Patents

Literature

46results about How to "Viscosity unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

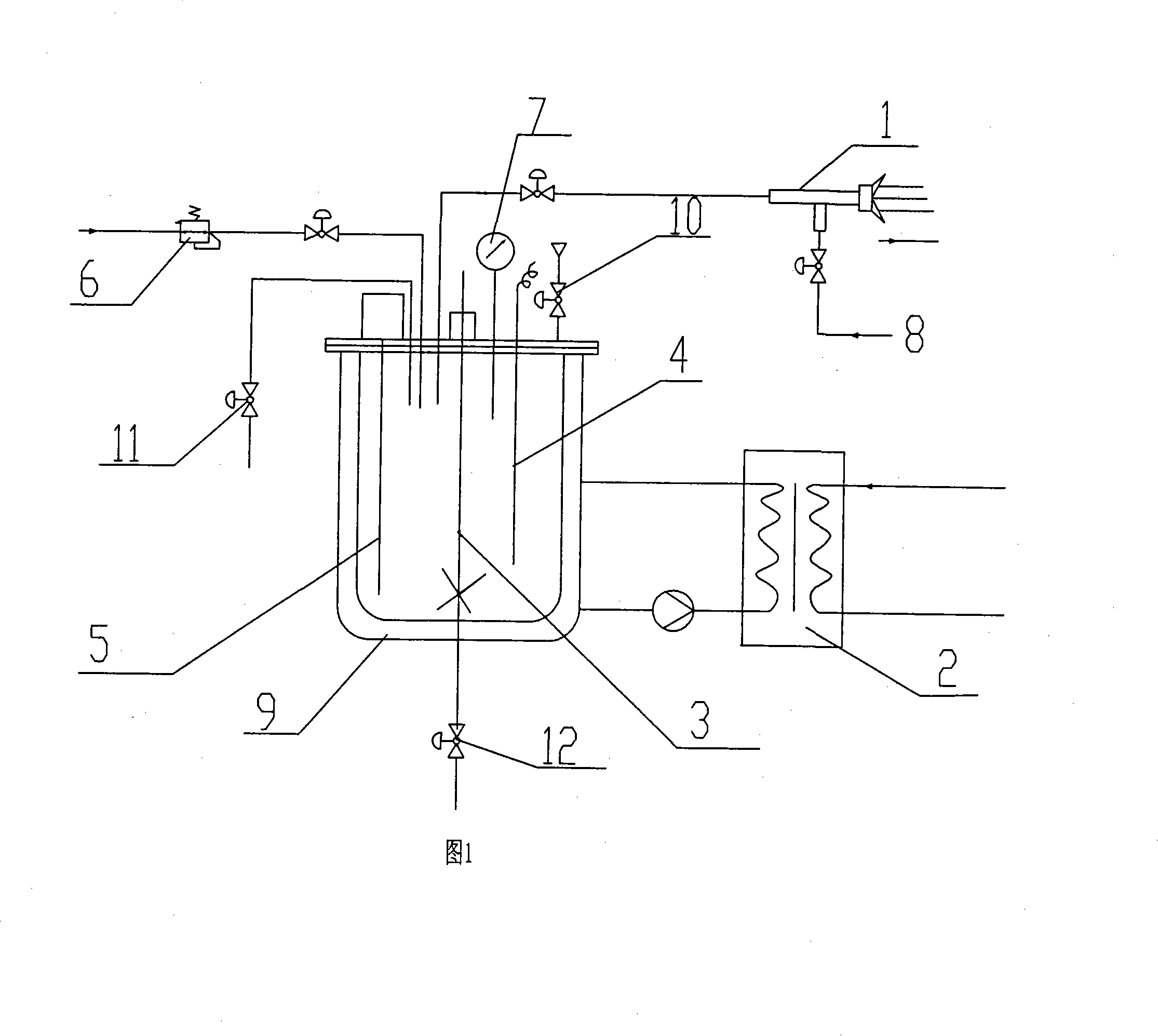

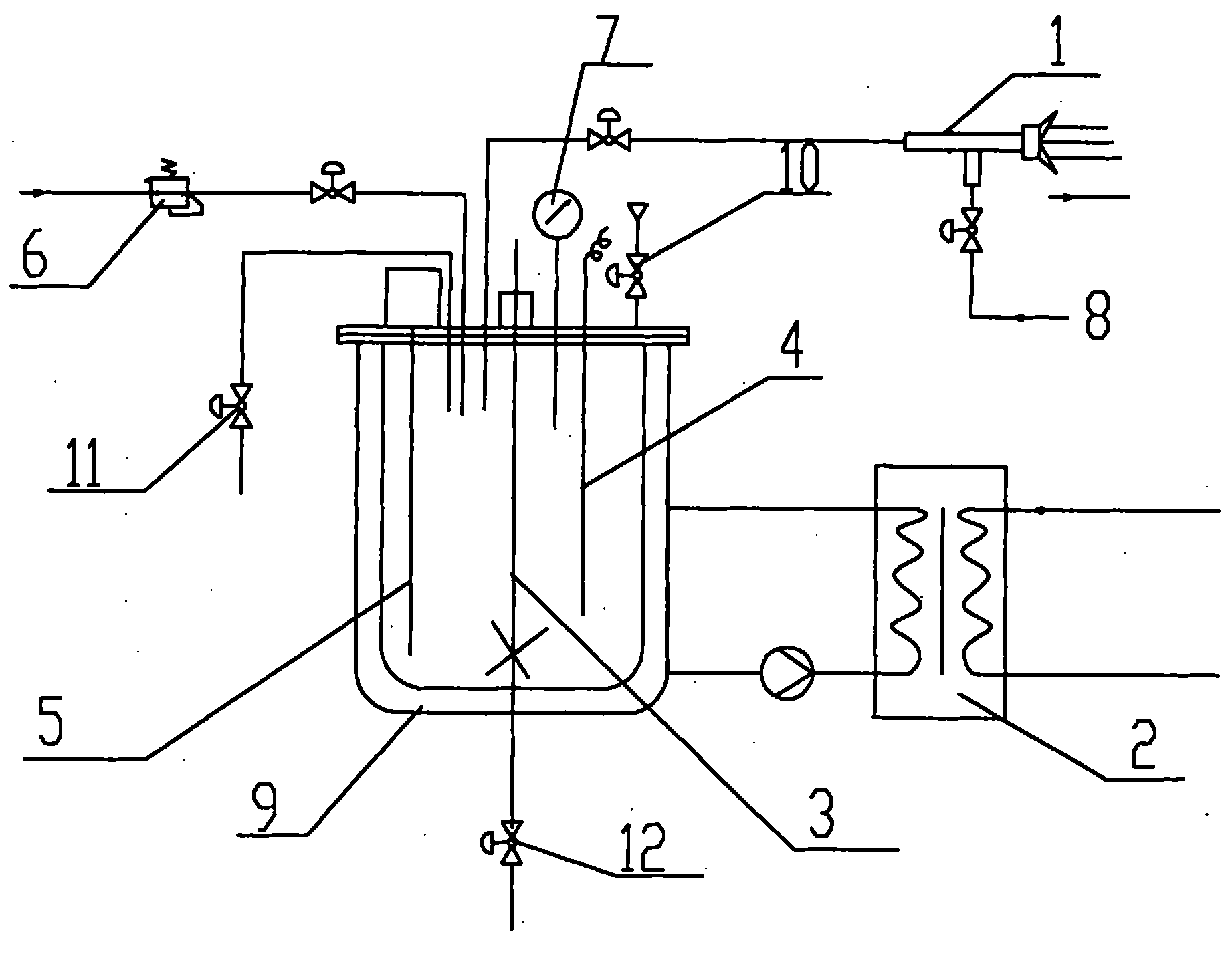

Shadow mask type plasma display fluorescent powder constant-temperature and constant-pressure spraying device

InactiveCN101143354AStable temperatureConstant pressureStatic indicating devicesLiquid spraying apparatusLiquid mediumPhosphor

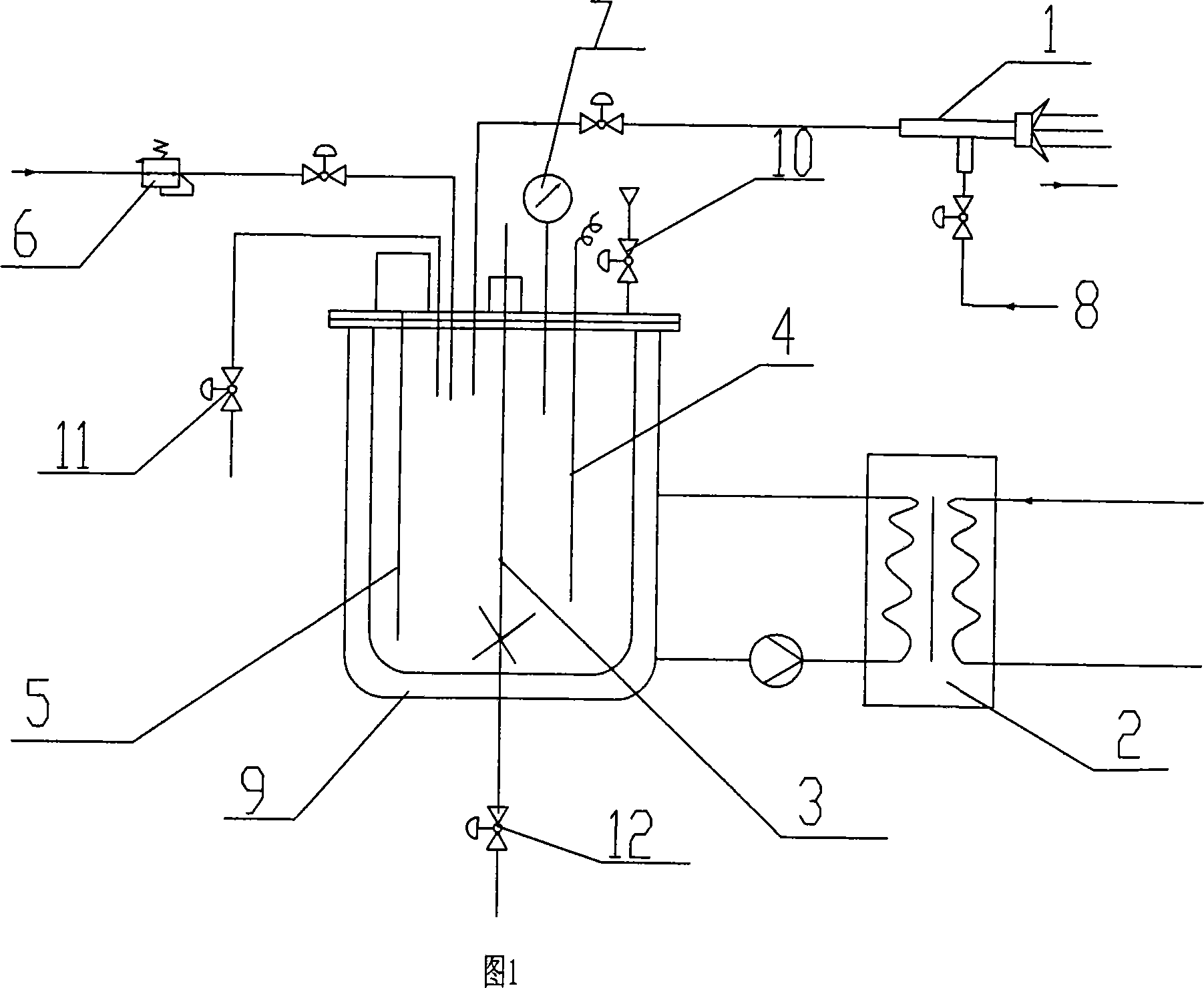

A phosphor constant temperature and pressure spraying device of a plasma display panel with shadow mask belongs to plate television manufacturing equipment, which includes a spray gun (1) and a slurry tank (9). The slurry tank (9) is connected with a feed port (10), an exhaust port (11) and a material discharging port (12). The feed port of the spray gun (1) is respectively connected with a compressed air source (8) and the slurry tank (9) and is characterized in that the tank wall of the slurry system tank (9) is a double-layer structure. Liquid medium is arranged in the tank wall and is connected with a heat exchange system (2). The compressed air source (8) is communicated with the space on the upper part of the liquid in the slurry tank (9) through an air pipe. The air pipe is equipped with a constant pressure valve (6). A stirring shaft (3) is installed in the slurry tank (9) and is driven by a stirring motor. The present invention solves a problem that a present spraying system sprays unevenly and has the advantages of simple structure and good spraying effect.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

