Organic-inorganic hybrid organosilicone electronic packaging glue and preparation method thereof

A technology of electronic appliances and organic silicon, which is applied in the field of organic-inorganic hybrid silicon materials, can solve the problems of insufficient solvent resistance and mechanical strength, poor adhesion of the coating film to the substrate, and high curing temperature, so as to achieve good product stability, Hard to phase separation, strong hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

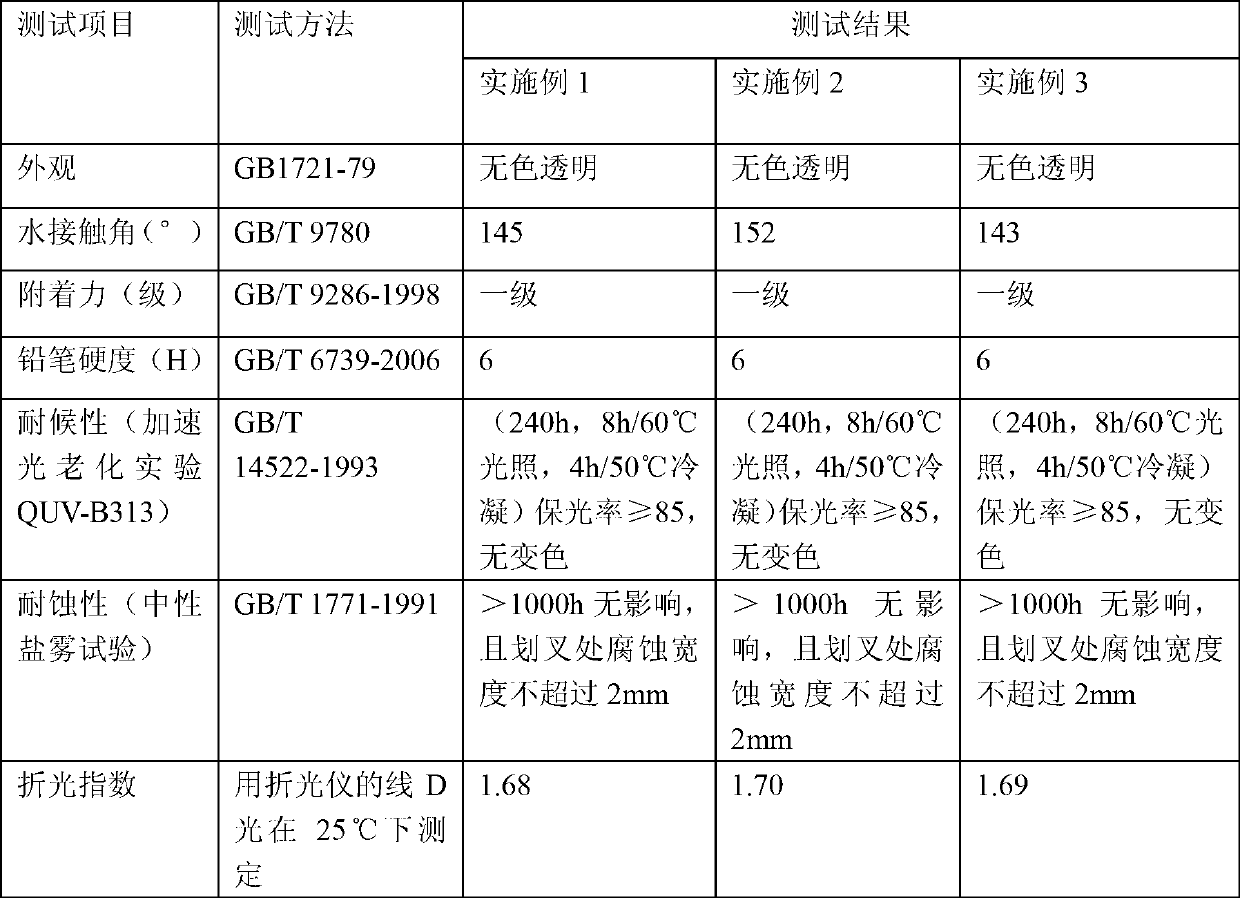

Examples

Embodiment 1

[0022] An organic-inorganic hybrid organosilicon electronic appliance encapsulation adhesive is prepared by the following preparation steps:

[0023] (1) Take 60 parts by weight of a solvent composed of absolute ethanol and isopropanol with a mass ratio of 7:2, and 1 part by weight of 2-amino-2-methyl-1- The catalyzer that propanol and tetramethyl ammonium hydroxide form, the distilled water of 5 weight parts add in the flask, stir and heat up,

[0024] (2) When the temperature is raised to 45°C, slowly add 10 parts by weight of tetramethoxysilane (TMOS) thereinto, and keep warm for 0.5h after the addition;

[0025] (3) Add 1 part by weight of a catalyst composed of 2-amino-2-methyl-1-propanol and tetramethylammonium hydroxide in a mass ratio of 8:2, and keep warm for 1 hour;

[0026] (4) After raising the temperature to 65°C and continuing the reaction for 2 hours, add dodecafluoroheptyltrimethoxysilane dropwise under stirring, the weight part of which is 15% of tetramethoxy...

Embodiment 2

[0030] An organic-inorganic hybrid organosilicon electronic appliance encapsulation adhesive is prepared by the following preparation steps:

[0031] (1) Take 80 parts by weight of a solvent composed of absolute ethanol and isopropanol with a mass ratio of 7:4, and 3 parts by weight of 2-amino-2-methyl-1- The catalyzer that propanol and tetramethylammonium hydroxide form, the distilled water of 15 weight parts add in the flask, stir and heat up,

[0032] (2) When the temperature is raised to 50°C, slowly add 15 parts by weight of tetramethoxysilane (TMOS) thereinto, and keep warm for 0.5h after the addition;

[0033] (3) Add 2 parts by weight of a catalyst composed of 2-amino-2-methyl-1-propanol and tetramethylammonium hydroxide in a mass ratio of 8:3, and keep warm for 1 hour;

[0034] (4) After raising the temperature to 70°C and continuing the reaction for 2.5 hours, add dodecafluoroheptyltrimethoxysilane dropwise under stirring, the weight part of which is 25% of tetramet...

Embodiment 3

[0038] An organic-inorganic hybrid organosilicon encapsulating adhesive for electronic appliances is prepared by the following preparation steps:

[0039] (1) Take 90 parts by weight of a solvent composed of absolute ethanol and isopropanol with a mass ratio of 7:5, and 5 parts by weight of 2-amino-2-methyl-1- The catalyst that propanol and tetramethylammonium hydroxide form, the distilled water of 20 weight parts add in the flask, stir and heat up;

[0040] (2) When the temperature is raised to 55°C, slowly add 20 parts by weight of tetramethoxysilane (TMOS) thereinto, and keep warm for 1 hour after the addition;

[0041] (3) Add 3 parts by weight of a catalyst composed of 2-amino-2-methyl-1-propanol and tetramethylammonium hydroxide in a mass ratio of 8:5, and keep warm for 1 hour;

[0042] (4) After raising the temperature to 80°C and continuing the reaction for 3 hours, add dodecafluoroheptyltrimethoxysilane dropwise under stirring, the weight part of which is 30% of tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com