Epoxy resin curing agent, preparation method thereof and epoxy resin

A technology of epoxy resin curing and epoxy resin, applied in the field of curing agent, can solve the problems of low environmental performance, poor hydrophobicity, poor impact resistance, etc., achieve strong environmental performance, improve heat resistance, and good impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

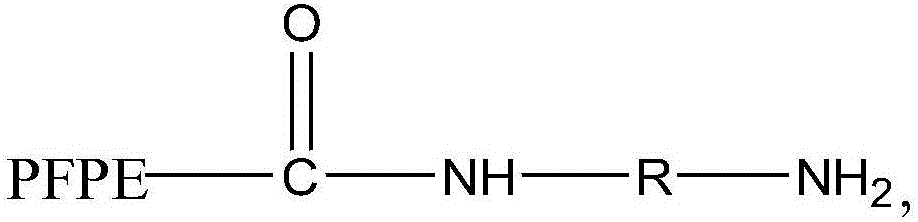

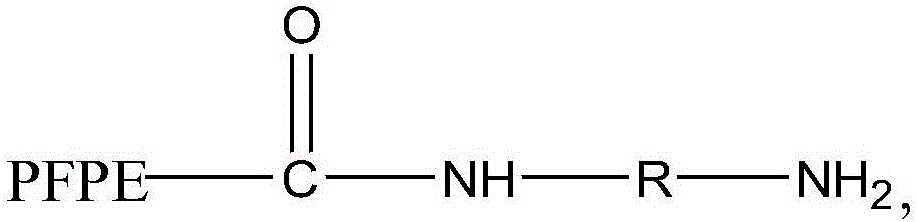

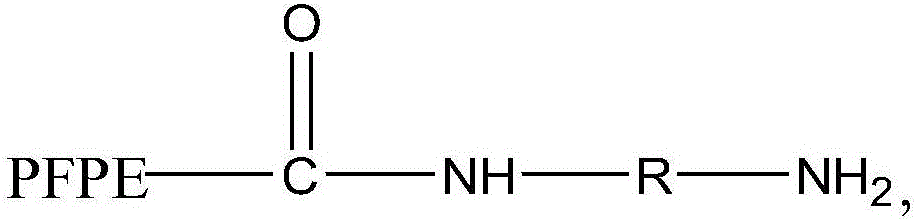

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of the epoxy resin curing agent, which comprises the following steps:

[0028] Step 1, under the protection of inert gas, put the solvent, perfluoropolyether acyl fluoride, polyamine and solvent into a reaction kettle equipped with a condensation reflux device, and react in an environment of 20-80 ° C for 2-24 hours;

[0029] Step 2, use one or more of methanol, ethanol, methyl acetate, butyl acetate, acetone to wash impurities, then remove the solvent by rotary evaporation under reduced pressure, and then remove solid impurities by filtration;

[0030] Step 3, extracting the solvent by rotary evaporation under reduced pressure to obtain the epoxy resin curing agent,

[0031] Wherein, the molar ratio of the perfluoropolyether acyl fluoride to the polyamine is 1: (0.8-1.5), and the input amount of the solvent is twice or twice the input amount of the perfluoropolyether acyl fluoride, so The usage amount of one or ...

Embodiment 1

[0039] Put 500g of trifluorotoluene into a reaction kettle equipped with a condensation reflux device, then dissolve 250g of perfluoropolyether acyl fluoride with a molecular weight of 3000 in trifluorotoluene under the protection of nitrogen, and then add dropwise under the protection of nitrogen 5 g of ethylenediamine was added dropwise for 0.5 hours, and the reaction was carried out at 25°C for 6 hours. After the reaction is completed, use 500g of methanol to wash the impurities, then remove the solvent by rotary evaporation under reduced pressure, remove solid impurities by filtration, and finally remove the solvent by rotary evaporation under reduced pressure to obtain a colorless transparent viscous liquid, which is perfluoropolyethylene. Ether-modified epoxy resin curing agent.

[0040] Mix 10 parts of the above epoxy resin curing agent with 100 parts of bisphenol A epoxy resin with an epoxy value of 0.51, and cure at room temperature for 24 hours to obtain an epoxy res...

Embodiment 2

[0042]Put 250g of tetrafluoroethyl butyl ether into a reactor equipped with a condensation reflux device, then dissolve 250g of perfluoropolyether acyl fluoride with a molecular weight of 5000 in tetrafluoroethyl butyl ether under nitrogen protection, Then, under the protection of nitrogen, 3 g of p-phenylenediamine was added dropwise for 0.5 hours, and the reaction was carried out at 50° C. for 12 hours. After the reaction is completed, use 250g of ethanol to wash the impurities, then remove the solvent by rotary evaporation under reduced pressure, then remove the solid impurities by filtration, and finally remove the solvent by rotary evaporation under reduced pressure to obtain a colorless transparent viscous liquid, which is perfluoropolymer. Ether-modified epoxy resin curing agent.

[0043] Mix 50 parts of the above curing agent with 100 parts of bisphenol A epoxy resin with an epoxy value of 0.42, and cure at room temperature for 24 hours to obtain an epoxy resin. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com