Functional master batch suitable for thin-wall high-length-diameter-ratio polypropylene cable tie as well as preparation method and application of functional master batch

A functional masterbatch and polypropylene technology, which is applied to the functional masterbatch of thin-walled high aspect ratio polypropylene cable ties and their preparation fields, can solve the problem of limiting the application of polypropylene cable ties, reducing physical and mechanical properties, and being intolerant to ultraviolet radiation. and other problems, to achieve the effects of excellent compatibilization and toughening, avoiding multiple thermal processing, and excellent mechanical (mechanical) properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

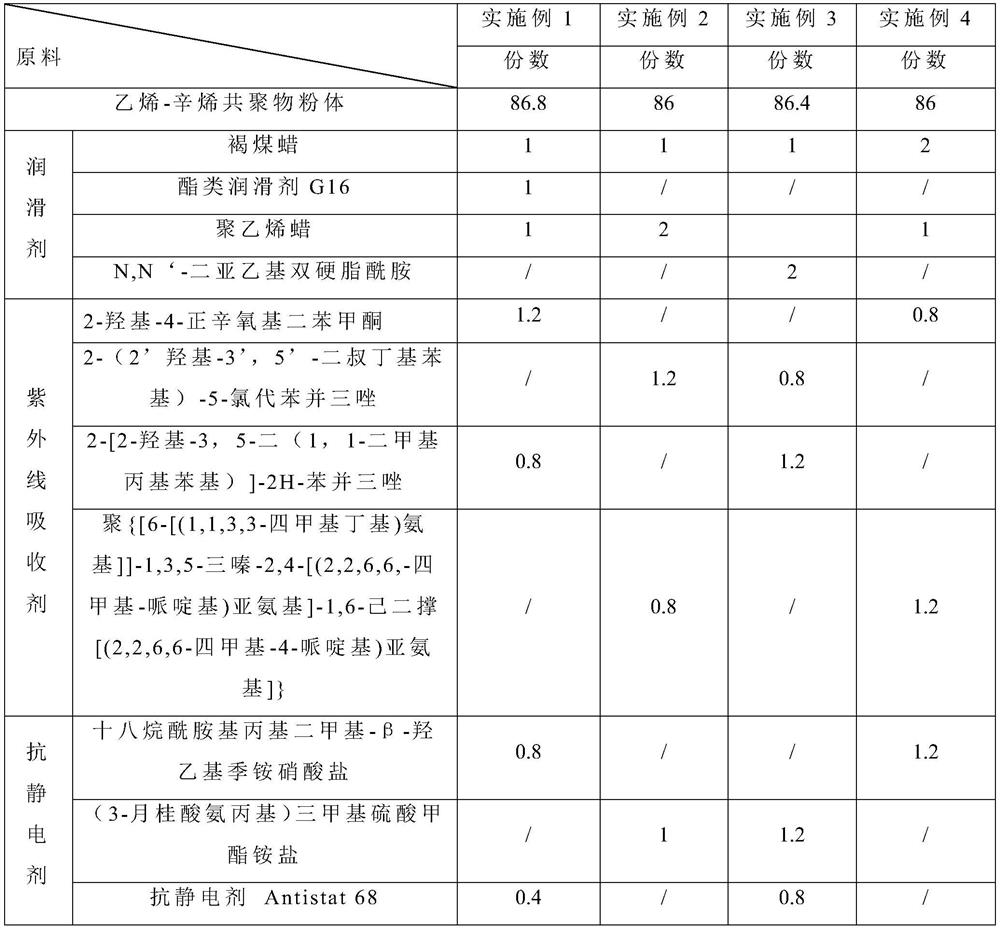

Embodiment 1-4

[0091] Preparation of ethylene-octene copolymer powder: Cool the ethylene-octene copolymer to -70℃ in the pre-cooling warehouse, then transfer the material to the grinding chamber of the main engine through screw conveying, and grind the material at -70℃ Grind to a particle size of about 75 microns (200 mesh), and then collect the powder through a cyclone separator.