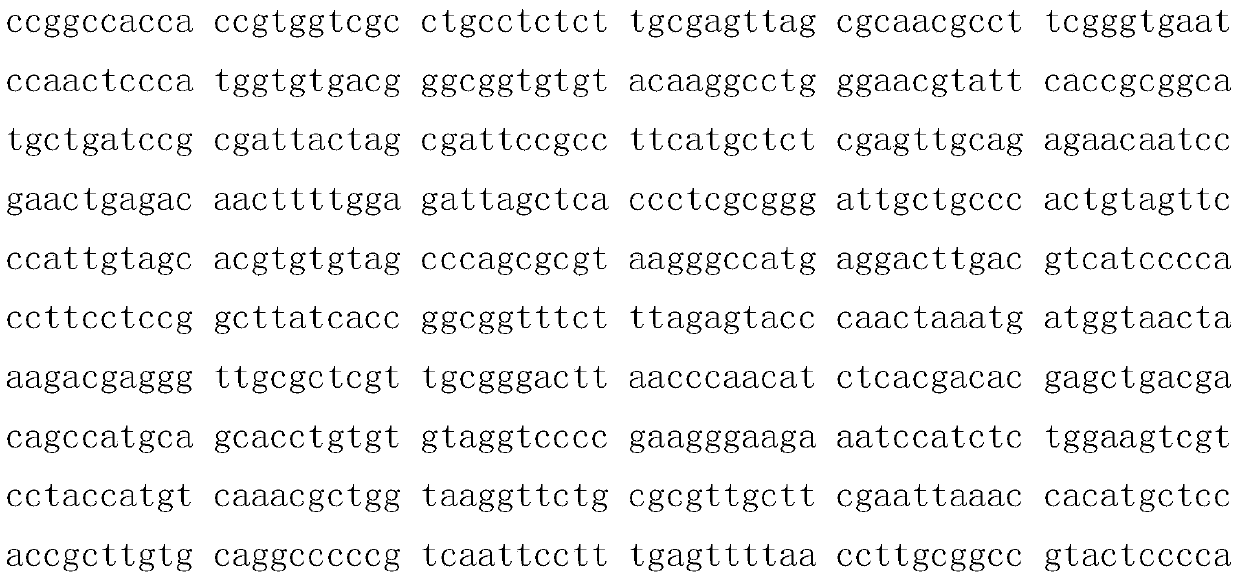

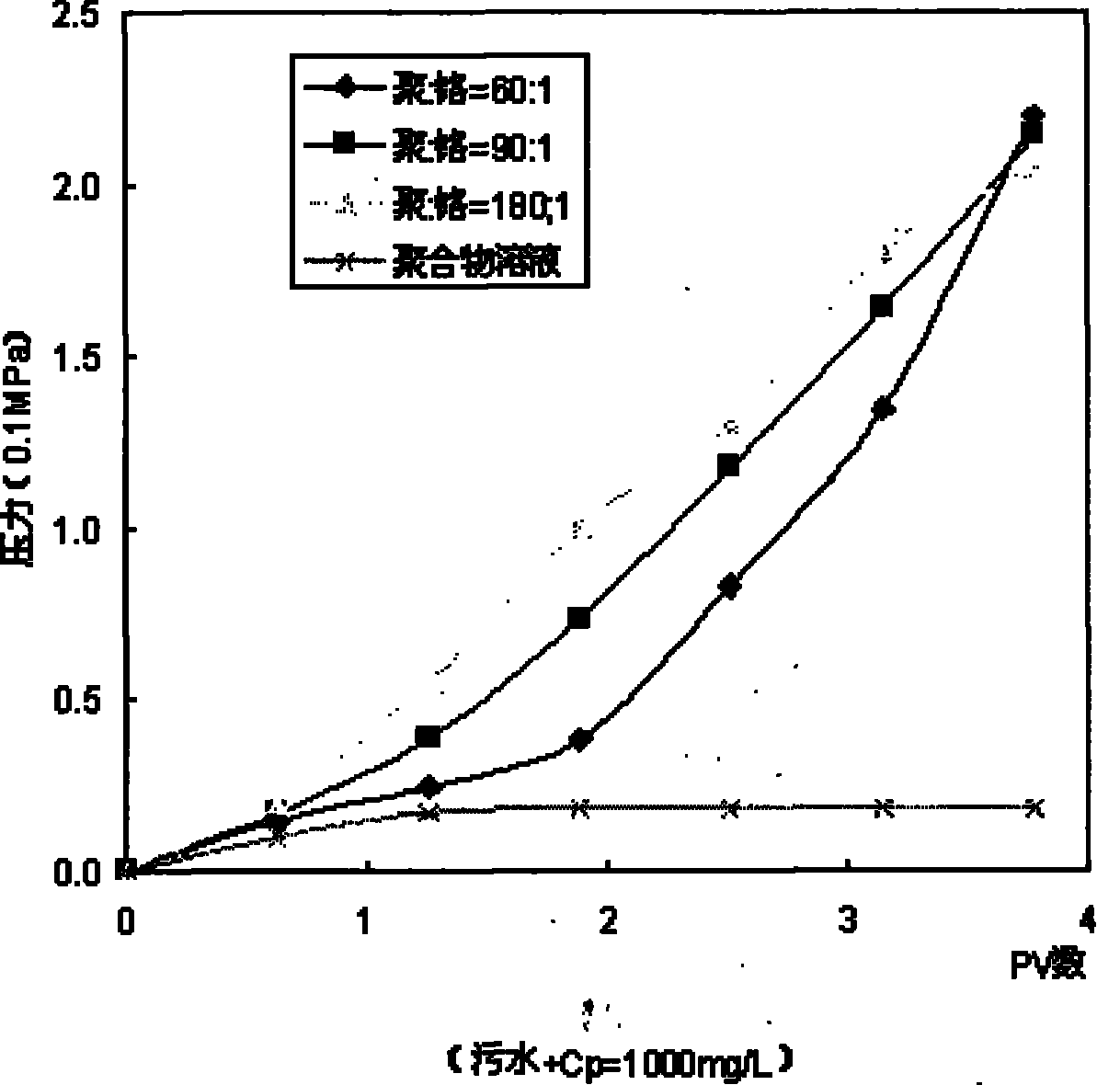

Intramolecular Cr3+ cross-linked polymer gel and its preparation method

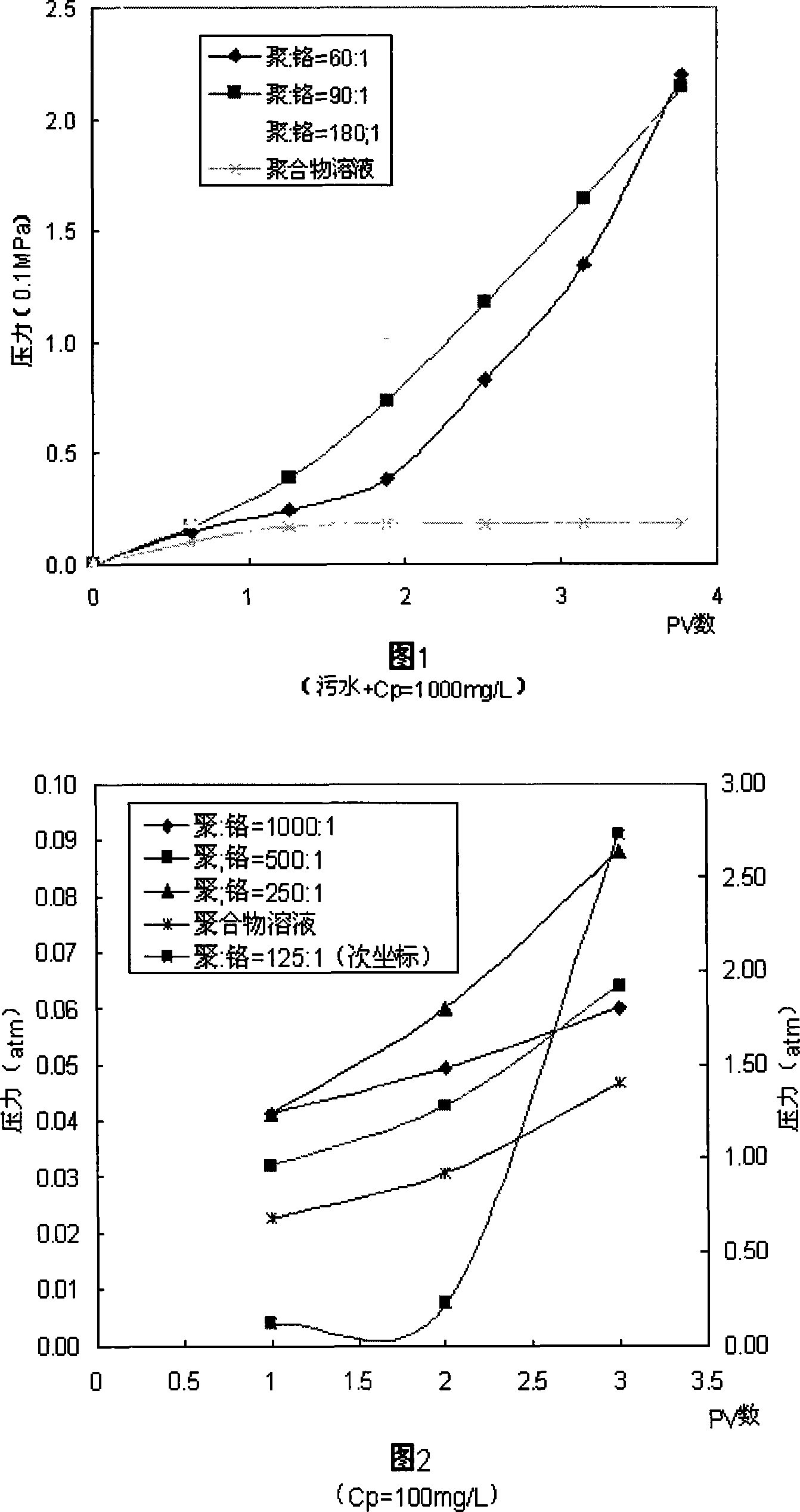

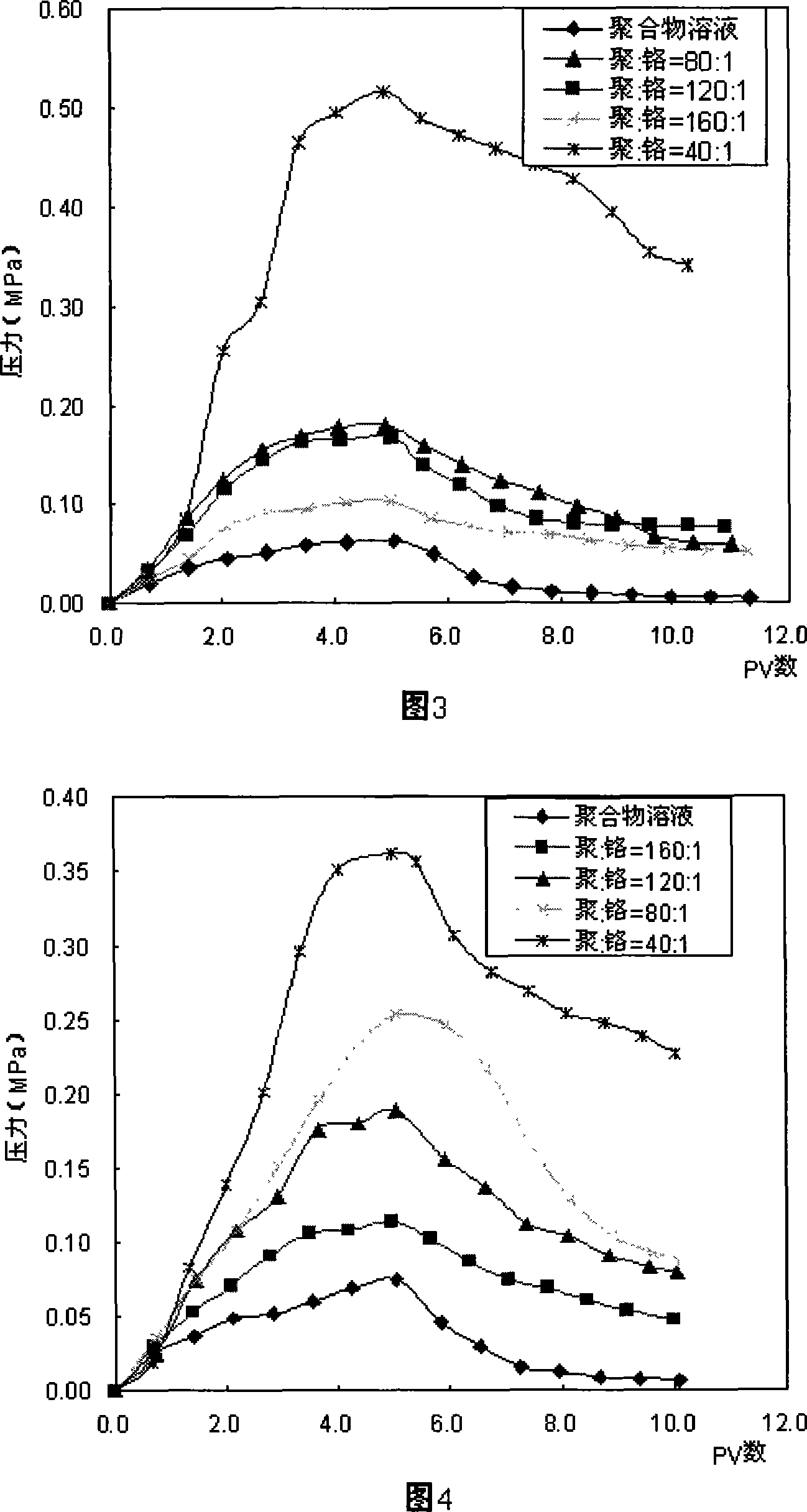

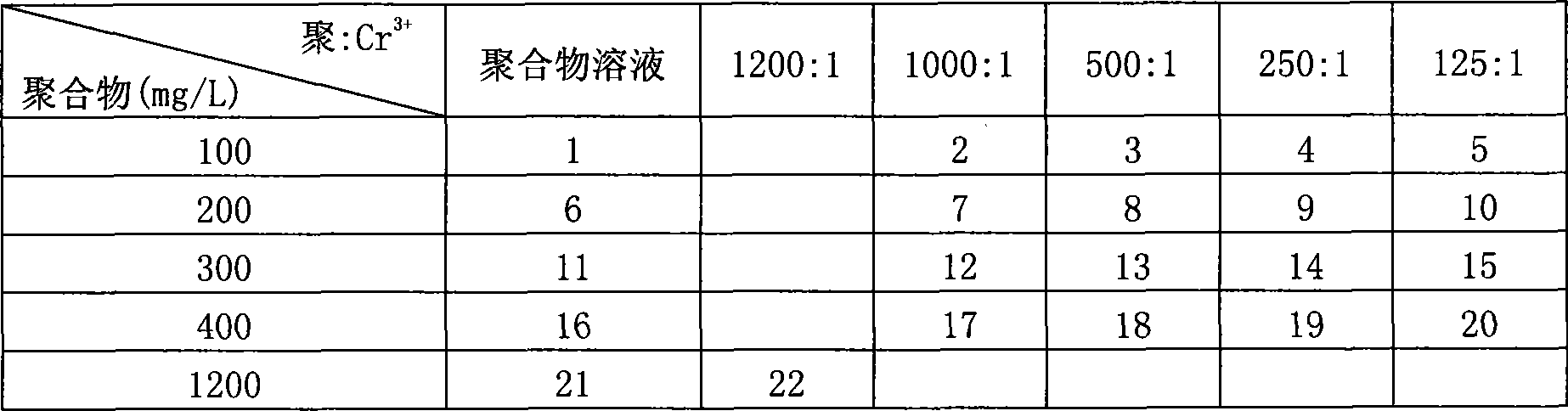

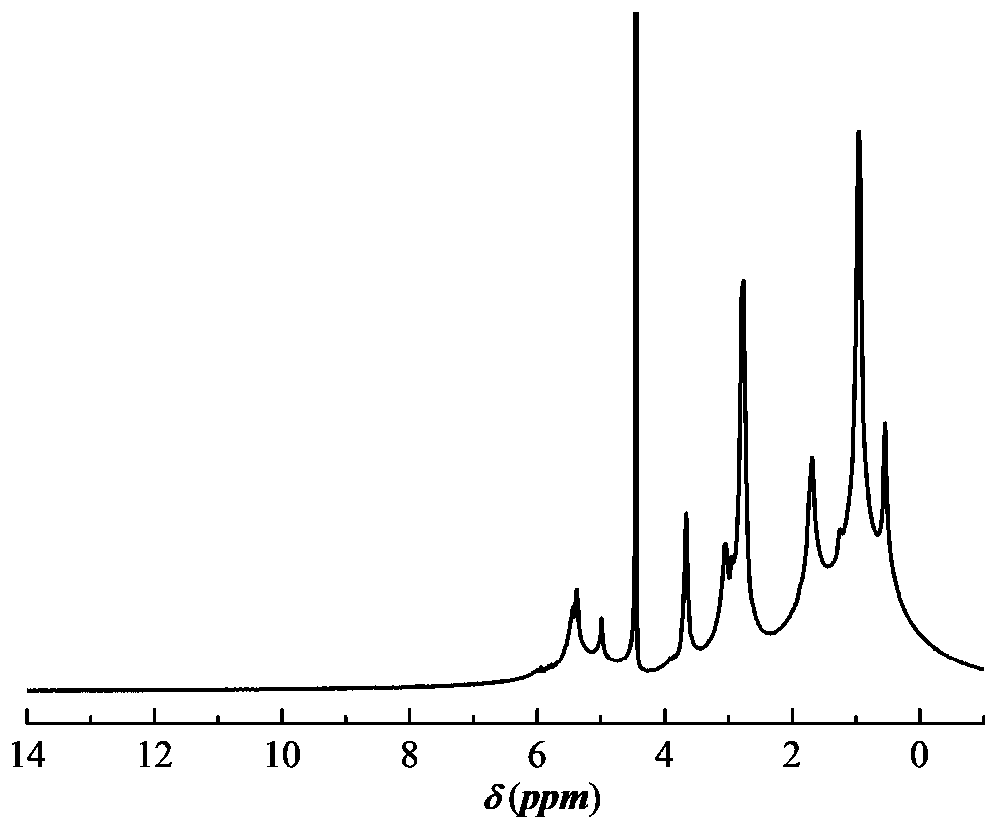

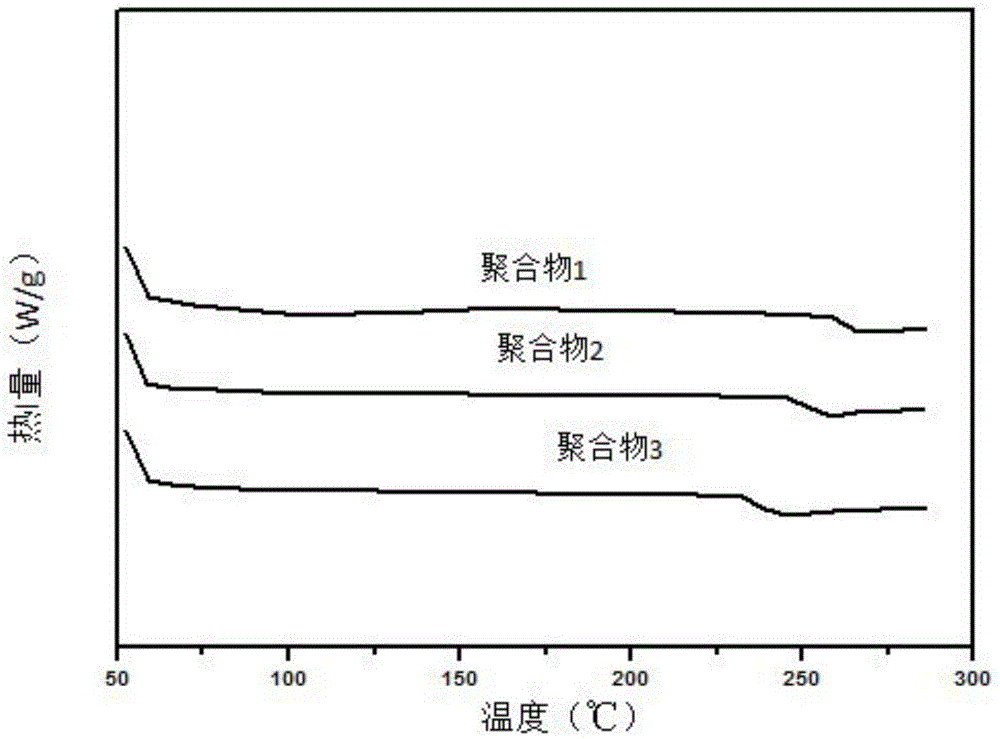

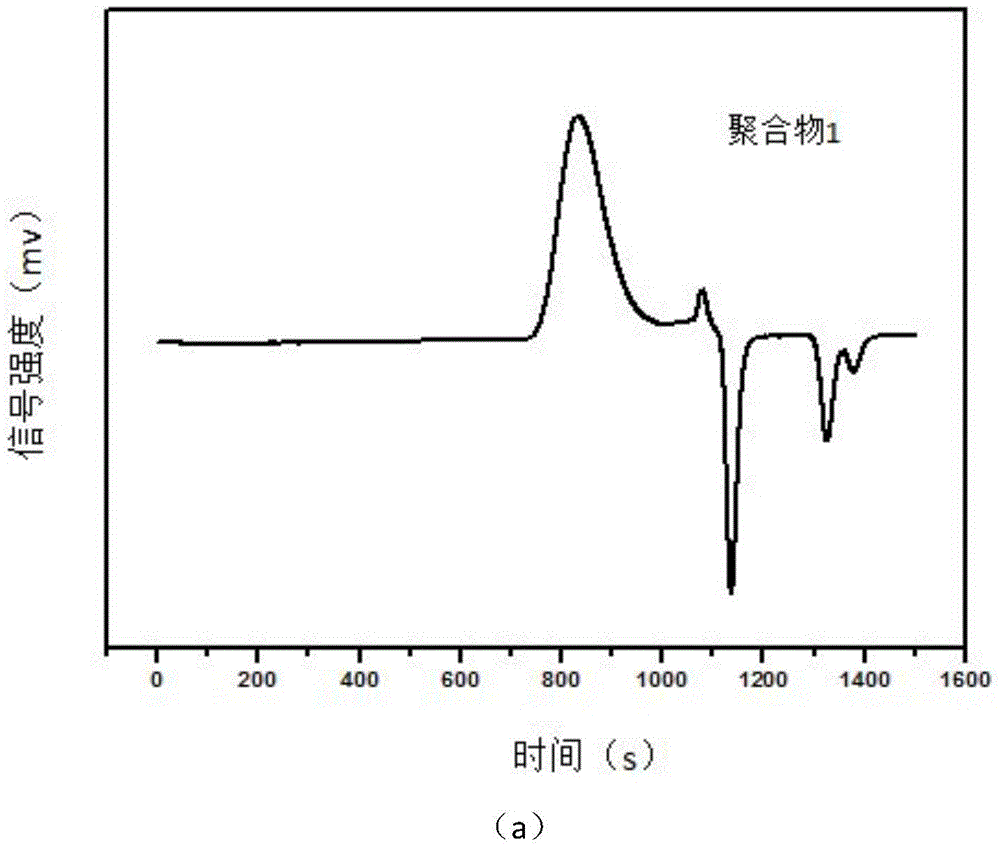

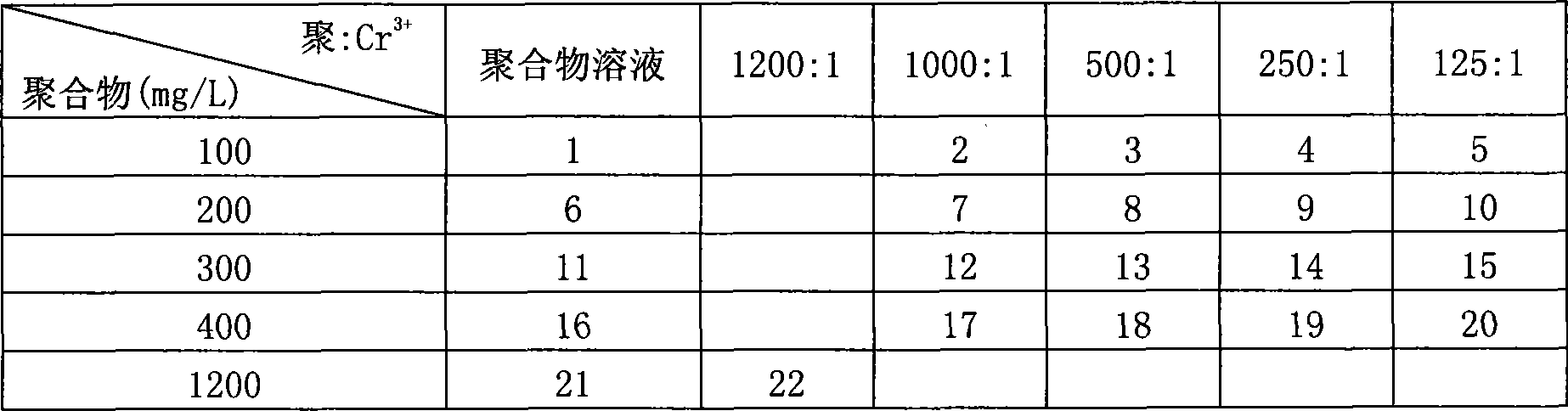

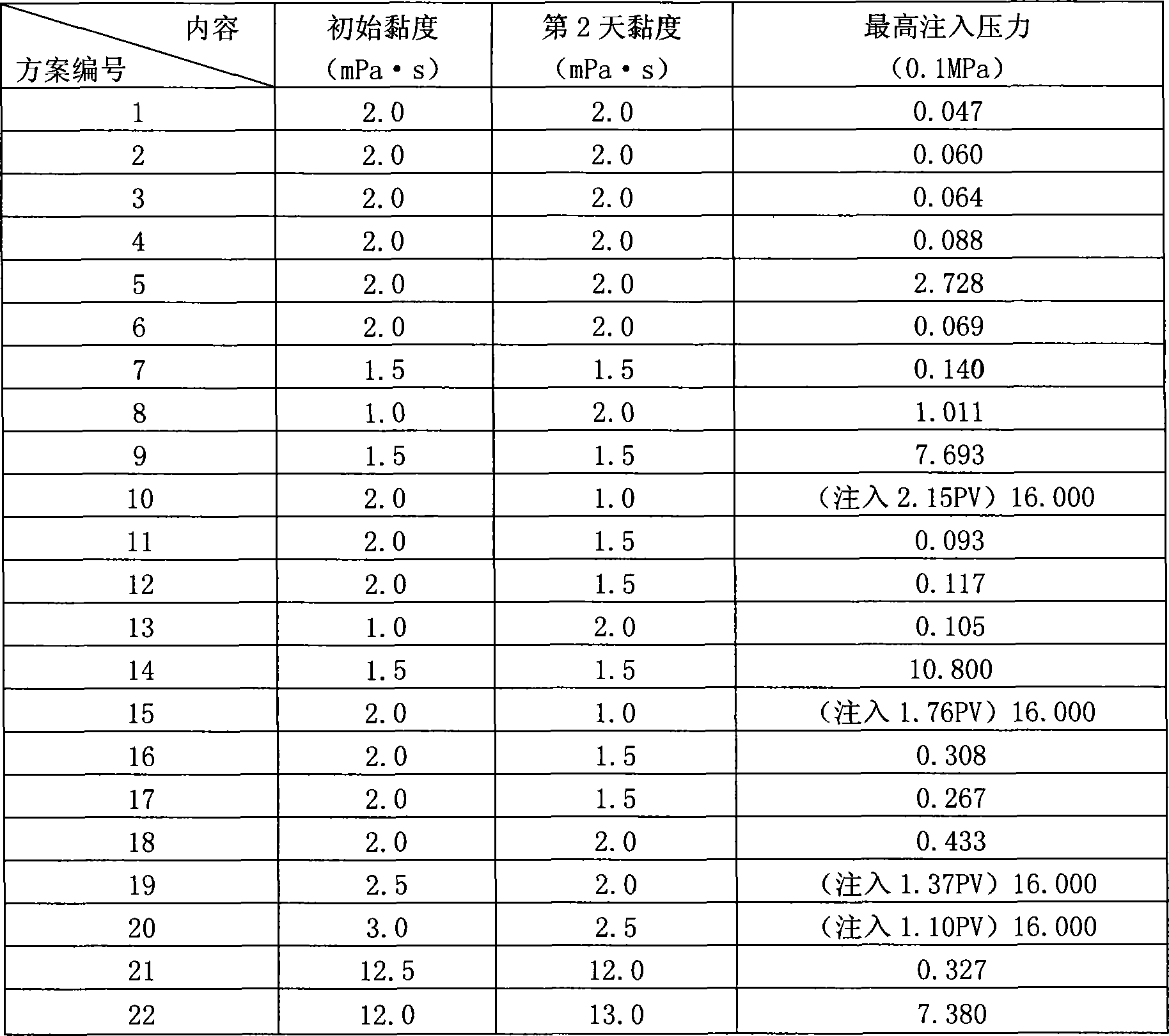

The invention relates to intermolecular Cr 3+ cross-linked polymer gel and a production process. The intermolecular Cr 3+ cross-linked polymer gel comprises the following components which are matched according to mass concentration, wherein partial hydrolysis polyacrylamide is used as host crystal whose concentration range is 0.04%-0.12 %, organic chromium is used as cross linking agent in