Graphene heating ink, preparation method and application thereof

A graphene and ink technology, applied in inks, applications, household appliances, etc., can solve the problems of powder not easy to disperse, unstable dispersion, high local temperature, improve thermal stability and mechanical properties, improve dispersibility, electrical conductivity Sex-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

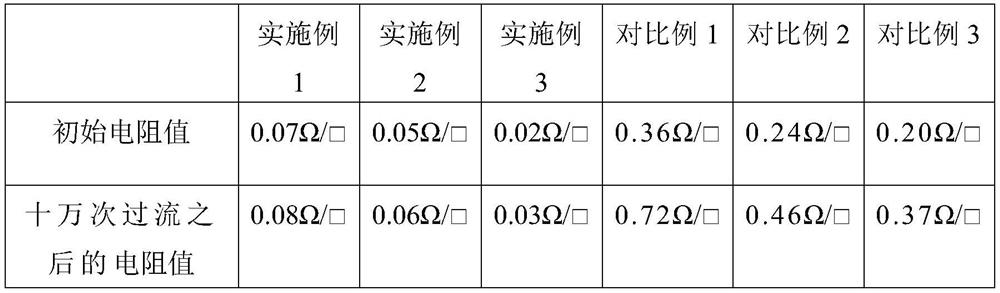

Embodiment 1

[0044] This embodiment provides a kind of graphene heating ink, its raw material comprises: graphene powder 18%, polysilazane solution 30%, polyvinylpyrrolidone PVP 1.0%, hydrophobically modified cellulose in terms of mass percentage Thickener 0.7%, modified polycarbodiimide crosslinking agent 1.8%, polyurethane resin 5%, polyether modified silicone oil 0.3%, and the balance is N,N-dimethylformamide.

[0045] The preparation method includes: weighing each raw material according to the formula, first fully stirring and mixing the graphene powder and polysilazane solution, after mixing evenly, adding polyvinylpyrrolidone PVP, hydrophobic modified cellulose Thickener, modified polycarbodiimide crosslinking agent, polyurethane resin, polyether modified silicone oil, N,N-dimethylformamide in the remaining mass percentage, fully stirred, and stood for 30 minutes to obtain the obtained The graphene heating ink described above.

Embodiment 2

[0047] This embodiment provides a kind of graphene heating ink, its raw material comprises: 15% of graphene powder, 30% of polysilazane solution, 1.2% of hexadecyltrimethylammonium bromide, Hydrophobic modified cellulose thickener 0.8%, modified polycarbodiimide crosslinking agent 1.8%, polyurethane resin 6%, polyether modified silicone oil 0.5%, the balance is N,N-dimethylformamide .

[0048] The preparation method comprises: weighing each raw material according to the formula, fully stirring and mixing the graphene powder and the polysilazane solution first, and after mixing evenly, adding cetyltrimethylammonium bromide in turn during the stirring process, Hydrophobic modified cellulose thickener, modified polycarbodiimide crosslinking agent, polyurethane resin, polyether modified silicone oil, N,N-dimethylformamide in the remaining mass percentage, fully stirred, let stand In 30 minutes, the graphene heating ink was obtained.

Embodiment 3

[0050] This embodiment provides a kind of graphene heating ink, its raw material comprises: 10% of graphene powder, 30% of polysilazane solution, 1.5% of polyvinylpyrrolidone PVP, hydrophobically modified cellulose Thickener 1.0%, modified polycarbodiimide crosslinking agent 2.0%, polyurethane resin 8%, polyether modified silicone oil 0.6%, and the balance is N,N-dimethylformamide.

[0051] The preparation method includes: weighing each raw material according to the formula, first fully stirring and mixing the graphene powder and polysilazane solution, after mixing evenly, adding polyvinylpyrrolidone PVP, hydrophobic modified cellulose Thickener, modified polycarbodiimide crosslinking agent, polyurethane resin, polyether modified silicone oil, N,N-dimethylformamide in the remaining mass percentage, fully stirred, and stood for 30 minutes to obtain the obtained The graphene heating ink described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com