Shadow mask type plasma display fluorescent powder constant-temperature and constant-pressure spraying device

A plasma, constant temperature and constant pressure technology, which is applied in the field of phosphor spraying devices and phosphor constant temperature and constant pressure spraying devices, can solve the problems of uneven spraying, achieve stable flow, reduce control failure factors, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

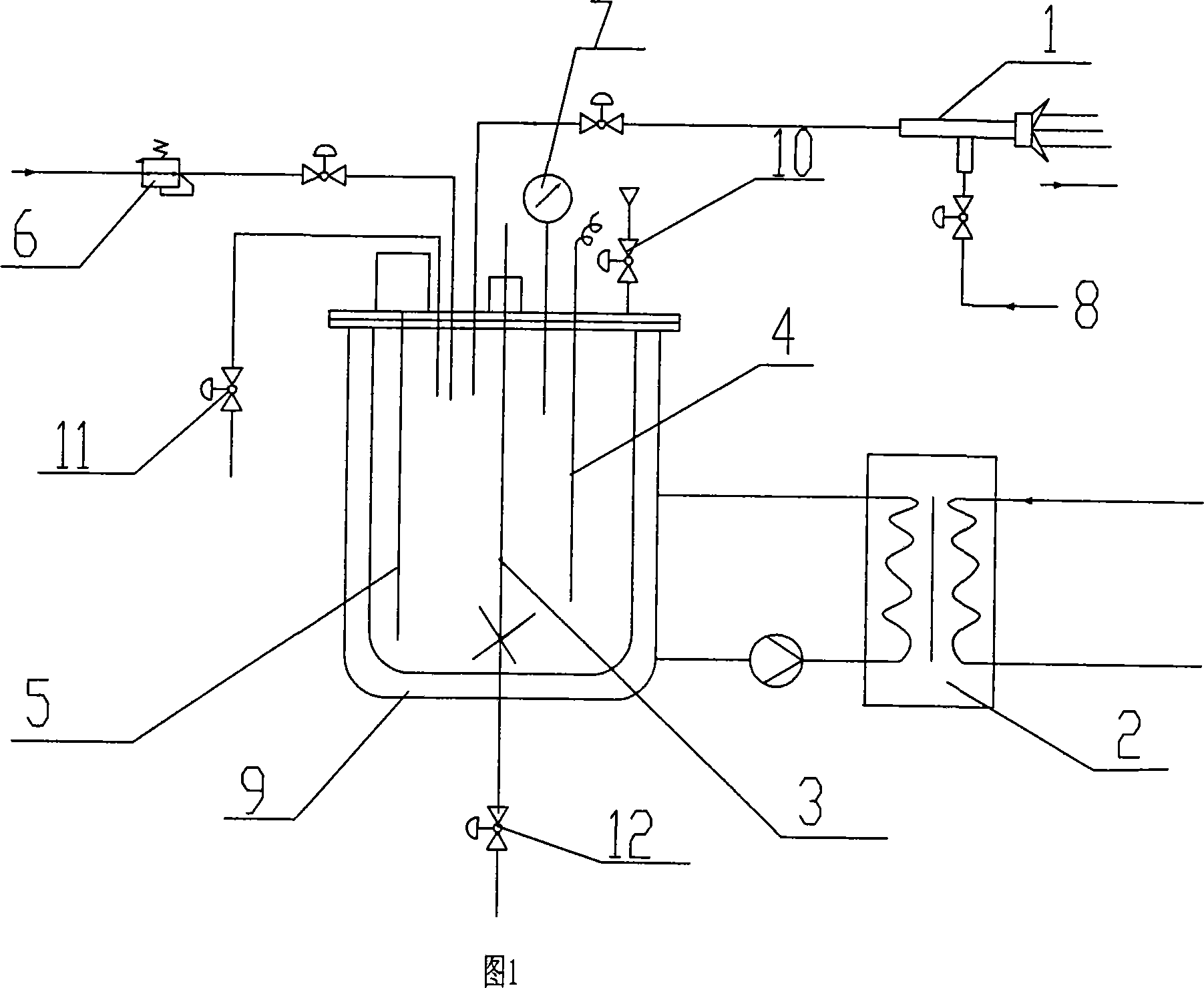

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] As shown in Figure 1.

[0012] In Figure 1:

[0013] 1. For the spray gun: under the action of compressed air, make the phosphor powder slurry produce a uniform coating.

[0014] 2. It is a constant temperature heat exchange system: keep the phosphor powder slurry in the tank at the set temperature.

[0015] 3. For the agitator: through the pneumatic agitation pump, the liquid slurry is fully mixed to prevent sedimentation.

[0016] 4. As a thermometer: measure the temperature of the slurry.

[0017] 5. For liquid level gauge: detect liquid level height.

[0018] 6. It is a constant pressure valve: make the pressure in the tank reach the set value, which is displayed by the pressure gauge 7.

[0019] 7. For the pressure gauge: display the pressure inside the tank.

[0020] 8. For compressed air source: provide power source.

[0021] 9. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com