Double-phase-change energy storage self-cleaning wall material and application thereof

A wall material and dual-phase transition technology, applied in the direction of building materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of water pollution, emulsifier cannot be recycled, leakage, etc., and the preparation method is simple and efficient. More and more, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

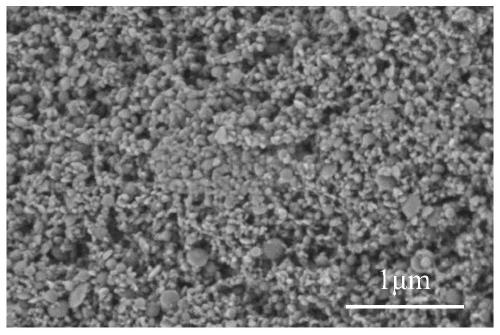

[0066] Mix 2g of polymerizable emulsifier allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate (DNS-86) with 80g of deionized water, and use a high-speed disperser to shear at a speed of 5000rpm for 15min. Then it was added into an ultrasonic cell disruptor, and dispersed for 15 minutes at an amplitude of 60%, to obtain an aqueous phase; wherein, the mass of the emulsifier was 2.4% of the mass of the aqueous phase. 6.6g of monomer (styrene: divinylbenzene=80%:20%), 13.4g of n-octadecane (n-ODE) and 0.2g of initiator azobisisobutyronitrile (AIBN) were mixed, Keep the temperature in a water bath at 30°C for 30 minutes to form an oil phase. The water phase was poured into the oil phase, stirred at a speed of 5000 rpm for 15 min, and the pre-emulsion was emulsified with an amplitude of 60% for 30 min using an ultrasonic cell breaker to obtain a fine emulsion. Pour the mini-emulsion into a 250ml four-neck flask, which has a feed port, a mechanical stirrer, a nitrogen in...

Embodiment 2

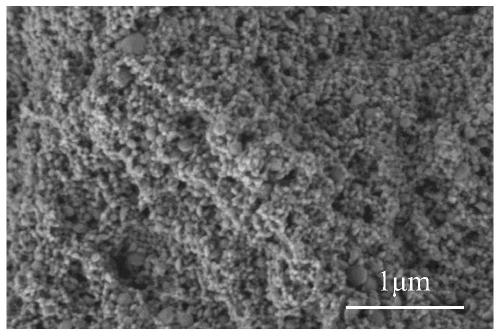

[0085] Mix 2g of polymerizable emulsifier allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate (DNS-86) with 85g of deionized water, and use a high-speed disperser to shear at a speed of 5000rpm for 15min. Then it was added into an ultrasonic cell breaker, and dispersed for 20 minutes at an amplitude of 60%, to obtain a water phase; wherein, the mass of the emulsifier was 2.3% of the mass of the water phase. With 8g monomer (styrene: divinylbenzene=70%: 30%), the n-octadecane (n-ODE) of 16g and the initiator azobisisobutyronitrile (AIBN) of 0.5g are mixed, at 30 ℃ in a water bath for 30 min to form an oil phase. The water phase was poured into the oil phase, stirred at a speed of 5000 rpm for 15 min, and the pre-emulsion was emulsified with an amplitude of 60% for 30 min using an ultrasonic cell breaker to obtain a fine emulsion. Pour the miniemulsion into a 250ml four-neck flask, which has a feed port, a mechanical stirrer, a nitrogen inlet and a reflux port, pu...

Embodiment 3

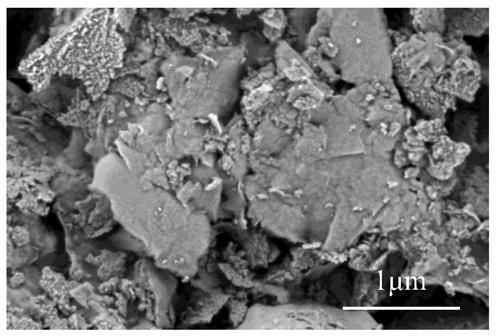

[0090] Mix 2.5g of polymerizable emulsifier allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate (DNS-86) with 85g of deionized water, and use a high-speed disperser to shear at a speed of 5000rpm for 15min. Then it was added into an ultrasonic cell disruptor, and dispersed for 15 minutes at an amplitude of 60%, to obtain a water phase; wherein, the mass of the emulsifier was 2.8% of the mass of the water phase. With 8g monomer (styrene: divinylbenzene=70%: 30%), the n-octadecane (n-ODE) of 18g and the initiator azobisisobutyronitrile (AIBN) of 0.3g are mixed, at 30 ℃ in a water bath for 30 min to form an oil phase. The water phase was poured into the oil phase, stirred at a speed of 5000 rpm for 15 min, and the pre-emulsion was emulsified with an amplitude of 60% for 30 min using an ultrasonic cell breaker to obtain a fine emulsion. Pour the mini-emulsion into a 250ml four-neck flask, which has a feed port, a mechanical stirrer, a nitrogen inlet and a reflux port,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com