which the mass concentration of Cr 3+ is calculated based on the mass concentration of polymer, wherein polymer: Cr 3+ = 40:1-100:1, and oil-field produced water or source water is used as solvent. The polymer gel has the characteristics of low viscosity, rapid gel forming speed, large flow resistance and controllable flow ability, which can be used to adjust water injection profile of a water injection well in oil fields which are driven by water, and simultaneously expresses excellent technology and economy.

Owner:BEIJING DONGRUNKE GASOLINEEUM TECH

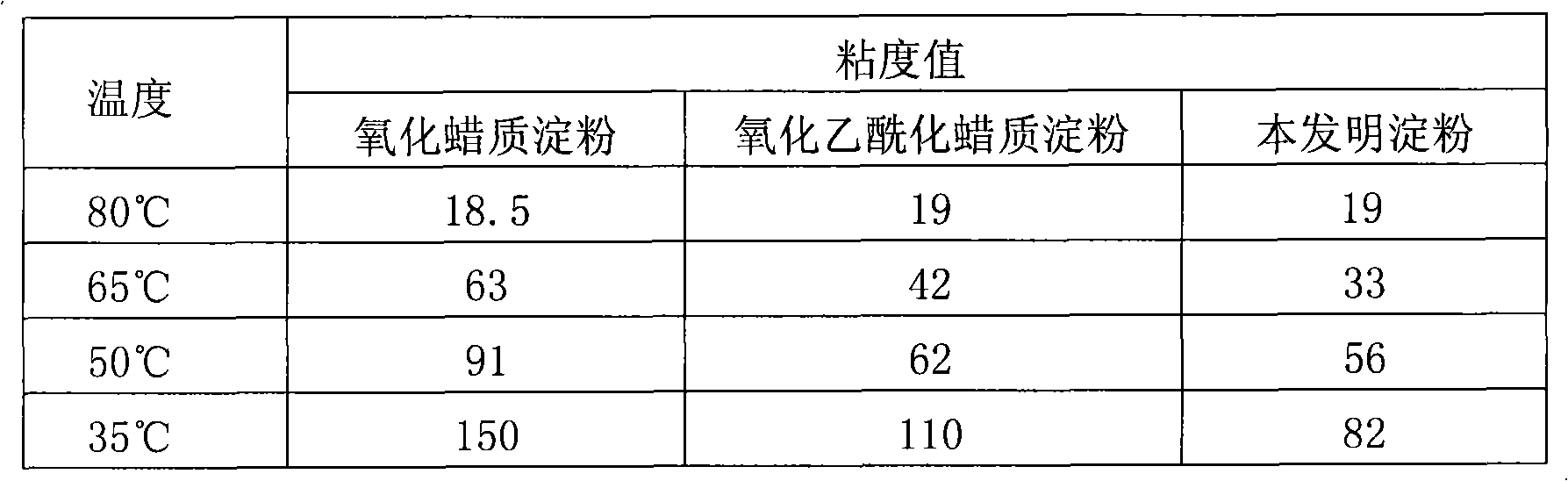

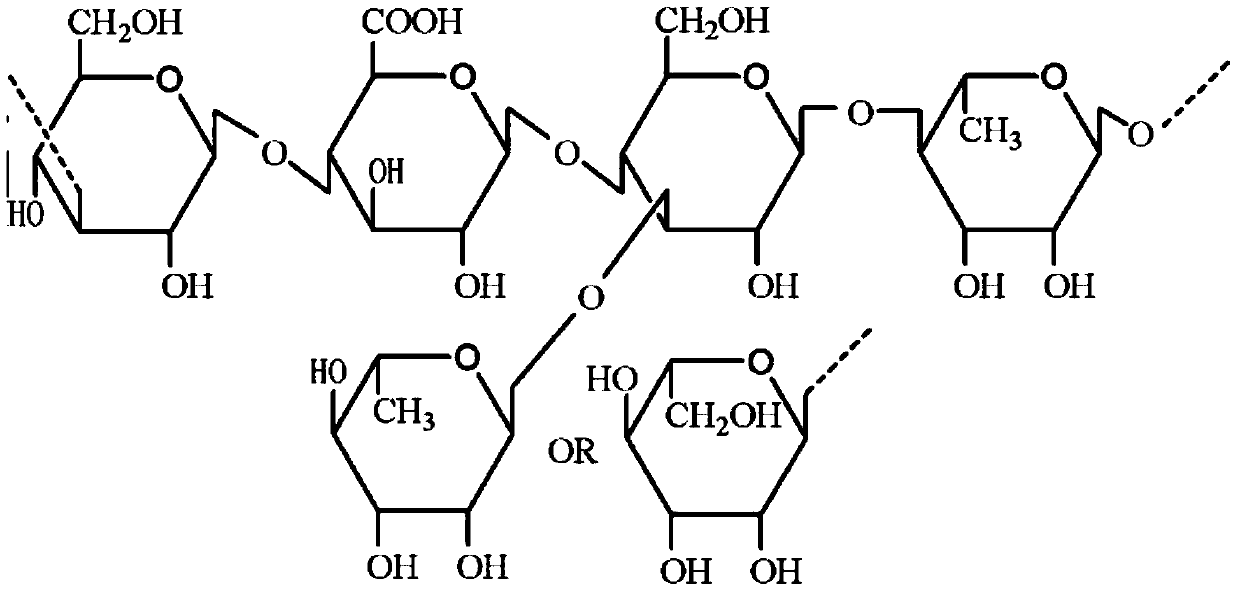

Waxy modified starch, preparation method and application thereof

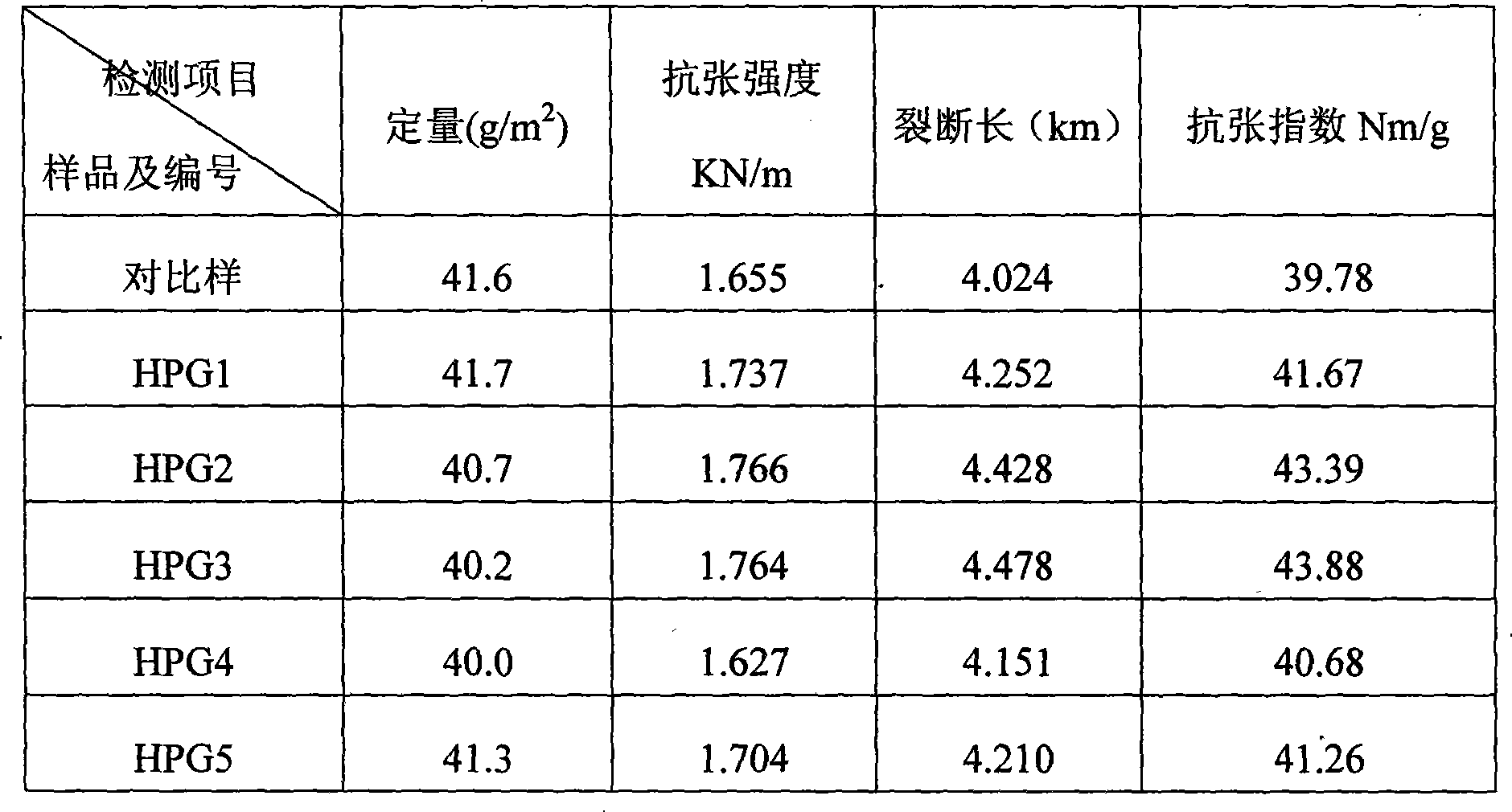

InactiveCN101676308AGood viscosity stabilityViscosity unchangedWater-repelling agents additionFibre treatmentFreeze thawingSolubility

