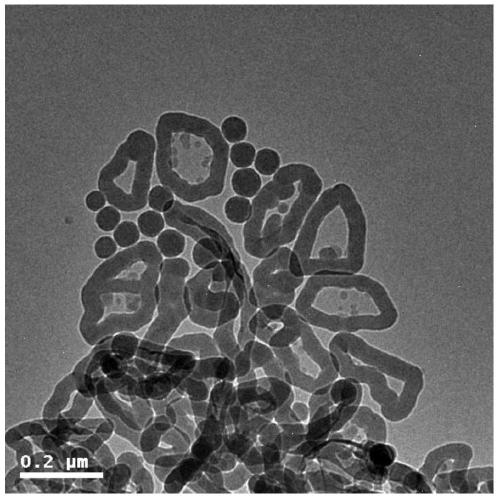

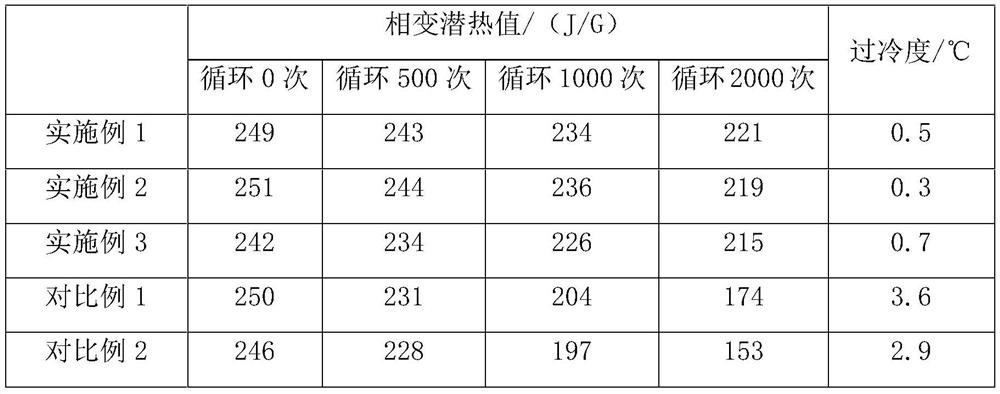

The invention provides a cellulose-based flexible heat storage composite material and a preparation method thereof, and the preparation method comprises the following steps: uniformly mixing an oil phase and a water phase to obtain an oil-in-water type high internal phase emulsion, wherein the oil phase is an organic phase change material, the water phase comprises a water-soluble emulsifier, a cellulose suspension and water; adding a cross-linking agent and a catalyst into the oil-in-water type high internal phase emulsion, realizing interfacial polymerization of the cellulose emulsion through heating, forming a cross-linked polymer at an interface, and obtaining the heat storage composite material through heating drying and freeze drying. The appearance of the heat storage composite material can be controlled through a mold for containing the high internal phase emulsion during polymerization, a nanofiber structure is arranged in the heat storage composite material, the heat storage density of the material after heating and drying can reach 200 J / g, the heat storage density of the material after freeze drying can reach 250 J / g, and the heat storage composite material has flexibility, can be curled and folded at the room temperature and the temperature of 40 DEG C or above and is good in heat conduction performance.

Owner:SUZHOU UNIV

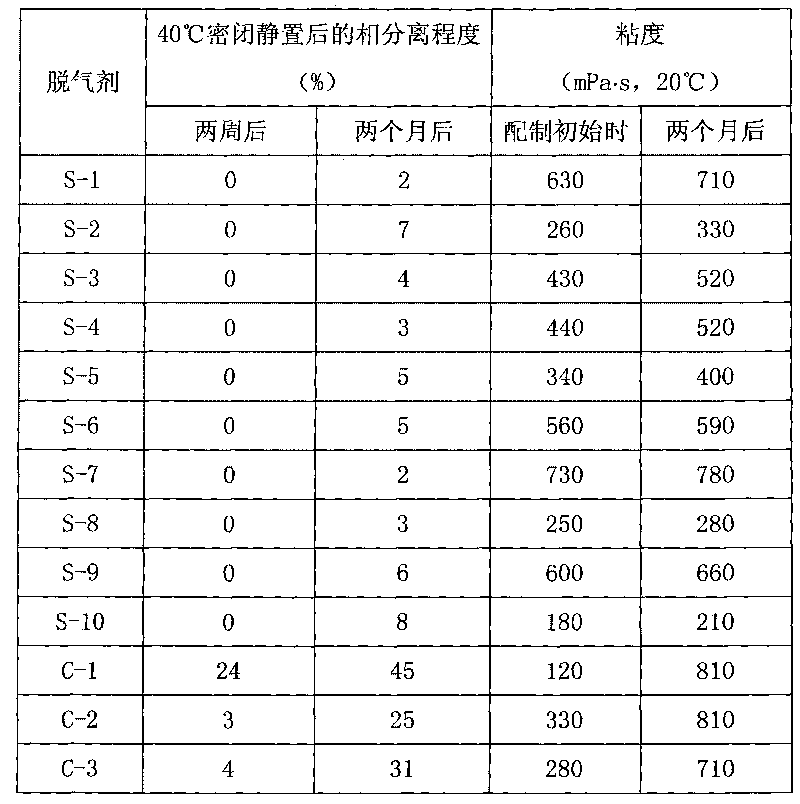

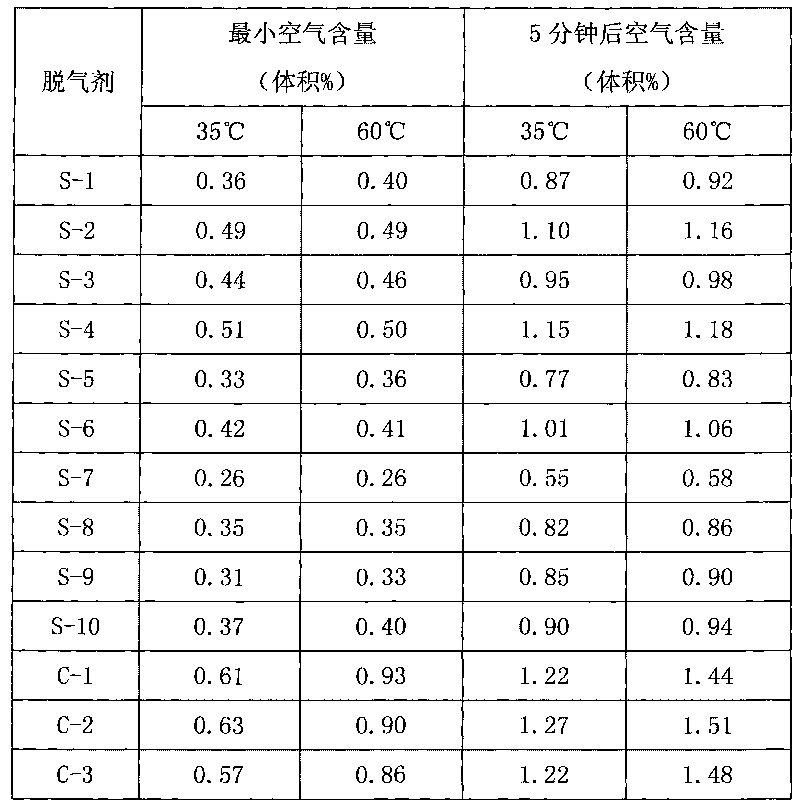

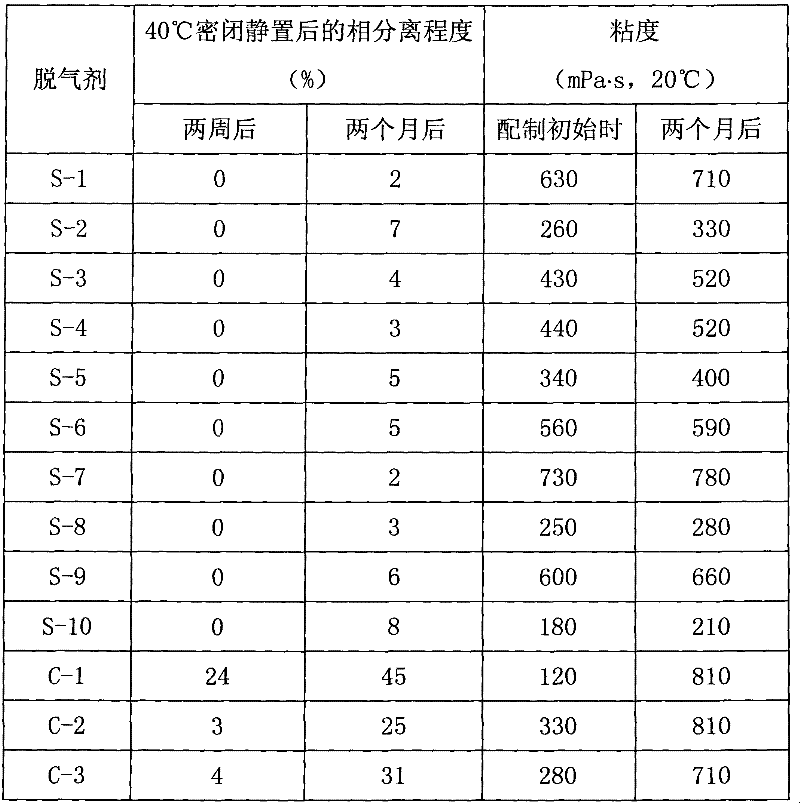

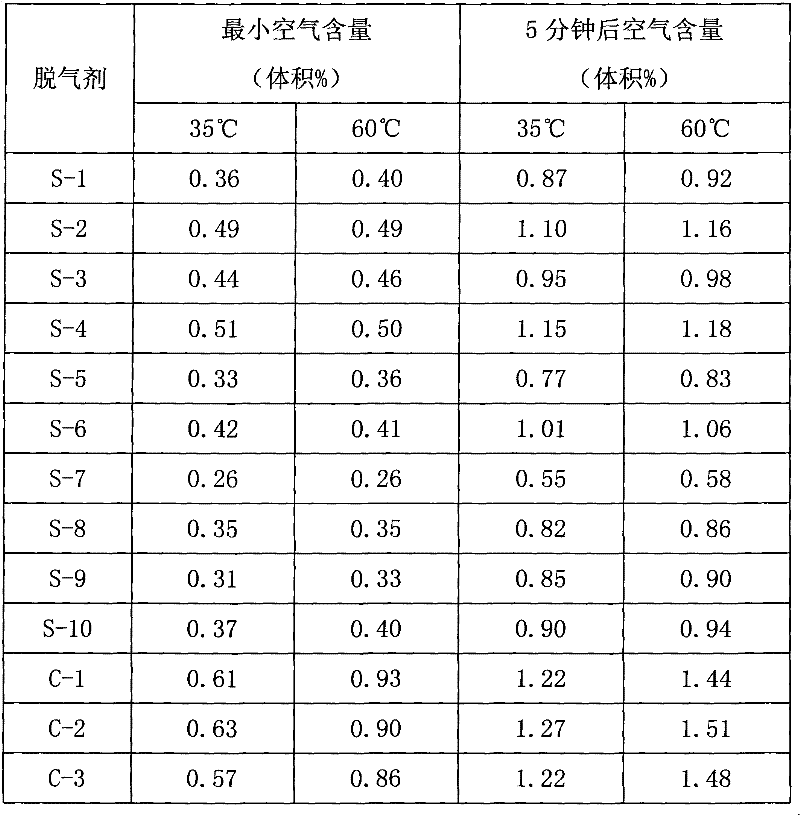

Emulsified high-alcohol degasifying agent for papermaking

The invention discloses an emulsified high-alcohol degasifying agent for papermaking. Based on the totally 100-percent weight of the components, the agent comprises the following components in percentage by weight: (1) 30 to 59 percent of degasifying active substance, (2) 0.01 to 5 percent of non-cationic surfactant and (3) 40 to 69 percent of water, wherein the degasifying active substance comprises the following components in percentage by weight: (A) 20 to 40 percent of high alcohols, (B) 40 to 20 percent of fatty acid ester, (C) 40 to 20 percent of low melting grease, (D) 0.05 to 0.25 percent of polysaccharide compound and (E) 0.01 to 0.1 percent of water-soluble styrene-maleamic acid copolymer which are added into 100 percent in percentage by weight. The emulsified high-alcohol degasifying agent for the papermaking has the advantages of good storage stability, good high-temperature degasifying property, moderate preparation condition and the like, and can be widely applied to a papermaking process in the papermaking industry and other industries to achieve highly-efficient degasifying and deforming effect.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

