Flame-retardant low-temperature-resistant organic silicon rubber and preparation method thereof

A technology of silicone rubber and low temperature resistance, applied in the field of silicone rubber, can solve the problems of short curing cycle, oil resistance, flame retardancy and low temperature resistance to be further improved, low curing temperature of silicone rubber, etc., and achieve low production cost. , The effect of high resilience and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

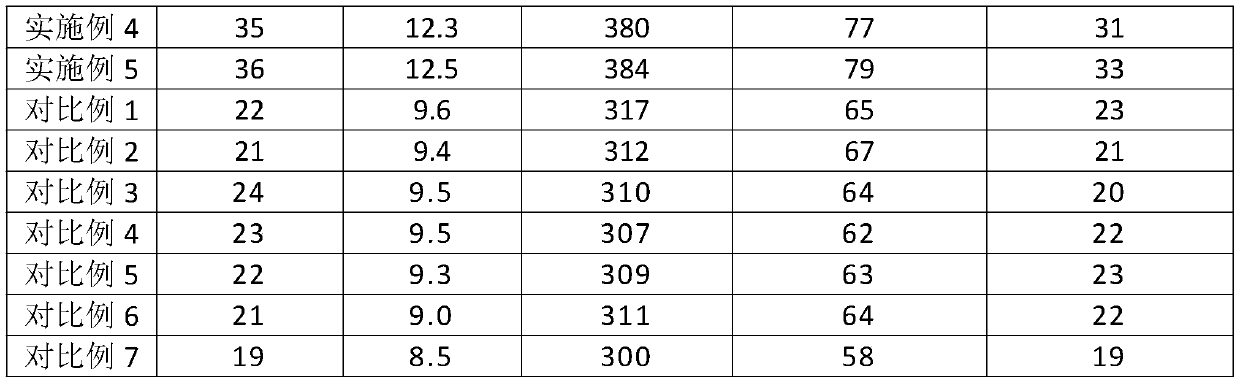

Examples

Embodiment 1

[0027] A flame-retardant and low-temperature resistant silicone rubber, characterized in that it is made of the following raw materials in parts by weight: 60 parts of vinyl-terminated fluorosilicone rubber, N-vinyl o-phenylimine modified hyperbranched polysiloxane 30 parts, 10 parts of benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate, 10 parts of chloropropyl polysiloxane, 10 parts of aluminum oxide, 3 parts of tert-butyl peroxy tert-valerate, silane 2 parts of coupling agent KH550.

[0028] The preparation method of the described benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate comprises the following steps: dissolving benzimidazole-5,6-dicarboxylic acid, amino-terminated polyurethane and phosphonothioate in two Form a solution in methyl sulfoxide, then add the solution into the reaction kettle, replace the air in the kettle with nitrogen, react at 100°C for 4 hours under normal pressure, then raise the temperat...

Embodiment 2

[0032]A flame-retardant and low-temperature resistant silicone rubber, characterized in that it is made of the following raw materials in parts by weight: 65 parts of vinyl-terminated fluorosilicone rubber, N-vinyl o-phenylimine modified hyperbranched polysiloxane 32 parts, 11 parts of benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate, 12 parts of chloropropyl polysiloxane, 12 parts of aluminum hydroxide, 3.5 parts of dicyclohexyl peroxydicarbonate, silane 2.5 parts of coupling agent KH560.

[0033] The preparation method of the benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate comprises the following steps: dissolving benzimidazole-5,6-dicarboxylic acid, amino-terminated polyurethane and phosphorous acid in dimethyl sulfoxide Form a solution in the reaction kettle, then add the solution into the reaction kettle, replace the air in the kettle with helium, react at 102°C under normal pressure for 4.5 hours, then rais...

Embodiment 3

[0037] A flame-retardant and low-temperature resistant silicone rubber, characterized in that it is made of the following raw materials in parts by weight: 70 parts of vinyl-terminated fluorosilicone rubber, N-vinyl o-phenylimine modified hyperbranched polysiloxane 35 parts, 13 parts of benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate, 15 parts of chloropropyl polysiloxane, 15 parts of silicon micropowder, 4 parts of azobisisobutyronitrile, silane coupling agent KH570 3.5 parts.

[0038] The preparation method of the described benzimidazole-5,6-dicarboxylic acid / amino-terminated polyurethane polycondensate comprises the following steps: dissolving benzimidazole-5,6-dicarboxylic acid, amino-terminated polyurethane and thiophosphoramide in N, Form a solution in N-dimethylacetamide, then add the solution into the reaction kettle, replace the air in the kettle with neon gas, react at 105°C for 5 hours under normal pressure, then raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com