The invention provides a method for producing multiplex composite modified starch using pure branched chain waxy starch as raw paderial and product obtained using the method and application thereof. The production method of the modified starch is a complex reaction of grafting, cross-linking and oxidizing. The multiplex modified starch has features of good paste viscosity stability, high transparency, strong shear force resistance, high water-solubility, good freezing stability and freeze-thawing stability. The modified starch is a good adhesive and can be widely used in food industry, paper industry and weaving industry, especially suitable for surface glue-applying and coating technology in paper industry and warp sizing technology for weaving industry.

Owner:长春大成特用玉米变性淀粉开发有限公司

Process for treating and reclaiming polymer-contained sewage

InactiveCN1381410AViscosity unchangedPut an end to the phenomenonMultistage water/sewage treatmentDisinfectantSewage

A process for deeply treating and reclaiming polymer-contained sewage incldues such steps as loading the said sewage in regulation pool, adding disinfectant; adsorbing 20-30% of suspended substance and bacteria, stage-1 membrane filtering to remove over 99% of suspended substance and bacteria, and filtrate out 80% of Ca2+ and Mg+2 ions, stage-2 membrane filtering to filtrate out 90% of Ca2+, Mg2+, K+ and Na+ ions, storing cleaned water 80%-85% in water tank, and using 15%-20% of concentrated liquid back for preparing polymer solution. Its advantages are high recovery rate of wate (72-81%), and no drainage.

Owner:大庆东昊投资有限公司

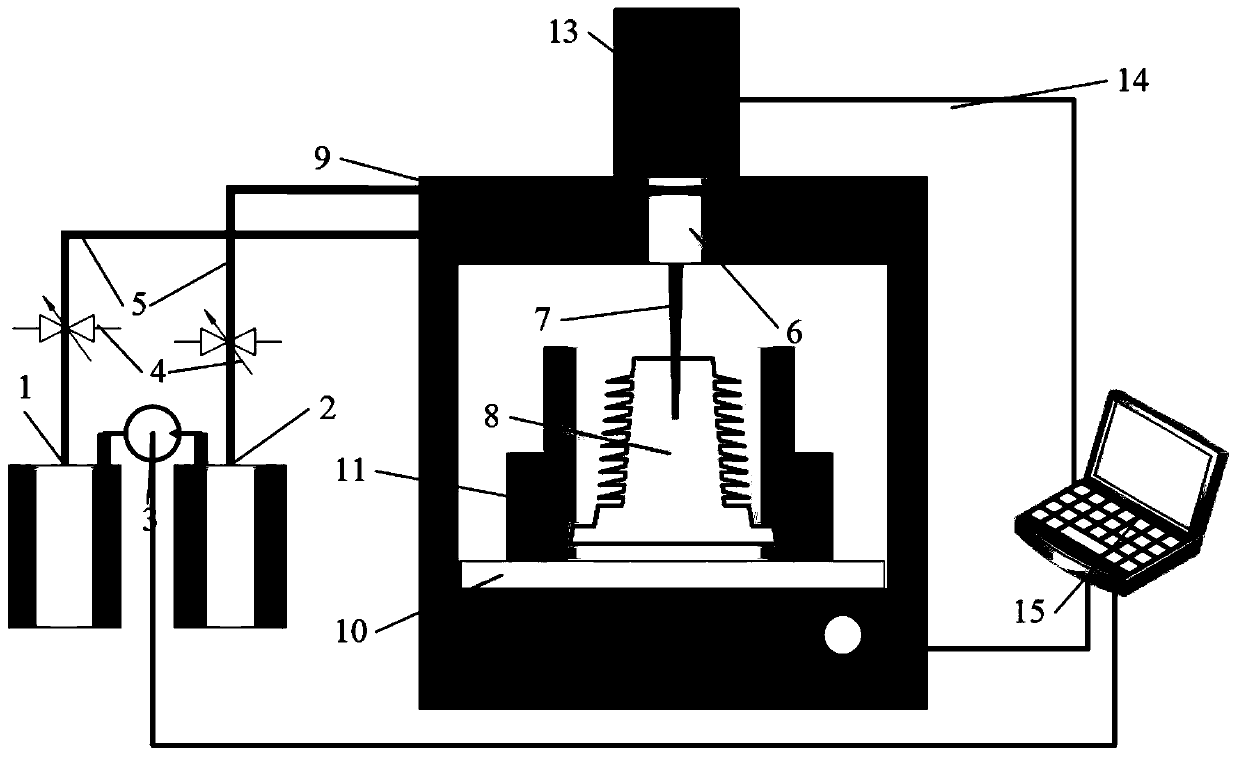

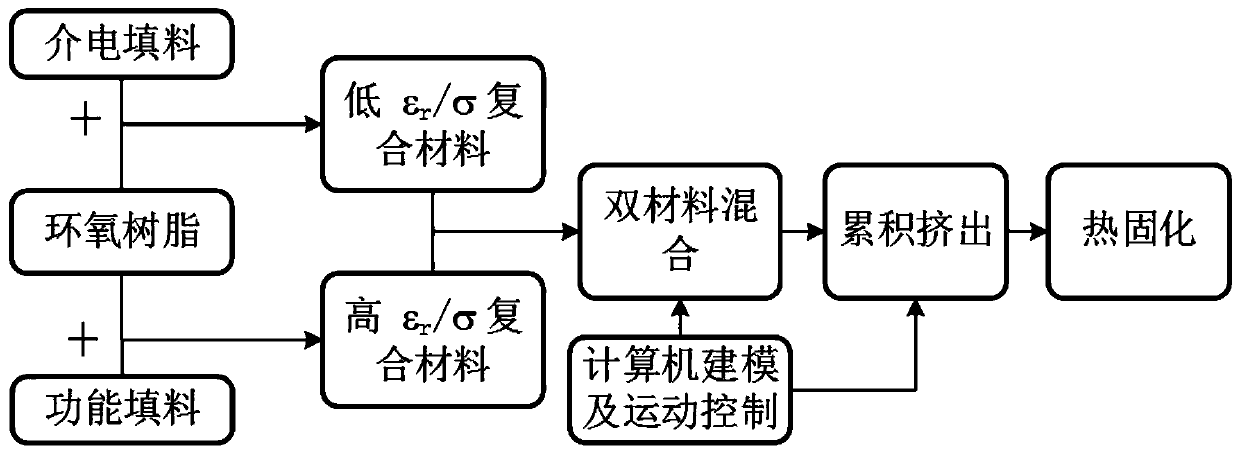

Manufacturing device and method for dual-component mixed epoxy casting dielectric functional gradient insulator

The invention discloses a manufacturing device and method for a dual-component mixed epoxy casting dielectric functional gradient insulator. The manufacturing device comprises a dual-material feedingsystem, wherein an extrusion head of the feeding system is arranged on a three-dimensional motion system; the diameter of a spray hole of the extrusion head is adjustable, and one end of the extrusionhead is positioned inside an epoxy casting metal mould; the three-dimensional motion system is connected to a control system; the control system and the feeding system are separately connected to a computer through cables for raw material supply, mixing and extruding as well as control, on X-direction, Y-direction and Z-direction positions, of the extrusion head, so that manufacturing of a dielectric-constant functional gradient insulator is accomplished. Two epoxy resin composite materials of different dielectric properties are mixed on line, so that materials are accurately transferred to specific positions in the mould through a three-dimensional motion platform, and a large-dimension insulator with continuous dielectric characteristic gradient distribution can be manufactured withoutchanging other characteristics of an insulating structure, and therefore, along-surface electrical resistance is improved.

Owner:XI AN JIAOTONG UNIV

Acrylic acid grafted polyvinyl alcohol enhancer, and preparation method and application thereof

The invention discloses an acrylic acid grafted polyvinyl alcohol enhancer, and a preparation method and application thereof. The preparation method comprises the following steps: adding 0.1-1 part of polyvinyl alcohol into 4-10 parts of water, and heating at 60-90 DEG C for 1-5 hours to gelatinize the polyvinyl alcohol; and adding 1-5 parts of acrylic acid, adding alkali to regulate the pH value to 7-8, adding 0.01-0.1 part of initiator, and reacting at 60-90 DEG C for 2-6 hours to obtain the acrylic acid grafted polyvinyl alcohol enhancer. The polyvinyl alcohol chain used as the framework is grafted with the polyacrylic acid branched chain with certain flexibility to form the block macromolecular structure with branched chain, so that the prepared enhancer has better enhancement effect; and the nano glaze slip with the enhancer can not easily crack after being applied to the ceramic billet surface. The enhancer has small influence on the viscosity and flowability of the glaze slip, so the glaze thickness on the billet surface can not be influenced when the traditional glazing method is adopted.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

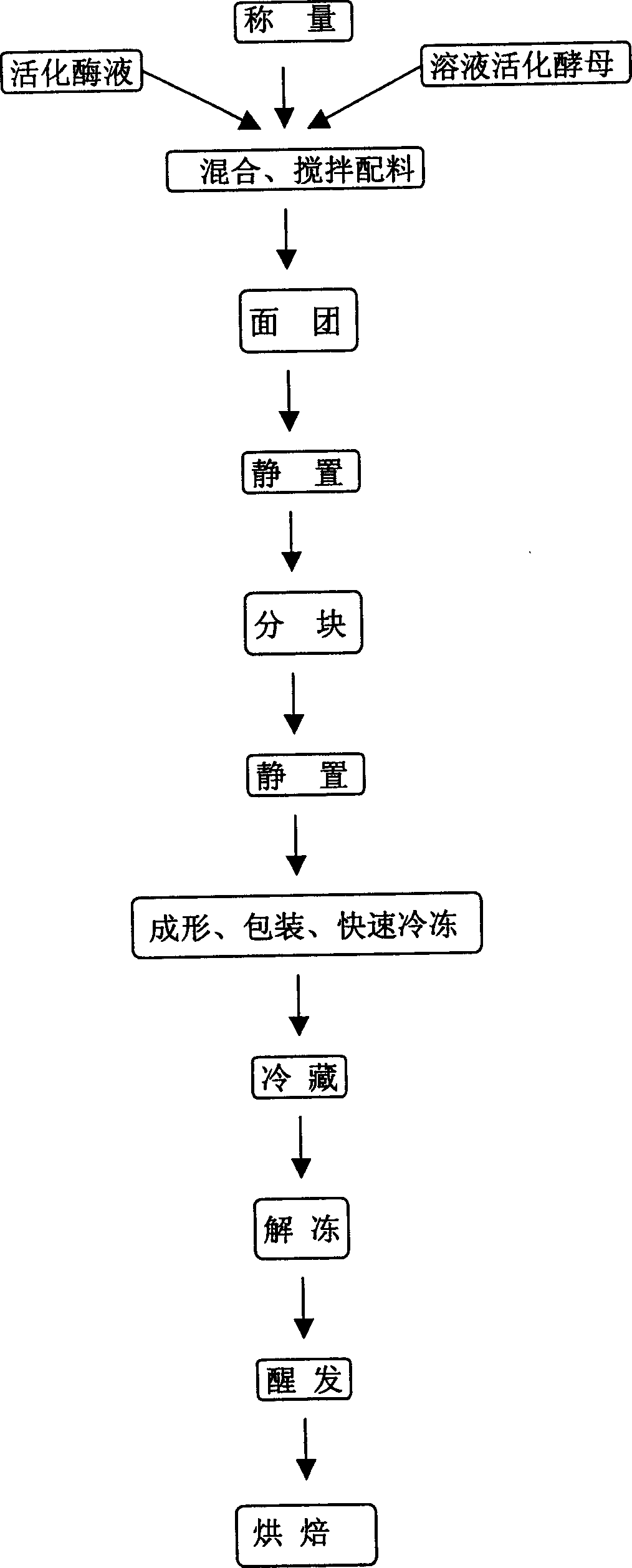

Method for improving protein frost resistance of fermented cryogenic flour dough

The invention relates to a method for improving the freezing resistance of protein in fermentative freeze flour dough, belonging to foodstuff technique field, mixing the flour, molecular distillation gly ester, sodium alginate, cane sugar, salt, milk powder, and shortening in the stirring tank, adding ice water and activated pentosanase and glucose oxidase solution and yeast solution; stirring until the flour dough forms, through static relaxation, measuring, block separation, rolling and static relaxation again to form flour dough, then freezing for convenient use and instant curing. The invention employs the natural matter of pentosanase and glucose oxidase to catalyze the cross-linking between protein to form more stable flour gluten net structure, which prevent the damage to flour gluten net structure by ice crystal in the froze flour dough, and employs molecular distillation gly ester and sodium alginate to reduce the ice crystal volume, improve the stability of froze flour dough under low temperature to make the specific volume of produced bread be increased obviously and the pulp structure be more delicate and uniform.