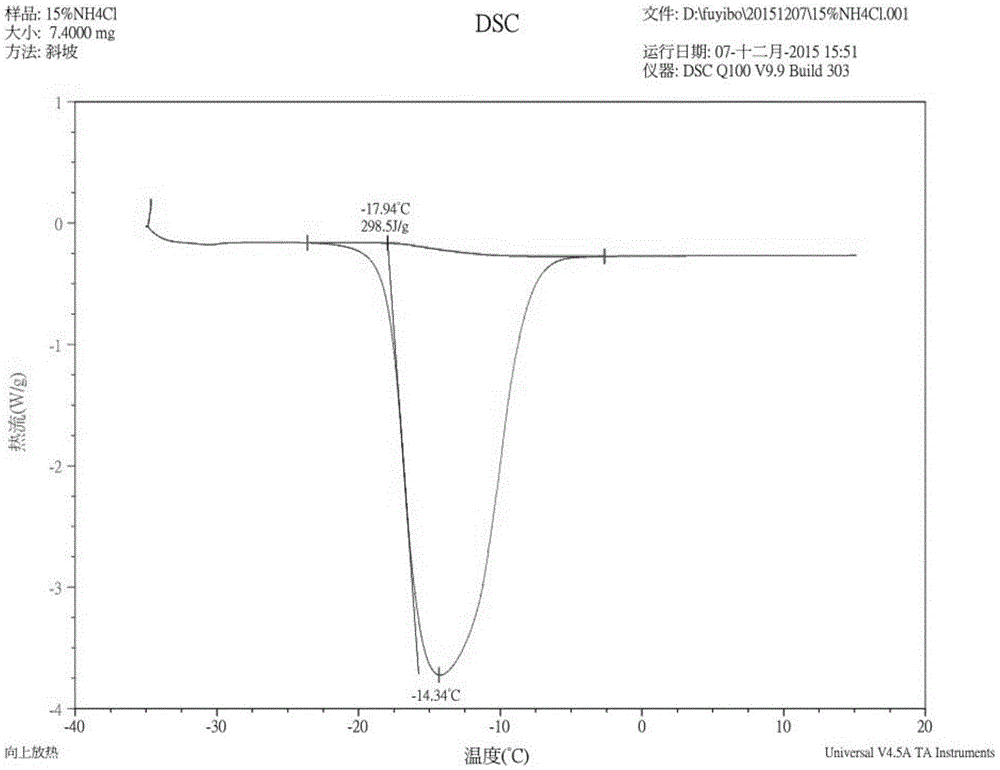

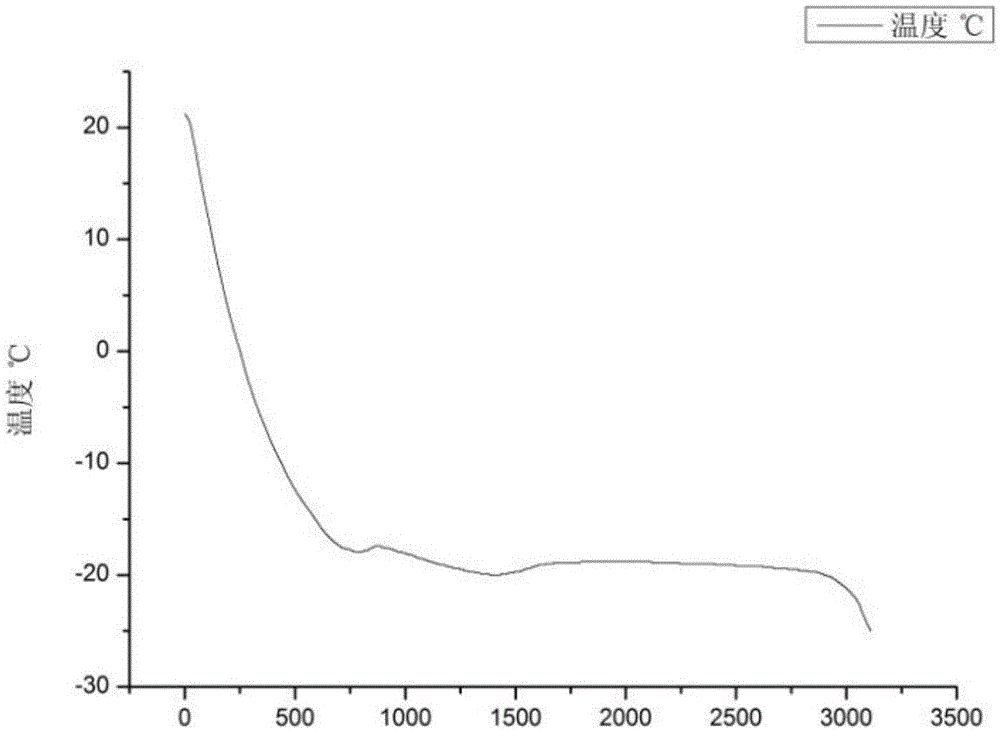

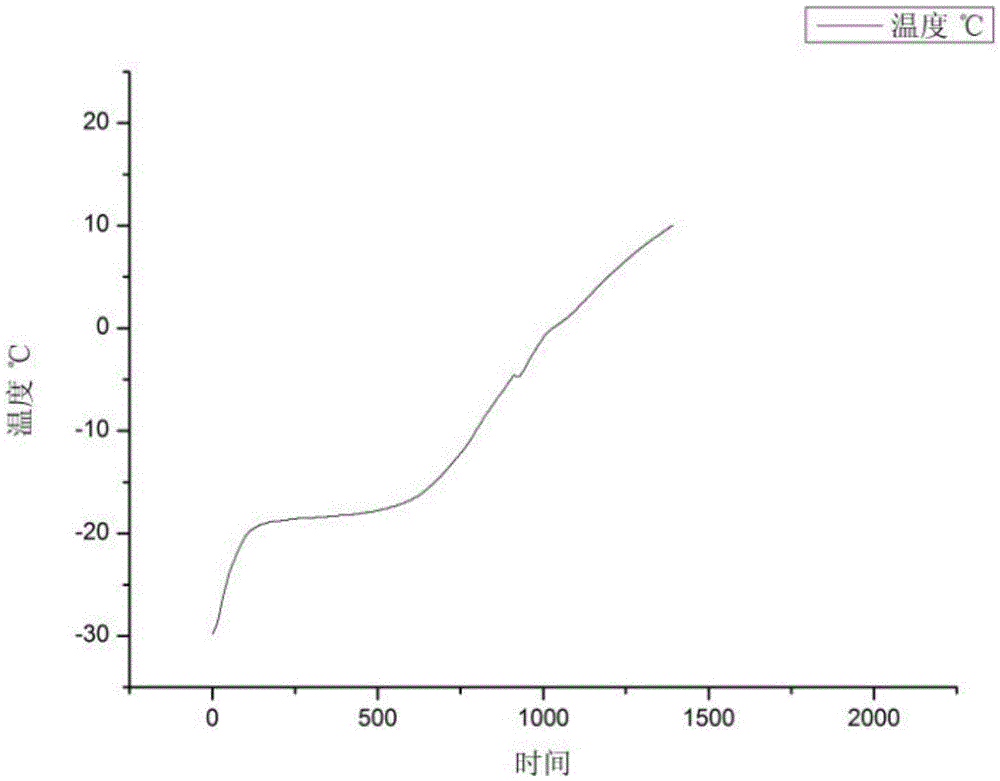

Low-temperature gel-state phase-changing cold storage agent and preparation method thereof

InactiveCN105601819AReduce fluidity and subcoolingAvoid heat damageHeat-exchange elementsChemistryEnvironmentally friendly

The invention provides a low-temperature gel-state phase-changing cold storage agent which comprises a konjac glucomannan-crylic acid-acrylamide grafted copolymer and a phase-changing cold storage material. The invention also provides a preparation method of the low-temperature gel-state phase-changing cold storage agent. The preparation method provided by the invention has the beneficial effects that the manufacturing cost is low, and the prepared cold storage agent is high in latent heat, long in cold storage time, non-toxic and odorless, and environmentally friendly.

Owner:SHENZHEN POLYTECHNIC

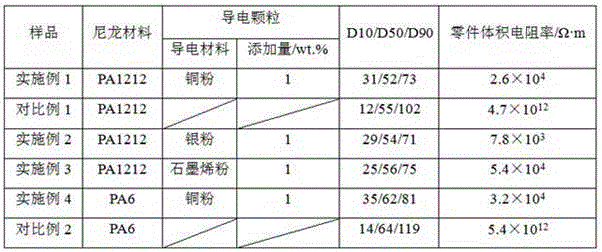

Nylon conductive powder preparation method for laser sintering

ActiveCN106832910AUniform particle size distributionUniform and concentrated particle size distributionMicrosphereSolvent

The invention provides a nylon conductive powder preparation method for laser sintering. The nylon conductive powder preparation method comprises the following steps: adding conductive particles and a surfactant into an alcohol-water solvent; stirring, dispersing, drying and grinding to obtain surface-activated conductive particles; then, adding the surface-activated conductive particles into a nylon solution; heating, cooling and crystalizing; uniformly coating the inside of the nylon microspheres with the conductive particles, filtering, drying and screening to obtain a nylon powder material coated with the conductive particles. By adopting the nylon conductive powder preparation method, the prepared nylon conductive powder has uniform and concentrated particle size distribution, the conductive particles are distributed more uniformly, the powder is prevented from being separated easily in a using process, and the conductive performance and other relevant performance of nylon three-dimensional parts are improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

