Diaphragm with uniform pore diameter and preparation method of diaphragm

A diaphragm and uniform technology, applied in the field of electrochemistry, can solve the problems of large distribution intervals and battery difficulties, and achieve the effects of uniform stretching, uniform pore size distribution, and good pore size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

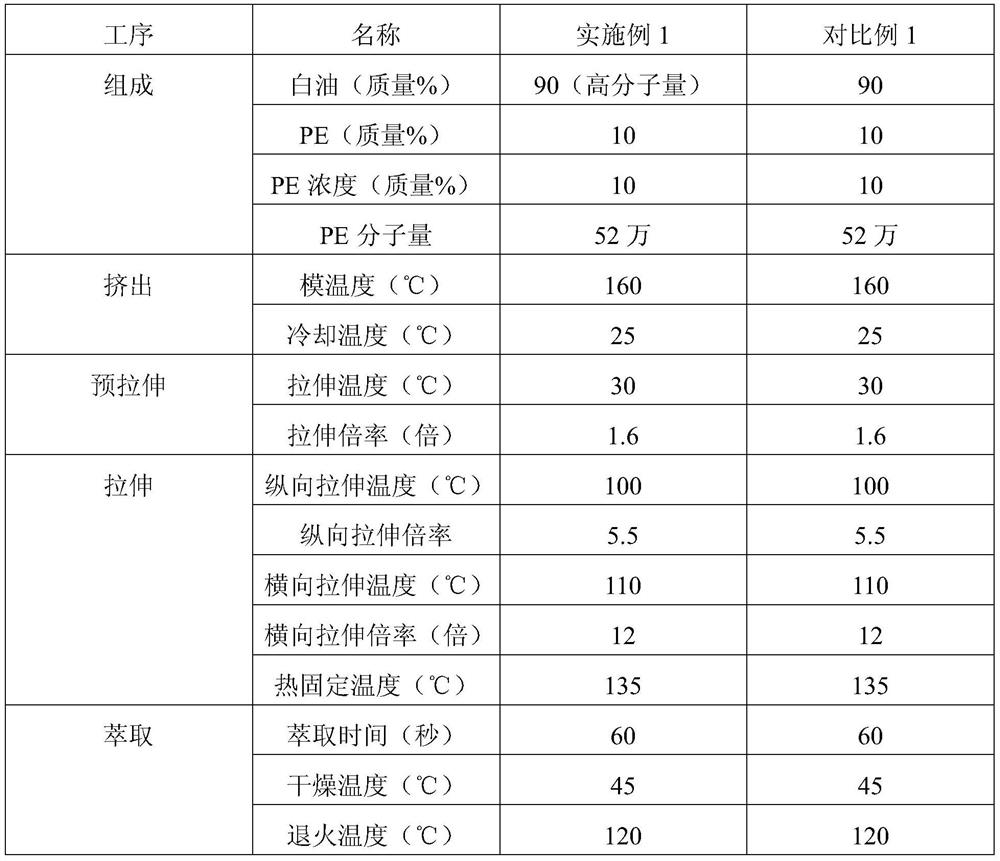

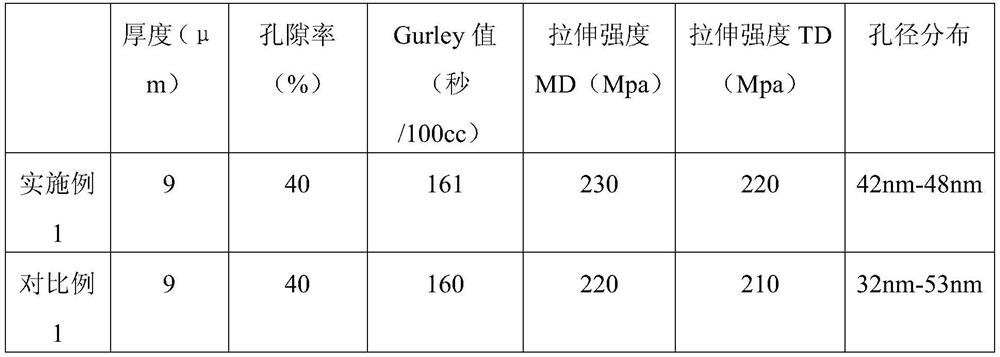

[0032] A method for preparing a membrane with uniform pore size, comprising the following steps:

[0033] Step S1, preparing a mixed solution composed of a polyolefin composition and white oil; the polyolefin composition accounts for 10% to 35% by mass of the mixed solution, and the mass average molecular weight of the polyolefin composition is more than 90,000; The white oil used is high-molecular-weight white oil, and the molecular weight of the white oil is between 2000-4000; if high-molecular-weight white oil is used, after the polyolefin and white oil are dissolved and mixed, phase separation is not easy to occur, so that the diaphragm is stretched It is more uniform during the extraction process, and the white oil is washed out in the subsequent extraction process to form a relatively uniform porous structure in the polyolefin. The pore size of the separator is consistent and the pore size distribution is more uniform. The molecular weight of white oil is preferably 2500...

Embodiment 1

[0041] Step S1, preparing a mixed solution composed of polyolefin composition and white oil; in this embodiment 1, the polyolefin composition accounts for 10% by mass of the mixed solution, the mass percent of white oil is 90%, and the polyolefin composition Select high-molecular-weight polyethylene with a mass-average molecular weight of 520,000 for use, and the concentration of polyethylene is 10%. The white oil used is high-molecular-weight white oil, and the molecular weight of the white oil is between 2000-4000. In the present embodiment 1, use The molecular weight of the white oil is 3000, and the mass percentage of the non-volatile solvent in the high molecular weight white oil is 85%.

[0042] Step S2, melting and kneading the above-mentioned mixed solution, extruding the obtained molten and kneaded product from the mold, cooling and solidifying to obtain a gel-like molded product; in step S2, when the molten and kneaded product is extruded from the mold The temperatur...

Embodiment 2

[0060] Step S1, preparing a mixed solution composed of a polyolefin composition and white oil; in Example 2, the polyolefin composition accounts for 20% by mass of the mixed solution, the mass percent of white oil is 80%, and the polyolefin composition Select high-molecular-weight polypropylene with a mass-average molecular weight of 520,000, and the concentration of polypropylene is 20%. The white oil used is high-molecular-weight white oil, and the molecular weight of the white oil is between 2000-4000. In this embodiment 2, use The molecular weight of the white oil is 2000, and the mass percentage of the non-volatile solvent in the white oil is 80%.

[0061] Step S2, melting and kneading the above-mentioned mixed solution, extruding the obtained molten and kneaded product from the mold, cooling and solidifying to obtain a gel-like molded product; in step S2, when the molten and kneaded product is extruded from the mold The temperature range is the melting point T~T+65°C of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Gurley value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com