Owner:JIANGNAN UNIV

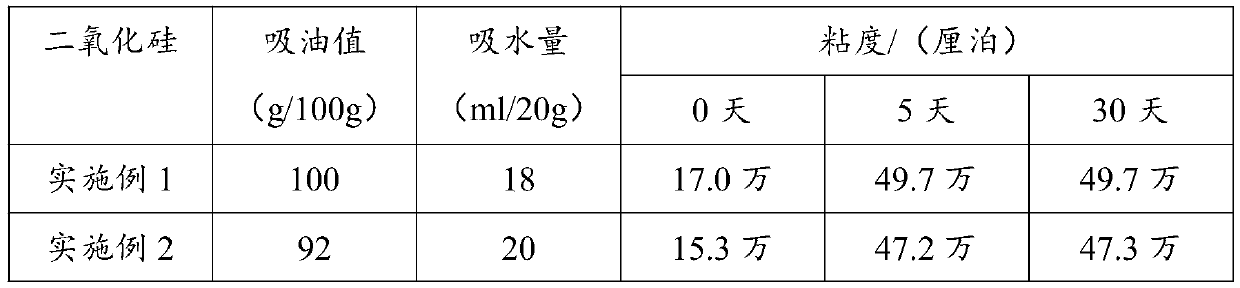

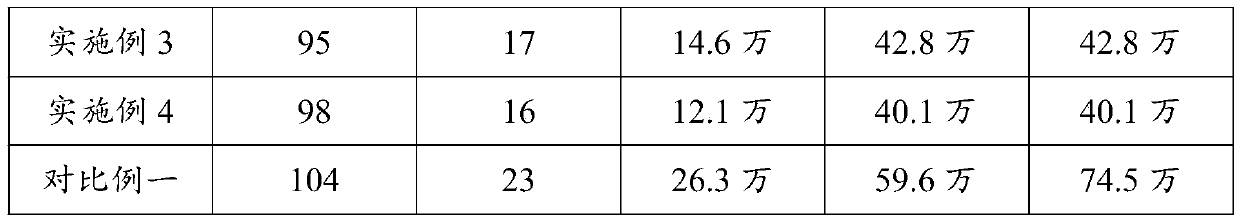

Precipitated silica for low-viscosity toothpaste and preparation method of precipitated silica

ActiveCN110015667AImprove adsorption capacityLow initial viscosityCosmetic preparationsSilicaFiltrationToothpaste

The invention belongs to the technical field of silica preparation, and particularly relates to precipitated silica for low-viscosity toothpaste and a preparation method of the precipitated silica. The preparation method comprises the following steps: S1, adding a sodium sulfate solution to a reaction kettle, conducting stirring and heating, and then adding a sodium silicate solution to adjust thepH value; S2, simultaneously adding a sodium silicate solution and a sulfuric acid solution for reaction, and controlling the pH value of the reaction process to be 9-10, and after the sodium silicate solution is completely added, continuing adding the sulfuric acid solution until an end point pH value, and conducting stirring to obtain a preliminary product of silica; and S3, subjecting the preliminary product of silica to pressure filtration and washing by dilute sulfuric acid, and then conducting drying, and finally conducting crushing, so as to prepare the silica. The silica of the present invention can reduce the initial viscosity of the toothpaste and inhibit the viscosity of the toothpaste from growing, enables the toothpaste to maintain a proper viscosity, a good pseudoplasticityand thixotropy, and has a good application effect.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

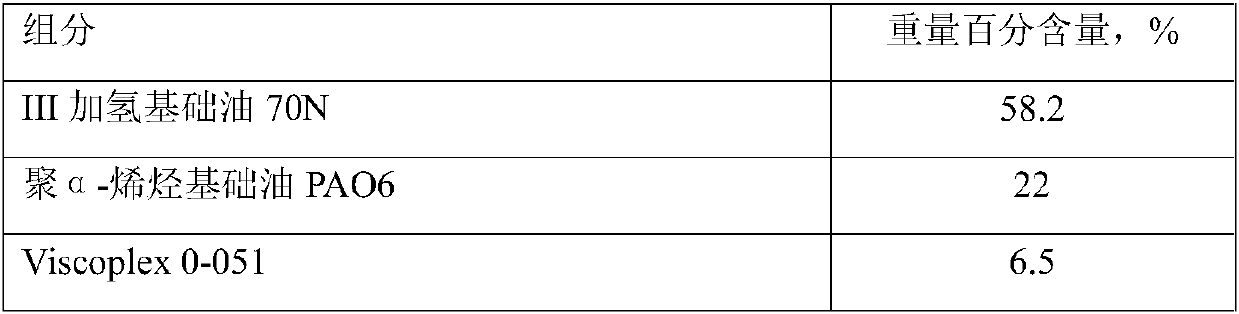

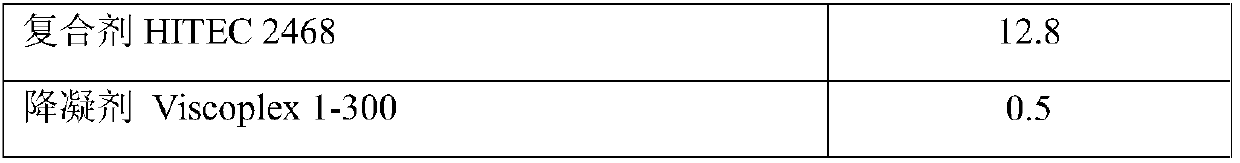

Lubricating oil composition for electric vehicle gearbox and preparation method of lubricating oil composition

ActiveCN107828481AGood shear stabilityViscosity unchangedLubricant compositionStability indexElectric vehicle

The invention discloses a lubricating oil composition for an electric vehicle gearbox and a preparation method of the lubricating oil composition. The composition is prepared from the following components in percentages by weight: 79.8 to 84.5% of base oil, 4 to 7% of polymethacrylate viscosity index improver, 10 to 13% of special complexing agent for transmission oil and 0.3 to 0.5% of pour pointdepressant, wherein the polymethacrylate viscosity index improver is a comb-shaped polymer, and a shear stability index of the polymethacrylate viscosity index improver KRL 20h is not greater than 28. The lubricating oil composition for the electric vehicle gearbox and the preparation method have the advantages that prepared oil maintains viscosity unchanged under long-term high-speed shearing force, provides reliable protection for the electric vehicle gearbox, has excellent shear stability, outstanding low-temperature rheological property, and capability of greatly increasing high-temperature thickening ability of the oil with low dosage, has good dispersibility, can reduce deposition of oil oxides, and can be used together with a special complexing agent for gearbox to improve cleaningand dispersion performance of the oil.

Owner:JIANGSU LOPALTECH

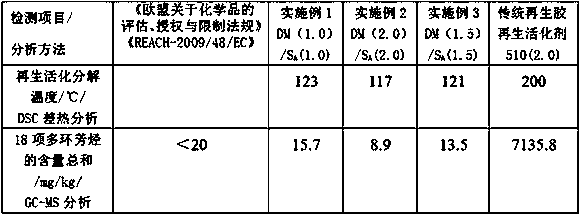

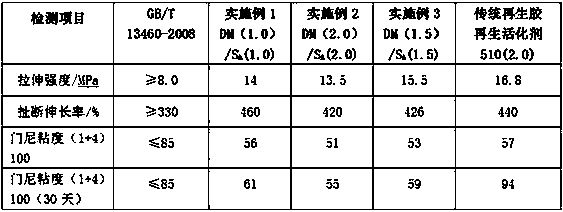

Method of producing environment-friendly regenerated rubber via low-temperature desulfurization

ActiveCN108219192AFast link breakImprove mechanical propertiesPlastic recyclingSocial benefitsPlasticizer

The invention discloses a method of producing environment-friendly regenerated rubber via low-temperature desulfurization. The method includes the steps of: 1) low-temperature desulfurization througha desulfurization tank or an internal mixer: feeding rubber powder, a composite regenerating activator, and a Mooney stabilizer into the desulfurization tank or internal mixer, performing pressurizedmixing for a certain time, adding an environment-friendly softener such as rosin, performing pressurized mixing for a certain time, heating the material to 120 + / - 5 DEG C for desulfurization regeneration; 2) after regeneration for a certain time, cooling the material to lower than 70 DEG C, discharging the material into a cooling stirrer; 3) at 120 + / - 5 DEG C, delivering the material to a doublescrew plasticizer, cooling the material and discharging the material to a storage plate, and delivering the material to a refiner; 4) circulating the rubber at 40 DEG C in a thin-passing manner for 5min, and automatically cutting and weighing the rubber. The technology has outstanding economic and social benefits.

Owner:XUZHOU COLLEGE OF INDAL TECH

Preparation method of sulfur-modified chloroprene rubber with high latex Mooney viscosity stability

The invention belongs to the technical field of chloroprene rubber preparation, and provides a preparation method of a sulfur-modified chloroprene rubber with a high latex Mooney viscosity stability in order to solve the problems that the final chain-broken products of conventional sulfur-modified chloroprene rubber are not stable, the Mooney viscosity of latex changes after being stored for a while, the storage stability of raw rubber is bad, the rubber will become hard and the rubber plasticity is reduced after long-term storage, the processing performance turns worse, and the performance of sulfurized rubber degrades. The preparation method comprises the following steps: dissolving sulfur, tetrabutyl thiuram disulfide, and 2-mercaptobenzothiazole into chloroprene monomers to prepare an oil phase; mixing the oil phase with a prepared water phase to carry out emulsification, adding an initiator to carry out reactions; stopping the reactions when the specific weight of the system reaches 1.075 to 1.077, allowing the system to stand still for a while, then adjusting the pH value, cooling on the drum to carry out gelation, and cleaning and drying the gel so as to obtain the target product. The polymerization can be easily controlled, the formula and the technology are simple and convenient, the chain breaking technology is omitted, the molecular weight can be adjusted to a proper value in a short time, the Mooney viscosity of the obtain latex is stable; and the problems that the latex viscosity is hard to control and the storage stability of the latex is bad are solved.

Owner:SHANNA SYNTHETIC RUBBER

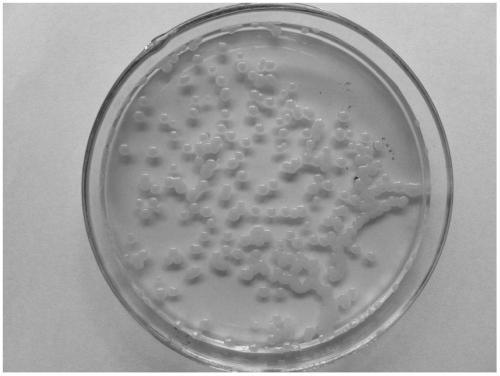

Sphingomonas paucimobilis strain and application thereof

InactiveCN105505816ANutrition Facts EasyEasy to operateBacteriaMicroorganism based processesInorganic saltsGellan gum

The invention discloses a Sphingomonas paucimobilis strain and application thereof and belongs to the technical field of bioengineering. The Sphingomonas paucimobilis strain is named Sphingomonas paucimobilis strain Y5, is collected in CCTCC (China Center for Type Culture Collection), which is located in Wuhan University, Wuhan, China, and has the collection number of CCTCC NO: M 2015523. Welan gum can be prepared from the train by fermenting under appropriate conditions through carbon sources, nitrogen sources, inorganic salts and water . The strain disclosed by the invention has relatively high sugar conversion ratio and welan gum yield and has a certain application value. The welan gum produced through fermenting the strain is high in quality and is resistant to acids and bases, a 1% aqueous solution viscosity of the welan gum reaches 3500mPa.S, and the viscosity is fundamentally unchanged at the temperature of 150 DEG C. During the fermentation of the strain, the sugar conversion ratio is relatively high and reaches 55% to 60%, and the yield is relatively high and reaches 25-32g / L (dry weight).

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

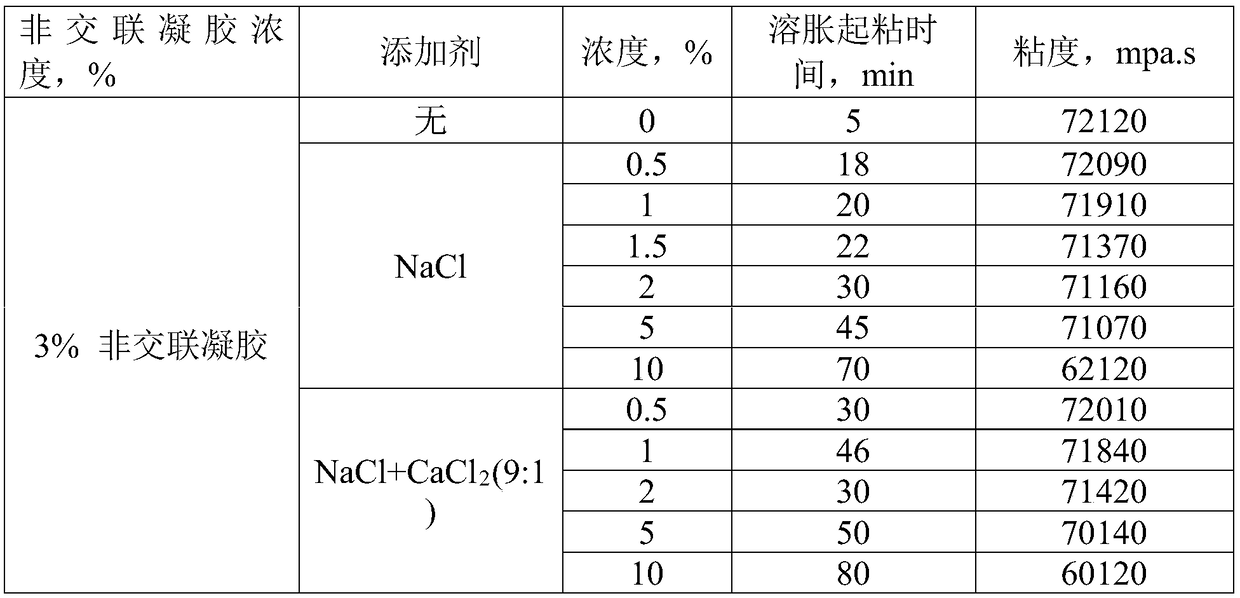

Method for slowing dissolving speed of non-crosslinked gel in blockage-adjusting agent for oil field

InactiveCN109370552AImprove swelling and sticking timeProlonged swelling and sticking timeDrilling compositionInorganic saltsOperability

The invention discloses a method for slowing the dissolving speed of non-crosslinked gel in a blockage-adjusting agent for an oil field. The blockage-adjusting agent is aqueous solutionon-crosslinkedgel solution prepared by adding the non-crosslinked gel into water on a construction site; in the preparation process, the non-crosslinked gel is added into aqueous solution containing soluble inorganic-salt additive to prepare the blockage-adjusting agent; the blockage-adjusting agent is prepared by the following specific steps: (S1) on the construction site, dissolving the soluble inorganic-saltadditive into clean water in advance to obtain salt solution; (S2) dissolving the non-crosslinked gel in the salt solution to obtain the blockage-adjusting agent. The inorganic-salt additive is sodium chloride or calcium chloride or a mixture of the sodium chloride and the calcium chloride. The method for slowing the dissolving speed of the non-crosslinked gel, disclosed by the invention, has thebeneficial effects that the problem that the sticky and rod-climbing phenomenon is serious due to excessively-fast dissolving speed of high-strength non-crosslinked gel and causes difficulty in pumping injection and failure in pumping injection when the non-crosslinked gel is injected into the stratum can be solved and technical support can be provided for operability of on-site construction.