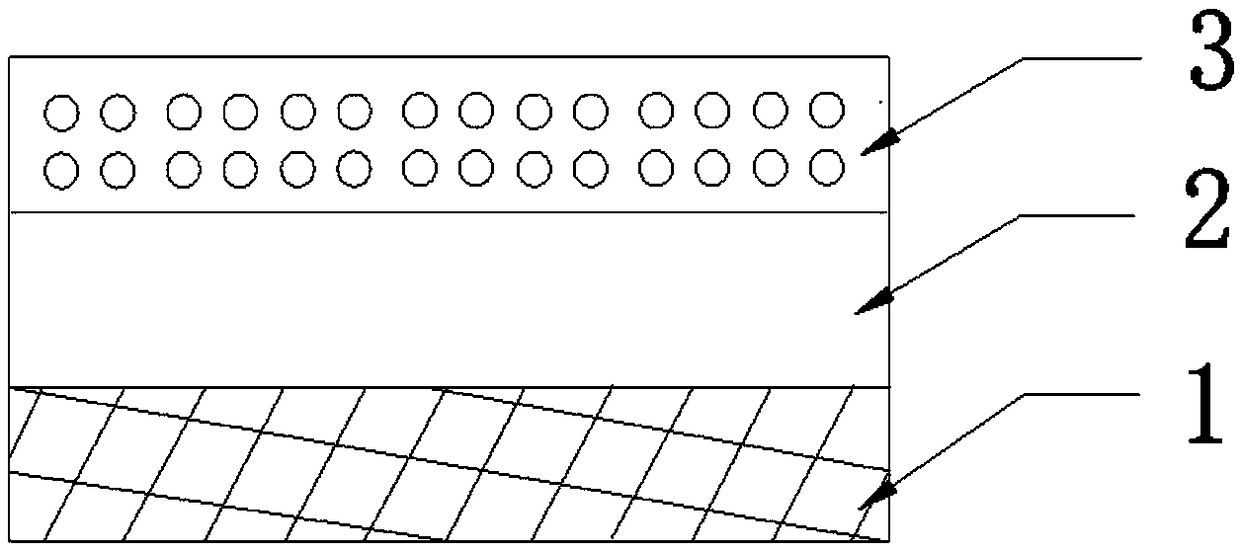

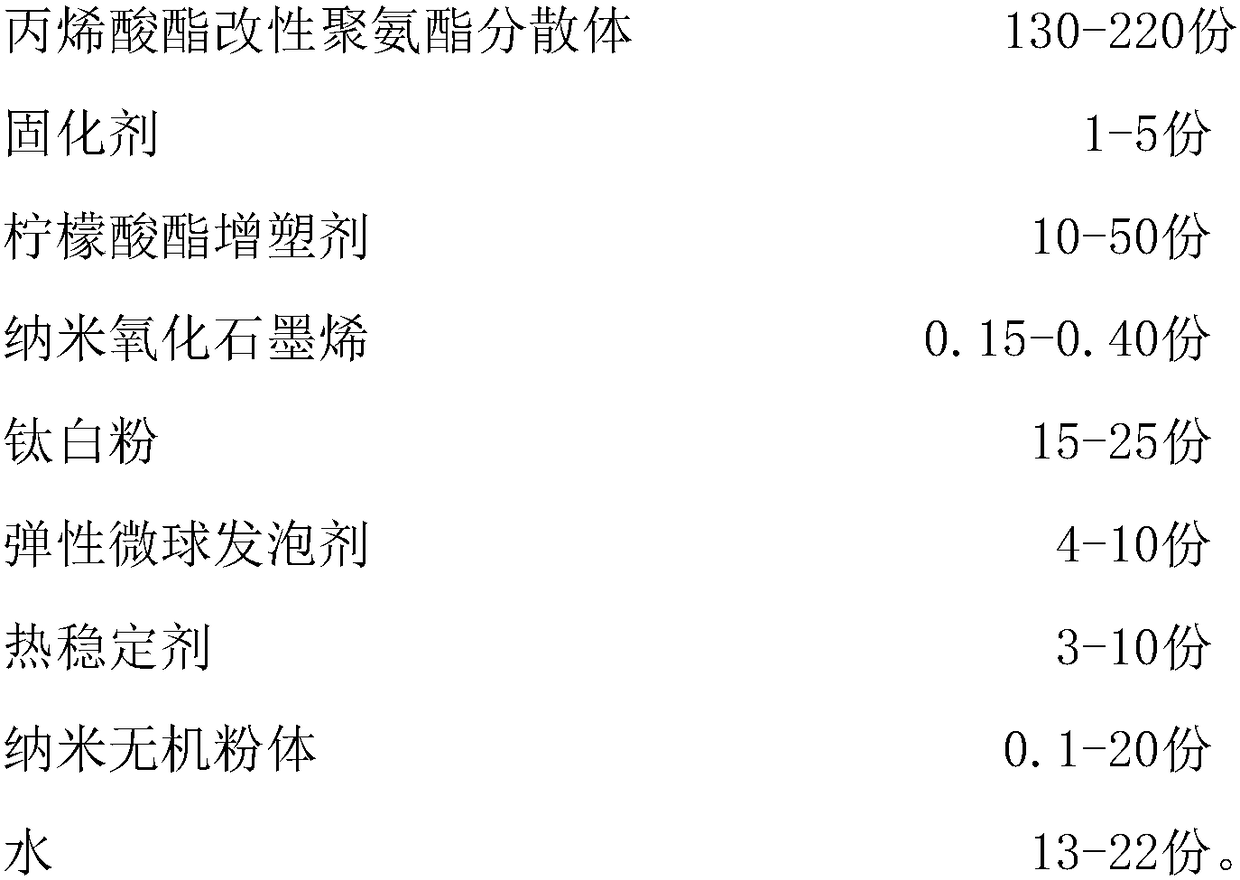

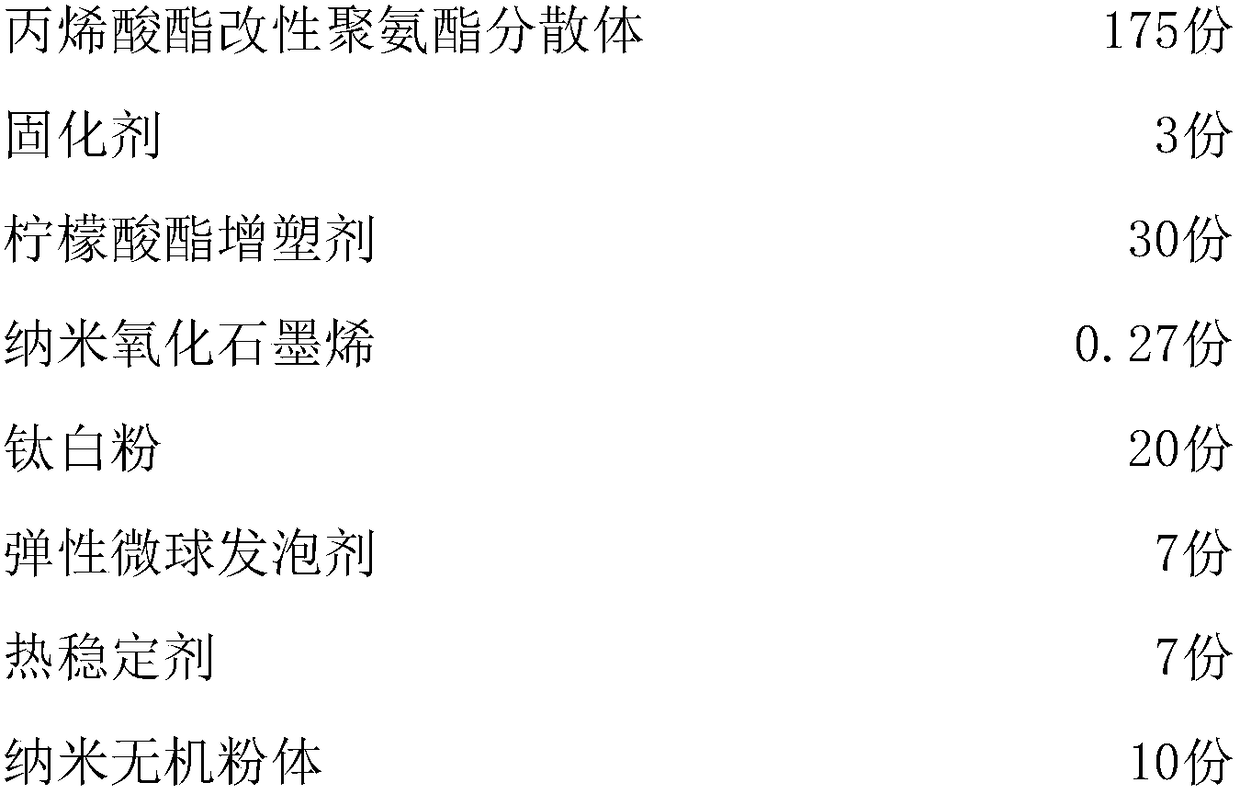

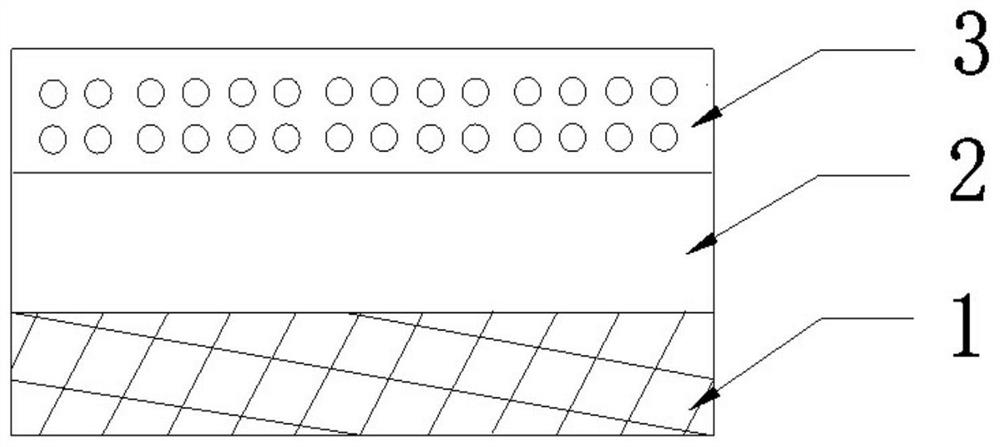

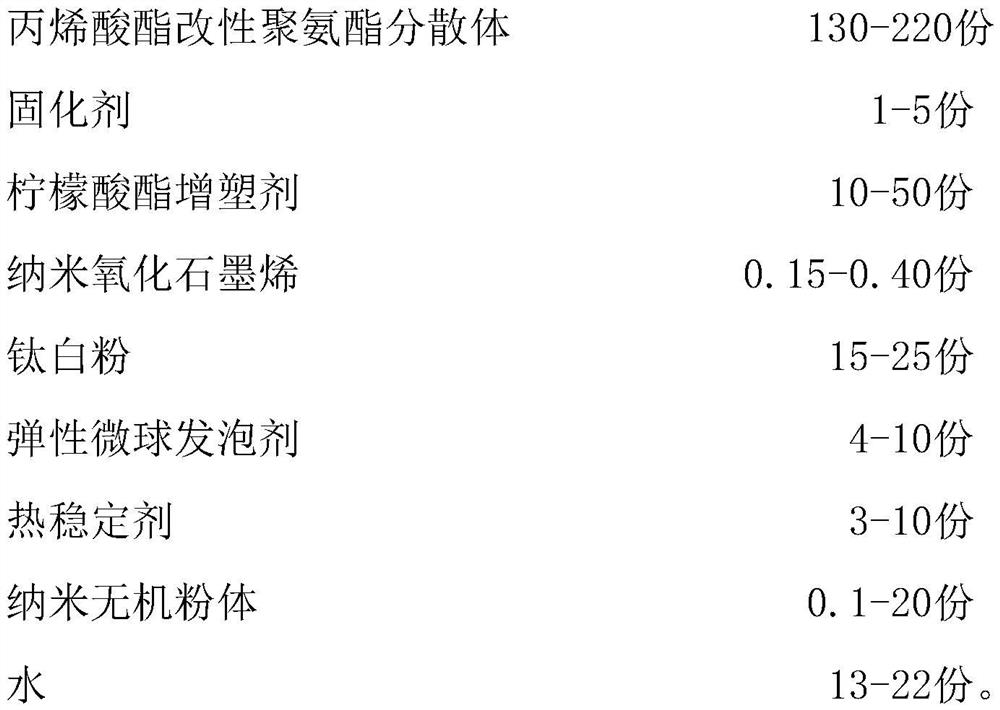

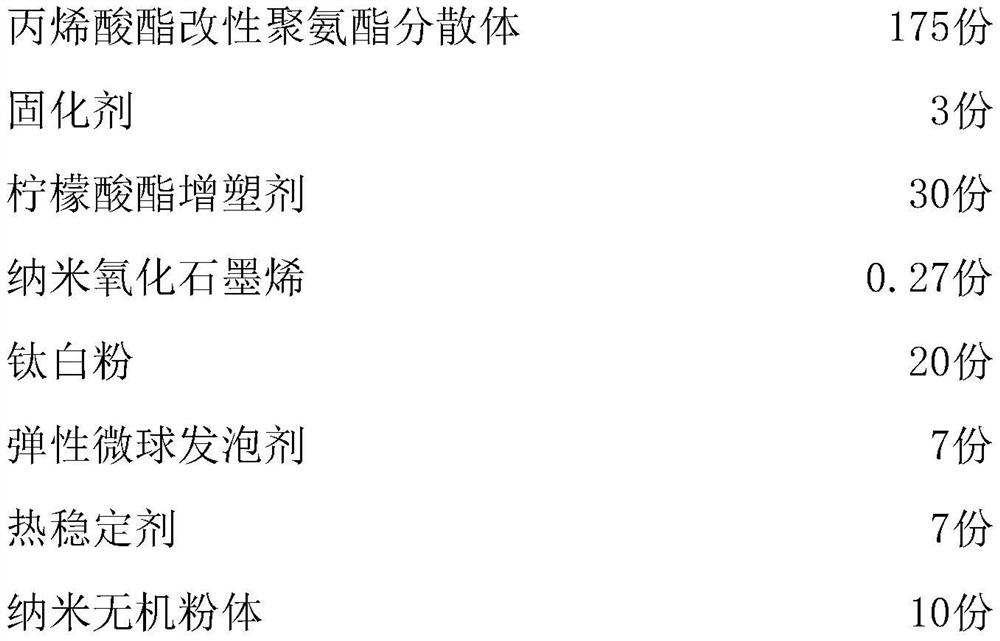

Anti-scratching foaming wall cloth

ActiveCN108978236AGood adsorption performanceUniform thicknessTextiles and paperActivated carbonWoven fabric

The invention relates to the technical field of wall cloth, and particularly relates to anti-scratching foaming wall cloth, comprising an activated carbon non-woven fabric layer, an anion layer compounded on the activated carbon non-woven fabric layer, and an anti-scraping foaming layer compounded on the anion layer, wherein the anti-scratching foaming layer is formed by anti-scratching foaming slurry, and the anti-scratching foaming slurry contains the following materials: an acrylic ester modified polyurethane dispersion, a curing agent, a citrate plasticizer, nanometer graphene oxide, titanium dioxide, an elastic microsphere foaming agent, a heat stabilizer, nanometer inorganic powder, and water. The wall cloth disclosed by the invention has the advantages of high hardness, scratching resistance and difficulty in falling-off of the coating, and the wall cloth disclosed by the invention also comprises the activated carbon non-woven fabric layer, which has strong 'physical adsorption'and 'chemical adsorption' effects, can effectively adsorb harmful gas, and is remarkable in antitoxin and deodorization effects.