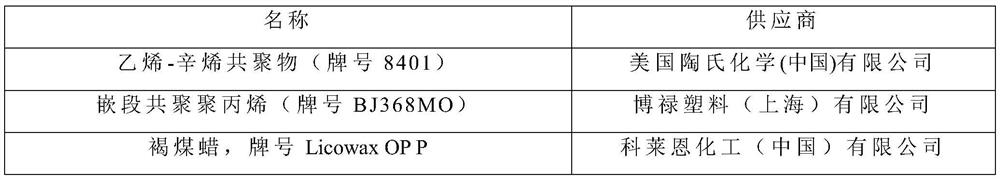

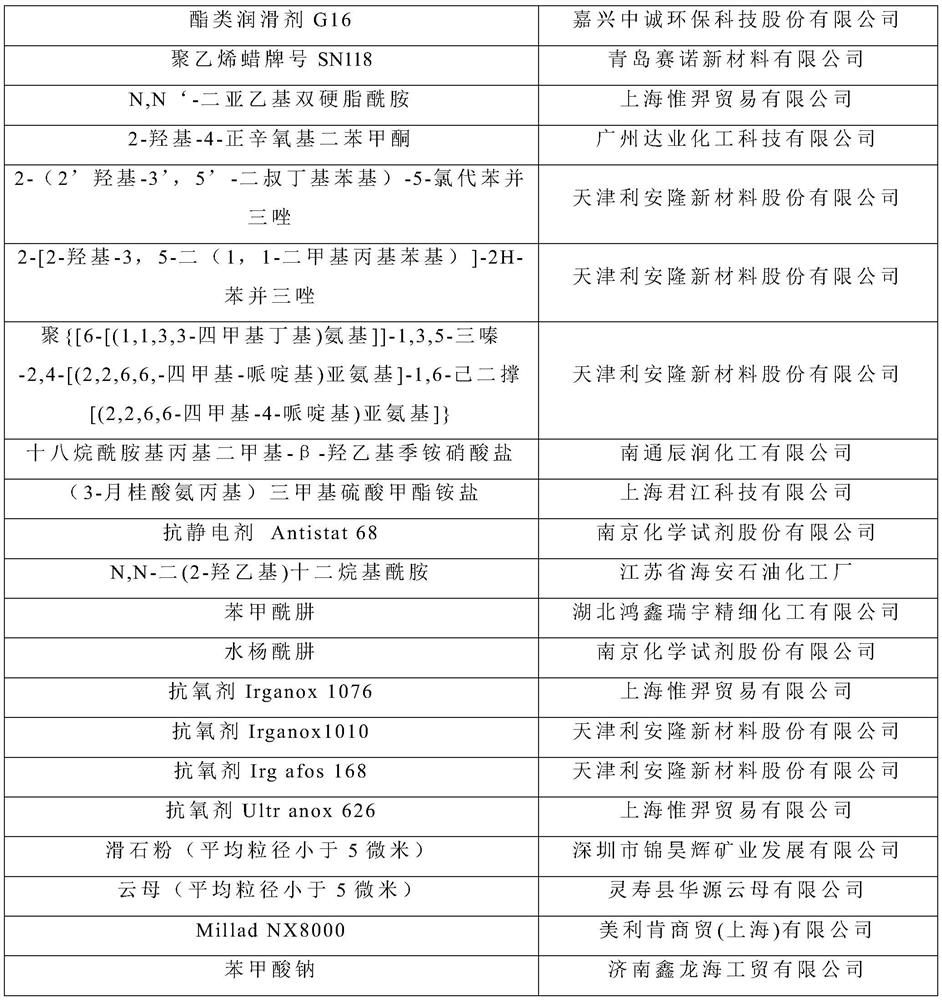

[0092] The functional masterbatches suitable for the preparation of polypropylene cable ties provided in these examples, the raw material formula of which is shown in Table 2 below.

[0093] Table 2

[0094]

[0095]

[0096] The preparation method of the above-mentioned functional masterbatch suitable for preparing polypropylene cable ties is as follows: weighing each raw material according to the formula, mixing, and mixing in a double-rotor continuous internal mixer, the mixing temperature is 80±2°C, and the rotor speed is 300 rpm / minute. The discharge port of the double-rotor continuous mixer is conn...

Embodiment 5-8

[0102] These examples provide polypropylene cable ties, the raw material formula of which is shown in Table 3 below.

[0103] table 3

[0104]

[0105] The preparation method of the above polypropylene cable tie is as follows: weighing raw materials according to the formula, mixing, injection molding, and making; injection molding temperature (zone 1-4): 130°C, 200°C, 225°C, 225°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com