Owner:CHINA NAT OFFSHORE OIL CORP +1

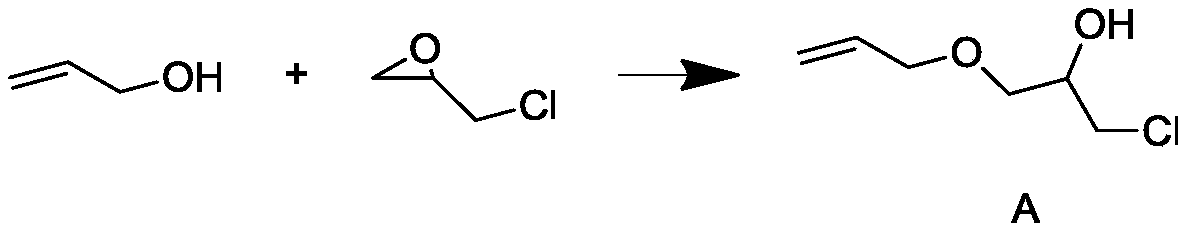

High-salt-resistant viscoelastic surfactant cleaning fracturing fluid and preparation method thereof

ActiveCN109705835AResistant to high saltHigh viscosityOrganic compound preparationCarboxylic acid amides preparationCarbon numberInorganic salts

The invention discloses a high-salt-resistant viscoelastic surfactant cleaning fracturing fluid and a preparation method thereof. The fracturing fluid contains a cationic surface active agent, and thestructural formula of the cationic surface active agent is shown as the following formula. In the formula, R<1>' is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and a compound as shown in the following formula, wherein R<1> is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24; and R<2> is selected from saturated alkyls with a carbon number C meetinga relationship of 3<=C<=7, unsaturated alkyls with a carbon number C meeting a relationship of 3<=C<=7, and short-chain alkylbenzene (C<=5). The cationic surfactant has good resistance to inorganic salts, and the principle is that the R<2> substituent groups block mutual proximity between polar head groups of the cationic surface active agent under a high-mineralization-degree condition, and thenprecipitation of the cationic surface active agent is avoided, so that the micelle continues keeping a dense three-dimensional network structure, and tackifying performance is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

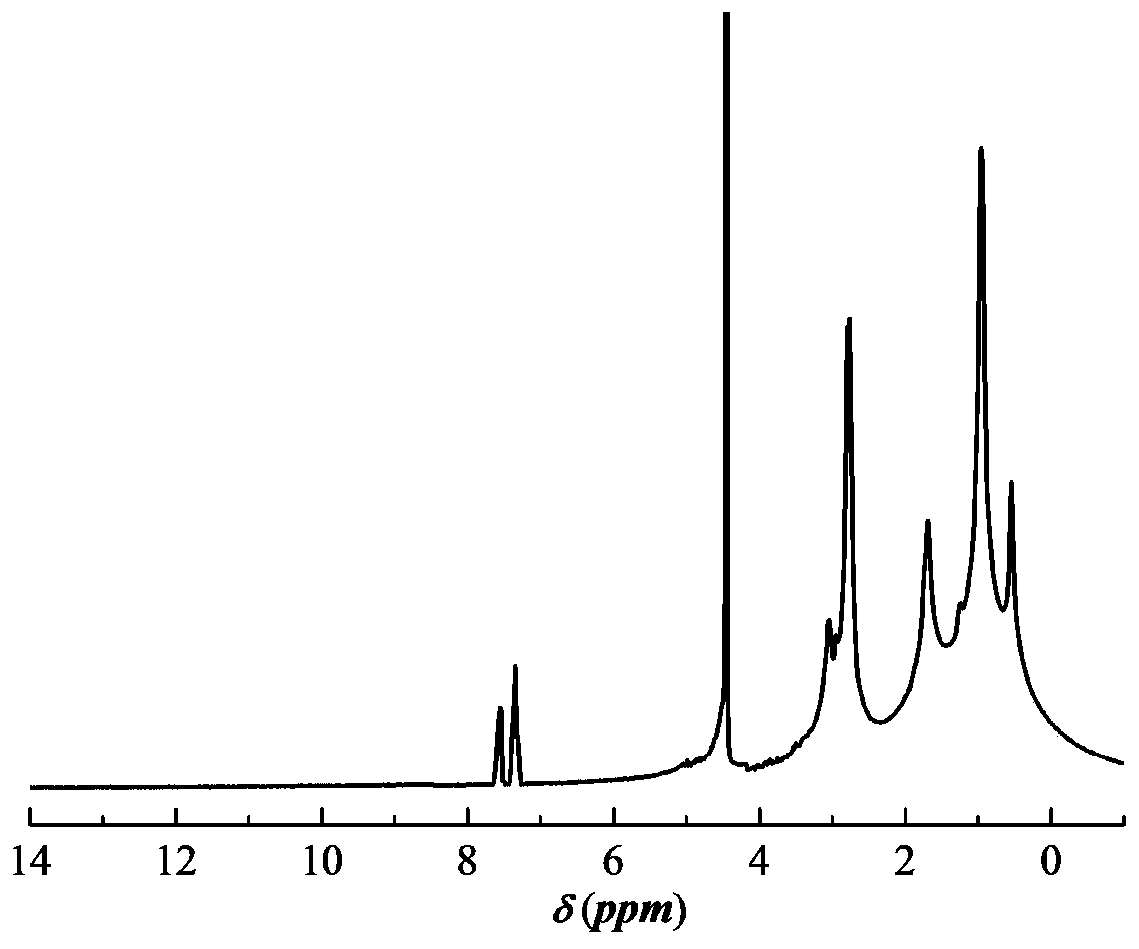

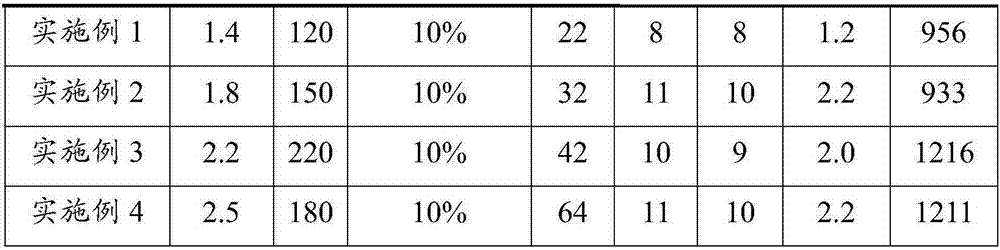

Low emulsifier-added oil-based drilling fluid

ActiveCN107043615AMeet basic performance requirementsPerformance unchangedDrilling compositionVoltageEnvironmental geology

The invention provides low emulsifier-added oil-based drilling fluid. The low emulsifier-added oil-based drilling fluid comprises the following components: oil, an emulsifier, an alkalinity conditioning agent, organic bentonite, a filtrate loss reducer, calcium chloride and water. The emulsifier content of the low emulsifier-added oil-based drilling fluid is low, but the low emulsifier-added oil-based drilling fluid can satisfy the basic performance requirement of the oil-based drilling fluid. According to the experiment result of the embodiments, the density of the low emulsifier-added oil-based drilling fluid is 1.4-2.5 g / cm<3>, the aging temperature can reach as high as 220 DEG C, the plastic viscosity can reach as low as 20 mPa.s, and the demulsification voltage can reach as high as 1763 V. In addition, after brine and bentonite invasion, the anti-aging temperature, viscosity, dynamic shearing force and demulsification voltage of the drilling fluid cannot be almost changed, and the drilling fluid has excellent anti-pollution performance.

Owner:JINGZHOU JIAHUA TECH

Intensifier for paper as well as preparation method and application thereof

The invention provides a paper reinforcer and a method for preparation and an application thereof, wherein the method for preparation comprises the following steps: (1) stirring and blending solvent 40-60 parts by weight and guar gum powder 10-20 parts by weight, then, charging catalyst 0.2-1 parts by weight to react in the temperature of 35-60 DEG C for 30-90 min, cooling to the temperature of 25-30 DEG C, aerating nitrogen to remove oxygen, (2) charging etherifying agent, then, heating to the temperature of 40-90 DEG C to react for 2-5 h, reducing temperature to 30-40DEG C, charging neutralization agent to control pH value of the reactant between 6 and 8, and collecting the paper reinforcer from the reaction product. The prepared paper reinforcer of the invention can rapidly dissolve after meeting water in the indoor temperature and is simple in operation, and good in powder fluidity and stability, which can be applied in thin paper, special paper, drawing paper and the like besides cigarette paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

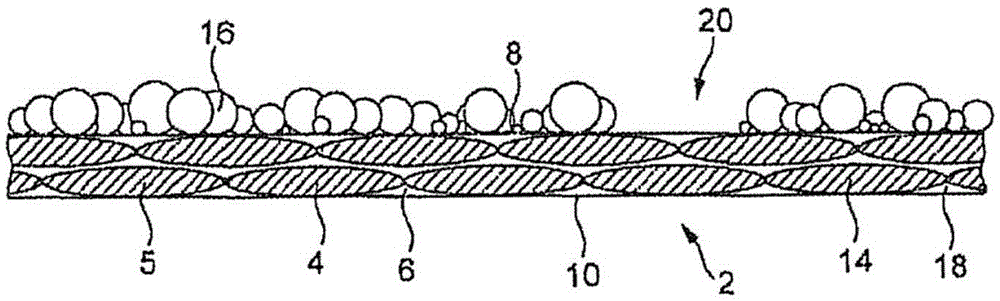

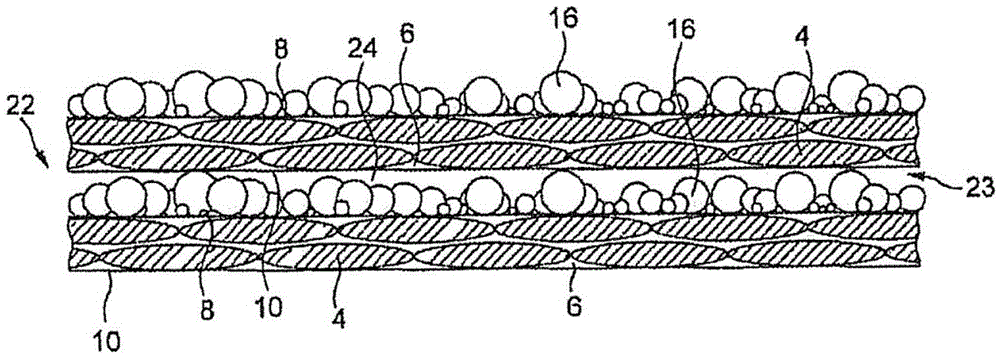

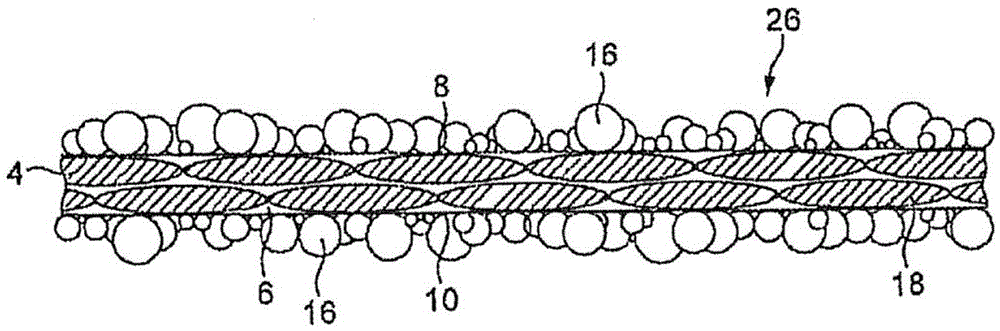

Prepreg for manufacturing composite materials

InactiveCN105531307ALow costViscosity unchangedSynthetic resin layered productsLaminationFiber-reinforced compositePowder coating

Owner:GURIT (UK) LTD

Color-adjustable water-based self-thickening building coating and preparation method thereof

The invention discloses a color-adjustable water-based self-thickening building coating and a preparation method thereof. The color-adjustable water-based self-thickening building coating comprises the following components: titanium-free base paint, continuous phase emulsion and a protective glue solution. The novel color-adjustable water-based self-thickening building coating can be suitable forvarious building outer wall surfaces, the coating spraying effect is adjustable, the coating has good water resistance and stability, construction can also be carried out in an environment with humidair, and a paint film of the coating cannot be damaged in rainy days after construction is completed. The water-based multicolor building coating is composed of green and environment-friendly components, and toxic and harmful components are greatly reduced (for example, the VOC content is smaller than or equal to 12 g / L, and the technical standard requirement is smaller than or equal to 150 g / L).The water-based multicolor building coating has good storage stability, the use amount of the thickening agent is greatly reduced due to the fact that a self-thickening effect exists in the system, the water whitening resistance of the coating is excellent, the post-thickening phenomenon is not obvious, and the viscosity is stable.

Owner:HANGZHOU RISHENG PAINT

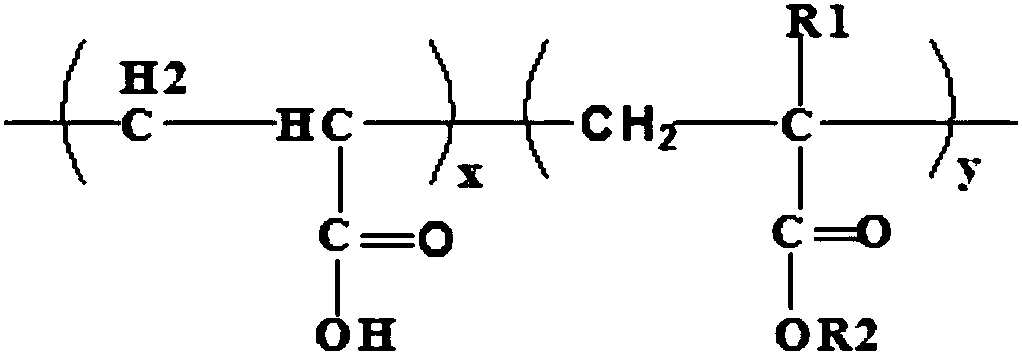

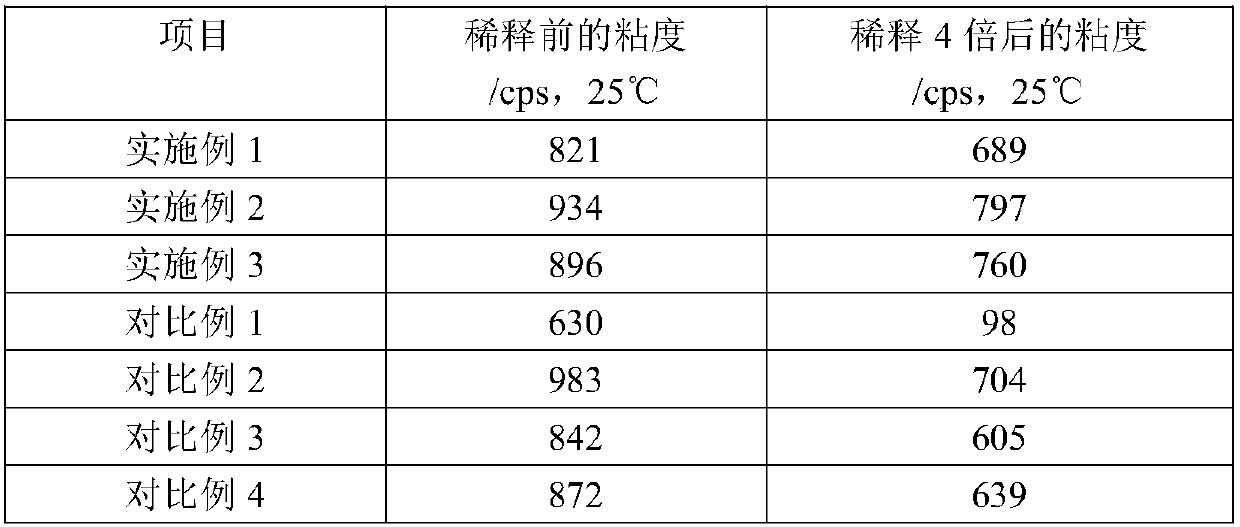

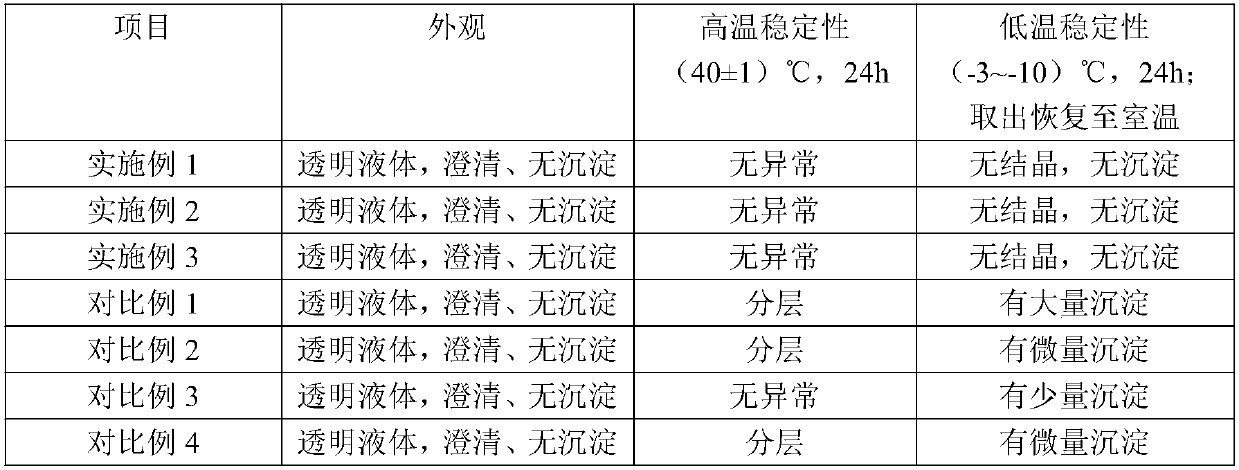

A concentrated dishwashing detergent

ActiveCN106590984BEasy to cleanViscosity unchangedInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHigh concentrationChemical products

The invention belongs to the technical field of daily chemical products and particularly relates to a concentrated tableware detergent. The concentrated tableware detergent is prepared from the following raw materials in percentage by weight: 1-5% of alkyl glycoside, 8-12% of fatty alcohol polyoxyethylene ether sodium sulfate, 1-5% of sulfonic acid, 18-24% of a fatty alcohol polyoxyethylene ether acrylate oligomer, 8-12% of sodium hydroxide, 14-17% of fatty acid methyl ester ethoxylate, 12-18% of lauramidopropyl betaine, 6-12% of a solubilizer, 0.1-0.2% of a preservative, 0.01-0.1% of essence, 0-10% of an assistant, and the balance water to complement to 100%. The concentrated tableware detergent is a stable high concentration system; the viscosity is basically not changed after the detergent is diluted by 4 times; the detersive power meets national standards GB9985-2000 ''detergents for hand dishwashing''; and the concentrated tableware detergent is rich in foam and gentle to hands.