Owner:GUANGDONG YULAN GRP

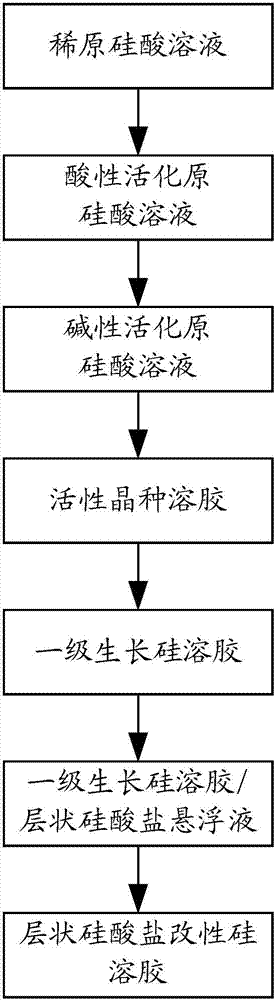

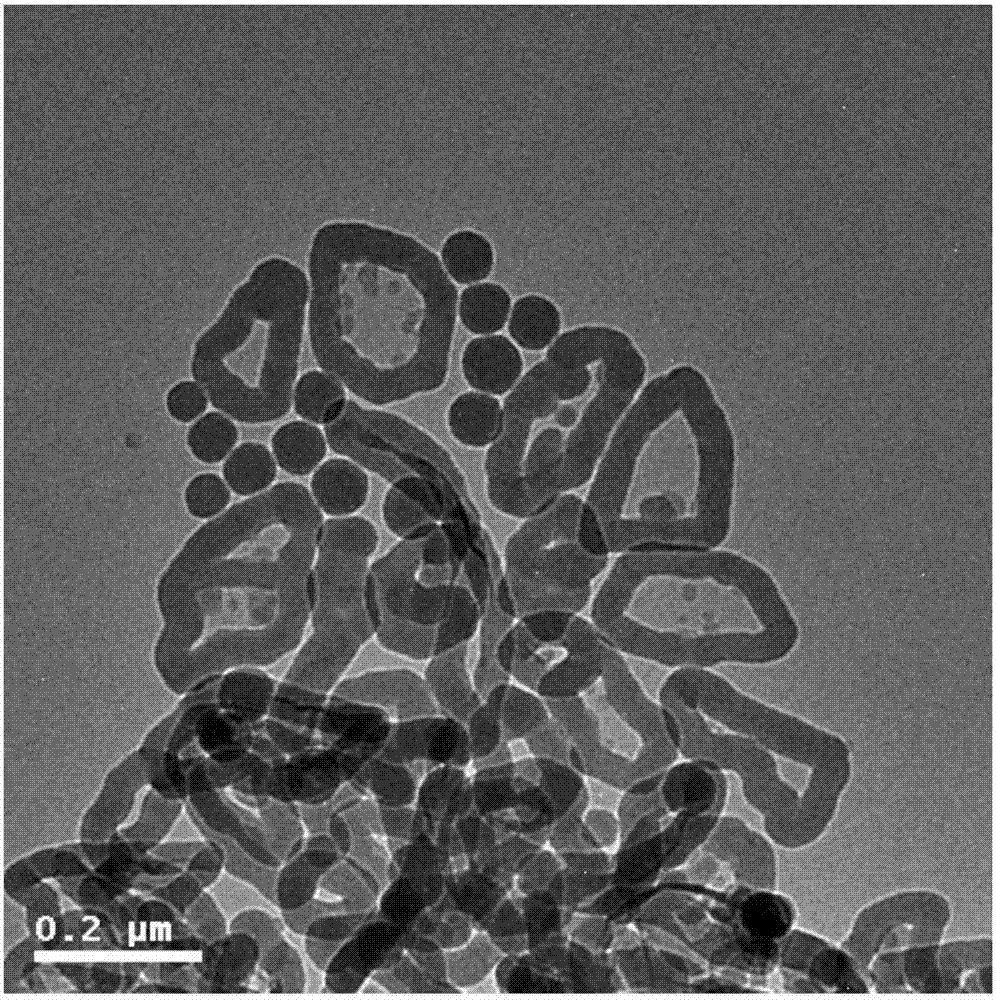

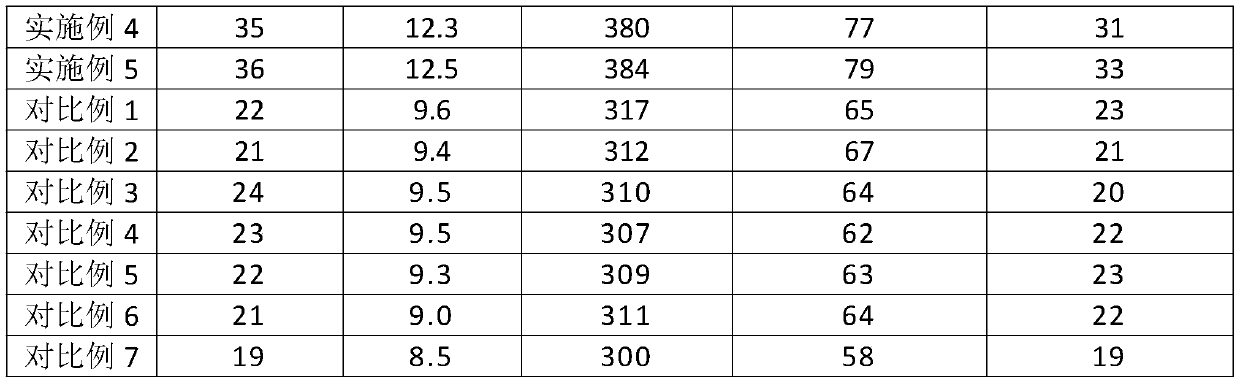

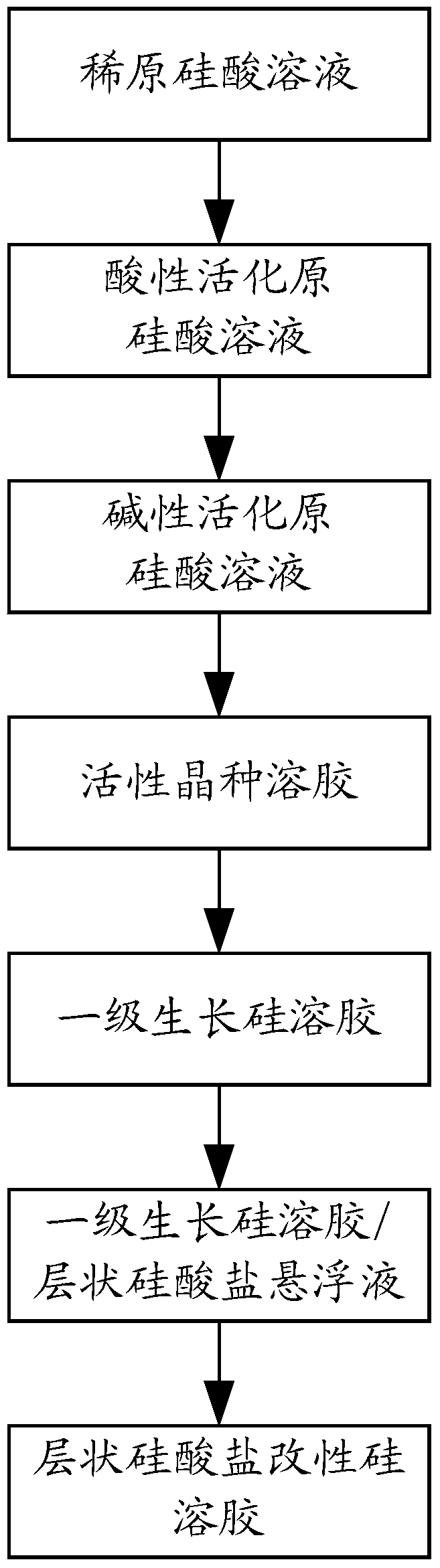

Method for layered silicate modified silica sol

ActiveCN107487774AReduce manufacturing costSimple processAluminium silicatesOrganic solventWorking environment

The invention provides a method for a layered silicate modified silica sol, wherein a dilute orthosilicic acid solution, an acidic activated orthosilicic acid solution, an alkaline orthosilicic acid solution, an active crystal seed sol, a first-stage growth silica sol and a first-stage growth silica sol / layered silicate suspension are prepared so as to finally obtain the layered silicate modified silica sol. According to the present invention, the cheap water glass is used as the raw material, and all the processes are carried out in the water phase without the organic solvents, such that the production cost is substantially reduced, the working environment is safe and health, and the method has advantages of simple process, low cost, and environment protection.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Flame-retardant low-temperature-resistant organic silicon rubber and preparation method thereof

The invention discloses flame-retardant and low-temperature-resistant organic silicon rubber Which is characterized in that it comprises the following raw materials in parts by weight: 60 to 80 partsof vinyl-terminated fluorosilicone rubber, 30 to 40 parts of N-vinylphthalimide modified hyperbranched polysiloxane, 10 to 15 parts of benzimidazole-5, 6-dicarboxylic acid / amino-terminated polyurethane polycondensate, 10 to 20 parts of chloropropyl polysiloxane, 10 to 20 parts of filler, 3 to 5 parts of initiator and 2 to 5 parts of coupling agent. The invention also discloses a preparation methodof the flame-retardant low-temperature-resistant organic silicon rubber. Compared with commercially available products, the flame-retardant and low-temperature-resistant organic silicon rubber disclosed by the invention is better in low temperature resistance, more excellent in wear resistance, fire resistance, flame retardance and weather resistance, higher in hardness and strength, higher in resilience and better in oil resistance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

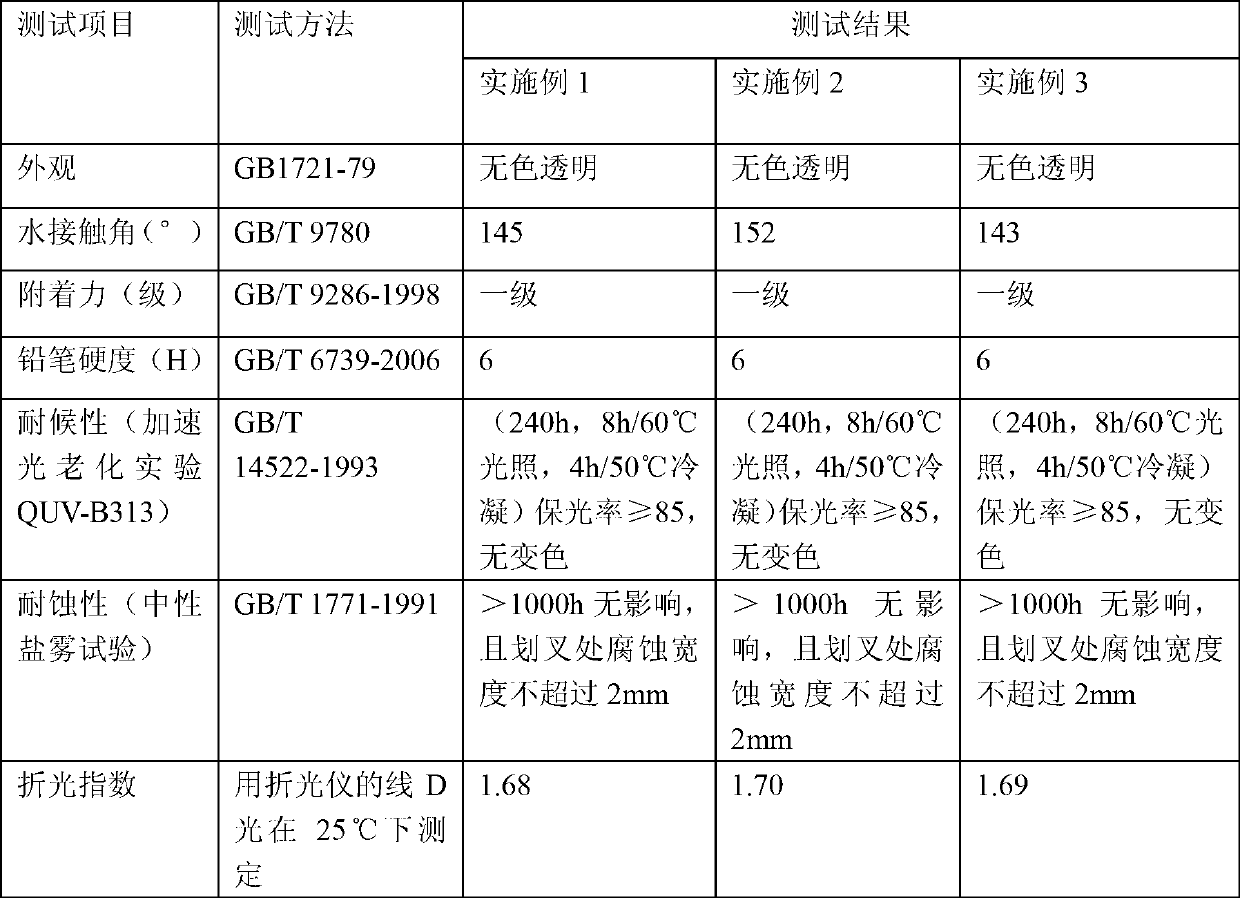

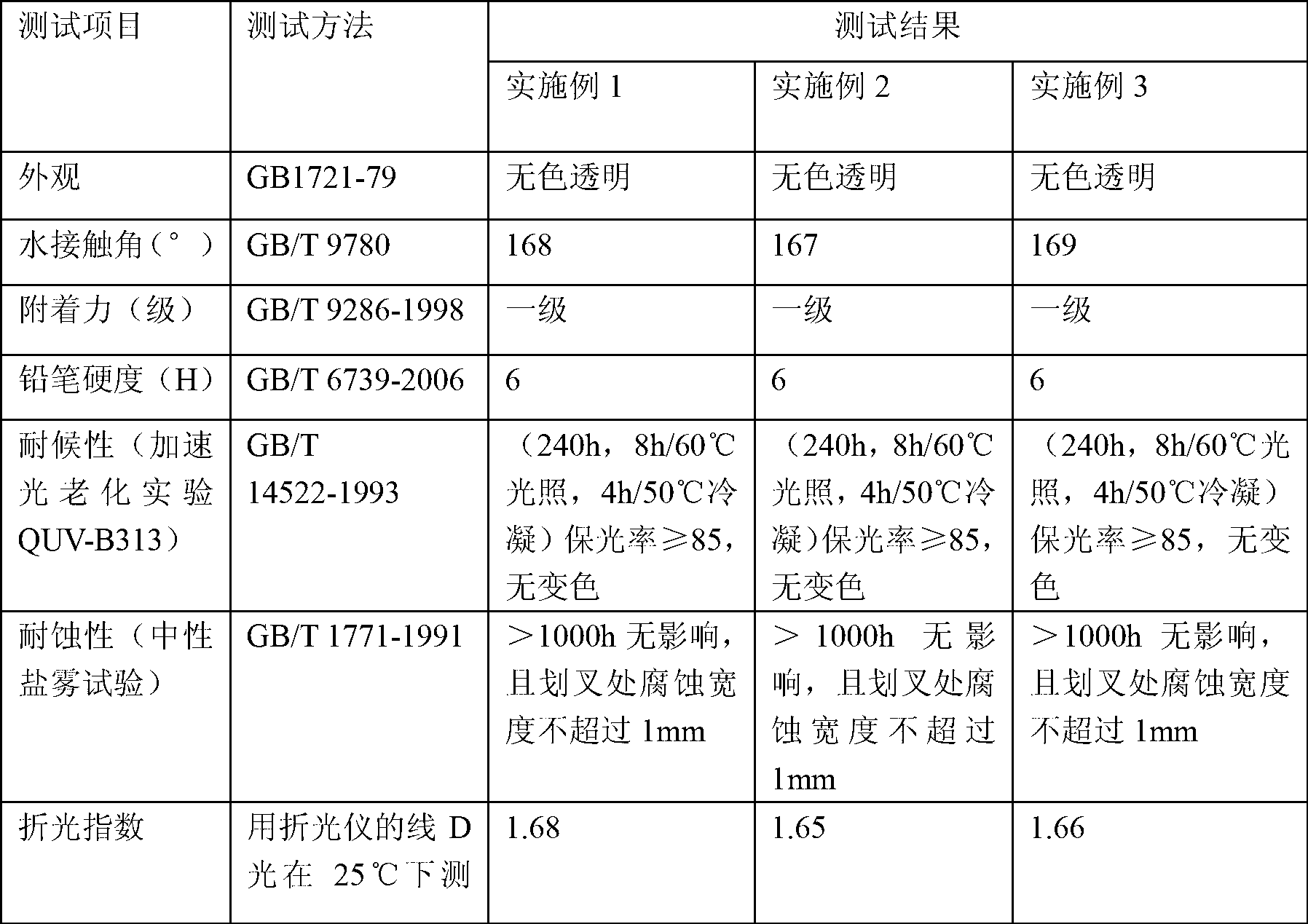

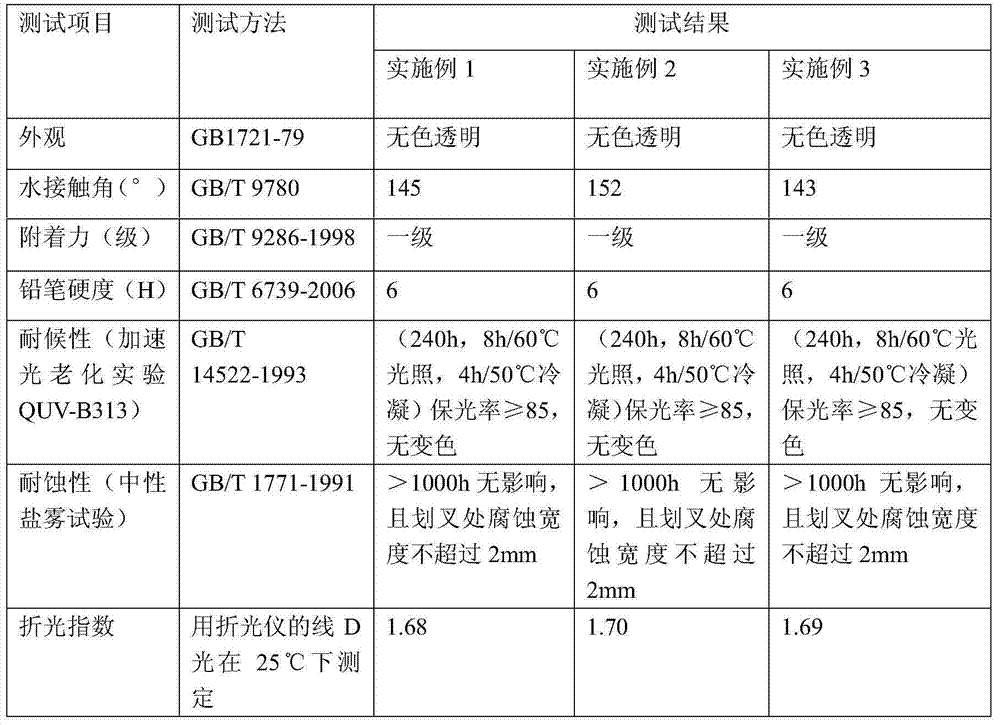

Organic-inorganic hybrid organosilicone electronic packaging glue and preparation method thereof

The invention provides organic-inorganic hybrid organosilicone electronic packaging glue and a preparation method thereof. A reaction system comprises tetramethoxysilane, a solvent consisting of absolute ethyl alcohol and isopropanol in a mass proportion of 7:(2-5), and a catalyst formed by mixing 2-amino-2-methyl-1-propanol with tetramethylammonium hydroxide, wherein the catalyst is added by two steps, and dodecafluoroheptyl trimethoxysilane is simultaneously introduced, and a film formed finally by the prepared organosilicone electronics packaging glue has the characteristics of strong hydrophobicity, soiling resistance, corrosion resistance, strong coated substrate adhesive force, and high refraction rate; and the preparation method is simple in preparation process and low in cost, and the process is easily controlled.

