Low-temperature gel-state phase-changing cold storage agent and preparation method thereof

A phase-change cooling storage agent and low-temperature gel technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of environmental pollution, poor degradability of cooling storage agents, etc., and achieve low production cost, avoid thermal damage, and latent heat. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a low-temperature gel state phase-change cold storage agent, the specific steps are as follows;

[0029] (1) Add 4-5 parts of konjac glucomannan to 100 parts of water, stir for 30 minutes to fully swell;

[0030] (2) Add potassium persulfate (0.1-0.2 parts) to the swollen konjac glucomannan as an initiator, and add 12-20 parts of acrylic acid (neutralized with 60% sodium hydroxide) and acrylamide 16 after a few minutes -20 parts, while adding N,N-methylenebisacrylamide (0.01-0.05 parts) as a crosslinking agent.

[0031] (3) Uniform mechanical stirring and at the same time, the temperature is raised to 55-65°C by means of temperature programming, and the reaction time is 2-3H;

[0032] (4) The mixture is washed, dried and pulverized to obtain a powder for use.

[0033] (5) Mix the prepared powder with ammonium chloride and potassium nitrate powder, add an appropriate amount of water, and stir evenly to prepare a transparent gel-state phase-chang...

Embodiment 1

[0035] (1) Add 5 parts of konjac glucomannan to 100 parts of water, stir for 30 minutes to make it fully swell;

[0036] (2) Add potassium persulfate (0.16 parts) to the swollen konjac glucomannan as an initiator, add 20 parts of acrylic acid (neutralized with 60% sodium hydroxide) and 20 parts of acrylamide after a few minutes, and add N,N-methylenebisacrylamide (0.03 parts);

[0037] (3) Uniform mechanical stirring and at the same time, the temperature is raised to 60°C by means of a temperature program, and the reaction time is 3H;

[0038] (4) The mixture is washed, dried and pulverized to obtain a powder for use.

[0039] (5) In terms of mass fraction, take 10% powder, 15% ammonium chloride and 7% potassium nitrate and mix the rest with water, and stir evenly to prepare a cold storage agent with a phase transition temperature of -18°C.