Owner:WALCH GUANGZHOU COMMODITY

Epoxy anticorrosive paint, and preparation method thereof

ActiveCN110157331AViscosity has not changedViscosity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxyViscosity

The invention discloses an epoxy anticorrosive paint, and a preparation method thereof. The epoxy anticorrosive paint comprises, by weight, 100 parts of modified epoxy resin, 80 to 120 parts of a pigment filler, 2 to 5 parts of a dispersant, 15 to 20 parts of a film forming auxiliary agent, 1 to 3 parts of a leveling agent, and 1 to 3 parts of an antifoaming agent. According to the preparation method, epoxy resin is modified without influencing the viscosity of epoxy resin, active anticorrosive functional groups are introduced into the epoxy resin through grafting, so that the epoxy resin paint is provided with excellent scrubbing resistance, shedding of the anticorrosive function groups is not easily caused, and the corrosion resistance of the epoxy resin paint can be maintained for a long term.

Owner:上海博歌建材有限公司

Modified alkoxylation products having at least one non-terminal alkoxy silyl group, with increased storage stability and improved elongation, and polymers produced using said products

The present invention relates to special alkoxylation products, a method for the production thereof, compositions which contain said alkoxylation products, and to the use thereof.

Owner:EVONIK DEGUSSA GMBH

A kind of phosphorus-containing polyarylether ketone and its toughened film capable of interlayer toughening dual-horse resin-based composite material

The invention belongs to the technical field of composite material preparation and specifically relates to phosphorus-containing polyaryletherketone capable of increasing interlaminar toughness of a bismaleimide resin based composite material and its toughening film. In allusion to specific technological requirements for preparing a composite material laminate from a bismaleimide resin system by a RTM forming process, an interlaminar-toughening phosphorus-containing polyaryletherketone film which matches the bismaleimide resin RTM forming process is designed. The invention is characterized in that the film is basically not dissolved in the resin system at the bismaleimide resin injection stage so as to maintain a complete film structure and effectively avoid problems such as resin flowing difficulty caused by abrupt increases in viscosity of the resin system due to the film dissolved during the injection process; but at the stage of heating and curing processes after resin injection, the toughening film and the resin matrix undergo dissolution and phase splitting so as to generate the toughening effect, form the interlaminar-toughening structure, raise damage tolerance of the composite material and greatly improve interlaminar toughness of the composite material. Meanwhile, the phosphorus-containing polyaryletherketone has excellent heat resistance, and heat resistance of the composite material will not be influenced.

Owner:JILIN UNIV +1

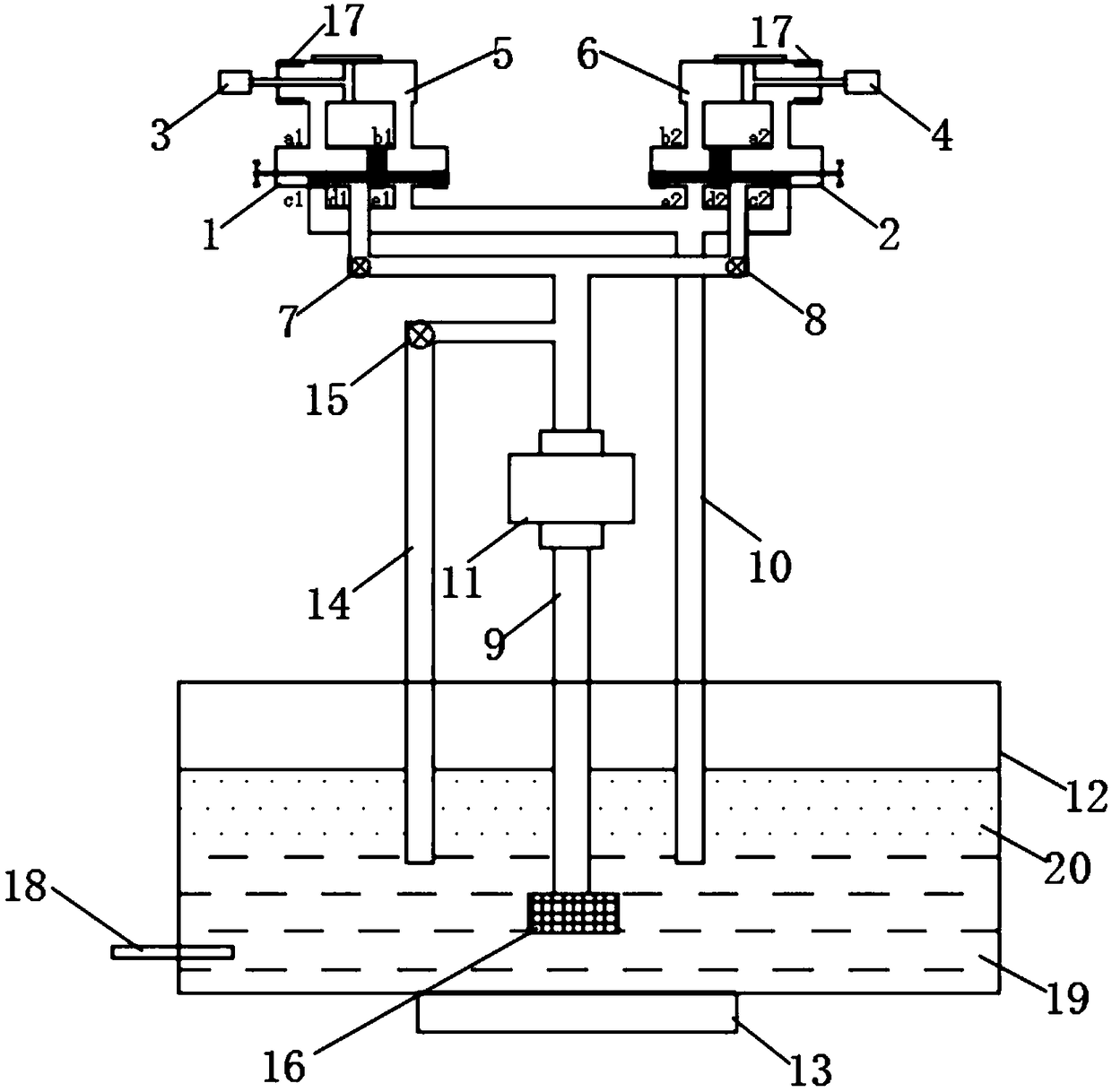

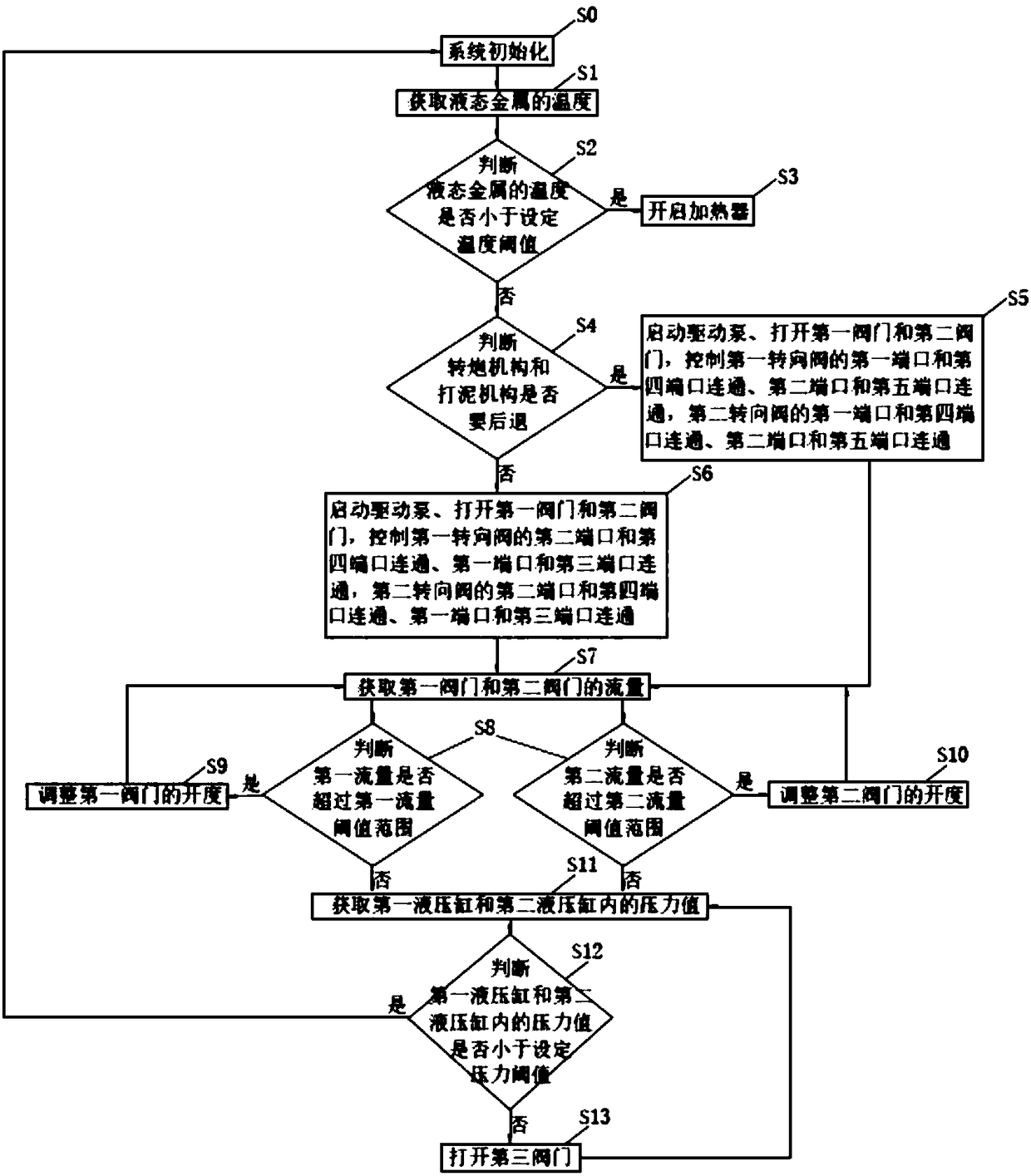

Hot metal based hydraulic clay gun and use method

PendingCN109207662AReduce the number of replacementsImprove securityBlast furnace componentsBlast furnace detailsHydraulic cylinderLiquid metal

The invention relates to the technical field of smelting stokehold equipment, and provides a hot metal based hydraulic clay gun and an use method. The hydraulic clay gun comprises a controller, a first hydraulic cylinder, a second hydraulic cylinder, a first turning valve, a second turning valve, a first flow rate sensor, a second flow rat sensor, a first valve, a second valve, a flow-in pipe, a reflowing pipe, a storing box filled with hot metal, a heater arranged on the storing box, a driving pump arranged on the flow-in pipe, a gun transferring mechanism which is connected to a piston rod of the first hydraulic cylinder, and a clay injecting mechanism which is connected to a piston rod of the second hydraulic cylinder. According to the hot metal based hydraulic clay gun and the use method, the use method is carried out; the hot metal is used as a pressure transferring medium, so that the viscosity of the pressure transferring medium under high temperature basically remains, and as aresult, the safety of the hydraulic clay gun is greatly improved, and the leakage is avoided; the times of replacing the pressure transferring medium is greatly decreased; and the cost is saved.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Phosphorus-containing polyaryletherketone capable of increasing interlaminar toughness of bismaleimide resin based composite material and its toughening film

ActiveCN103554478AGood compressibilityImproves fiber reinforced compressibilityResin matrixResin-Based Composite

The invention belongs to the technical field of composite material preparation and specifically relates to phosphorus-containing polyaryletherketone capable of increasing interlaminar toughness of a bismaleimide resin based composite material and its toughening film. In allusion to specific technological requirements for preparing a composite material laminate from a bismaleimide resin system by a RTM forming process, an interlaminar-toughening phosphorus-containing polyaryletherketone film which matches the bismaleimide resin RTM forming process is designed. The invention is characterized in that the film is basically not dissolved in the resin system at the bismaleimide resin injection stage so as to maintain a complete film structure and effectively avoid problems such as resin flowing difficulty caused by abrupt increases in viscosity of the resin system due to the film dissolved during the injection process; but at the stage of heating and curing processes after resin injection, the toughening film and the resin matrix undergo dissolution and phase splitting so as to generate the toughening effect, form the interlaminar-toughening structure, raise damage tolerance of the composite material and greatly improve interlaminar toughness of the composite material. Meanwhile, the phosphorus-containing polyaryletherketone has excellent heat resistance, and heat resistance of the composite material will not be influenced.

Owner:JILIN UNIV +1

Shadow mask type plasma display fluorescent powder constant-temperature and constant-pressure spraying device

InactiveCN101143354BStable temperatureConstant pressureStatic indicating devicesLuminescent coatings applicationLiquid mediumPhosphor

A phosphor constant temperature and pressure spraying device of a plasma display panel with shadow mask belongs to plate television manufacturing equipment, which includes a spray gun (1) and a slurry tank (9). The slurry tank (9) is connected with a feed port (10), an exhaust port (11) and a material discharging port (12). The feed port of the spray gun (1) is respectively connected with a compressed air source (8) and the slurry tank (9) and is characterized in that the tank wall of the slurry system tank (9) is a double-layer structure. Liquid medium is arranged in the tank wall and is connected with a heat exchange system (2). The compressed air source (8) is communicated with the space on the upper part of the liquid in the slurry tank (9) through an air pipe. The air pipe is equipped with a constant pressure valve (6). A stirring shaft (3) is installed in the slurry tank (9) and is driven by a stirring motor. The present invention solves a problem that a present spraying system sprays unevenly and has the advantages of simple structure and good spraying effect.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