Owner:GUANGZHOU GLORYSTAR CHEM +2

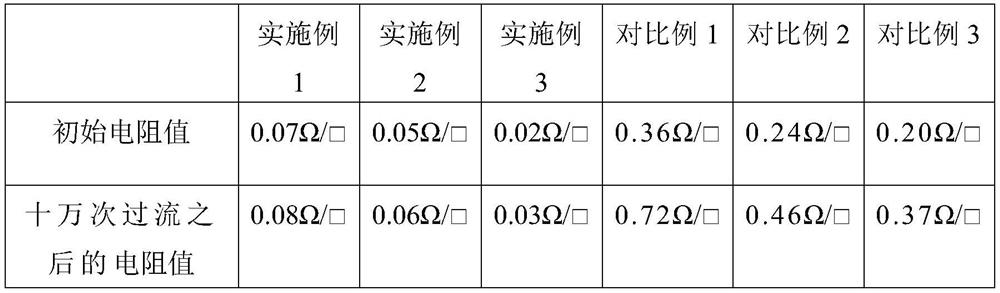

Graphene heating ink, preparation method and application thereof

ActiveCN112521796AGood film formingImprove basic performanceInksHeating element materialsPolymer scienceResin matrix

The invention discloses graphene heating ink, a preparation method and application thereof. The graphene heating ink comprises a resin matrix, conductive filler, an assistant and a solvent, wherein the conductive filler comprises graphene, the resin matrix is composed of an organic polymer and polysilazane in a mass ratio of 1:0.08-1.5, and the graphene heating ink further comprises a cross-linking agent; the preparation method comprises the following steps of: stirring and dispersing graphene in a powder form and polysilazane in a polysilazane solution form for fully mixing, and then adding the rest raw materials under stirring to obtain the graphene heating ink. The invention also relates to an electric heating film prepared from the ink, on the premise that excellent conductivity at a low temperature is guaranteed, the characteristic that the resistance is greatly improved at a high temperature is achieved, then self-temperature-limiting is achieved, meanwhile, when the electric heating film returns to a normal temperature, the resistance value of a material is not greatly changed, and reversibility is good, therefore, the recycling performance and the safety of the electric heating film are improved.

Owner:SU ZHOU CSTAR MATERIAL TECH CO LTD

Acrylic resin/organosilicon hybrid composite electronic potting adhesive and preparation method thereof

ActiveCN103012690AImprove impact resistanceGood acid and alkali resistanceGraft polymer adhesivesCross-linkAcrylic resin

The invention provides an acrylic resin / organosilicon hybrid composite electronic potting adhesive and a preparation method thereof. A fluoride-containing hybrid silica sol / fluoride-containing polyacrylate integrated high-performance composite electronic potting adhesive is prepared by in-situ emulsion polymerization; and the formed composite electronic potting adhesive is in a shell-core structure using fluoride-containing inorganic-organic hybrid silica sol as the core and fluoride-containing polyacrylate as the shell. The coated film formed by the shell-core structure composite electronic potting adhesive has favorable impact resistance, acid / alkali resistance, heat resistance and abrasion resistance, and also has the advantages of favorable film-forming properties, favorable blanching resistance and high storage stability. A certain amount of organosilane MEMO is introduced into the polyacrylate to further enhance the glossiness of the coated film; and the formed Si-O-Si cross-linked network has high stability and can not easily produce aggregation of large-size sol particles.

Owner:GUANGZHOU GLORYSTAR CHEM

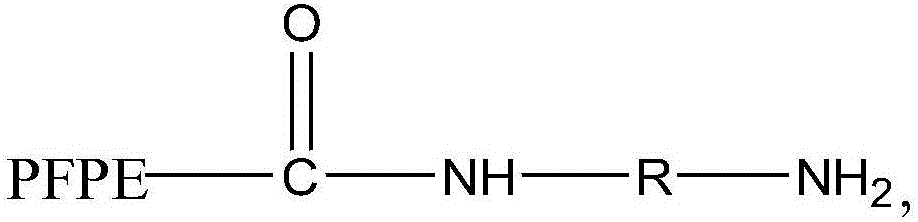

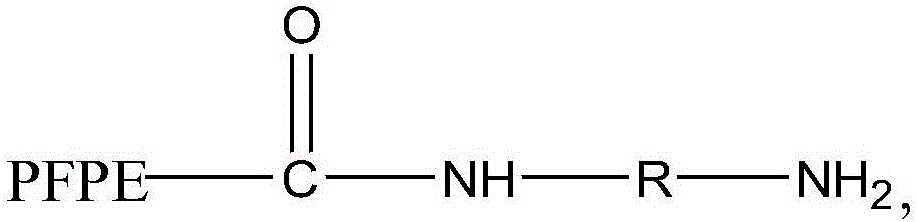

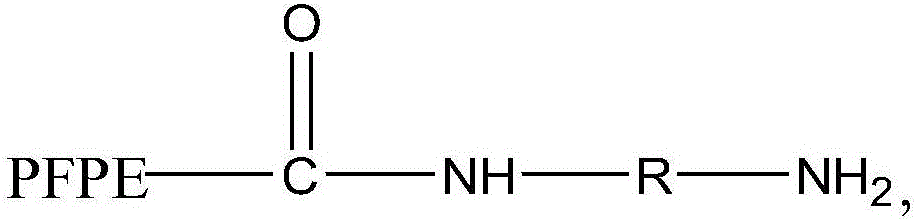

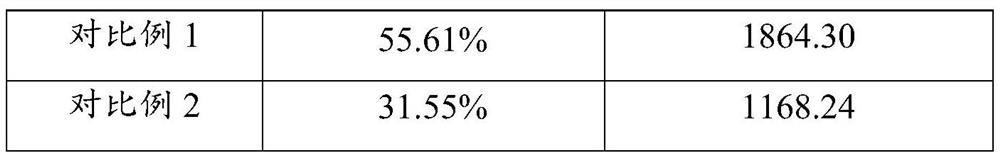

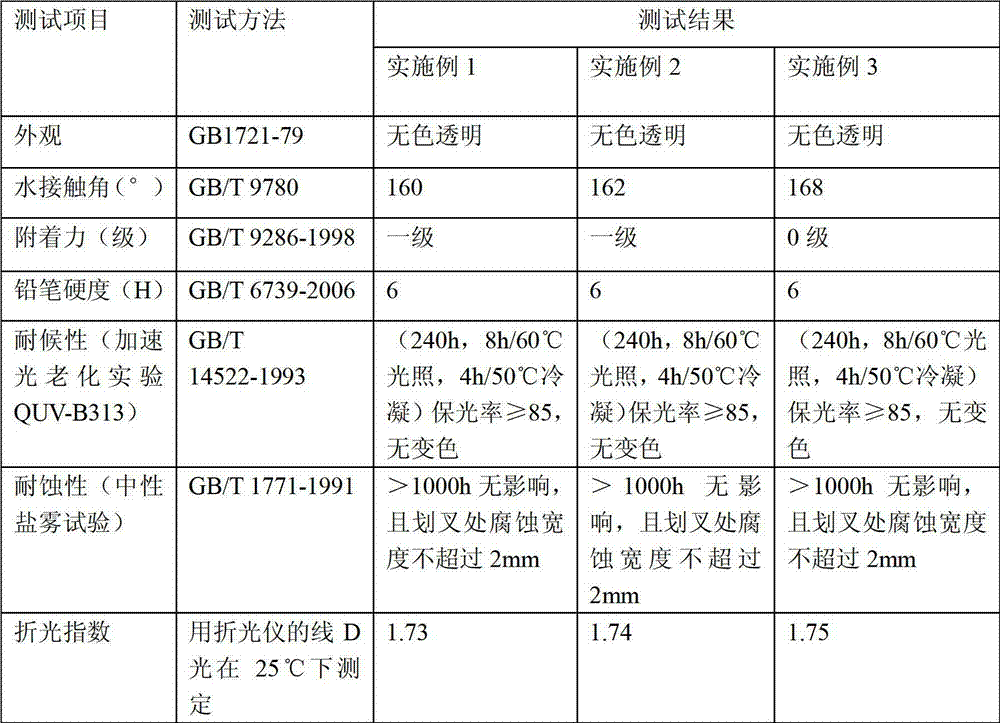

Epoxy resin curing agent, preparation method thereof and epoxy resin

The invention provides an epoxy resin curing agent. The epoxy resin curing agent is characterized in that a structural formula is shown as follows, wherein PFPE refers to a perfluoropolyether chain segment, one or multiple repetitive units of -CF2CF2O-, -CF2CF(CF3)O-, -CF2O-, -CF(CF3)O-, -CF2CF2CF2O- and -C(CF3)2O- are contained in the chain segment, molecular weight of the epoxy resin curing agent is 300-10000, and R refers to fatty or aromatic divalent group which contains fatty group and aromatic group with at least two carbon atoms. Compared with related technology, the epoxy resin curing agent has the advantages of high heat resistance, high weatherability, high waterproofness, high flexibility, high impact resistance and high environment friendliness.

Owner:湖南天氟新材料有限公司

Polyethersulfone enhanced composite material and preparation method of polyethersulfone enhanced composite material

The invention discloses a polyethersulfone enhanced composite material and a preparation method of the polyethersulfone enhanced composite material. The composite material disclosed by the invention is prepared from the following raw materials in parts by weight: 1.0 to 15.0 parts of basalt fiber, 85.0 to 99.0 parts of polyethersulfone, 1 to 3 parts of a coupling agent and 10 to 25 parts of an activating agent; wherein the basalt fibers contain barium phosphate; the activating agent is one or more of ethylenediamine phosphate, propylene diamine phosphate and sodium fluorosilicate; the composite material has excellent performance and the polyethersulfone composite material is easily popularized and applied in all fields.

Owner:DEYANG LIJIU YUNZHI KNOWLEDGE PROPERTY OPERATIONS CO LTD

Blood fat adsorbent and preparation method thereof

ActiveCN112569909AImprove adsorption efficiencyCoupling reaction promotionOther chemical processesEpoxyGlycine

The invention provides a blood fat adsorbent and a preparation method thereof. The method comprises the following steps: firstly, carrying out activation reaction on an adsorption carrier to obtain anepoxy group-containing activated carrier; then adding a blood fat adsorption ligand into a glycine-sodium hydroxide buffer solution to obtain a ligand solution; mixing the obtained epoxy group-containing activated carrier with a tertiary amine reagent, then adding the mixture into a ligand solution, mixing and stirring to carry out a coupling reaction, and after the reaction is completed, carrying out solid-liquid separation, cleaning and drying to obtain the blood fat adsorbent. According to the invention, the tertiary amine reagent is added into the coupling reaction system, the tertiary amine reagent is firstly adsorbed on the surface of the epoxy group-containing activated carrier, and then the coupling reaction is carried out in the glycine-sodium hydroxide buffer solution ligand solution, so that the coupling reaction efficiency and the ligand utilization rate can be improved, the adsorption efficiency of the adsorbent is improved, and the production cost is reduced.

Owner:WUHAN RUIFA MEDICAL DEVICES CO LTD

Silicon hybrid composite coating electronic adhesive and preparation method thereof

ActiveCN102964983BHigh transparencyUniform size distributionHyaluronic acid coatingsChitin coatingsAdhesiveRefractive index

The invention provides a silicon hybrid composite coating electronic adhesive and a preparation method thereof. The preparation method comprises the following steps: under the action of acid catalysts which are respectively added in multiple steps, performing catalytic reaction on ethyl orthosilicate, PDMS (polydimethylsiloxane) and methyltriethoxysilane to form sol A; and compounding the sol A and chitosan to form the novel silicon hybrid composite coating electronic adhesive. The prepared coating electronic adhesive has favorable comprehensive properties; a coated film formed by the coating electronic adhesive has excellent hydrophobicity, favorable stain resistance and corrosion resistance, high adhesive force onto a coated substrate, high refracting index, fine mechanical property and good oxygen barrier property; and the preparation method is simple in preparation technique, easy to control in technical process and low in cost.

Owner:GUANGZHOU GLORYSTAR CHEM

Epoxy anticorrosive paint, and preparation method thereof

ActiveCN110157331AViscosity has not changedViscosity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxyViscosity

The invention discloses an epoxy anticorrosive paint, and a preparation method thereof. The epoxy anticorrosive paint comprises, by weight, 100 parts of modified epoxy resin, 80 to 120 parts of a pigment filler, 2 to 5 parts of a dispersant, 15 to 20 parts of a film forming auxiliary agent, 1 to 3 parts of a leveling agent, and 1 to 3 parts of an antifoaming agent. According to the preparation method, epoxy resin is modified without influencing the viscosity of epoxy resin, active anticorrosive functional groups are introduced into the epoxy resin through grafting, so that the epoxy resin paint is provided with excellent scrubbing resistance, shedding of the anticorrosive function groups is not easily caused, and the corrosion resistance of the epoxy resin paint can be maintained for a long term.