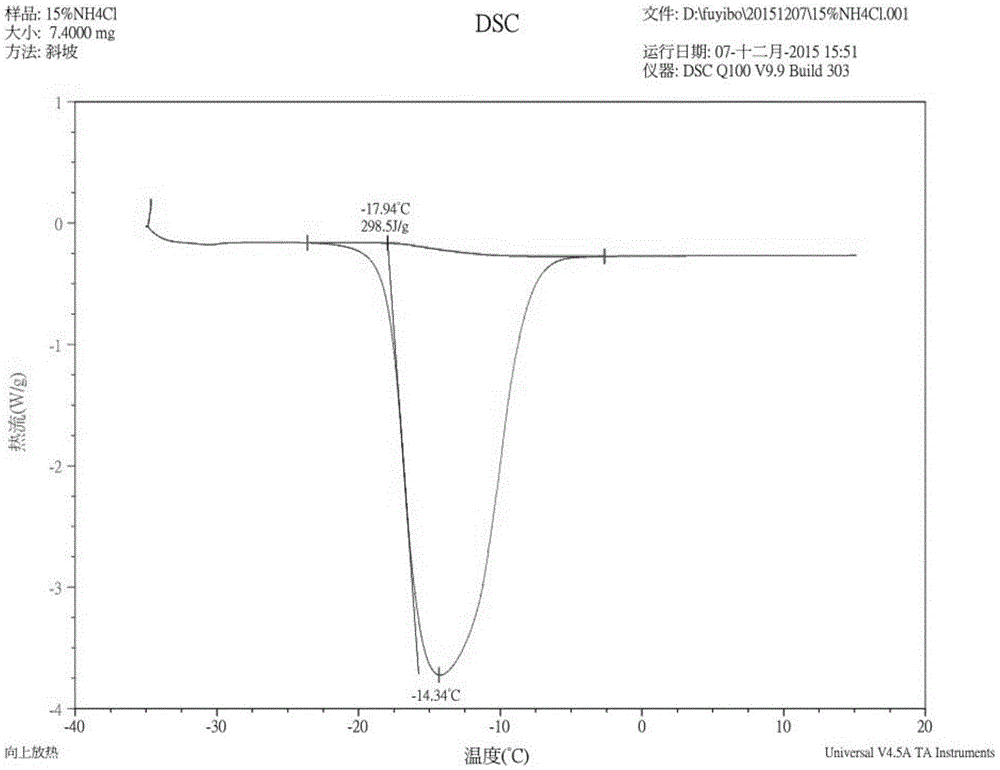

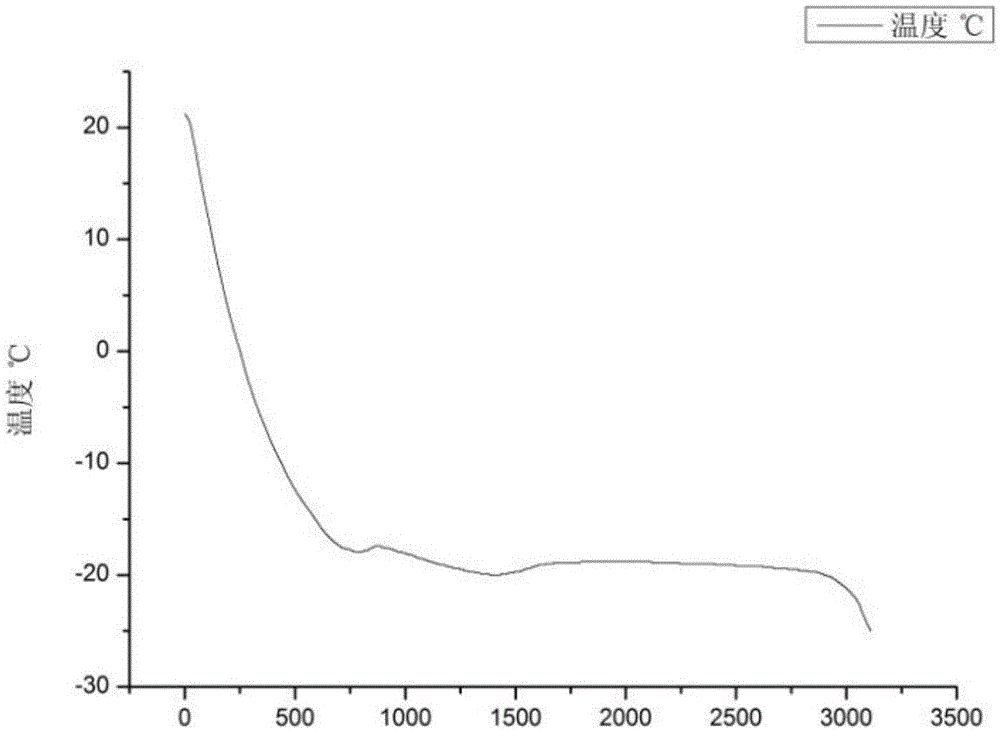

[0040] Test of cooling agent performance: DSC detection and step cooling curve test for the prepared cooling agent (such as figure 1 ...

Embodiment 2

[0042] (1) Add 5 parts of konjac glucomannan to 100 parts of water, stir for 30 minutes to make it fully swell;

[0043] (2) Add potassium persulfate (0.16 parts) to the swollen konjac glucomannan as an initiator, add 20 parts of acrylic acid (neutralized with 60% sodium hydroxide) and 20 parts of acrylamide after a few minutes, and add N,N-methylenebisacrylamide (0.03 parts);

[0044] (3) Uniform mechanical stirring and at the same time, the temperature is raised to 60°C by means of a temperature program, and the reaction time is 3H;

[0045] (4) The mixture is washed, dried and pulverized to obtain a powder for use.

[0046] (5) In terms of mass fraction, take 10% powder, 15% ammonium chloride and the rest as water, mix them with water, and stir evenly to prepare a cool storage agent with a phase transition temperature of -15°C.

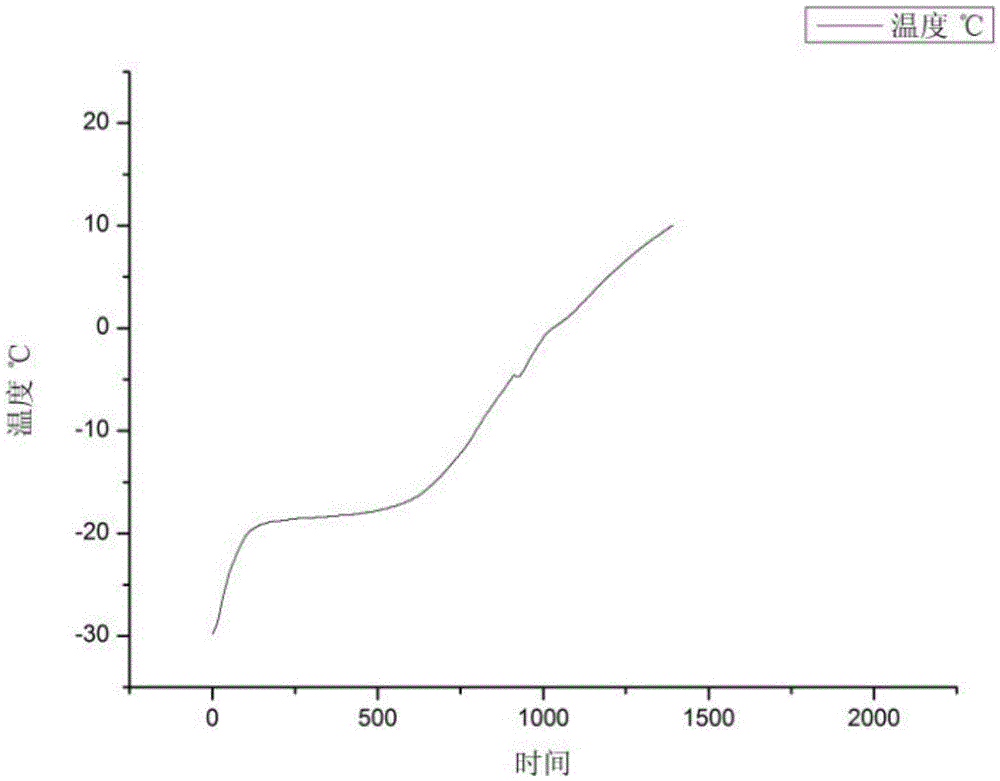

[0047] Test of cooling agent performance: DSC detection and step cooling curve test for the prepared cooling agent (such as Figure 4 , 5 , 6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com