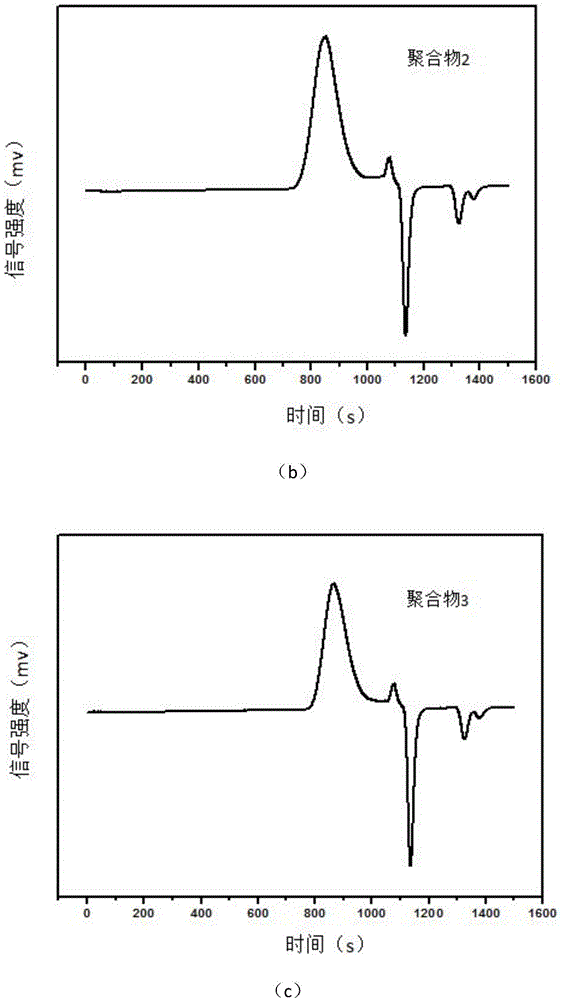

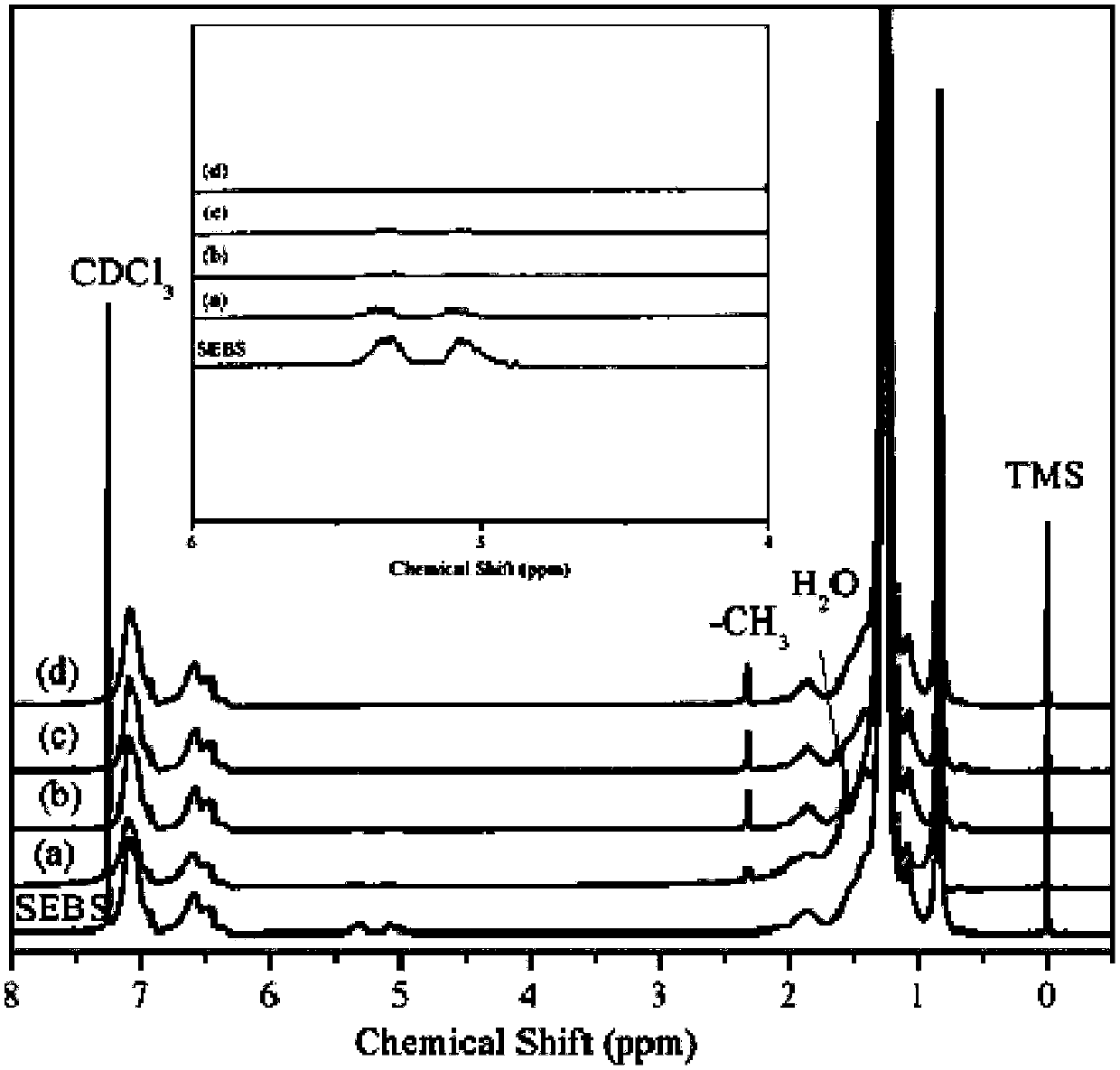

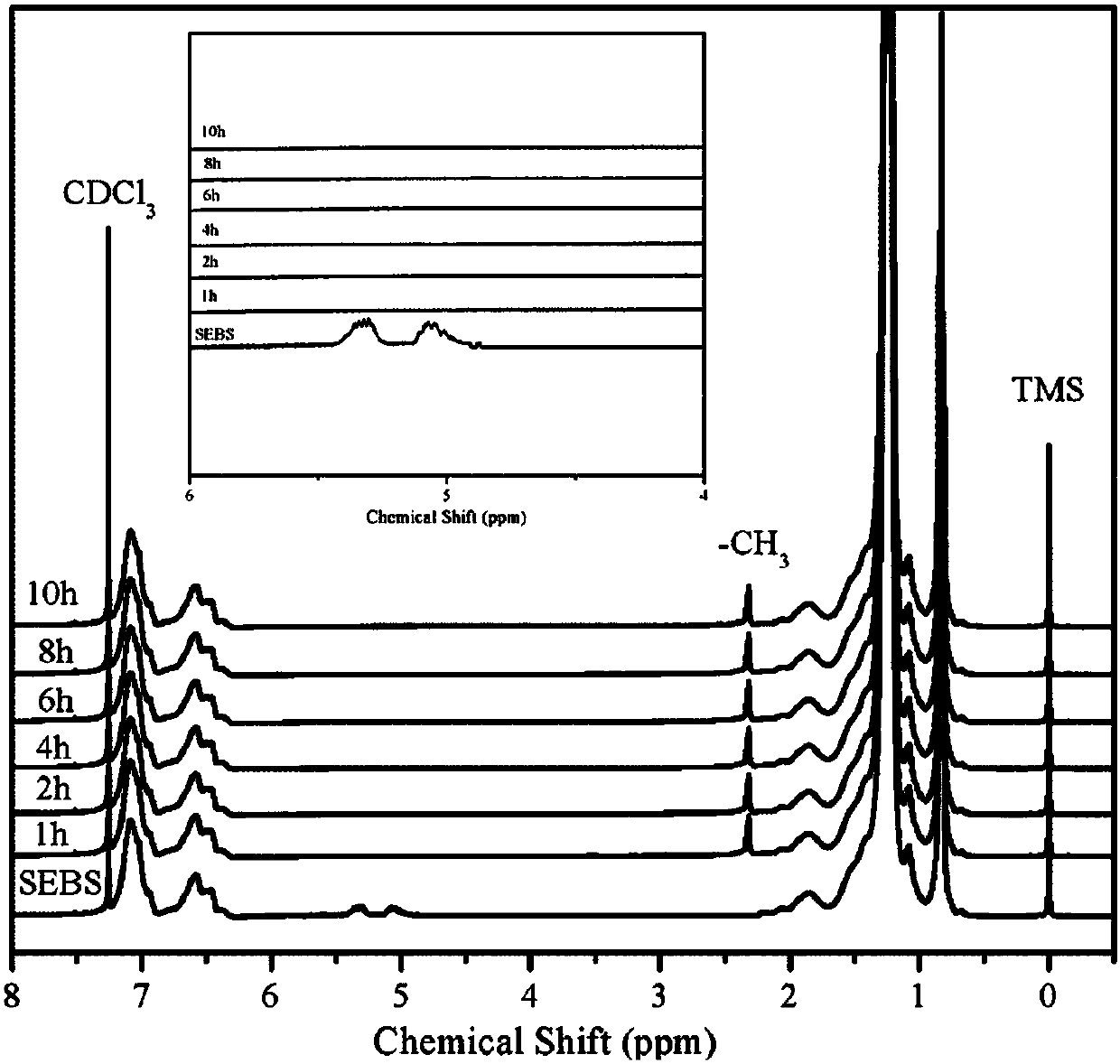

Method for eliminating unsaturated double bonds in hydrogenated styrene thermoplastic elastomers

ActiveCN109836516AAvoid cross-linking reactionsImprove athletic abilityThermoplasticThermoplastic elastomer

The invention belongs to the field of hydrogenated styrene thermoplastic elastomer modification, and concretely relates to a method for eliminating unsaturated double bonds in hydrogenated styrene thermoplastic elastomers by a Lewis acid catalyst system. The method concretely comprises the following steps: sufficiently dissolving a certain amount of incompletely hydrogenated styrene thermoplasticelastomers in a certain amount of an aromatic hydrocarbon reagent under normal pressure, then adding a certain amount of the Lewis acid catalyst, carrying out a reaction at a certain temperature for acertain period of time to eliminate the double bonds in the hydrogenated styrene thermoplastic elastomers, and carrying out steam distillation after the reaction is completed in order to recover thesolvent and achieve the purposes of terminating the reaction and recycling the solvent. The method has the advantages of completeness in elimination of the unsaturated double bonds in the hydrogenatedstyrene thermoplastic elastomers, simple reaction process, mild conditions, stable process, and keeping of the viscosity of the system substantially unchanged.

Owner:CHINA PETROLEUM & CHEM CORP +1

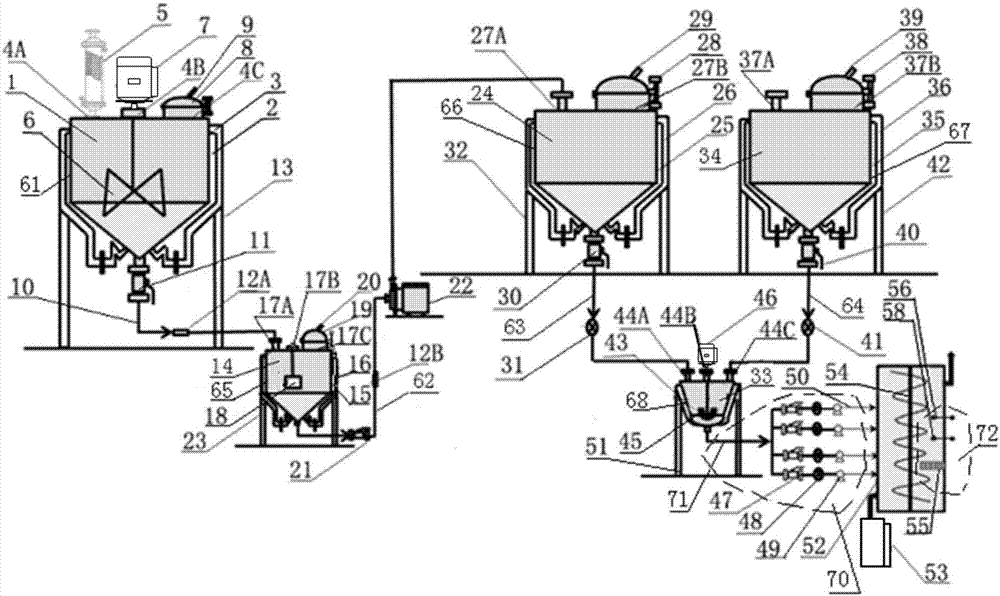

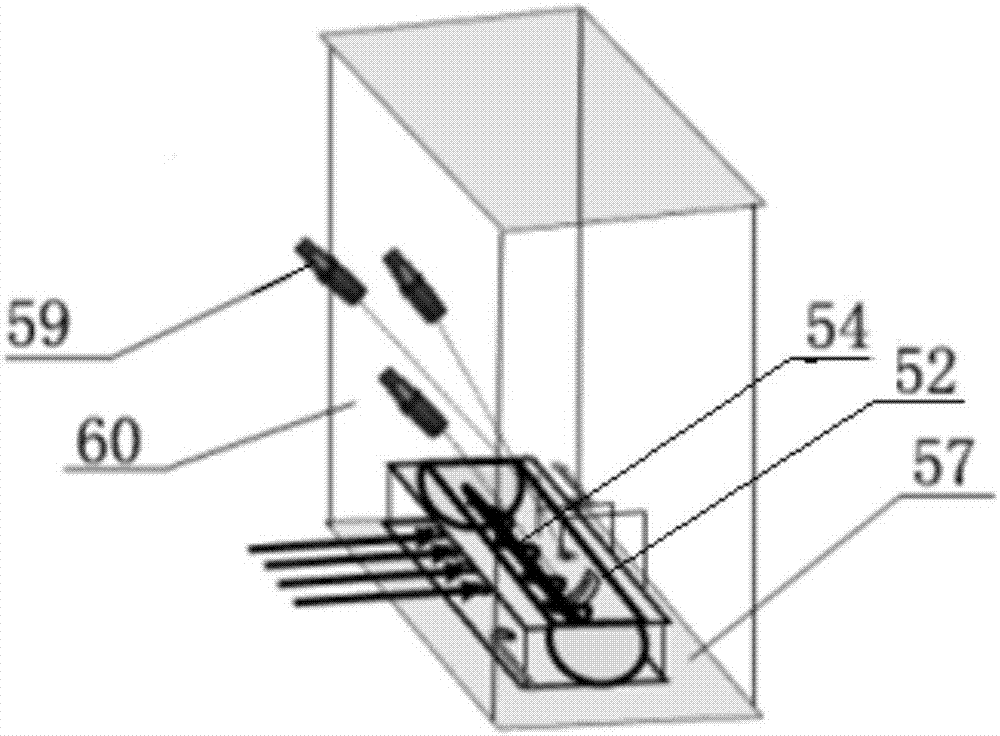

A continuous compensation electrospinning feeding device

ActiveCN104651960BConcentration unchangedAdjust feed rate in real timeSpinning head liquid feederFilament/thread formingNeedle freeElectrospinning

The invention discloses feeding equipment for continuous compensated electrostatic spinning. The feeding equipment comprises a sample stirring device, a solution buffering device, a solution storage device, a solvent storage device, a uniformly-mixing device, a spinning solution tank and a detecting device, wherein the sample stirring device is used for stirring a spinning sample to form a uniform fluid to obtain a spinning solution; the solution buffering device is used for defoaming the spinning solution; the solution storage device is used for storing the defoamed spinning solution; the solvent storage device is used for storing a solvent; the uniformly-mixing device is used for uniformly mixing the defoamed spinning solution and the solvent; the spinning solution tank is used for spinning; and the detecting device is used for monitoring the spinning solution tank. The feeding equipment is capable of continuously feeding and regulating the concentration of the solution in a compensated way, controllable in condition and reliable in operation, and easily assists a needle-free electrostatic spinning device in realizing industrialization.

Owner:杭州中科润德生物技术发展有限公司

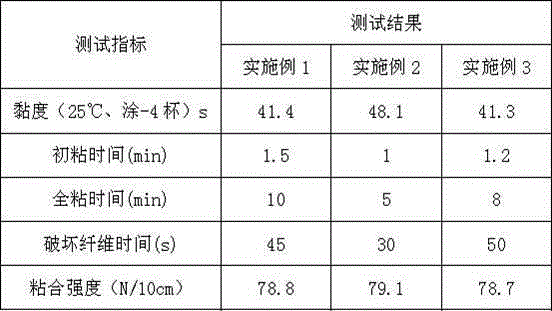

Low-temperature boron-free paper starch adhesive and preparation method thereof

InactiveCN103709958BQuality improvementExtended shelf lifeNon-macromolecular adhesive additivesStarch derivtive adhesivesOXALIC ACID DIHYDRATEFiber

The invention discloses a low-temperature boron-free starch adhesive for paper products and a preparation method thereof. The components and parts by weight of the adhesive are: 100 parts of corn starch, 320-400 parts of water, and 2.3-400 parts of potassium permanganate. 2.6 parts, 0.5-0.8 parts of sodium fatty acid, 2-2.4 parts of oxalic acid, 0.3-0.5 parts of tributyl phosphate, 8-12 parts of sodium hydroxide, 1.2-1.8 parts of sodium trimetaphosphate, 3-5 parts of drier, The adhesive with this formula has a simple production process and does not require heating. It only takes 40-50 minutes from feeding to the finished product. The adhesive cartons dry quickly, have high strength, do not run rough, do not absorb moisture, do not flood, and do not pan-alkali , long storage period, the viscosity remains unchanged after storage for 3 months, no mildew and precipitation, initial adhesion is 1-1.5min, full adhesion is 5-10min, fiber damage is 30-50s, the relevant physical and chemical indicators are better than the national standard requirements, and can be widely used Corrugated boxes for general commodity packaging and corrugated boxes for food packaging.

Owner:中山振兴纸品制造有限公司

A strain of Sphingomonas paucimobilis and its application

InactiveCN105505816BNutrition Facts EasyEasy to operateBacteriaMicroorganism based processesGellan gumInorganic salts

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Intramolecular Cr3+ cross-linked polymer gel and its preparation method

The invention relates to intermolecular Cr 3+ cross-linked polymer gel and a production process. The intermolecular Cr 3+ cross-linked polymer gel comprises the following components which are matched according to mass concentration, wherein partial hydrolysis polyacrylamide is used as host crystal whose concentration range is 0.04%-0.12 %, organic chromium is used as cross linking agent in which the mass concentration of Cr 3+ is calculated based on the mass concentration of polymer, wherein polymer: Cr 3+ = 40:1-100:1, and oil-field produced water or source water is used as solvent. The polymer gel has the characteristics of low viscosity, rapid gel forming speed, large flow resistance and controllable flow ability, which can be used to adjust water injection profile of a water injectionwell in oil fields which are driven by water, and simultaneously expresses excellent technology and economy.

Owner:BEIJING DONGRUNKE GASOLINEEUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com