Owner:上海博歌建材有限公司

Double-phase-change energy storage self-cleaning wall material and application thereof

InactiveCN109913177AIncrease energy densityHigh phase change enthalpyConstruction materialHeat-exchange elementsMicrosphereDouble phase

The invention discloses a double-phase-change energy storage self-cleaning wall material and an application thereof. The material is a plate comprising a first nanocapsule, a second nanocapsule and abuilding carrier material, and the surface of the plate is a hydrophobic material layer; a super-hydrophobic coating is a substance formed after a coated dispersing liquid is dried; the dispersing liquid is a strawberry-like organic / inorganic hybrid microsphere dispersing liquid; each of the first nanocapsule and the second nanocapsule comprises a main material, a monomer, an initiator and an emulsifier; the first nanocapsule and the second nanocapsule are different in composition of the main material and are two different higher alkanes including hexadecane, heptadecane, octadecane and eicosane. The defects that traditional emulsifiers cannot be recovered and attached to water bodies after demulsification to cause water pollution are overcome; more flexible temperature control can be realized; the super-hydrophobic coating applied to the surface can prevent pollution and resist bioadhesion, and the surface self-cleaning purpose can be achieved.

Owner:HEBEI UNIV OF TECH

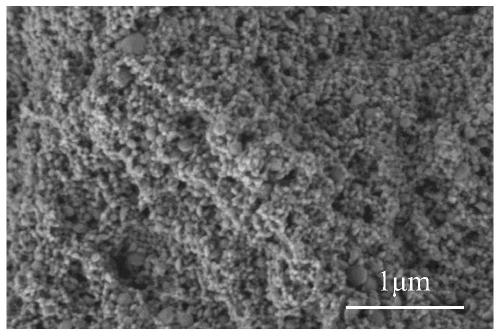

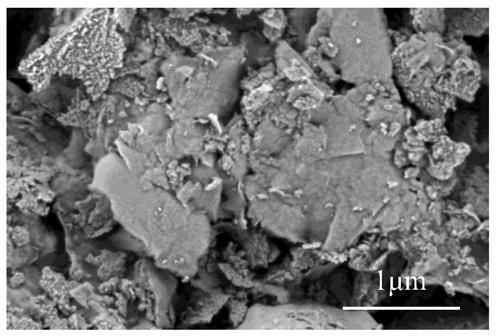

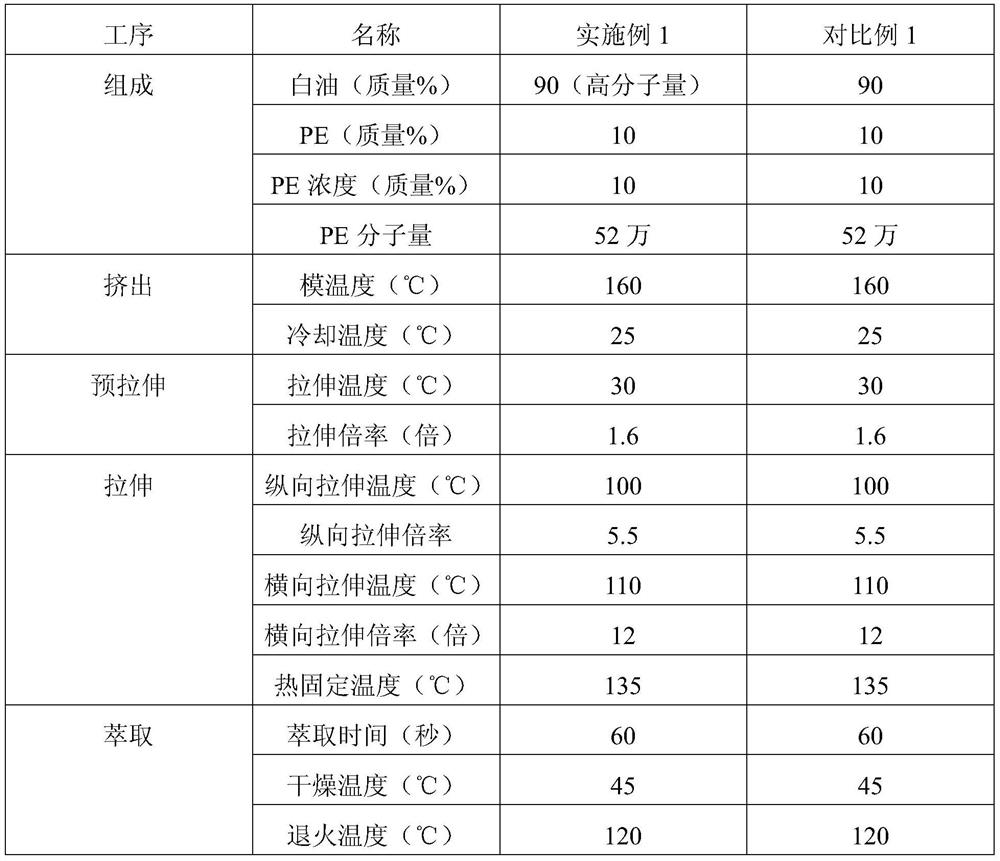

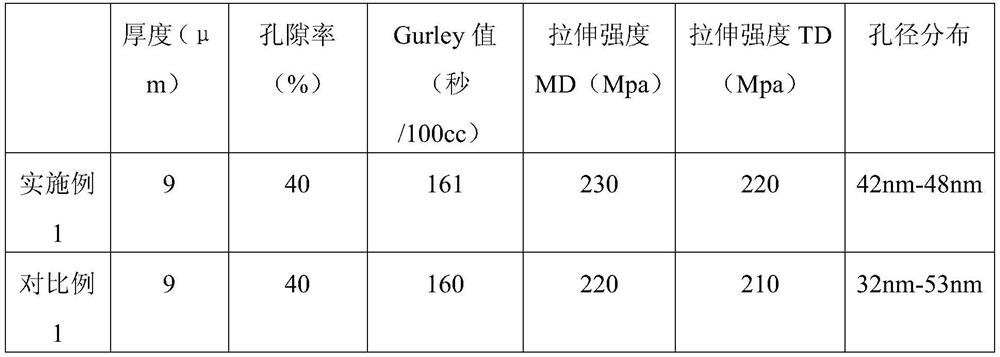

Diaphragm with uniform pore diameter and preparation method of diaphragm

InactiveCN111933873AStretch smoothlyUniform pore size distributionSecondary cellsCell component detailsPolyolefinPhysical chemistry

The invention discloses a diaphragm with uniform pore diameter and a preparation method of the diaphragm. The pore diameter of the diaphragm ranges from 40nm to 50nm, the porosity ranges from 20% to 90%, and the diaphragm thickness ranges from 2mu m to 27mu m. According to the invention, high-molecular-weight white oil is used as a solvent; the molecular weight of conventional white oil is generally about 400, and when the white oil is used as a processing aid and the molecular weight of the white oil is relatively large, phase separation is not liable to occur after polyolefin and the white oil are dissolved and mixed, so that the diaphragm is more uniform during stretching, and through subsequent extraction, the diaphragm can be more consistent in pore diameter and more uniform in pore size distribution.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Emulsified high-alcohol degasifying agent for papermaking

ActiveCN101718055BGood storage stabilityGood high temperature degassing performanceDefoamers additionPapermakingWater soluble

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Anti-shearing flame-retardant glass fiber composite material

InactiveCN111303640ADevice dependency is smallHigh preparation efficiency and yieldFlame resistanceBis epoxide

The invention discloses an anti-shearing flame-retardant glass fiber composite material. The material is characterized by being prepared from the following components in parts by weight: 70 to 90 parts of hyperbranched borate, 4 to 8 parts of epoxy fluorophenyl sulfuryl calixpyrrole, 20 to 30 parts of glass fiber, 1 to 3 parts of 2, 2'-dihydroxy-4, 4'-dimethoxybenzophenone-5, 5'-disulfonic acid, 1to 2 parts of coupling agent and 0.2 to 0.5 part of phosphorus pentoxide. The invention also discloses a preparation method of the anti-shearing flame-retardant glass fiber composite material. The anti-shearing flame-retardant glass fiber composite material disclosed by the invention is better in comprehensive performance, better in performance stability, higher in shearing force strength, more excellent in heat resistance and flame retardance and easier to process and form.

Owner:邓华斌

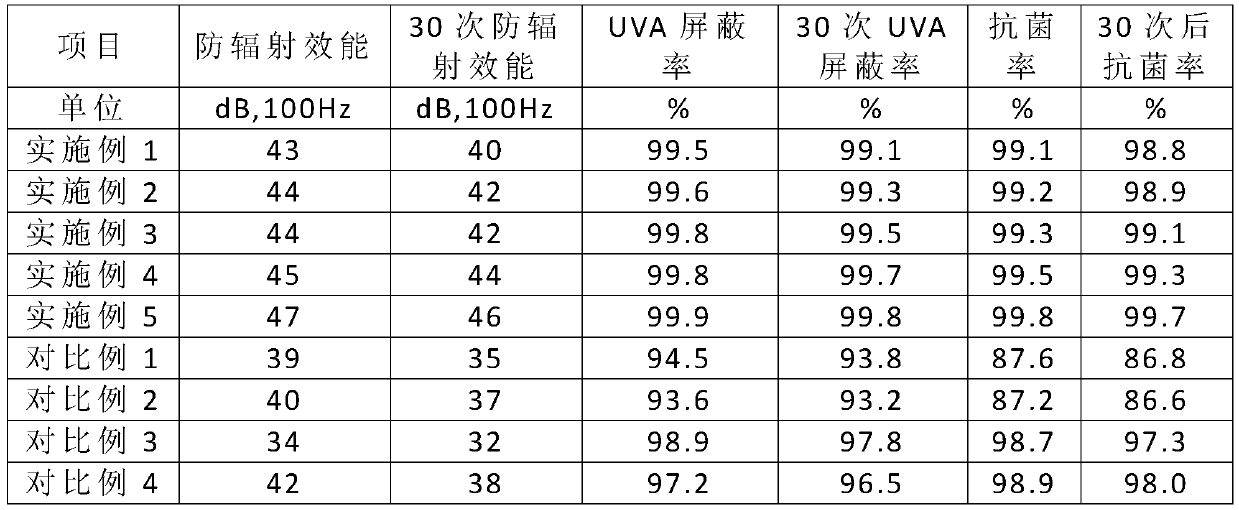

Radiation-proof antibacterial fabric

The invention discloses a preparation method of a radiation-proof antibacterial fabric. The preparation method comprises the steps of: S1, preparation of a 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazole amine / limonene-1 2-epoxide / bis(triethoxysilyl)ethylene copolymer; S2, preparation of a thieno[3, 2-b]thiophene-3, 6-dicarboxylic acid / amiphenazole polycondensate; S3, preparation of a fiber yarn; and S4, weaving and after-finishing. The invention further discloses the radiation-proof antibacterial fabric prepared according to the preparation method of the radiation-proof antibacterial fabric. The radiation-proof antibacterial fabric disclosed by the invention is good in ultraviolet aging resistance and flame retardance, remarkable in radiation-proof, antibacterial and antistatic effects, excellent in air permeability and moisture absorption performance, and excellent in wearing comfort and performance stability.

Owner:顾正明

A kind of PBT aluminum-plastic composite film and its production process

ActiveCN111016335BSimple production processReduce energy consumptionPolyureas/polyurethane adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

The invention discloses a PBT aluminum-plastic composite film, which comprises a middle layer, an inner layer arranged on the inner side of the middle layer and an outer layer arranged on the outer side of the middle layer, wherein the middle layer and the inner layer are bonded by a first adhesive layer, the middle layer and the outer layer are bonded by a second adhesive layer, the middle layeris an aluminum foil layer, the inner layer is a polyolefin layer, the outer layer is formed by a blend formed by blending poly 1,4-naphthalic acid 3-(trimethylsilyl)-1,2-propylene glycol ester and a PBT resin according to a weight part ratio of 1:(5-8), and the first adhesive layer and the second adhesive layer are respectively and independently formed by an aluminum-doped hyperbranched polyurethane acrylate adhesive. The invention further discloses a production process of the PBT aluminum-plastic composite film. The PBT aluminum-plastic composite film disclosed by the invention has the advantages of high-temperature resistance, corrosion resistance, scratch resistance, good performance stability, excellent comprehensive performance, good mechanical properties and good water vapor barrierproperty, and can significantly improve the thermal resistance and the safety performance of a lithium ion battery.

