Preparation method of mirabilite-based solid-liquid composite phase change energy storage material

A technology of solid-liquid and composite phase change of Glauber's Nitrate, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of shortened service life, unfavorable popularization and utilization, and reduced performance of Glauber's Nitrate, so as to prolong the service life , Phase change energy storage effect is better, the effect of solving supercooling and phase stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

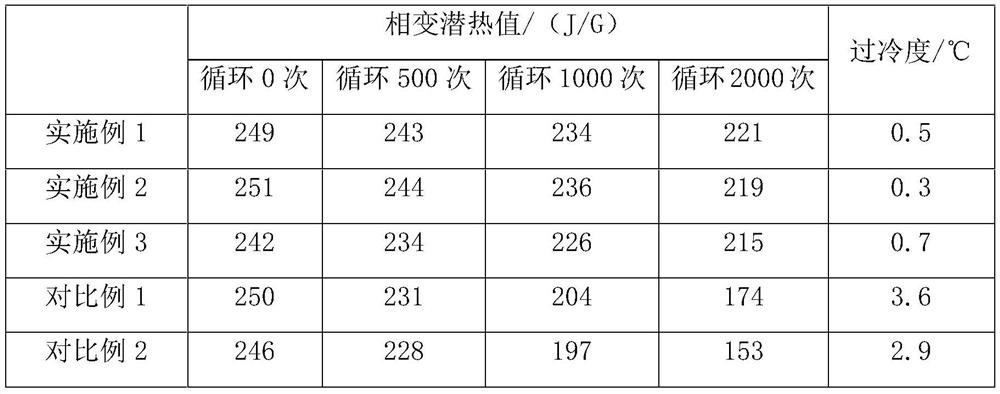

Examples

preparation example 1

[0030] Preparation of Graphene Oxide (GO)

[0031] The preparation method of graphene oxide suspension (GO) adopts the common Hummers method, and the concentration is 8.4mg / mL.

preparation example 2

[0033] Preparation of cuprous oxide particles

[0034] Take 10 mg copper chloride dihydrate crystals (CuCl 2 2H 2 O) Dissolved in 15mL of distilled water to form a blue-green solution, add 6mL of 2mol / L NaOH solution under stirring, a blue precipitate appears in the solution, add 12.0mg of ascorbic acid after stirring for 15min, and continue stirring for 10min after the solution turns yellow completely. Filter the solution and dry it under vacuum to obtain yellow cuprous oxide particles with a particle diameter of about 30-60 nm.

Embodiment 1

[0037] A preparation method of mirabilite-based solid-liquid composite phase change energy storage material is as follows:

[0038] S1. Take 4 mL of the GO solution obtained in Preparation Example 1, sonicate for 15 minutes, add 30 mg of cuprous oxide powder and 100 mg of ascorbic acid, stir evenly, adjust the pH to 10.5, transfer the obtained mixed solution into a reaction kettle, and pass through After 15 hours of hydrothermal reaction, the modified nano-graphene composite cuprous oxide hydrogel was obtained.

[0039] S2, the modified nano-graphene composite cuprous oxide hydrogel is added to deionized water and then freeze-dried to obtain block-shaped modified nano-graphene composite cuprous oxide (rGO / Cu 2 O) Airgel composites.

[0040] S3. Take by weighing 5.4g Glauber's salt, 0.6g Sodium Carbonate Decahydrate and 0.3g Calcium Carbonate, put them into a container, add 5L of water, stir to fully dissolve Glauber's Salt and Sodium Carbonate Decahydrate, and obtain Glauber'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com