Owner:苏州市新广益电子股份有限公司

A kind of method of layered silicate modified silica sol

ActiveCN107487774BReduce manufacturing costSimple processAluminium silicatesSilicic acidPhysical chemistry

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing nano composite fiber membrane based on electrostatic spinning technology

PendingCN113584712AChemically stableIncrease acidityElectro-spinningConjugated synthetic polymer artificial filamentsFiberPolymer science

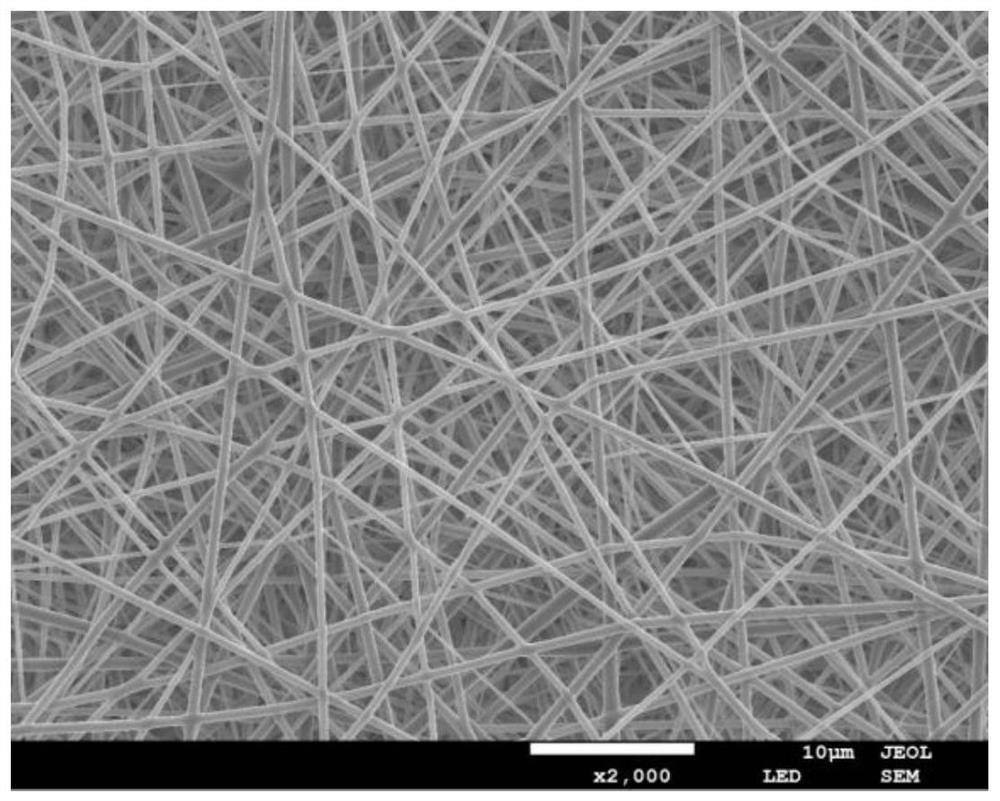

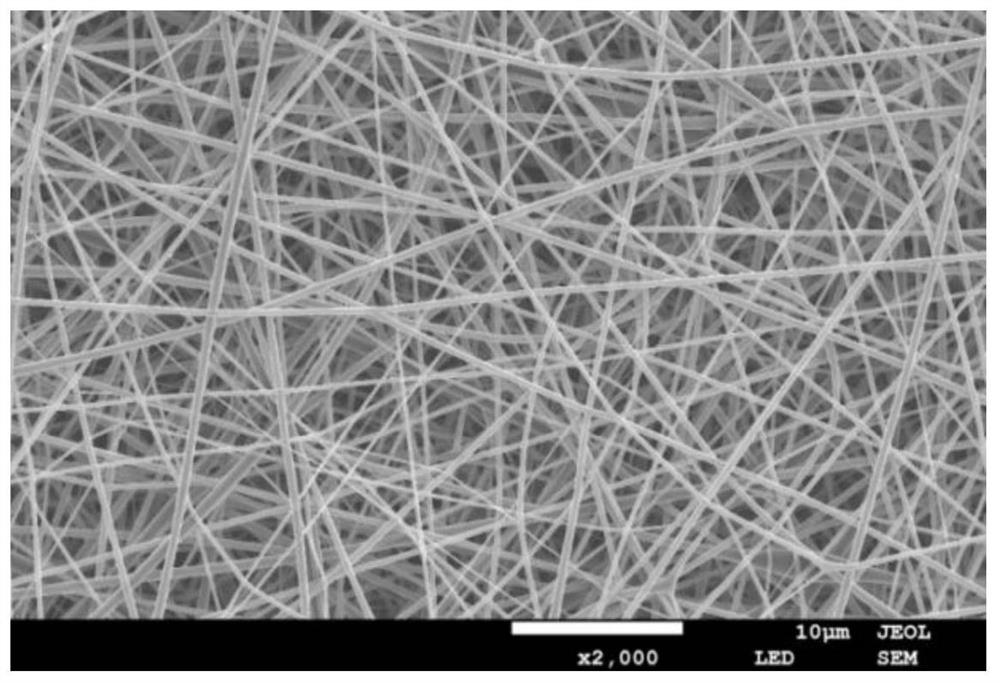

The invention belongs to the technical field of electrostatic spinning, and particularly relates to a method for preparing a nano composite fiber membrane based on an electrostatic spinning technology. The preparation method comprises the following steps of (1) dissolving polycaprolactone and polyvinylpyrrolidone in trifluoroethanol, and magnetically stirring and uniformly mixing to obtain a spinning solution; and (2) carrying out electrostatic spinning on the spinning solution obtained in the step (1) in an electrostatic spinning machine, and drying to obtain the nano composite fiber membrane material. Two substances including polycaprolactone and polyvinylpyrrolidone are blended for electrostatic spinning to obtain the nano composite fiber membrane with small diameter and large specific surface area, the structure is similar to that of collagen in an extracellular matrix, and the nano composite fiber membrane can be applied to the field of tissue engineering materials and has good application prospects, and the nano composite fiber membrane can be used as a good base material to load a nano functional material, so that a functional fiber membrane material is prepared.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method of mirabilite-based solid-liquid composite phase change energy storage material

PendingCN113969142AEasy to useRealize stereotyped packagingHeat-exchange elementsFreeze-dryingGraphite

The invention relates to the technical field of phase change energy storage materials, and particularly discloses a preparation method of a mirabilite-based solid-liquid composite phase change energy storage material. The preparation method comprises the following steps: S1, uniformly mixing graphene oxide and cuprous oxide powder according to a mass ratio of 1-2: 1, adjusting the pH value to 10.5, and carrying out a hydrothermal reaction to obtain modified nano graphene composite cuprous oxide hydrogel; S2, cleaning the modified nano graphene composite cuprous oxide hydrogel, and freeze-drying the modified nano graphene composite cuprous oxide hydrogel to obtain block-like modified nano graphene composite cuprous oxide aerogel; S3, preparing a mirabilite-based phase change material; and S4, cutting the modified nano graphene composite cuprous oxide aerogel into a proper size, and adsorbing and shaping the mirabilite-based phase change material by adopting dipping and suction filtration technologies in sequence. The preparation method provided by the invention has the advantages that the problems of super-cooling degree and phase stratification of the mirabilite phase change energy storage material are solved, and the service life of the phase change energy storage material is prolonged.

Owner:QINGHAI UNIVERSITY

Mothproof and mildewproof material for finance management cabinet and preparation method thereof

InactiveCN107400183ASimple preparation processRaw materials are easy to getBiocideBook cabinetsPentachlorophenolHydrolysis

The invention provides a method for preparing a moth-proof and mildew-proof material for financial management cabinets, including chitosan quaternization, ion exchange, preparation of quaternized chitosan grafted acrylonitrile hydrolyzate and moth-proof and mildew-proof material preparation and other steps; the preparation method of the moth-proof and mildew-proof material for the financial management cabinet provided by the present invention is simple and easy, with low cost, and can prevent moth and mildew at the same time. The effect is excellent, and at the same time, it can also absorb water. Putting it in the cabinet can make the environment inside the cabinet dry and play the role of moisture-proof, which has a good market application prospect.

Owner:成都优瑞商务服务有限公司

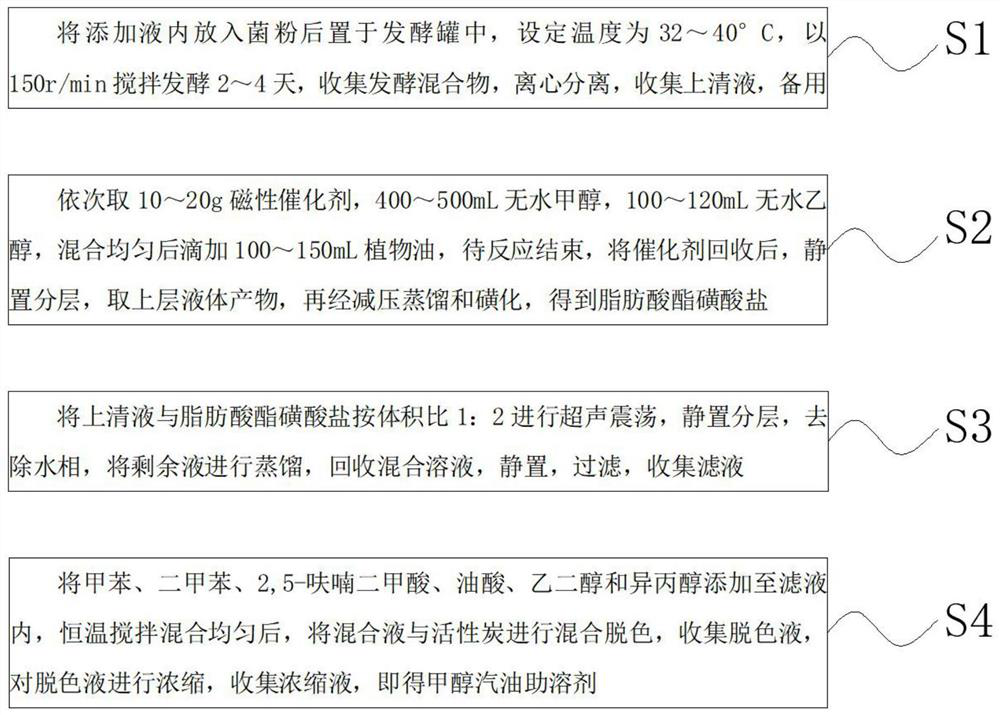

Cosolvent for methanol gasoline and preparation method of cosolvent

PendingCN113637504AGood dispersionGood emulsificationLiquid carbonaceous fuelsXylyleneGlycol synthesis

The invention discloses a cosolvent for methanol gasoline in the technical field of cosolvents for methanol gasoline. The cosolvent is prepared from the following raw materials in parts by weight: 50 to 70 parts of fatty acid ester sulfonate, 10 to 15 parts of methylbenzene, 8 to 15 parts of xylene, 0.3 to 0.5 part of 2, 5-furandicarboxylic acid, 10 to 15 parts of oleic acid, 8 to 10 parts of ethylene glycol, 10 to 20 parts of isopropanol, 50 to 60 parts of additive solution and 1 to 5 parts of magnetic catalyst. According to the invention, beeswax and grape skin are used as basic fermentation raw materials for fermentation, fatty acid methyl ester is added into the fermentation raw materials to serve as an induction factor, and substances such as alcohol lipids are generated in the fermentation process by utilizing strains. Meanwhile, the grape skin is easy to generate methanol in the fermentation process, organic matters with dissolution stability on methanol in fermentation products are extracted, and meanwhile, beewax is decomposed in the fermentation process, so that active substances are generated, and the dispersing performance of methanol in gasoline is promoted.

Owner:GUIZHOU LONGHE ENERGY

Anti-scratch foam wall covering

ActiveCN108978236BLess prone to phase separationImprove adhesionTextiles and paperPolymer scienceMicrosphere

The invention relates to the technical field of wall coverings, in particular to an anti-scratch foamed wall covering, comprising an activated carbon non-woven fabric layer, an anion layer compounded on the activated carbon non-woven fabric layer, and an anti-scratch anti-scratch layer compounded on the anion layer. Foaming layer, the anti-scratch foaming layer is formed by anti-scratch foaming slurry, the anti-scratch foaming slurry includes the following raw materials: acrylate modified polyurethane dispersion, curing agent, citrate plasticizer, Nano graphene oxide, titanium dioxide, elastic microsphere foaming agent, heat stabilizer, nano inorganic powder, water. The wall covering of the present invention has the advantages of high hardness, scratch resistance, and the coating is not easy to fall off, and the inventive wall covering also includes an activated carbon non-woven fabric layer, which has strong "physical adsorption" and "chemical adsorption" effects, and can effectively absorb harmful substances. Gas, anti-virus and deodorizing effect is remarkable.

Owner:GUANGDONG YULAN GRP

Organic-inorganic hybrid organosilicone electronic packaging glue and preparation method thereof

The invention provides organic-inorganic hybrid organosilicone electronic packaging glue and a preparation method thereof. A reaction system comprises tetramethoxysilane, a solvent consisting of absolute ethyl alcohol and isopropanol in a mass proportion of 7:(2-5), and a catalyst formed by mixing 2-amino-2-methyl-1-propanol with tetramethylammonium hydroxide, wherein the catalyst is added by two steps, and dodecafluoroheptyl trimethoxysilane is simultaneously introduced, and a film formed finally by the prepared organosilicone electronics packaging glue has the characteristics of strong hydrophobicity, soiling resistance, corrosion resistance, strong coated substrate adhesive force, and high refraction rate; and the preparation method is simple in preparation process and low in cost, and the process is easily controlled.

Owner:GUANGZHOU GLORYSTAR CHEM +2

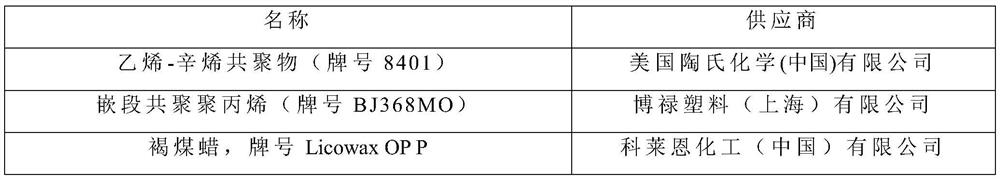

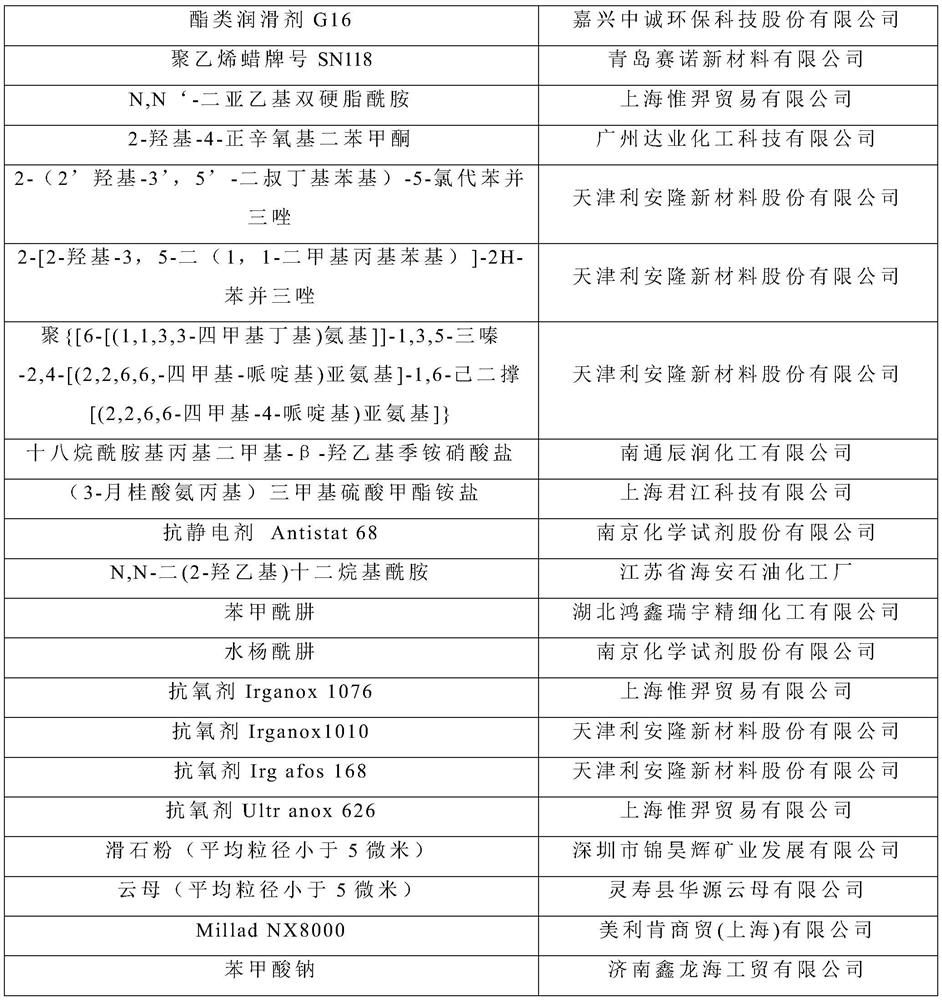

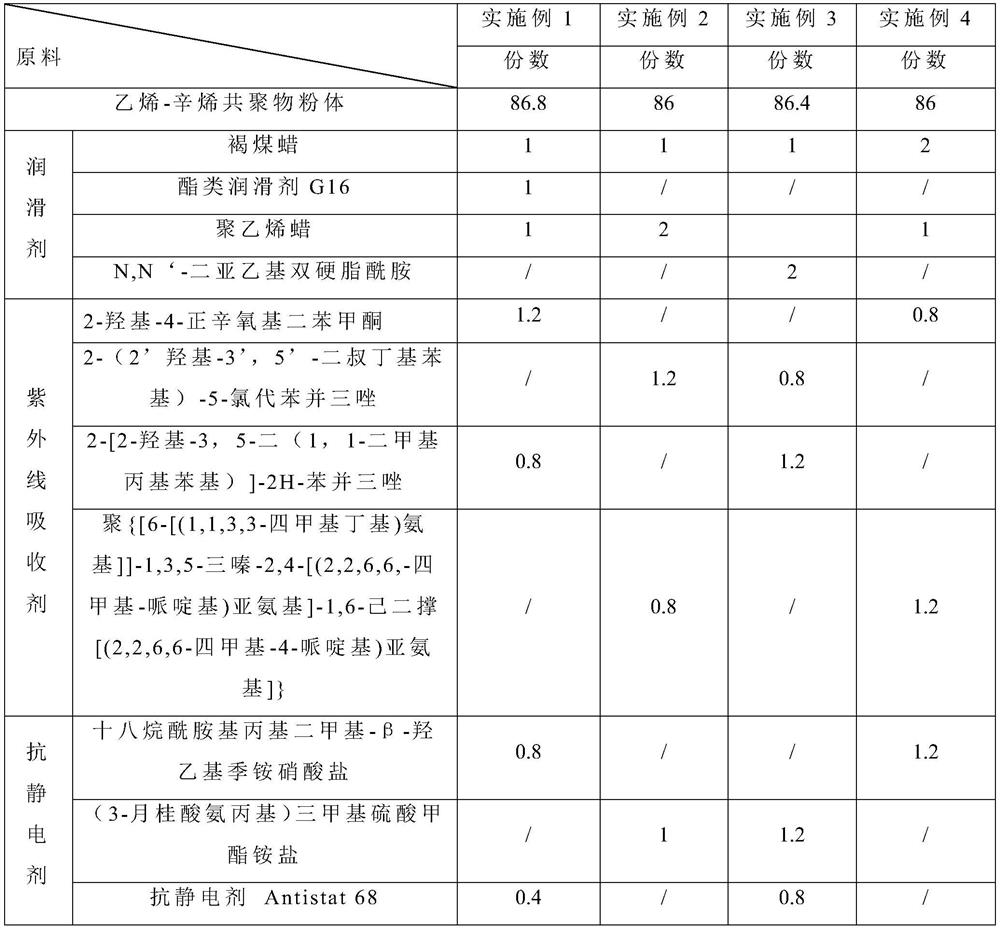

Functional master batch suitable for thin-wall high-length-diameter-ratio polypropylene cable tie as well as preparation method and application of functional master batch

PendingCN114702755AEnhance low temperature toleranceExcellent mechanical (mechanical) propertiesPolymer scienceUltraviolet lights

The invention discloses a functional master batch suitable for a thin-wall high-length-diameter-ratio polypropylene cable tie as well as a preparation method and application of the functional master batch. The functional master batch comprises an ethylene-octylene copolymer, a first functional aid and a second functional aid, the first functional aid comprises a lubricant, an antioxidant and a nucleating agent, and the second functional aid comprises at least one of an ultraviolet light absorber, an antistatic agent and an anti-copper agent; the functional master batch is prepared by mixing, extruding and granulating all the components, the processing temperature is controlled so that the solid ethylene-octylene copolymer is partially melted, and in the prepared functional master batch, the ethylene-octylene copolymer coats other components; the master batch can be directly mixed with polypropylene to be subjected to injection molding to form the thin-wall polypropylene cable tie with the high length-diameter ratio, multiple times of hot processing of the polypropylene can be avoided, the auxiliary powder is well dispersed in a system in the injection molding process, and the system is endowed with excellent low-temperature resistance, mechanical (mechanical) performance and other functions.

Owner:张家港绿洲新材料科技有限公司

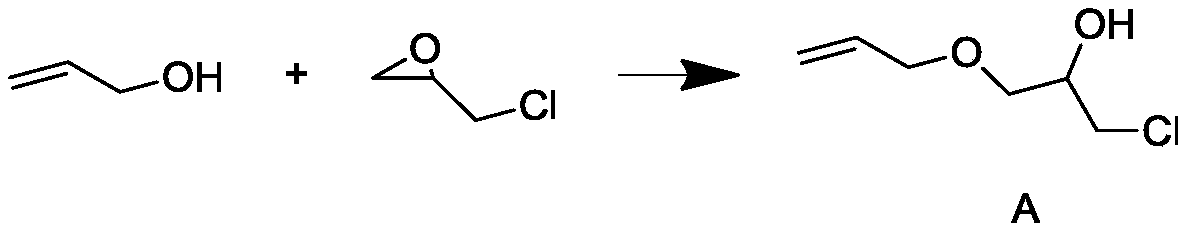

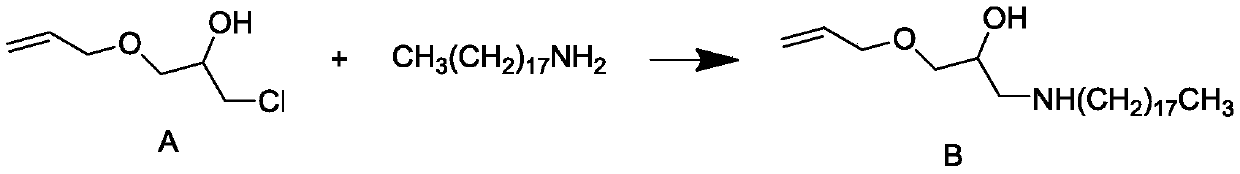

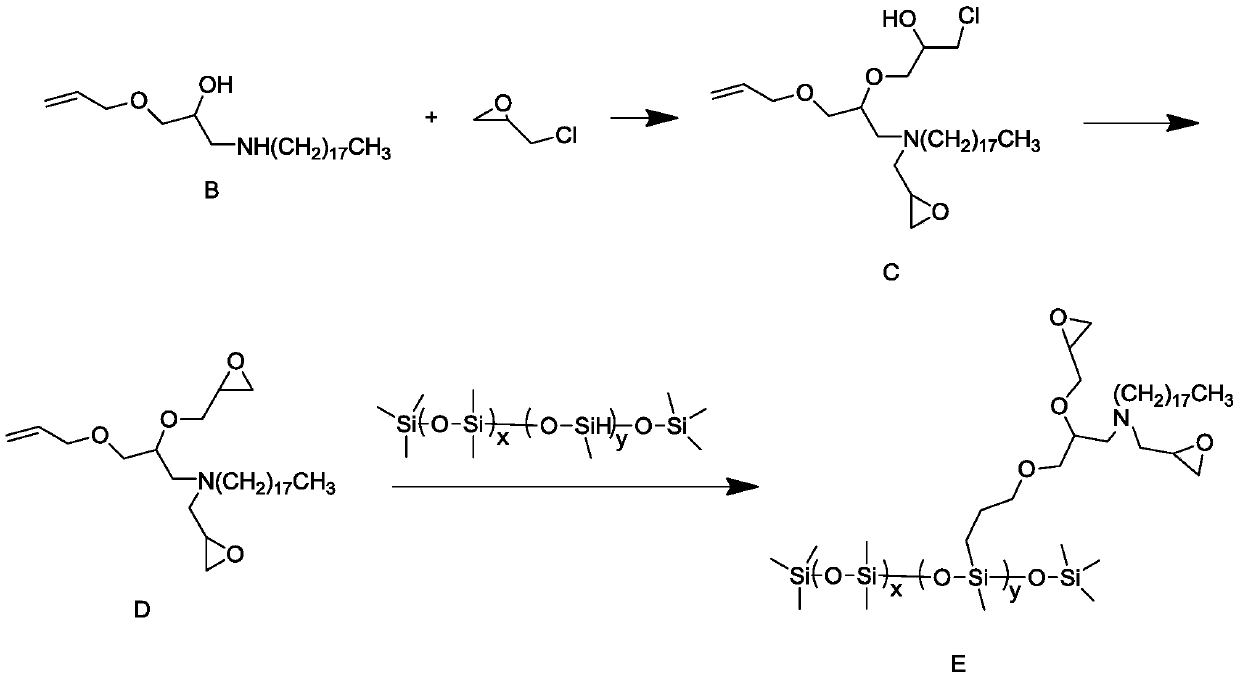

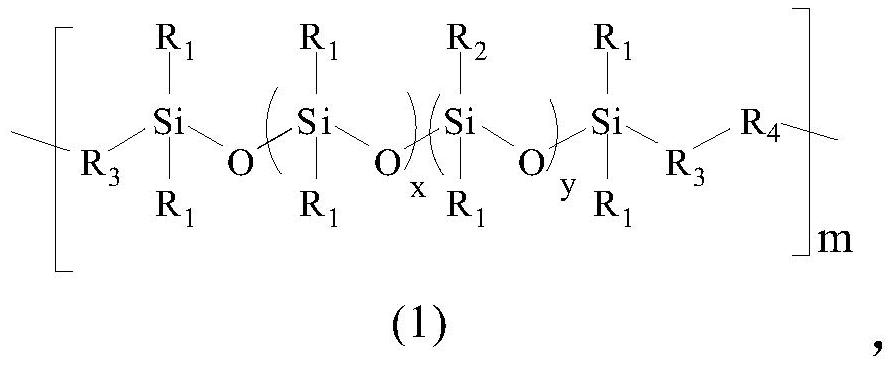

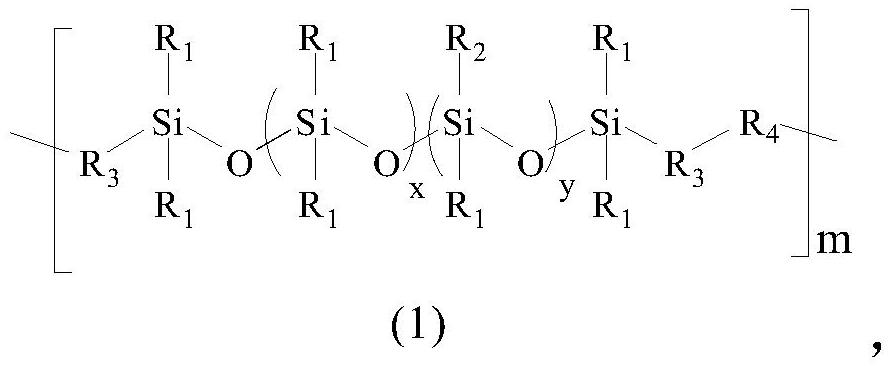

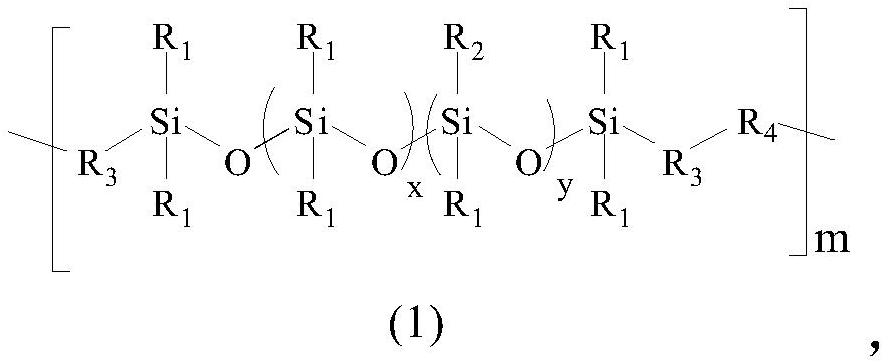

Reactive type inhibitor and preparation method thereof, silicone rubber composition, silicone rubber and preparation method thereof

The invention relates to a reaction type inhibitor and a preparation method thereof, the structural formula of the reaction type inhibitor is shown in the following formula (1), R1 comprises at least one of alkane, cycloalkane and aryl, R2 is alkylene, R3 is -(CH2) n-, n is an integer of 0-4, R4 is one of -(CH2)n-, x and y are integers, and the sum of x and y is less than or equal to 20000. The invention also relates to a silicone rubber composition, silicone rubber and a preparation method thereof. The reactive inhibitor is mainly used in the silicone rubber composition, so that the activity of a noble metal catalyst is reduced, the controllability of hydrosilylation reaction is enhanced, and the operable time of the silicone rubber composition is prolonged; and in addition, the reactive inhibitor can also form a uniform molecular cross-linked network structure with the silicone rubber to become a part of the silicone rubber, so that the reactive inhibitor cannot migrate out of the silicone rubber to pollute a silicone rubber product.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com